The brake disc is no less important in the braking system of a car than the pads. And if the latter are replaced when worn out, then almost no attention is paid to the former. But the efficiency of the system also depends on them. Let's find out how to determine the wear of brake discs so that they can be replaced on time.

Most of the discs that lie on the shelves of car dealerships are made of cast iron. The popularity of such products lies in their low cost and good friction characteristics. But the problem is that in the process of reducing the speed, the cast iron alloy product heats up. This leads to deformation, warping, and uneven abrasion. To reduce wear and tear from heat, manufacturers began to produce products with ventilation. Grooves are also cut on the surface of the disk. This allows you to increase the life of the disk.

What affects wear?

Each manufacturer prescribes brake disc wear standards. These parameters are obtained based on engine power, vehicle weight and other factors. But it is very difficult to calculate the mileage after which you will need to change the discs. Wear is influenced by various factors that cannot be taken into account.

First of all, it's your driving style. If the car owner prefers to drive more extreme, where sharp accelerations are replaced by equally sharp braking, then the service life of the disc is significantly reduced.

Mechanical factors also affect the service life. The material from which the brake disc is made is important here, as well as the quality of the pads. Often, discs are made from cast iron and its alloys - the material wears out more often than ceramics. The use of low-quality pads (for example, with asbestos) also leads to uneven wear.

Symptoms of wear

Many people do not know how to determine the wear of brake discs, but it is very simple. There are several signs that it is time to change the disk.

The first indicator is vibrations, grinding noises, and extraneous sounds during the process of reducing speed. The second symptom is the car skidding due to the brake system being blocked. After the driver presses the pedal, the brakes may jam.

How to find out the abrasion thickness?

In order to find out the permissible maximum thickness of the brake disc, you should look at the end of the product. There are two meanings to this part. This is the original thickness, as well as the minimum allowable. The numbers may vary depending on the car and wheel manufacturer. How to determine the degree of wear of brake discs? It is enough to simply measure with a caliper and compare the numbers with acceptable standards. This is how you determine whether the product can still be used or not. The disc should also be changed if it has different thicknesses at different points.

Reviews from car enthusiasts on forums about wheels from different companies

- “I installed Ashika discs and pads on all wheels. Overheating and temperature changes are tolerated calmly. I am completely satisfied with the quality. Once I had to slow down at a speed of 140 km/h, and at the end I also drove into a puddle. So, everything is fine after that, the minimum thickness of the brake discs still doesn’t smell.”

- “The life of the driver depends on the brakes, so I settled on Bosh. I installed them two years ago, they are not noisy, they quickly got used to the pads, and it’s hard to overheat them. The material is high quality, packaged well, so initially there were no scratches. I installed it without any problems. High quality and inexpensive at the same time.”

- “I bought avantech. The car traveled 4 thousand km with them. So far I'm happy with the purchase. The brakes work great, the avantech is well balanced and there are no squeaks. I hope they will continue to enjoy driving.”

We recommend

“Which lubricant to use for calipers: making the right choice” Read more

- “I installed TRW seven years ago, the car still stops clearly. TRWs are suitable for city driving, but not for racers. They can quickly thin out to a minimum thickness and stop slowing down.”

- “I recommend NK to my friends. I buy these myself. The packaging is good, and the products themselves are clearly of high quality. The car brakes “excellent”, there were no problems with them at all. Their wear is below average, but, of course, it also depends on the pads.”

- “The car has already traveled more than 50 thousand km on Trialli. This is in three years. Trialli has perforations to avoid overheating. This does not contribute to pad wear, as some people think. And these holes do not add any noise during braking: no squeaks, no squeaks. There were no cracks in the hole area. The kit included its own pins for fastening. These discs did not turn blue, unlike standard ones. In terms of price, they are not much more expensive than their analogues. To summarize: I liked it, they were strong enough and didn’t deform.”

