About the design

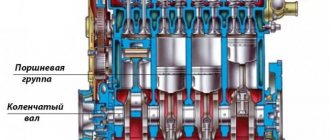

What does an AMT gearbox consist of? This transmission includes several components:

- Drive and clutch discs.

- Gear shift lever.

- Electronic control system.

Any robot uses a double friction clutch. On conventional mechanics, one disk is used. This design allows for faster gear shifting on AMT. The Lada Vesta, on which robotic gearboxes began to be installed, is much faster than its manual counterpart. And this despite the fact that the AMT does not have a clutch pedal as such. But not only the Volkswagen-Audi concern and AvtoVAZ use such a box.

Factory AMT gearbox on Priora: price and article number

The new gearbox in VAZ was developed on the basis of an old frozen project. In 2009, the development of a manual transmission for golf-class cars was closed, but good performance led engineers to the idea that the VAZ-2116 gearbox, a new generation of manual transmission, could become a prototype for an automatic transmission.

A robotic automatic transmission with electric actuators from ZF is now used in front-wheel drive Ladas. The automatic transmission has code 2181 for Kalina and Granta, and the Priora has an automatic transmission with code 2182. A Lada Priora car with AMT at the dealer and on the secondary market costs about 20 thousand rubles more than a Priora with a “mechanics”. It works in four positions: R, N, A and manual gear shift (“+” is responsible for upshifting, “-” is responsible for downshifting).

Clutch types

There are several types of clutches for AMT gearboxes:

In the first case, electric motors are used. This type of drive has a slower response speed. Gear shifting is three to four times slower than a similar one with a hydraulic drive. Switching time ranges from 0.3 to 0.5 seconds. But still faster than an automatic transmission.

What's on the road: reviews from some owners of the 2016 Lada Vesta robot?

Experienced motorists liked the ability to move the gearshift handle from the forward position to Reverse when slipping at a speed of less than 3 km/h. At the same time, switching time is reduced to 0.7-0.8 seconds. However, drivers do not recommend abusing this - the clutch overheating indicator may go off, and you will have to wait until the clutch cools down.

Manufacturers of the Lada Vesta robot and reviews from owners in 2016 claim that shifts have become smoother than those of Kalina or Priora, but longer. The box was reconfigured and the original control unit was installed on it. Loss of traction for 1.7 seconds in city traffic threatens, at a minimum, with the horns of hurrying drivers. Meanwhile, it is possible to select manual mode and work ahead.

Advantages

The main advantages of an automated transmission:

- Low fuel consumption. A robotic car spends almost the same amount as a manual one.

- Small amount of oil. Up to 4 liters of liquid must be poured into such a box. This is two times less than with a similar automatic transmission or CVT.

- High clutch life. Since the switching process is controlled by electronics, and not by the driver, the risk of burning the clutch is close to zero (unless you intentionally press the gas and brake pedals at the same time).

- Availability of semi-automatic mode. At any time, the driver can switch to manual mode and independently choose the moment when to shift to a higher or lower gear.

Drivers also note high switching speeds even in automatic mode. And all thanks to the use of a multi-disc clutch. When the car is moving in first gear, the second disc is already engaged with the next one.

Lada cars with AMT reviews from owners

Most often, owners of cars with such a manual transmission complain about delays or jerks when switching. They are especially noticeable when driving in city traffic or when starting up a hill. Sometimes this robot generally behaves inappropriately, sometimes it will drop several gears for no reason, sometimes, on the contrary, it drives for a long time and strainedly at high engine speeds, without even intending to shift.

The second inconvenience is the lack of a rolling mode, as on a hydromechanical automatic transmission, which is so convenient in traffic jams. When a car slowly crawls in automatic mode, after releasing the brake pedal, everyone expects that they will move on, because the gearbox is in gear. But no, you need to press the accelerator. Update: version 21827 received a rolling mode.

Operating modes of the automated box

While driving, the driver can set the gear shift lever to automatic or semi-automatic mode. In the first case, the transmission operates by relying on sensor readings and impulses from the electronic control unit. As for the semi-automatic mode, “Tiptronic” is activated here, which can be found on Mercedes cars with their automatic transmission. There is a plus/minus switch on the gear lever.

Editorial Lada Vesta: searching for a common language with the AMT box

What is a robotic box

I have always been sure that robotization of a conventional manual transmission is far from a dead end. In the end, few people complain about the poor performance of the manual transmission itself, about the slowness and jerkiness of shifts, about “dullness” and other shortcomings for which automated transmissions are usually criticized.

Automation can switch gears faster and more accurately than a person - this is a simple task in which a living organism has no chance against electronics. It simply cannot achieve the precision, speed and coordination that a simple microcontroller provides. The shortcomings of even the simplest “robots” are the shortcomings of people who tried to make them cheap, and at the same time, even the algorithms for operating service electronics were cheap.

If you do it better, then the result will be at least no worse than that of a person. With only one exception - the automatic transmission does not know when the gas will be pressed and when it will be released, which means it cannot switch in advance, and is forced to act “after the fact”. Often - at the most inopportune moment, which increases the requirements for switching time several times.

"Never again"

The skeptical attitude of most drivers towards VAZ’s AMT “robots” has many reasons. First of all, this is the experience of those who have operated similar transmissions produced by Opel, Ford, Toyota and Honda. Until recently, Opel Zafira, Ford Fusion, Toyota Corolla and Honda Civic were among the bestsellers on our market. In addition to these models, the companies had other carriers of similar units, but slightly less popular.

Numerous reviews clearly stated that it is not recommended to buy a car with such a transmission. The Japanese especially distinguished themselves - their “robots” really exhausted the soul, and the most neutral opinion of the owners was “never again.” European models were better. I've driven a Zafira, a Corsa and a Fusion and can say that with good maintenance, regular grip point adjustments and a very relaxed driving style, the cars were easy to use.

