The fifteenth model of the Tolyatti auto giant was produced in 1997–2012. But only since 2000, injection engines with an on-board control system were installed on it. Many car owners of “tag” cars unwittingly became acquainted with the problems of the fuel system and electronics. One of the painful mysteries of the VAZ 2115 was the idle speed sensor. The controller does not always detect its failure, so the owners had to figure out the problem by trial and error. Next, we will tell you where the idle speed sensor is located on the VAZ 2115, what symptoms indicate its breakdown, as well as how to check and change this device.

For reference. In technical language, the XX sensor is called a regulator, and is written in diagrams as IAC.

Purpose

The idle speed sensor assumes the performance of a rather important function, which is to constantly regulate engine speed while driving in neutral gear, as a result of which you will not have to worry about the normal and uniform movement of the vehicle. This device also controls the speed during the process of switching from one speed to another, which is also quite important, since in the absence of such control, switching may occur unevenly, as a result of which the car will simply stall, which is unacceptable while driving, especially at high speed.

The valve, which is located on the outer part of the housing, is responsible for regulating the air supply to the combustion chambers, as a result of which the throttle valve opens slightly if it is necessary to connect the fuel mixture and air. Only proper operation of the sensor guarantees the ability to increase idle speed.

Video “Visual instructions for replacing IACs in a garage”

If you have any questions regarding replacement, you can find the answers to them in the visual instructions for performing IAC repairs (the video was filmed by the AvtoRemont and Not only channel).

First, I’ll explain why I decided to post a post about this seemingly simple procedure. There were no problems with replacing the sensor on the 1.5i and on the Kalina (the 1.6i Kalinovsky engine was running on 15s) - I unscrewed 2 bolts and changed the sensor. Here everything is more interesting - one bolt can be unscrewed, but the second cannot be unscrewed due to the fact that the answer only goes there at a very unpleasant angle.

Sensor location and design

The idle air control is located in the mounting hole on the throttle body. It is a small cylinder that has two small ears, with the help of which the sensor is directly attached with a cone-shaped needle at the end.

Due to the fact that the sensor is small in size and has a very simplified design, the likelihood of various malfunctions and problems appearing is quite high, and therefore it is important to pay attention to the appearance of the first signs of a malfunction. If problems are observed, it is not recommended to use the vehicle, as the performance of internal structures will deteriorate.

Location of IAC VAZ 2115

Do-it-yourself IAC cleaning

How to clean the IAC? The procedure for cleaning the device begins with removing the device, we described this above. Once you have the device in your hands, you first need to clean it with a dry cloth and cleaning fluid, which is usually sold in aerosol form. Alternatively, you can use WD-40. In addition to the controller itself, you should also clean the seat. Press the canister with the product several times, with the aerosol stream directed towards the tip of the IAC, which is also called the needle.

It is best to use carburetor cleaning fluid.

Depending on the design features of the IAC, this needle can be either plastic or metal. Clean the sensor needle directly, since liquid should not be allowed to get under the spring into the inside of the device . If you do hit the spring, the regulator will have to be purged with a large volume of air; for this you can use a pump or compressor. If liquid gets into the device mechanism itself, it can damage the lubricant inside it, and this, in turn, will cause a quick breakdown of the device. Choose the correct dosage of the product and do not dose the liquid too much, as this will also force you to clean the spark plugs in the future.

Symptoms of a problem

If one of the following symptoms appears while using the car, this indicates a malfunction that will need to be eliminated:

- Some vibration of the engine appears during idling, that is, the vehicle shakes and rattles, and makes strange sounds.

- The machine stops functioning when switching to XX. Switching off can occur at the moment when the gears are changed or when driving in neutral gear.

- When starting the engine in a cold state, there is no increase in speed. If the part is working normally, there is a constant increase in indicators, otherwise they remain in one place, that is, at a fairly low level in comparison.

- There is a sharp increase or decrease in engine speed when idling, which can cause an emergency situation on the road. It is quite easy to notice such changes - sharp fluctuations of the instrument needle occur during movement.

