Any extraneous noise in a car engine often makes owners feel wary. And although these sounds do not affect driving performance in any way, their very appearance makes the driver think about diagnostics. Many cars experience finger tapping during acceleration, but this problem is often ignored. The sound appears when the car picks up speed. If you do not pay attention to this in time, much more serious problems arise. At the same time, motorists cannot determine the causes of impacts, nor solve this problem. Let's look at the reasons for these unpleasant sounds in the driver's ear, and also find out how to fix these engine problems.

Knocking fingers

When the engine is running under load, ringing metallic sounds are heard. They disappear when you reach a certain speed. Old-school mechanics will say that the “fingers” knock when accelerating. However, the driver will be surprised and absolutely right: the sound has nothing to do with the “fingers” installed in the pistons.

Priora does not develop speed when you press the gas pedal a little harder!

Because You are not logged in. To come in.

Because you are not a trust user. How to become a trustee.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Why "fingers"?

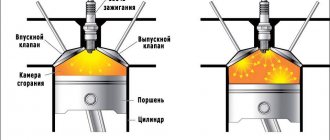

The combustion process of the combustible mixture in a fully operational engine occurs sequentially. A flame flares up near the candle and gradually fills the entire cylinder. But there is another combustion option - detonation. The explosion of the fuel mixture in the combustion chamber occurs suddenly. This increases pressure and temperature. This explosion itself is called detonation. Therefore, the driver hears a knock - it comes from the shock wave. Proper combustion requires a fire propagation speed of up to 30 m/s. The gas pressure gradually increases. During this combustion, the flame gradually fills the cylinder. The gases gently press on the piston. There is no detonation of gas along the walls of the combustion chambers, since there is no explosion. If the burning rate is higher, this is a prerequisite for an explosion. By the way, this phenomenon is very harmful to the engine.

Replacing spark plugs yourself

Replacing spark plugs on a Lada

Since faulty spark plugs occur most often during acceleration failures, auto mechanics recommend Lada Priora owners learn how to change this element of the ignition system themselves. This should be done after the car has traveled 20 thousand km. However, if the engine starts to trip, the spark plugs should be replaced before this date:

- Initially, you will need to clean the engine compartment from dirt and debris,

- Next, it is necessary to dismantle the engine elements to gain unhindered access to the spark plugs. Adapters and extensions are used for this. Before performing this work, you will need to wait until the engine has completely cooled down.

- The spark plugs are unscrewed one by one, and the high-voltage wires are disconnected. To prevent an accident, you must first remove the battery from the car. Otherwise, electricity may be supplied. When performing this procedure, it is recommended to monitor the force applied. It is better to seek help from specialists if the candle does not budge.

- To prevent debris from getting into the resulting holes, you need to cover them,

- The candles are screwed in manually at the first stage. Next, they are tightened using a special mechanism that allows you to measure the amount of force applied,

- high voltage wires are connected,

- engine operation is checked,

- The previously dismantled elements are assembled in the reverse order.

