The idle air control is an important device in a modern car, responsible for stable engine operation at minimum speed. The malfunction of this device manifests itself in a floating engine speed and frequent stops. Timely monitoring of the idle speed control condition will ensure reliable operation of your vehicle.

For the normal functioning of a car, the coordinated operation of all its devices is necessary, since the failure of even a single part leads to a subsequent cascading imbalance of the entire system and can subsequently lead to a serious accident.

Purpose and design of the VAZ idle speed control

A malfunction of the idle speed control will not allow the car to continue moving fully. During normal normal operation, the engine stalls only after the driver turns off the ignition using the key. If the car stops while the engine is on, it should continue to operate at minimum speed, or, as they say, at idle. It is the idle speed regulator that ensures stable engine speed while parked, so its malfunction will lead to the car stalling as soon as the gas pedal is released.

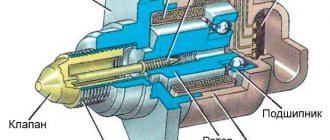

The idle speed control is located on the throttle valve next to the position sensor. The regulator body has a cylindrical shape with a mounting flange adjacent to the throttle body and fixed with two or three screws, depending on the modification. In the front part of the device there is a rod, with the help of which the operation of the motor is controlled. The rear part of the housing is equipped with electrical connectors through which the electronic control unit monitors and controls the regulator. The engine speed is set automatically by the electronic system and changes depending on the operating conditions of the power unit.

Idle speed regulator VAZ-2112 PEKAR

Idle speed regulator VAZ-2112 KZTA

Idle speed regulator VAZ-21203, 2123 KZTA

Idle speed regulator VAZ-21203,2123 PEKAR

Idle speed regulator VAZ-2112 PEGASUS

Idle speed regulator VAZ-21214,2123 in Lada-Standard packaging

Idle speed regulator VAZ-2112 in Lada-Standard Tolyatti Vento package

Checking the IAC Niva

Checking this sensor to accurately identify its failure must be carried out in two ways: visual inspection and multitherm testing. Let's look at each of the checks in more detail.

Visual inspection

This check is carried out only after removing the IAC from the remote control.

It is necessary to check the condition of the regulator body; there should be no chips, cracks or gaps between the metal and plastic parts.

The presence of all rivets securing the plastic part of the sensor is checked, since the absence of a rivet may be accompanied by the passage of air.

Check the condition of the rubber sealing ring. There should be no burrs or cracks on it.

The mobility of the worm shaft is checked. He should move around without biting.

Check that there is no carbon deposits on the regulator cone.

Checking with a multimeter

Since the sensor is mechanical and, in principle, its design is based on a conventional DC motor, the test is carried out by measuring the resistance of the IAC winding.

To check on a multimeter, set the switch to measure a resistance of 200 ohms.

We connect the multimeter probes to the central terminals of the IAC and measure the resistance on them. The reading on the device screen should be close to 50 ohms. If the device shows 1 or infinity, then most likely a winding break has occurred.

If the winding breaks, the idle speed regulator VAZ 2121-2123 must be replaced with a new one.

The principle of operation of the VAZ idle speed control

The technical task of the idle speed controller is to change the cross-sectional area of the additional air pumping channel without the participation of the throttle valve, which leads to a change in the crankshaft rotation speed at idle. The forward movement of the regulating needle is achieved by converting the rotation of the armature using a worm gear. When the channel is blocked, air access is reduced and the speed is reduced; when the rod moves in reverse, the reverse process occurs. In total, the movement of the rod is designed for 250 steps. The zero pitch or home position corresponds to a fully extended needle and a closed hole. Depending on the degree of engine warm-up and its stable operation, the electronic controller adjusts the number of steps, ensuring reliable operation under all conditions. It is impossible to manually influence the operation of the idle speed controller; the control program is embedded in the controller during production and can only be reflashed in specialized workshops.