In some cases, such symptoms indicate the presence of other problems, but it is worth noting that in any case it is necessary to check the idle speed sensor, just for your own safety.

Principle of operation

Turning on the ignition, the on-board computer begins to test the system. You can hear the fuel pump starting and all the lights on the instrument panel light up. At the same time, the idle air control completely blocks the air flow, and the control unit calculates the required number of steps and removes the needle, slightly opening the channel to the desired position.

The distance to the air flow can be different and depends on the parameter: hot or cold motor. For example, for warming up a rich mixture is required, which means the needle is extended as much as possible, but for operation on a hot engine the mixture is lean, that is, the regulator removes the lead screw, increasing the air supply.

For reference! The number of steps of the idle speed sensor on the VAZ 2115 depends on the type of software (firmware). For example, on a hot engine with a “January 5.1” controller the usual distance is 110 shg, and on a Bosch it’s 50 shg. (The maximum stroke reaches 250 shg.).

Examination

To carry out an independent test, you will need a multimeter, which will need to be used in two stages: checking the state of the power circuit and checking the sensor itself.

Checking the power circuit condition:

The sequence of actions during verification is quite simple and understandable:

- The multimeter is turned on and the measurement is configured with a limit of 20 Volts

- Remove the corresponding connector from the sensor and turn on the ignition

- The probes of the device are connected to the connector, and a direction of at least 5 Volts must be shown - then everything is normal

Checking the functionality of the sensor:

In order to check the condition of the sensor, you will need to:

- Switch the multimeter to the device voltage measuring state

- Connect it to the terminals on the idle speed sensor

- Rotate the central part of the sensor, while constantly monitoring the state of the indicators - they should change smoothly

If all conditions are met, then the sensor is operational.

How to check the idle speed sensor on a VAZ 2115?

Some difficulties in servicing the IAC on the VAZ 2115 are that the error codes of this unit are not displayed on the on-board computer display. Unlike, for example, TPS, the data of which is reflected on the on-board vehicle. Therefore, the car owner can only check the serviceability of the idle speed sensor manually. To do this, of course, you need to remember where this sensor is located. You can carry out the test armed with a multimeter and asking an assistant to participate.

First you need to open the hood and disconnect the block that provides power from the sensor. In addition, you will need to move the throttle mount some distance from the IAC.

You should not ignore the condition of the regulator circuit; it is best to check it first. Or the problem may be a faulty or discharged battery. In any case, the multimeter will show exactly where the problems occurred. The verification itself can be carried out using the following steps:

- Set the multimeter to voltmeter mode.

- Connect the black probe (minus) to ground, and the red probe (plus) to the outer side terminals of the block (A and D).

- Now the assistant needs to turn on the ignition, and the inspector needs to look at the voltmeter. The device must show at least 12 volts. If the reading is lower, then the battery or alternator needs checking. If there is no reading at all on the multimeter, this is a signal of a faulty wiring or engine control unit. These are the elements that need to be diagnosed.

If everything is normal in the circuit, you should proceed directly to checking the IAC. You will also need a multimeter, but in ohmmeter mode. Diagnostics is as follows:

- The multimeter leads are connected to the terminals on the left side of the valve (A and B) and then to the terminals on the right side (C and D). Normally, the reading on the multimeter should be approximately 53 ohms.

- The probes are connected to terminals A and C, and then to terminals B and D. An infinity symbol should appear on the device.

Other readings on the multimeter indicate a valve failure. There are two options: either replace the faulty part with a new one, or clean it with carburetor cleaner.

Replacement

Replacing the idle air control sensor on a VAZ 2115 is a fairly simple task that does not require much experience in car repairs. To replace, you only need a Phillips screwdriver and nothing else.

Let's start replacing the sensor:

- Remove the connector from the regulator;

- Unscrew the two screws securing the sensor to the remote control housing;

- Using a rotating motion, remove the IAC;

We install the new IAC in reverse order without damaging the O-ring.

