Why knock?

It’s easier to list what can’t knock there. But in order to diagnose and identify the causes of knocking with minimal time, you will still have to comprehensively identify potential sources of sound:

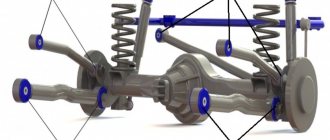

- the suspension itself, or rather its guide vane;

- springs, that is, elastic elements;

- damping devices known as shock absorbers or struts;

- transmission wheel drives;

- steering components and parts;

- hubs with bearings;

- anti-roll bar with its own struts;

- brake mechanisms;

- fastenings and other parts related to the engine;

- any threaded fasteners or press fittings.

Naturally, not all of the above can be attributed to suspension parts, but there is no doubt that any knock in the suspension when driving over uneven surfaces will be attributed to it. It can be justified that the bumps should be really small, since on a large wave the parts experience accelerations that last longer, but are smaller in magnitude, and therefore may not knock.

Problems with springs

On cars with springs, the springs may wear out during the operation of the car, resulting in a characteristic knocking sound when driving over uneven surfaces. Unfortunately, it can be difficult to independently determine such faults, so you need to contact a service center and perform a comprehensive diagnosis of the car. Identified faulty springs should be replaced as soon as possible.

It's the suspension that makes the sound.

Usually we can talk about this for sure only after diagnosis. At the stage when all that remains is to replace the faulty parts. Otherwise, by trial and error, you can move ad infinitum, and then still find a forgotten glass bottle rolling along the bottom of the front glove compartment, or other numerous exotic cases from repair practice.

Levers and articulations

Each guide vane arm begins and ends with a hinge.

They can be rubber-metal (silent blocks) or rigid (ball joints and supports, bearings). As a result of wear, any of them can knock. In terms of frequency of occurrence, ball joints hold the lead. As the name suggests, they are a spherical tip rotating in a metal housing with nylon liners. The bushings are pressed with springs, the fit is tight, and the new part works without play, that is, it cannot knock. As the balls and bearings wear out, a gap forms, the part gains unintended freedom, and a knock is heard in the suspension on small irregularities.

Diagnostics here consists of applying force in the opposite direction from the joint prestress. This depends on the kinematics of the suspension; sometimes the pin needs to be pulled outward from the body, at least with the help of a mount, but occasionally in the opposite direction. For example, in a MacPherson-type suspension, the lower support works differently than in a classic double wishbone.

Silent blocks usually creak, not knock. But they can also be brought to such a state that all the rubber has already run out, and the blows are metal on metal. One glance is enough to reveal the catastrophic nature of the situation, in which it is often necessary to change the lever assembly.

Stabilizer

There are usually two places on the anti-roll bar where wear can occur. These are bushings for attaching to the body or subframe and struts. The bushings are a collapsible silent block, in which it is enough to replace the rubber elastic element. Although in severe cases such wear forms on the stabilizer bar itself that replacing the bushings is not enough; a new large part will be required.

Stabilizer links are a very weak point on all cars. They experience heavy loads, but are compact. It doesn’t matter how they are designed, on the basis of ball joints or with rubber elements, the assemblies are always changed. Nobody at the factories is going to strengthen them; the parts are simple, inexpensive, can be diagnosed by simply shaking the rack rod, and therefore are considered consumables.

Springs and shock absorbers

Knocks can be heard very rarely from the springs.

Usually only in case of fatigue failures of the outermost turns. It’s not even always noticeable, but it sounds loud while driving, and the car’s posture changes even more noticeably. The body seems to sit on one side, and often on both, since the springs like to break in pairs. At the same time, you need to replace the cushions on which the spring rests on its upper and lower sides. Shock absorbers make themselves known much more often. Both by themselves and in places where they are attached. In order of frequency of occurrence, several sources can be identified that cause knocking in the front suspension on small bumps:

- the upper supports of the front struts in the MacPherson suspension, where the bearings and rubber couplings are destroyed;

- lower and upper silent blocks of shock absorbers of classic suspension on A-shaped triangular arms;

- internal failures in the shock absorbers themselves.

Diagnosis is usually carried out by touching the suspicious area with your hand while rocking the front of the car. Play in the upper supports, knocks inside the shock absorber or wear on the rubber elements are clearly visible. Moreover, all this is not noticed immediately, the car manages to drive in a faulty state, and the sounds are accompanied by visual effects, oily sweating of the bodies, sticking out of the body from the body higher than usual, or rubber rags coming out of the silent block clips. Racks, like supports, are usually replaced as an assembly; it is illogical to leave rusty and tired metal, even if it is not yet broken.