Rating 5 out of 5. Voted: 2

Alina

2019-09-30 10:04:41

I began to notice a grinding noise when braking, it turned out that the brake discs were worn out, the thickness was minimal. I had to change it.

Fix defects or replace?

When the measurements are completed and the exact diagnosis is clear, the car owner is faced with the question of whether to restore the old product or purchase a new one. It should be remembered that the disc can be sharpened only if there is residual thickness (from 22 millimeters). This is true for ventilated discs. Many experts recommend replacing only. However, if the price of a new disk is too high, and there is a spare thickness, you can try to restore it.

Small beads and grooves can be removed by grooving using special equipment. Some even do the grooving with a file, but this is unreliable. The essence of the operation is that a thin layer is removed from each side of the disc. Then the product receives a perfectly flat surface.

Before boring the disc, the cause that caused the deformation or beads on the surface should be resolved. Otherwise there is no point in restoration. Among the causes of uneven wear, brake pads are in first place. If they are of poor quality or installed incorrectly, they can easily damage the surface of the disk.

When to change pads?

We know how to determine the permissible wear of brake discs. But it’s worth paying attention to the pads, since these elements work in pairs and together affect braking efficiency.

One of the signs of pad wear is a squeaking sound when the speed is reduced. The sound is produced by a special wear sensor. This is a special plate. When the friction layer of the pad is worn away, the plate touches the disc and causes the sensor to operate.

You can determine that the pads are worn out by the operation of the brake system. Brakes that are too weak or too harsh can indicate wear. In the first case, the braking is not intense, although the pedal is pressed quite deeply. In the second, the wheels are blocked due to the lack of friction lining.

How to determine the wear of brake discs and pads? This can be determined by vibrations during braking, as well as by visual inspection and a measuring tool. There are no other options.

Groove

During operation, the brake disc can become deformed; cracks, irregularities and other defects may appear on it. Their presence is manifested by vibration when the brake pedal is pressed. If the thickness of the disk is sufficient, then in this case it can be ground (grinded). Otherwise you will have to buy and install a new one.

High-quality grooving can be done using a special machine, which is installed in place of the caliper. The disc itself is not removed from the wheel.

Some craftsmen sharpen with a grinder, but in this case it is difficult to vouch for the quality. It is also impossible to guarantee accuracy when using a lathe, when the groove is made relative to its bobbin, and not to the wheel hub.

After grinding, the brake pads should be replaced, otherwise vibrations and beatings during braking will appear again.

We determine the mileage based on the condition of the disks

Today, cars are sold by so-called resellers, who often deceive buyers. Cars come with low mileage. Many of them only look normal outwardly, but technically they are in a deplorable state. Resellers often change the pads, but simply forget about the discs. And this is in vain - the average mileage of a car can be determined by the condition of the disk.

On average, brake discs are changed every 180-200 thousand kilometers. But this is not true for all cars. Also, different drivers drive differently. Some people manage to drive 150 thousand kilometers until they are completely worn out, and some even 250. But if the mileage of a car is 70 thousand, and the total thickness of the disk is 20 millimeters, this car has probably traveled at least two hundred. It is worth refusing to purchase such a copy.

Why do brake pads fail quickly?

Another question that some motorists ask is: why do I have to change the pads on my car every 5-7 thousand kilometers? On most vehicles, brake pads are changed during maintenance every 15 or even 30 thousand kilometers. There are different drivers and different habits - this is the only answer to this question. Driving habits determine how long it will take for your car to require certain investments and major repairs. So it is the travel style that will become the main cause of all the problems and malfunctions that arise. Some of the most important habits that keep your pads in good condition include the following driving skills:

- absence of sudden braking without a vital need to perform such an action on the road;

- the ability to foresee all situations on the road and perform smooth braking in advance;

- the ability to use the braking forces of the engine, which completely preserve the pads in their original form;

- smooth ride, absence of fast acceleration and sharp braking simply because such a habit has developed;

- avoiding pressing the brake pedal, using other braking methods that are effective;

- lack of desire to constantly save on parts for regular maintenance, including brake pads.