Reverse Controller Replacement Guide

How to replace the reverse sensor:

- First, the car should be driven into a pit or overpass. Raise the parking brake lever and set the gear selector to first speed. This will prevent the machine from possibly rolling away.

- Next, you need to remove the protective cap from the contacts of the device; you need to disconnect the contacts from the RZH. When dismantling the gearbox regulator, some of the working fluid will come out, so you should place a container to collect the oil under its installation site.

- After this, you can begin to remove the device. Usually it can be removed by unscrewing it by hand, but sometimes, if the regulator is installed very tightly, it is advisable to use a wrench or socket. The head size should be 22. If the regulator is very stuck to the seat, then it may not be possible to unscrew it with the head. Try spraying the installation area with WD-40 and wait a few minutes. If this does not help, then you will have to use a chisel and hammer to remove it, but be careful not to damage the gearbox housing.

- After the old RZH is removed, you will need to install a new regulator in its place.

- If, during replacement, some fluid gets onto the transmission housing, it must be removed using a dry rag. Also clean the location where the regulator is installed, as contamination may cause it to malfunction or become inoperable.

- Reinstall the connection connector and the protective cap. If, during the replacement, a significant amount of transmission fluid comes out of the gearbox, then lubricant must be added to the box. Please note that the oil must be fresh, and not used oil that came out of the gearbox. If you notice that the drained fluid is too dirty and contains wear products, then it makes sense to think about replacing it.

Photo gallery “Replacing RZH”

Fault marker and cause

Many car owners will say that it is very difficult to calculate the failure of the IAC on a VAZ 2115, since signs of a malfunction do not always indicate problems with the regulator. Moreover, the control unit is often treacherously silent and does not signal the owner with the Check Engine icon. It’s just that the ECU is quite primitive and cannot always determine where exactly the failure occurred. Because of this, drivers are guilty of bad fuel, a clogged filter, low-quality spark plugs, etc. But thanks to the inquisitive owners of the “tags”, the main signs of an IAC malfunction have become known:

- painful starting of the internal combustion engine, especially in winter;

- floating speed when hot, in the range of 850–1100;

- the engine freezes if you switch to neutral and release the gas;

- The firmware reduces the speed to 800–900 on a cold internal combustion engine (less than 40 °C), without waiting for it to fully warm up.

The listed symptoms most likely indicate problems with ICC. There is constant movement inside the sensor, causing natural wear and tear. Often in the lead screw and rotor. Even a small amount of play does not allow the ECU to set the steps correctly, so the fuel mixture is incorrect, causing the engine to operate incorrectly. Sometimes the air valve simply becomes clogged, which also negatively affects the operation of the fuel system.

Price

The table shows IACs, which, according to reviews from Lada car owners, are the most reliable and affordable.

| Manufacturer | vendor code | Price, (rubles) |

| LADA | 2112114830002 | 990 |

| AvtoVAZ | 21120114830004 | 600 |

| Standard | 21120-1148300-81 | 680 |

| Pegasus | 2112-1148300-03 | 805 |

| ERA | FJ480 | 370 |

Description of RZH

Now we suggest that you familiarize yourself with the basic information regarding the reverse control. Where is it located, how to check the device and replace it? Read on.

Location and purpose

The main purpose of the RZH is to activate the white lights in the rear headlights, which indicate that the vehicle is starting to reverse. Thanks to this, other drivers know that the car will make a maneuver. Correct operation of the RZH allows you to prevent a possible collision on the road. As for the location, the device itself is installed on the gearbox; looking at the box, you can see two speed controllers and a speed controller.

Principle of operation

The main component of any RZH is the limit switch. When the driver engages reverse, this switch is activated and powered by the battery. The device closes the electrical circuit, resulting in voltage being supplied to the lighting sources located in the rear lights. If the driver disengages the reverse gear, the limit switch is pressed out, as a result, voltage is no longer supplied to the light bulb and it goes out.