But we couldn’t forget for a second that this was a “robot.” Algorithms taken from classic automatic transmissions and multiplied by design imperfections sometimes made passengers twitch like clowns on strings. The advantages in the form of efficiency usually faded when calculating the cost of the next repair - the clutch life turned out to be frankly insufficient, just like that of clutch drives during city use.

In general, such boxes deservedly received the fame of problematic transmissions. Against the backdrop of all this “disgrace,” the release of VAZ cars with an AMT transmission was perceived with doubly skepticism. It is clear that such “automation” is due to a lack of funds for more advanced designs. But the reviews about the driving characteristics turned out to be surprisingly positive, but I don’t see any Prior owners with AMT. Everything changed when the new Lada Vesta came out, and it again has an AMT “robot” as an automatic transmission; there are no other options yet. What has changed in the design and why does Vesta’s “robot” objectively work better than the others?

A few words about the design

Nothing has changed fundamentally: it is a conventional mechanical transmission, to which an automatic control system has been installed. Moreover, the gearbox is original VAZ, with its very short first gear and inevitable howling under thrust and under throttle release. In contrast, by the way, from cars with “mechanics”, which now use a Renault-made gearbox.

Why was the AMT for Vesta made on the basis of the VAZ gearbox? The designers say that the load on the box when automating the switching process is even lower than usual, and the design features and lower price make it more competitive. The control system is supplied by ZF, which has extensive experience in mechanical automation. True, for the most part this experience was not very successful, because Opels and Fords also had their production systems. But the latest generation with more recent switching algorithms is offered for VAZ. And it seems that the whole point is in the settings and logic of operation, because the car, as they say, “drove.”

The selector lever does not have a Parking position - only reverse, neutral, auto mode (analogous to Drive) and manual switching. Moreover, when shifting manually, you cannot go into neutral or engage reverse, only forward gears.

Why is the absence of “creeping mode” a good thing?

To start, you need to move the gearbox selector to position “A” (auto mode) and lightly press the gas, otherwise the car will not move. Unusual? But it is very useful in terms of reliability!

The AMT gearbox does not try to imitate hydraulic automatic transmissions and avoids the problematic mode that so often overheats the clutch on DSG robots in traffic jams. The essence of the problem is well understood by those who have driven a manual car for quite a long time. Without traction, the clutch has to be closed for a very long time and carefully, it manages to get very hot, or even start to “burn”. When adding traction, the start is much faster, and there are no jerks or vibrations.

Moreover, the clutches close most quickly when you carefully operate the gas; when starting “to the floor,” there is again a clear pause in operation, but even in this case there are no jerks. The most unpleasant outcome is, again, when copying the “automatic” algorithms of machines with classic gas turbine engines . If you sharply press the gas at the start and then release it, there will be a pause at the start, a jerk, and an unpleasant vibration of the engine.

Test drive Lada Granta Cross on a “robot”: tests on the M5 highway and village dirt

Sometimes it is difficult to take on the role of a lawyer because you know in advance that the case will be lost. But it’s either passion, or duty and a matter of honor - and you take it on. It's boring at first: all the scripts are known in advance and differ only in details, like good remakes. But as you dive in, something clicks inside, and the “bartender” you’ve known since birth slips you a strange cocktail of sympathy, empathy and hope... And with this Lada Granta Cross it couldn’t be otherwise.

What does it look like

Everyone has already been able to get an idea of the appearance of Granta Cross. This is the same Kalina Cross, which, after restyling in the summer of 2018, had to unite with the Grants family, forming a powerful clan with the best sales results that have been maintained for many months. If you want a quick summary, the Lada Granta Cross looks great.

Vesta "robot" - AMT

AMT for Lada Vesta was initially created only for the Lada Priora car. The fact is that the design of this model did not allow the use of full-fledged automatic transmissions, and the plans were to produce this car for a long time. To develop the “robot,” we took an ordinary mechanical box as a base and added a computer and drives from the German company ZF. The unit turned out to be so successful that it subsequently appeared on Grants and Kalinas, completely replacing automatic transmissions.

The AMT box has also reached the Lada Vesta. Successful operating experience of this unit made it possible to use it on more modern cars without any modifications. Among the technical features of the “robot”, it is worth noting the low weight - only 5 kg heavier than the “mechanics”, low cost - 20,000 rubles, versus 40,000 rubles for the JATCO “automatic”, as well as the simplicity of the design - a well-known gearbox and several controls.

Disadvantages of the "robot":

- When parking uphill, the car rolls back, so you need to fix the position with the gas pedal or hand brake.

Advantages of the “robot”:

- Protection against incorrect gear engagement;

- Two switching options are possible, fully automatic and manual;

- Possibility of sharp acceleration as on mechanics;

- One or two gear reset mode;

- Average fuel consumption is 6.5 liters per 100 km in urban modes and 5.1 liters per 100 km on the highway;

- The required oil volume is 2-3 liters, for automatic transmissions and CVTs from 7 to 10 liters;

- You can start driving immediately after starting the engine, including in severe frosts;

- Automatic adjustment of the transmission mode to the driving style of a particular driver;

- There are no vibrations in the gearshift lever;

- Ability to tow trailers or other vehicles;

- Quick gear changes, no jerking.

Features of the robotic gearbox:

The clutch closes very smoothly, even if you press the gas sharply; If necessary, you can manually reset one or two gears for quick acceleration; There is protection against engaging reverse gear when moving forward; There is a howl in certain gears, but it is several times less than in the “mechanics” from AVTOVAZ; The service life of the AMT is 10 years.