Guys, do you have any thoughts? Priora 2009 I bought it in 2015. I drove it for a week, I realized that it wasn’t driving at all, before that I drove Priors, I know how they should drive. What was done: Replaced pistons with stock (butt-in) 82.0 E Block was not sharpened (measured) perfect cylinders without ellipse, original hone) Main bearings Connecting rod bearings DPDZ about 5 pieces of new IACs, about 4 pieces of new ones Cleaned the throttle 4 times Checked for new suction Mass air flow sensor Air filter New Bosch 022 injectors Gasoline filter Gasoline pump removed new mesh Rail pressure 3.9 whether hot or cold The computer was changed (mine was soldered with something) they installed it from the Niva 797+ and it went like that After that I changed the timing rollers, nothing but Without touching it, I drove out of the garage and still didn’t move. Afterwards we checked the marks 4 times, everything is in place! There were rollers from 12 pulleys with shoulders, I installed the same ones, although the pump was Priorov’s and the shaft gears were also Priorov’s and the belt. I don’t know why this is so, they were collective farmers before me. After that)))) Detonation began after it warms up for about half an hour and sits at idle, you start driving and it starts to detonate, drive about 3 km and it goes away. UOZ at the same time, according to diagnostics, 13 It was decided to open it...))) Once opened, the pistons dangle a little back and forth, but this is normal for a Priora. Completely overhauled the head, installed new valves, shafts, seals, and treated it with Loctite. Some hydraulic valves make noise, I haven't changed them. I installed the original timing rollers from Priora. (The belt is very displaced towards the block, it runs along the very edges of the rollers and a dotted line appears on it, it’s getting stuck somewhere, I’ll take a look) Oh yes, 3 clutch sets were changed, it twitched a lot when starting off, I didn’t know what was wrong. I changed the flywheel, in the end I sharpened the old original flywheel and installed everything. Spark plugs 4 sets changed, one coil Alternator belt roller Alternator bearings Starter rebuilt Retractor Brake discs Pads Clutch cable Gaskets under the intake manifold I installed the spider, then I put the catalytic converter back, because the sound is terrible, I didn’t notice the difference. Euro 2 was flashed. Lambda was turned off, no difference. In short, I don’t have any more strength... The car is practically new))) All this took about 100,000. Maybe someone will say that I’m sick, but I can’t drive a car when it doesn’t drive at all. It gains power very slowly and when you throw 4th gear at 80 to the floor, there is some kind of intrauterine hum and it gains power very slowly. In short, after assembling the head and installing it, the clutch began to twitch))))) Just like that, after 3 days of sitting in the garage, they didn’t go anywhere to the clutch at all. In short, remove the box, the primary and crankshaft oil seal runs. Changed the result zero (((((((((Help... P/S: who needs advice on repairing priors, please contact)))

Detonation - what is it?

If your “fingers” knock during acceleration, this indicates detonation in the engine. This is called an instantaneous and very destructive explosion of any flammable substance after impact or detonator activation. This is the definition according to Ushakov’s dictionary. Detonation of flammable substances in car engines is the rapid depletion of a mixture of gasoline and air. Occurs when the engine operates at low speeds and low-quality fuel. This process is accompanied by shocks, shocks, and increased temperature. As a result, the “fingers” knock during acceleration (including on the VAZ-2112).

Reasons for cars with HBO

- The settings of the gearbox or dispenser are incorrect. Solution: Adjust according to instructions.

- The gas filter is clogged. Solution: buy a new one and replace it.

- The valve on the flow line has failed. Solution: replace the valve, having previously specified its brand in the instructions.

Video: Expert advice on how to troubleshoot problems

Most problems that cause loss of power can only be fixed by an experienced auto mechanic. The common car enthusiast is left with only the most obvious faults, such as clogged filters or jets, the blockages of which are hard to miss. But not everyone can understand that there is a problem in the engine with the adjustment of the valve timing. So the most reasonable option when failures appear is a trip to a car service center.

Often, Lada Priora car owners notice that their vehicle jerks when accelerating when pressing the gas pedal. Such dips are felt only when you sharply press the gas and at low speeds. In such a situation, it is recommended to check the idle speed sensor, throttle level position, and spark plugs for serviceability.

More about the reasons for knocking

When a car picks up speed, it creates a stressful situation for the engine. Especially if you need to suddenly accelerate the car. When the driver presses the accelerator pedal to the floor for a series of sharp turns, for example from one to six thousand, the driver hears the sound of “fingers” during acceleration (Priora is no exception).

Detonation device on Priora

The knock sensor on the Priora is made in the shape of a circle, it has a hole for connecting wires. Inside it, in a special place, there are certain threads that, when detonation occurs, begin to emit impulses. The threads are made of a thin and rather soft alloy, and even though they are protected by a certain substance, it is under no circumstances recommended to throw the sensor forcefully onto the floor.

Detonation device on Priora

Where is

To improve the sensitivity of the knock sensor, it was installed on the Priora engine block. It is attached to a special ledge, as well as a platform, which is located near the second cylinder. This is where the noise from the detonation process is strongest. This place is located on the radiator side, just below the engine itself.