Modern cars require some attention from their owners. In most cases, they are of fairly high quality and reliable, but sometimes driving style has an incredible impact on the design of the car. Most problems in vehicle operation are due precisely to the fact that drivers do not pay attention to the needs of the vehicle, but simply carry out ruthless operation of the car. However, if you have the latest models of luxury cars, you can safely continue to do this. Just don’t forget to come to the service at the right time and pay a tidy sum for full service and high-quality vehicle diagnostics. We offer a short video answering the question about determining the quality of pads:

Wear limit

Each brake disc has its own limited resource. It is set by the manufacturer from the factory, and resource wear is affected by mileage, braking intensity, the condition of the entire braking system, the characteristic features of the vehicle itself, etc.

When buying a new set of brake discs for his car, the driver must always follow the recommendations of the car manufacturer. Therefore, first we look at the instruction manual, or according to convenient catalogues, based on the characteristics of our particular machine, we select a part via the Internet. If you take a high-quality kit from a trusted manufacturer, you can be sure that wear will not occur very quickly, and when braking hard, the car will definitely stop, as you expected. The same applies to buying new pads.

There are international norms and standards for the production of such components for passenger cars. They oblige all manufacturers to make appropriate engravings or markings on products.

The essence of the engraving is to indicate information that relates to the maximum permissible degree of wear.

There is such a thing as the thickness of the brake disc. And it has a certain maximum wear limit.

To obtain the relevant information, you should look at the end part of the product. It is there that, according to international standards, all manufacturers of certified parts are required to display data regarding the wear of the brake part. Information about the initial thickness, as well as what thickness is considered minimal, should be located here. As soon as the disk reaches this value, it must be replaced. In fact, the manufacturer thereby relieves itself of responsibility. If a driver wears a disc below normal and causes an accident, he will not be able to blame the brake manufacturer or auto company for this.

There is an interesting feature here. When the question arises about when to change brake discs, many people look at the end side of the old product, but find nothing there.

This happens, but only on products that have not been certified or are counterfeit. It is strictly not recommended to buy such parts without information about wear.

Additional questions and answers

What is the service life of brake pads and brake discs?

There are many factors that influence the average lifespan of your brake components. These include pad type, rotor type, your personal driving style and maintenance. According to most brake pad companies and qualified mechanics, brake pads can last between 30,000 and 120,000 kilometers. At the same time, the front ones wear out about 3 times faster than the rear ones. On average, it is recommended to change pads on domestic cars approximately every 10,000 km, and on foreign cars - every 20,000 km. Actual service life can vary greatly, the main thing is to prosodicly check them and their thickness.

Left - new pads, right - old

The service life of brake discs is quite long - 3-4 times longer than that of pads. But again, it all depends on many other factors, such as how you maintain your braking system and how you drive your car. On average, this is more than 100,000 km. Here you also need to rely on the thickness of the rotors when taking measurements.

How much do new brake discs cost?

The average cost of new brake discs varies from 3,000 to 5,000 rubles each. Some rotors with the best characteristics can cost from 7000+ rubles each. Additionally, prices vary greatly depending on the type, brand, and quality.

New brake discs

When it comes to replacing brake rotors, some people often wonder whether they should buy new or remanufactured parts. Each of these types has its own advantages and disadvantages. For example, aftermarket parts tend to be cheaper and available in a wide range of options, while new brake rotors are easier to select and offer greater quality assurance.

Can I drive with worn rims?

Brake rotors play an important role in allowing your car to stop while it is in motion. If the rotors are not working properly, you may not be able to stop the machine properly in an emergency. This can lead to many dangers if you need to stop to avoid pedestrians, bicycles, car accidents or other traffic situations. So when you find that your brakes aren't performing as well as they should, you need to take your car to a mechanic as soon as possible to have the thickness of your rotors checked.

Determining the degree of wear

You have received basic information about the maximum and permissible wear. Now you need to find out exactly how the wear of a part is determined and what is required for this.