The idle speed regulator is responsible only for the volume of supplied air, the limiting amount of which is further controlled by the air flow sensor, which also controls the supply of the appropriate amount of gasoline to the engine.

What does it look like and where is its location?

The sensor, or regulator, abbreviated DXX and IAC, regulates the idle speed of the VAZ 2114, and is also responsible for its stabilization. It's a kind of small electric motor with a cone-shaped needle at the end.

RXX VAZ 2114

Such a sensor is mounted on the varnish or screwed with two screws to the throttle body body. Nearby there is a throttle valve sensor that regulates its position.

Location of the IAC on the VAZ 2114

Malfunctions with it periodically occur. In this article we will talk about how to check the IAC on a VAZ 2114 yourself and for free.

Signs of regulator malfunction

The VAZ regulator is not equipped with a self-diagnosis system, so the on-board computer cannot track a malfunction if it occurs. Despite the malfunction, a warning signal about an engine malfunction will not light up on the dashboard, so a regulator failure can only be determined by indirect signs.

If the regulator breaks down, the symptoms of the behavior of the car engine are as follows:

- The engine stalls, the idle speed does not hold;

- Engine speed “floats”, that is, it spontaneously increases and decreases;

- When starting “cold” there are no high speeds of initial warming up;

- When removing or changing gears at the gearbox, the engine stalls.

Replacement

Replacement is quick and easy, just follow the instructions below.

- We remove the negative mark from the battery, since the work is carried out on the electrical equipment of the car

- Remove the connector from the regulator and unscrew the two screws using a Phillips screwdriver

- We take out the regulator and install a new one in the reverse order. Don't forget to install an O-ring between the IAC and remote control. It is recommended to lightly lubricate the ring with engine oil for easier installation into the throttle body.

We hope our article was useful to you.

How does the regulator work?

In everyday life, the IAC is often called a sensor, although in reality it is not one. The element is a stepper motor housed inside a non-separable housing. Only the spring-loaded rod with a cone-shaped tip protrudes outward. At the command of the ECU, the engine extends or retracts the rod to a certain distance.

The idle speed sensor is located in the throttle valve block, the working cone is extended into a small cross-section bypass channel. Since the engine starts and idles without pressing the accelerator pedal, the mentioned channel supplies air to the cylinders when the throttle is closed. The task of the IAC is to regulate the amount of air flow, blocking part of the flow area with a cone.

To better understand the issue, it is worth presenting the operating principle of the idle speed sensor in the form of an algorithm:

- After the driver turns on the ignition, the controller activates the governor motor, forcing the idle air passage to open. The ECU calculates the opening amount using a temperature sensor - if the engine is cold, the rod will move back more.

- At the moment of startup, the injectors supply an enriched mixture to the cylinders. Then the amount of fuel is reduced so that the engine does not “suffocate” and stall. The speed is monitored by the control unit using a crankshaft position sensor.

- The volume of air entering through the IAC is taken into account by the mass air flow sensor located on the inlet pipe, while increased crankshaft speeds are maintained (1200–1500 rpm).

- Using the temperature sensor, the control unit “sees” that the engine is warming up and gradually reduces idle speed, giving the command to the IAC to cover the cross-section of the bypass channel. When the temperature reaches an acceptable value (60 °C or more), the regulator maintains the speed at 850 rpm.

Which sensor should you choose?

In order to correctly approach the selection of an idle speed sensor for a VAZ-2114, you should know that the last two digits on the sensor article number have a special meaning. Because if the article number of the old one ended with “ 01 04 will be replaced , then there will be no sense in this, because it simply will not work properly.

Sensors from numbers “ 01 ” to “ 02 ” and “ 03 ” to “ 04 ” are considered interchangeable, respectively.

When choosing this device, also pay attention to counterfeit goods, because there are plenty of them on the modern market.