If the Priora is equipped with such technologies, in particular as power steering, air conditioning and many others, then access to them will be a little complicated, but still possible. Simply put, it is accessible from the front bumper of the car.

knock sensor location

Symptoms of a problem

The main malfunctions in the car's knock control system are:

- The device has failed.

- The wire to it broke.

- The device connector is broken.

In all these cases, eliminating all these troubles is an easy task. The main thing is to be able to identify them correctly. In any case, when working with a car with an ECM, diagnosing problems is a rather complex and important area of repair. Fixing the first two problems will require having the following kit on hand:

- Multimeter tester.

- Indicator light.

- Wires.

- Insulating tape.

- Wire cutters or knives.

Then connect the multimeter to the 2 holes of the connector and turn on the ignition. If everything is fine with the circuit, the tester will indicate a voltage of up to 5 Volts. And if nothing happened to the indicators, then the circuit may have broken and needs to be found. You need to disconnect the connector from the ECU and examine both circuits. Find the break and fix it using wires and electrical tape. If the tester shows a working circuit, then the problem is with the sensor.

Typical causes of ringing “fingers” during normal operation of the internal combustion engine

If the “fingers” knock during acceleration in the Kalina, the mass air flow sensor may fail. If it does not work properly, the ECU will receive incorrect information and issue incorrect commands. Another reason is that the ignition timing is incorrectly set. For this reason, the point at which the fuel will burn to the maximum extent possible is close to TDC. This leads to an increase in pressure in the combustion chamber. If your toes are clattering when accelerating on your Ford Focus, the shock suppression sensor may have failed. You should definitely check this item. If it stops working, it should be replaced.

Types of knock sensors: design features and operating principles

On fuel-injected cars, it is impossible to manually set the ignition timing, since electronics are responsible for this process. The appropriate amount of advance depends on various factors. The ECU collects information from all sensors, and based on their readings, as well as the operating mode of the internal combustion engine, it adjusts the SOP and the composition of the fuel assembly.

To prevent a prolonged detonation process, a sensor is used. It sends a corresponding signal to the computer, as a result of which the latter has the ability to adjust the ignition timing. We will find out further what signal the device sends to the ECU, and how it detects unstable operation of the internal combustion engine.

Before you understand the peculiarities of the operation of the DD, it is necessary to inform you that such devices come in two versions:

- resonant or frequency;

- broadband or piezoceramic.

Priora cars are equipped with broadband knock sensors.

The principle of their operation is based on the piezoelectric effect. Its essence is that when the plates are compressed, an electrical impulse is formed. Below is a diagram of the operation of the broadband sensor.

The operating principle of such a device is as follows:

- When the engine is running, the sensor generates a signal with a certain frequency and amplitude, which is recorded by the ECU. Based on this signal, the controller understands that the sensor is functioning properly.

- When detonation occurs, the engine begins to vibrate and “clatter,” which leads to an increase in the amplitude and frequency of vibrations.

- Under the influence of vibrations and third-party sounds, a voltage is induced on the piezoelectric sensitive element, which is transmitted to the ECU block.

- Based on the received signal, the controller understands that the engine is operating abnormally, so a signal is sent to the ignition coil, as a result of which the ignition timing changes towards the advance (a later ignition is set) in order to prevent the development of a dangerous detonation process.

The photo below shows examples of broadband and resonant type sensors.

The broadband sensor has the shape of a washer with a central hole and output contacts through which the device is connected to the ECU. Inside the housing there is an inertial mass (weight), insulators in the form of contact washers, a piezoceramic element and a control resistor. The system works as follows:

- when the engine detonates, the inertial mass begins to affect the piezoceramic element;

- the voltage on the piezoelectric element increases (on Priora up to 0.6-1.2V), which is supplied to the connector through contact washers and transmitted via wire to the computer;

- Between the contacts in the connector there is a control resistor, the main purpose of which is to prevent the controller from detecting an open circuit after the ignition is turned on (this resistor is also called an open circuit recorder). If it fails, then error P0325 is displayed on the BC.