Eliminated the knocking in the front suspension, finally... — Lada Priora Hatchback, 1.6 liter, 2008 year on DRIVE2

When starting, stopping, or driving over a bump in a certain way, a single dull thud was heard. I took a quick look at the suspension and then decided that it was the crab's silent block sending greetings

Here is the blog entry: www.drive2.ru/l/6936436/

Moreover, the car pulls a little to the right; a wheel alignment is still needed.

Before installing new tires, it was decided to change all the silent blocks, since they were pretty worn out and cracked.

It can be seen that the chamomile has fallen apart...

All that remains of the stabilizer is the structure...

The tires are cracked and need to be replaced.

I bought almost everything from SEVI-Evspert, I only bought the stabilizer bar cushions from BRT, because... There was no SEVI.

Donor organs)

To remove the levers, I sat on stumps in front of the car.

The car looks very scary, I’m horrified by the photo myself

During disassembly, as one would expect, judging by 1 photo, the chamomile fell apart

As is usually customary with any repair, there were some excesses, which takes all the time... The forces of evil tested me with a non-unscrewing tension nut, which is on the daisy side. The socket head cannot be reached, the nut is screwed in too deeply, the head does not reach the wrench rib. Which means I can’t turn it all with a pipe. I had to use a socket: I put the wrench on the nut, and because... There is no way to lengthen the key, Archimedes is retired, so to speak, Herax kicks the key. So I unscrewed it until I got tired of it and sawed off part of the thread with a hand hacksaw... :D In the photo above you can see that it was sawed off

The true source of the knock was also found

The metal core walked inside the rubber. It looks like it's been polished

And the end of the core is broken off

I knocked out the daisies with a chisel, but I had to burn the silent block of the lever

I pressed everything back with bolts, it was not easy, but I managed it without special equipment. I was afraid that I couldn’t do it YEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEIED I DID IT!

Well, I assembled a homemade press puller for the crab silent.

Here it is, a miracle of engineering.

Pressing is proceeding as normal. The homemade puller works like a charm! Everything is quick and simple.

And finally, photos of the finished work

It still pulls to the right, but weaker, but the knocking noise is gone. I think after the wheel alignment everything will be OK! :) In the meantime, I’ll ride for a week until everything falls into place...

Price: 1,350 ₽ Mileage: 170,000 km

Features of the behavior of front wheel drives

They consist of a splined shaft, two constant velocity joints (CV joints) and elastic boots made of thermoplastic or rubber.

Each hinge is usually made according to a six-ball design, where the trajectories of the balls’ movement along grooves cut into the cages are thought out with high precision. The balls are separated by separators. Problems with the CV joint manifest themselves as crunching noises when turning the steering wheel and accelerating. But if no attention is paid to this, then the backlash increases to such an extent that the hinges begin to rattle in the manner typical of suspensions, that is, on small irregularities. This is already a dangerous symptom; the drive can collapse at any moment. It is urgent to carry out diagnostics and change the CV joint or drive assembly if element-by-element replacement is not provided.

Drives rarely survive natural wear and tear; usually it all starts with a rupture of the protective cover. The hinge loses its seal, grease comes out, and water and dirt appear in its place. Due to its high accuracy, the unit does not tolerate this for long; after a few hundred kilometers it is no longer suitable for use. Visually, this is clearly visible on the pit or lift by traces of grease and cracks in the cover.

In addition to “grenades,” the source of knocking in the drive can be the splined joints of the shaft. When backlash appears, a massive part cannot work silently and will make a knocking sound when driving in neutral gear. This can be determined by shaking the shaft in a perpendicular direction; the gap should almost not be felt. Unfortunately, if the shaft wears out, the drive assembly will most likely need to be replaced.

How to fix the situation?

First you need to determine the cause of the knocking. The situation can be corrected by replacing the non-functioning element, since it is impossible to disassemble the shock absorber. By the way, replacement should only be done in pairs. That is, if you changed the shock-absorbing device on the left side, change it on the right as well.

Some car enthusiasts still try to make minor repairs to a defective item. To do this, they cut off the rolling of the body. After cutting, you can remove the piston with rod. This allows you to check the rod and pistons and, if necessary, replace them - and also add new working fluid. During assembly of the mechanism, the cut rolling area will have to be welded. This is a complex process - it is much easier to buy new elements and install them.

To prevent knocking, it can be recommended to avoid “forcible” operation of the car. It is clear that the roads need to be chosen more evenly - it is hardly worth talking about. Pay special attention to the condition of the oil. In cold weather, you should not pick up speed too quickly, because at the very beginning of movement, the temperature of the working fluid corresponds to the air temperature. Excessive oil viscosity is a common cause of valve disc failure. To avoid this, it is better to pick up speed a few minutes after the start.