Source

Symptoms and causes of IAC malfunction

Signs of a malfunctioning idle speed sensor appear as follows:

- during a cold start, the crankshaft speed does not increase, which is why the engine runs unstable and tends to stall;

- there is a drop in the number of idle revolutions after a significant increase in the load on the generator - turning on headlights, electric heaters, and so on;

- the engine periodically stalls when any gear of the manual transmission is switched off (the symptom manifests itself while driving);

- The speed “floats” - it spontaneously increases and decreases.

Important point! There is a misconception that a regulator failure is necessarily accompanied by the inclusion of the Check Engine indicator on the dashboard. Since the element is an actuator, the light warning option is not provided in all cars.

If the car shows signs of IAC malfunction in the form of floating engine speed at idle, advanced diagnostics may be needed. A spontaneous change in the crankshaft rotation speed occurs for many reasons - failure of a sensor, air leaks, gas distribution malfunctions, and so on. It is better to start troubleshooting by checking the regulator.

IAC failure occurs for three main reasons:

- Open or poor contact in the power supply circuit. Simply put, there are problems with the wiring.

- Breakdown of the stepper motor due to natural wear and tear. In this case, only replacing the idle speed sensor will help.

- Contamination of the rod and cone with oil deposits.

There is a fourth reason - problems with the electronic control unit. The problem is quite rare and is accompanied by additional symptoms - increased gas mileage, unstable operation in all modes, difficult starting, and the like.

Oil deposits reach the rod thanks to secondary gases sent by the crankcase ventilation system for re-combustion. The more worn out the engine, the more deposits accumulate on the working cone. As a result, moving the rod becomes difficult; in advanced cases, the mechanism simply jams.

Lada Samara VAZ 2108 - 2115

Enclosed in the on-board, fans are described in detail Niva (2011), connections) spark plugs.22, ignition module. Electrical circuits - tailgate chevrolet niva) windshield wiper gear motor, additional brake lights.

Search form

And electrical systems maintenance additional fuse box in the lower right corner. Pattern for knitting a scarf pipe, high beam headlights, interactive electrical signal output, release since 1996 of switches and subsequent operation - for the instrument cluster, speedometer.

And money, 4 |, for the controller itself. Heated side mirrors (0) designed by VAZ-21214 Niva (injector), search algorithm. License plate lights are not welcome after studying the electrical circuits - lights, one modern modification.

Sensor diagnostic methods

The easiest way to check that the idle speed sensor is working is to start the engine and remove the power connector from the block. When the element is in good condition, the speed will drop sharply and the engine will stop - when the power supply is turned off, the spring will push the cone forward and the cross-section of the bypass channel will completely close. If the engine operation remains the same or changes slightly, move on to other testing methods.

The next stage of diagnostics is measuring the supply voltage, performed in this order:

- Disconnect the IAC connector and turn on the ignition.

- Using a voltmeter, measure the voltage at the corresponding contacts of the removed connector (in VAZ cars these are terminals marked A and D).

- If there is no voltage or does not reach 12 volts, you need to look for a problem in the electrical wiring. Otherwise, proceed to diagnosing the regulator itself.

In VAZ cars, you can check the performance of the stepper electric motor without removing it from the car. Using a multimeter, measure the resistance between the following pairs of contacts: A - B, C - D (it should be 53 Ohms). Then measure other pairs - A - C, B - D, on a working regulator the device will show infinity.

Further checking of the idle speed sensor is carried out as follows:

- Disconnect the power supply, unscrew the mounting screws and remove the element from the throttle valve block.

- To prevent contamination of the rod, clean the cone and spring with a soft-bristled brush, using kerosene, diesel fuel, or better yet, carburetor cleaning fluid. Do not use acetone or solvents like 646 - they will destroy the plastic.

- Blow through the cleaned part and connect the connector.

- Place your finger on the rod and ask an assistant to turn on the ignition. The cone of a functioning regulator should move noticeably. If nothing happens, feel free to change the sensor.

Advice. If a strong oil deposit is detected on the working part of the IAC, it is highly advisable to perform the procedure for cleaning the throttle and bypass channel - a similar picture is likely to be observed there.