The photo below describes the operating principle of resonant type sensors. Such devices are used on cars, for example, Toyota.

Determining the type of knock sensor that is installed on a car is not difficult. To do this, you need to inspect the part, and by its appearance you can understand the type of device. If broadband elements have the shape of a tablet, then frequency-type products are characterized by the shape of a barrel. The photo below shows a frequency-type sensor and its device.

This is interesting! Prioras are equipped with broadband sensors that have code 18.3855. Products are produced by different manufacturers, for example, AvtoKom, Bosch, AvtoElektronika and AvtoTrade (Kaluga plant). The cost of a Bosch sensor differs from other analogues by approximately 2-3 times.

How to avoid detonation?

Without exception, all modern cars are equipped with a special sensor and unit that reacts and suppresses this destructive phenomenon.

How to remove and check the sensor?

Access from above to the Priora DD is difficult due to the intake module located above it. The easiest way to get to the sensor is from below, first removing the engine protection or at least unscrewing and folding its front part. When working from above, you will have to do everything by touch. In any case, before starting work, it is necessary to disconnect the ground wire attached to the “negative” terminal from the battery.

To remove the crankcase protection, you need to:

- unscrew 5 nuts with a 10mm head;

- unscrew the 2 19 nuts installed on the back of the shield;

- remove protection.

- by pressing the metal latch of the DD connector, disconnect the block of wires going to the controller;

- using a 13mm wrench, loosen the bolt securing the sensor;

- Unscrew the bolt and remove it from the threaded hole, removing the sensor.

Photo of dismantling the knock sensor

- We connect a multimeter to the DD terminals. We set the device to voltmeter mode, choosing a measurement limit of up to 200 mV.

- We take a metal object - pliers or a bolt - and lightly tap it on the DD.

Engine detonation: main symptoms

Consequently, detonation is an uncontrolled chaotic process of fuel combustion, which is more like explosions in a cylinder. Additionally, these conditional breaks do not occur in a timely manner (for example, during the compression stroke while the piston is still moving up). As a result, the shock wave and high pressure cause severe loads on the elements of the CPG and the crankshaft, literally destroying the engine.

Detonation is determined not only by sound, but also by a number of other signs. First of all, the engine loses power when you press the throttle, and the engine may smoke a little when you press the accelerator pedal hard with gray-black smoke. Typically, severe detonation is accompanied by engine overheating; at idle and under load, the operation of the internal combustion engine can be extremely unstable, speed surges, etc.

Causes of failures when pressing the gas pedal

Let's look at the main reasons:

- Spark plugs and high-voltage wires;

- Clogged fuel injectors;

- The throttle valve is dirty;

- The ignition is set incorrectly;

- Errors in the ECU;

- The air filter is clogged;

- Problems with the fuel pump.

Often, failures occur due to a breakdown of the power system. After pressing the gas pedal, the power system increases the volume of fuel supplied to the cylinders. Breakage causes a change in these proportions. Those. The motor just can't do its job.

In addition, it is possible that there may be a breakdown in the ignition system. It occurs much less frequently. It's either spark plugs or ignition wires. The spark plugs must be removed and checked. The presence of carbon deposits or too clean spark plugs indicate a rich or lean fuel mixture, respectively. This indicates that the ignition system is adjusted incorrectly.

Dips when pressing the gas pedal during acceleration

It is determined both using computer diagnostics and by the steps described below (some of the points below can be performed independently, but specialists in car services in Moscow will be able to determine the problem area more quickly and accurately):

- The first thing you need to do is inspect the spark plugs. To do this you need to remove them. The presence of carbon deposits on the spark plugs, poor contact with the wires, or an excessively lean or rich mixture lead to spark plug malfunctions.

- High voltage wires can also cause engine malfunction, as can ignition coils.

- The throttle needs to be checked. If it is clogged, this causes the engine to respond untimely when pressing the gas pedal.

- It is necessary to check the condition of the air, fuel and oil filters. They tend to get clogged, which worsens dynamics, increases fuel consumption and causes pedal failure. They need to be changed constantly, you can do it yourself, they are inexpensive and easy to install.