Not a single specialist or auto parts manufacturer can say 100% exactly how long a brake disc will last or how many kilometers it can travel. There is only a calculated resource, which is influenced by many additional factors. Yes, for starters it’s worth focusing on the quality of the disc itself, the raw materials used and adherence to technology. This is a question for the manufacturer. It's definitely not worth saving on brake discs. It is better to give preference to more expensive, but reliable and proven parts from leading manufacturers.

But there are other factors that provoke gradual or rapid erasure of the disk, exceeding the calculated values. These are driving style, condition of the brake unit, pad wear, climatic conditions, road surface condition, etc.

All this suggests that diagnosing discs is the task of the car owner himself.

It is unlikely that it will be possible to carry out an accurate diagnosis without removing the wheel. You can only visually try to take a closer look at the condition of the element through the wheel rim and roughly assess its current condition. But it will not be possible to check the disk for curvature or accurately determine the degree of wear.

And it doesn’t matter what kind of car we’re talking about. Brakes wear out everywhere, be it:

- VAZ 2110;

- Mercedes E-Class;

- Skoda Octavia;

- Subaru Forester;

- Daewoo Lanos;

- Chevrolet Aveo;

- VAZ Niva;

- Chevrolet Niva;

- Nissan Qashqai;

- Mitsubishi Galant;

- Chevrolet Captiva;

- Lada Kalina;

- Opel Astra, etc.

The first step is to remove the wheel from the side where there is a potentially problematic part.

Another feature is that it is recommended to replace both wheels at the same time, even if the second disk is in better condition and has not completely worn out.

Measurements are taken first and then a visual inspection is performed. Then an appropriate decision is made. You may need to groove the discs, which in theory can be done with your own hands.

Other reasons for replacing pads

In addition to situations with critical wear, it is necessary to change brake pads in the following cases:

- the thickness of the friction material is more than 5 mm, but the lining itself has begun to peel off from the steel base;

- cracks and chips appeared on the surface, the material began to crumble;

- stains of oil or brake fluid that reduce friction properties were found on the parts;

- when the brake drum or disc is replaced.

Another reason for replacement is due to the abundance of low-quality fakes on the automotive spare parts market . New pads purchased from an unreliable retail outlet begin to squeak or squeak terribly after 1-2 thousand km, although the working part is still far from completely worn out. The culprit is the material of the part, whose hardness is comparable to metal, causing the surface to “slick” and create a creaking sound. If the elements made from unknown materials are not replaced, then the production on the brake discs will increase sharply.

Many modern cars are equipped with special sensors that detect a decrease in the thickness of the friction layer and send a signal to the driver when it reaches a critical level. This is also a reason to remove parts with worn linings and install new ones.

True, the sensors often become clogged with dirt and lose their functionality, so it wouldn’t hurt for the car owner to check the condition of the brakes himself.

Stages and features of diagnosis

The measuring stage of the test involves the use of a caliper, which will help make thickness measurements. At approximately 5-8 points, moving around the disk, measure the thickness. If it varies along the radius of the part, there are signs of curvature and uneven wear.

Check the information from the manufacturer to understand whether the wear limit has already reached or not. I cannot say which indicators are correct and which are not, since different discs have their own wear limits.

Then a visual inspection is carried out. The disc should be examined for cuts, chips, dents, scratches and other defects on its surfaces. If they are, the spare part will have to be replaced.

Do not forget about the rule of pairwise replacement on the same axis. That is, when the left front disc is changed, the front right one also changes at the same time.

If you want to assess the condition of the elements without removing the wheels, this can be done by checking while driving. With severe wear, characteristic signs appear:

- the car brakes jerkily;

- a grinding sound appears;

- there is a squeaking sound when you press the brake;

- other extraneous sounds are heard;

- the driver feels a beat on the steering wheel;

- the beating is also felt in the gas pedal;

- When the brake pedal is pressed, the braking system is locked.