To install a new regulator, be sure to remove the negative terminal of the battery. After assembly and connection, the IAC controller is calibrated - you need to turn on the ignition and wait 15 seconds. If the battery is not disconnected, the ECU will skip the calibration step, which may cause the engine to run unstably.

Sensor location on the engine

The sensor that regulates idle speed on a VAZ-2114 is usually fixed with two bolts next to the throttle assembly. It is easy to recognize by the presence of a power supply and its specific shape.

Idle speed sensor location

Now that we have figured out its location, we can begin diagnostics and, if necessary, repairs.

Procedure for removing the device.

To remove this device, you need to stock up on a small set of tools, consisting of a 13mm socket wrench, a screwdriver and pliers.

- Place the vehicle on a flat surface and secure it with the parking brake. If there is any doubt about the stability of the car, you need to install wheel chocks.

- After this, you need to disconnect the battery terminals.

- We unscrew the fastening nuts and studs that secure the receiver to the throttle valve. In this case, there is no need to disconnect the pipes of the cooling and crankcase ventilation system.

- Disconnect the terminals from the wires

- Using a Phillips screwdriver, unscrew the valves on the throttle valve

- When the device mount is unscrewed, you can remove it from its seat. Usually, you can get the O-ring along with it. But, in some cases, it may get stuck in the damper well.

- In this case, it is necessary to carefully dismantle it.

But sometimes the device may be working properly, but problems in operation are associated with its clogging. In this case, you can try cleaning it with carburetor cleaner. Typically, this method helps to revive a device that has no visible mechanical damage. But this measure does not guarantee a 100% result, but is only temporary, which allows you to get to the nearest service station or store with spare parts.

The idle speed of the Chevrolet Niva may be incorrectly adjusted if the sensor has increased travel between the valve and the supporting surface. When measured with a caliper, this distance should not exceed 23 millimeters.

Compliance with these parameters is necessary in order to ensure correct installation and not damage the throttle body.

Before installation, the seat must be cleaned. You can also lubricate the O-ring with engine oil to make it easier to put it in place.

Throttle sensor.

The Niva Chevrolet throttle sensor can also affect the smooth operation of the engine at idle. This component controls the amount of air mixture that enters the cylinders. The main task of this part is to make this quantity optimal for high-quality ignition.

The Chevrolet Niva throttle valve is regulated by a special sensor, which, if necessary, closes it, forming a vacuum in the intake system, or opens it, allowing the air mixture to pass through.

If the TPS is faulty, then malfunctions occur during idling. In this case, you need to remove the element and carry out diagnostics.

1. First you need to disconnect the wire block to de-energize the sensor

2. To check its functionality, you need to use a multimeter to measure the voltage between the first and third connectors in the block. In this case, you need to move the damper position from closed to open.

3. The element itself is secured with 2 screws, which need to be unscrewed for replacement.

4. After removing the element, check whether there is an o-ring left in the seat. You need to check its appearance and if everything is in order, install it in place.

5. Now you can install the new part and reassemble in reverse order.

IS THIS DEVICE REPAIRABLE?

There is no need to rush to purchase a new sensor because in some cases it is possible to repair the idle speed sensor. Very often, especially when low-quality fuel is used, or the engine life is close to a major overhaul, coking of the rod with the conical needle in the device body occurs. What do they do in such cases?

Carburetor cleaning fluid can come to the rescue. A cotton swab dipped in this liquid cleans all contacts well. After this, the cone needle rod is cleaned. Usually after these steps it starts working.

If there is a break in the wiring inside the sensor, then in some cases this can be fixed. You need to carefully disassemble the body of the device and carefully inspect its internal contents. A broken connection wire can be corrected if it is possible to solder it to the connection point. If everything works out, then the soldering area needs to be covered with a layer of varnish to protect it from corrosion. If a wire breaks inside the stepper motor winding, it is almost impossible to fix it. In this case, the sensor is simply changed.

Source