The service life of shock-absorbing elements is limited. But to prevent them from breaking prematurely, you must follow the rules for operating the car.

Steering linkage and steering gear

This system has many joints, any of them can knock:

- steering tips, these include everything said above about ball joints, the design is identical;

- ball joints of steering rods in conjunction with the rack and pinion steering mechanism, usually these parts can be replaced separately from the ends;

- guide bushings at the exit from the rack housing; the rack will need to be rebuilt and the repair kit replaced;

- connecting the steering shaft drive gear to the rack; sometimes it is possible to tighten and adjust the gap;

- the gap between the worm and the sector in the worm steering mechanism is eliminated by adjustment.

The steering column may also knock, but this sound is quite easily localized and is not disguised as knocking in the suspension.

Life hack: hydraulic compensators for a Priora car with 16 valves, device, price

Compensators are needed for automatic valve adjustment; if they were not there, it would be necessary to adjust the valves every 10 thousand, as on 2109. On the Prior, hydraulic compensators knock under different circumstances - and this is not always a malfunction.

They have a special knock, so experienced car enthusiasts will recognize it almost immediately. A knock that comes from the engine of a Priora car is not a very good sign that should alert you. Each car needs to be approached differently. Therefore, when hydraulic compensators on a Priora knock, make proper preparations for repairs - you need to find out what is the reason for what is happening and how you can eliminate it by correcting the situation. In this article, we have collected for you the main signs: why these parts make noise, whether the car is cold or hot.

These parts have 16 valves on the Priora. (if taken as a complete set) they are not so little. The price starts from 4000 rubles and above. Replacing hydraulic compensators is labor-intensive and I don’t recommend getting into the engine yourself without experience. At a service station, such work for a Priora car will cost from 5,000 rubles and more.

Wheel bearings

The modern design of these units with double-row ball or roller bearings does not require adjustments, is reliable and operates with virtually no play.

Although there is no tension there either, a slight play can be felt. But if it increases to a clearly noticeable size when the suspended wheel rocks, then the bearing must be replaced immediately. Otherwise, it will begin to heat itself up and may quickly collapse. The knocking is clearly noticeable when driving, often accompanied by a howl from the bearings that have begun to collapse. There are also earlier designs where the bearings require periodic adjustment. It boils down to bringing the gap with the hub nut to the value specified in the instructions, after which the nut is locked. The gap may increase if the bearings are in good working order, which will manifest itself as if the front suspension is knocking.

Front brakes

Disc brakes, especially those with a floating caliper, often become the source of a clearly audible knocking noise. Parts are subject to cyclic overheating and exposure to all road troubles in the form of water and abrasives, which causes them to wear out and corrode. And the pads themselves are not secured by anything, they are only pressed by weak springs in their guides.

Diagnostics is difficult, since there are always gaps here, and the necessary accelerations can only be created while driving. In general, you can follow the rule that if the knocking noise disappears when you press the brake pedal, then it is either the caliper or the wheel bearing, but the second one is easy to check separately.

Repair comes down to replacing the pads, guides, lubricating parts, but if this no longer helps, then you will have to reject the caliper assembly. Having first checked all other causes of knocking in the front suspension, since the parts are expensive.

Failure of shock absorbers

Critical wear of shock absorbers can be determined not only by the appearance of dull knocks when driving over uneven surfaces and defects in the road surface, but also by strong lateral and longitudinal rolls of the vehicle. Checking the shock absorbers is not difficult; you can press on the fender of the car, and then sharply lower the car body. If the car quickly returns to its original position and practically does not sway, then this indicates the good condition of the shock absorbers. If, during such a check, constant long-term rocking of the body is noted, then the shock absorbers should still be replaced as soon as possible.

Other sources

Sounds masquerading as suspension can be created by any part of the power unit under the hood, and even by any loose fasteners.

In this case, great difficulties arise in diagnosis due to the significant volume of checks. It can be very difficult, after going through the entire suspension, steering, brakes and half of the engine, to eventually find a fragment of a destroyed catalyst hanging in the exhaust system pipes or a driven disc damper spring flying along the clutch housing. Particular attention should be paid to the power unit supports, which elastically separate the engine and transmission from the body. If one of them sank, then touching on bumps is possible anywhere. Body parts, such as a bumper, fender liner, or even the hood, can also rattle due to lost support bushings.

Not all drivers react adequately to such a knock in the front suspension on small bumps. Some continue to adhere to the old rule that good sound will manifest itself. Undoubtedly, this will happen, but even without talking about safety, we can accurately predict that the consequences will cost more than prevention.