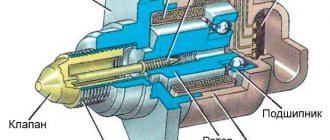

IAC device

As mentioned above, the IAC is a DC electric motor with a worm gear. The picture below shows a cross-section of the IAC with a description of all its elements located inside.

- Movable head (valve);

- Pressing plane;

- Stator winding;

- Worm shaft;

- Connector;

- Bearing;

- Frame;

- Rotor;

Diagnostics of the mass air flow sensor

To check this sensor you will also need a multimeter, but it must be set to the “voltmeter” mode. We diagnose the air flow sensor as follows:

- De-energize the car by removing the battery terminals

- We measure the voltage between the contacts of the green and yellow wires

- Normal value - voltage ranges from 0.99 to 1.02 V

In some cases, simply cleaning the sensor or cleaning its oxidized contacts helps. But such actions do not always lead to the desired result. It is best to replace the mass air flow sensor with a new copy and forget about the problem, especially since this is an inexpensive mechanism.

see also

Comments 53

Such garbage, I changed the rcx and the car won’t start at all, the sensor checked that the power supply is good, it also checked that it’s normal, what could it be?

Tell me, did your check light come on? I bought myself one with a 1.5 engine and it also shakes at idle, but the speed does not fluctuate. and the check light is on. the previous owner said the diagnostics ordered the camshaft sensor to be replaced, he changed it, but nothing changed

the same nonsense(((on the previous chepyrka 1.5 volume, replacement took five minutes... today it fit. And here is a 1.6 engine, ceramic manifold. Even not a single hinge fits

My car stalls periodically while driving when you let off the gas... does this IAC need to be changed?)

More likely. It was like this - I changed it, the problem went away

My car stalls periodically while driving when you let off the gas... does this IAC need to be changed?)

Yes! and there may also be air leaks after the mass air flow sensor!

My car stalls periodically while driving when you let off the gas... does this IAC need to be changed?)

I had the same issue! It turned out that the vacuum seal was sucking in air!

Guys, this is a problem, the fact is that when unscrewing the throttle assembly, the thread on one of the screws broke, on the one further away (closer to the front windshield), how can I now remove the piece of bolt that is left to replace it with a new one, maybe someone has Was there a similar problem?

I drilled this out. I don't know any other options

I stupidly unscrew this sensor without removing anything unnecessary)

Can you tell me the name of the tube that needs to be disconnected in the first photo?

Breather. Crankcase ventilation

Good afternoon I changed the IAC, when the engine is cold and keeps a speed of 1500, I turn on all the electrics and everything is fine. When the engine warmed up a little and the revolutions dropped to 1000, with all the electrics turned on, the engine continued to run smoothly. And when the temperature reached even higher speeds dropped to 800, and then when all the electrics were turned on, the engine speeds began to fluctuate and it stalled. I have a three-level relay on the gene and the switch is set to max 14.7, but it gives out all 15. At 1500 rpm and the electrics are on, it sags to 14.3, at 1000 rpm it gives out 13-13.4, and at 800 it sags to 11.9 and the revs start to fluctuate and it stalls. So what could be the problem in the gene or IAC, because... On the IAC box, the maximum voltage is from 13 to 14.2, but the gene gave 15 and the IAC came up, or does the gene still not provide that voltage at low speeds? The battery is charged and the starter turns well. I'm already tired of maintaining idle speed at every traffic light so as not to stall... Does anyone have any thoughts on this matter?

I have the same problem, if you solved this problem, tell me too!)

We disassembled the gene, it turned out that the diode bridge had been released. But the problem has not been completely solved, the revs just began to fluctuate less and the stalling became less frequent...

List of main reasons

Reasons why idle speed fluctuates

Incorrect operation of the power unit may be caused by a malfunction of certain elements:

- Failure of sensors:

- RXX;

- DMRV;

- DPKV;

- Lambda probe;

- DSA.

- The XX solenoid valve is faulty;

- The air filter is clogged;

- Heavy carbon deposits on candles;

- High-voltage wires are damaged or oxidized;

- Air leak in the intake manifold;

- Incorrect throttle position.