I strongly do not recommend waiting for such symptoms to appear. It’s better to periodically do simple diagnostics in your garage through visual inspection and measurement. This is usually done every 10-15 thousand kilometers, if wear symptoms do not appear earlier.

What are car brake discs?

The safety of the driver and passengers, as well as other road users, depends on the condition of the brake system, in particular the discs. Emergency braking, stopping on a slope - there are a lot of situations in which the brakes must function without the slightest complaints. According to traffic rules, a driver is not allowed to drive a vehicle if the brakes are in a faulty condition. In short, it is extremely important to check the car in a timely manner, diagnose any problems associated with the brake discs, and fix them.

The brake disc is part of the hydraulic brake unit. The disk itself is made of metal. While driving, it rotates parallel to the wheel at the same speed, and when the driver presses the brake, it is pressed against the brake pads.

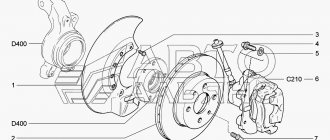

What is a disc brake system? Firstly, it is the brake disc (rotor) itself, which is located on the axis of the car’s wheel. Secondly, a caliper consisting of two brake pads (the pads move under the influence of hydraulic pressure). When you press the brake, the pads come into contact with the brake disc on both sides, friction leads to a decrease in speed. If we compare disc brakes with drum brakes, the former are considered more reliable and efficient, especially in conditions of high temperatures and humidity.

We recommend

However, such brakes have one drawback: the disc can overheat, which ultimately leads to a decrease in the effectiveness of the entire braking system. To avoid this, manufacturers create ventilated and perforated disks: heat is removed from them using a system of internal channels or through holes. Perforated discs are considered more efficient in terms of cooling; in addition, due to their design, wear products of friction linings disappear from the friction zone of the pads and disc.

Design features

The bulk of the front and rear discs are made of cast iron. Its popularity was facilitated by its low cost and good friction properties. But the trouble is that during the braking process this material heats up. This can lead to warping, changing the shape of the working surface and ultimately uneven erasing. To minimize these phenomena, manufacturers began producing front and rear discs with internal ventilation. They also began to cut grooves on their surface and perforate this product. This made it possible to significantly reduce overheating and increase their operating time.

Effective adhesion between the pads and the disc begins only after they are ground in. At this time, you should not press the brake sharply, but stop smoothly. This usually happens with a mileage of no more than 1000 km. You can check the effectiveness of lapping on a special stand.

How to check the condition of brake discs yourself

1. How to check brake discs for runout

Disc runout may occur when the car is braking if:

- the disc is worn out or its surface is slightly deformed;

- the chassis of the car is not functioning correctly;

- the nuts on the wheel are not tightened;

- the disk is curved;

- There is a hernia on the tire.

You can check the brake discs yourself using a runout measuring device:

- first remove the brake caliper (without disassembling it first) and secure it with wire;

- then the brake disc is attached using the hub nuts;

- the device for measuring runout is fixed 5 mm from the brake disc. Now you can check it: for the front wheel the value should not be higher than 0.06 mm, and for the rear wheel - 0.08 mm.

Such a device is sold in automotive supply stores and looks like this:

If after measurements the values are higher than acceptable, you need to do the following:

- the place where the beating is heard especially well is marked with chalk (on the hub);

- then the brake disc is dismantled;

- take a dial indicator and use it to measure the amount of play; to do this, you need to move the hub along the axis;

- if play is found, remove the wheel hub and steering knuckle;

- then change the position of the disk and measure the runout.

If the runout is not eliminated even after the brake disc is installed differently, you will have to buy a new one.

2. How to check brake discs for deformation

The deformation of the brake disc is usually visible: there may be ribs, waves or bumps on it. But diagnosing curvature can be much more difficult.

Deformation of brake discs occurs when the vehicle is not used properly. For example, when the disks are very heated and suddenly cooled. This can happen while driving in a big city with heavy traffic and traffic jams, or when braking for a long time and hard, followed by water getting on the discs. Sudden cooling of the disk after severe overheating leads to distortion of the metal. And this can seriously affect the performance of the vehicle.

How to check brake discs for deformation? You need to jack up the car. When turning the wheel, you need to pay attention to how it rotates - calmly or slightly braking. In the first case, the disk will be fine, but if it slows down in the same place, it indicates the presence of curvature.

When you need to check which wheels - rear or front - affect the steering wheel wobble, you should use the parking brake. If vibration is noticeable when using it, this indicates a problem with the rear wheels.

It is easier to check the front brake disc for deformation than the rear one. Actually, the car owner will feel its curvature immediately. But a problem with the rear axle wheel rims may not be immediately noticed and you may drive with this problem for quite a long time. Often, the driver is able to feel something is wrong only in a situation of braking at high speed.

There is another way to check the brake disc for curvature. If there is constant beating, especially during braking, the disc is rotated directly on the hub. If he is the leader, then they spin the wheel, starting the engine. Next, press a screwdriver against the caliper and move it to the upper side surface of the disc until friction becomes obvious. This sound is used to determine the presence or absence of curvature: a uniform sound indicates the absence of a problem, and an intermittent sound indicates that the disk is curved. The degree of curvature can be checked by eye based on the size of the gap, but it would still be better to use a special device.

In some cases, a turner can correct the situation. If the disk is new and quite thick, a specialist will remove a layer of metal on a machine, due to which it will become even. However, such manipulation leads to thinning of the brake disc, which in itself is not very good. Sometimes turners also work with thin discs, performing transfusion, but this procedure is not the safest for the further operation of the car and it is better to avoid it.

collage

After grooving, you need to change the pads, otherwise the friction linings that have worked on a crooked disc will kill the treated disc. For the sake of experiment, take such a block and rub it on sandpaper that lies on a flat plane - dangerous depressions will appear on the visually flat surface!

In Moscow, the cost of turning discs for one axle is no less than 2000 rubles. It is recommended to treat both discs so as not to shift the brake balance.

RISK AREA

Cast iron is the most common material for brake discs. And quite insidious: with sudden temperature changes, cast iron noticeably changes its physical properties - hardness, volume and even internal structure. This feature leads to excessive warping of the working surfaces of the disk. Of course, there are more durable analogues (for example, ceramic or composite) that provide better stability and braking dynamics, but their price is off the charts.

The brake disc shield does not protect against water: it gets abundantly on both its surfaces. If a cast iron disc is exposed to too much temperature change, its internal structure may be damaged. Processing on a machine will remove the bent top layer, but after a couple of intense braking (that is, heating and cooling), the surface will move again - this happens in five cases out of a hundred. Only an experienced turner can identify a damaged disk during turning - by the change in the tonality of the rustling sound from the cutters.

More often than not, the inner part of the disc leads more strongly than the outer part. This happens on cars with calipers with a so-called floating caliper: the inner pad is activated first - and, accordingly, this surface of the disc heats up more.

The runout of the front discs usually responds to vibrations on the steering wheel, the runout of the rear discs - on the brake pedal and on the body. The front discs more often suffer from temperature changes (they are more heavily loaded), and the rear discs suffer from corrosion. Vibrations increase with increasing temperature of the disk and the environment - due to the expansion of the metal. Sometimes the noticeable beating disappears in the winter.

Source www.zr.ru

The longer a car is used, the more problems the car owner encounters due to failed components and parts. In such cases, you should not hesitate and try to immediately find the cause of the troubles that have arisen, especially if it concerns the brake system of the car. If you do not pay attention to the vibration and beating of brake discs in time, you can be left without a car in the literal sense of the word, putting not only your life in serious danger, but also other road users.

Severe vibration and beating are a consequence of incorrect wheel balancing or premature wear of tire material, failure of car suspension elements or the working surface of the brake system discs. Therefore, it is recommended to periodically check the brake discs to avoid troubles.

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"