- The presence of errors in the ECU leads to failures.

- Clogged injectors. If necessary, replace or repair injectors.

The wires, as well as the rubber bands on them, should not be damaged and should not spark when the engine is running. If damage is found, this indicates that the engine is shaking and jerking begins. This may occur due to the age of the car, worn-out or low-quality spare parts, poor contact with the spark plugs, or due to the temperature of the engine.

The resistance of the coils and the temperature change together, as a result of which a gasoline car begins to jerk during acceleration. In diesel cars, jerking cannot be associated with the coils, since they are not present.

Dips when pressing the gas pedal at idle

Problems also occur at idle speed; of course, there will be fewer reasons. However, this is also a serious problem and cannot be ignored, because... The car will have difficulty starting and simply stall.

Troubleshooting is performed in the following order:

- The first thing to check is the spark plugs. If the spark plugs are faulty, they should be replaced. We recommend replacing all spark plugs at the same time. Buy spark plugs specifically for your engine. If necessary, adjust the gap; it should be 1 mm for 92 gasoline.

- The fuel filter and fuel pump diagnostics are checked. If a malfunction is identified, fix it.

- The breakdown may be in the idle speed sensor.

- Checking the injectors. If clogged, replacement or cleaning is necessary.

- Diagnostics of the ECU for errors.

- Checking the injector.

Why does detonation occur in engine cylinders?

Experts identify several main causes of fuel explosion in an engine.

- First of all, it is worth immediately highlighting the use of low-octane gasoline in units with a high compression ratio. Simply put, the octane number of gasoline (AI-92, 95 or 98) actually indicates its resistance to detonation, and not its quality, as many people mistakenly believe.

Using fuel with the wrong octane rating for a particular engine will naturally cause the fuel-air charge to explode under high compression. We also add that simple engines that do not have an engine control unit and a knock sensor are at increased risk.

- Coke engine. It is important to understand that modern engines not only in foreign cars, but also in domestic cars are very different from their analogues from the times of the USSR. Simply put, if the engines of the Moskvich 2141 model had a compression ratio of about 7 units and worked normally on any fuel, today the units have from 9 to 11 or more units.

- Violation of the mixture formation process. In this case, a too “rich” mixture, in which there is a lot of fuel in relation to the amount of air, may begin to detonate.

Please note that such an explosion may be short-lived and often goes unnoticed by the driver, but there is no evidence of engine failure.

- Ignition timing (IDA). Simply put, the ignition angle determines at what point the spark will be delivered to the combustion chamber. If we consider that normally fuel does not explode, but burns, it becomes clear that the combustion process also takes time.

In this case, it is important to ensure that the maximum pressure of gases on the piston, resulting from the combustion of part of the fuel, drops precisely at the moment of the piston’s working stroke. This is the only way to effectively transfer the energy of the expanding gases to the crankshaft through the piston.

To do this, the spark can be applied shortly before the moment when the piston reaches top dead center (TDC). During this time, the fuel will have time to ignite, and the expansion of gases and an increase in pressure on the piston will occur as soon as the piston has already reached TDC, and, therefore, will fall.

- Design features of the combustion chamber. It happens that some engines are naturally prone to detonation. In some cases, the reason is the combustion chamber itself, its cooling, etc.

Another culprit may be pistons that have an unsatisfactory thermal balance (for example, the piston head is thicker closer to the center, which greatly impairs the quality of excess heat removal). One way or another, the risk of detonation on such engines is much higher.

- Motor overheating. If you pay attention to the previous point, it becomes clear that the cause of detonation is an increase in temperature in the combustion chamber. It is clear that a decrease in the efficiency of the cooling system can lead to overheating of the engine.

Under such conditions, detonation is quite likely to occur, and detonation itself also leads to local and general overheating. For this reason, engine detonation due to a faulty cooling system is especially dangerous, since the power unit can not only be severely damaged, but cannot even be repaired in the future.

Causes and solutions

This phenomenon can be caused by a large number of factors. They have varying degrees of danger. Sometimes, a small detonation is quite acceptable. All possible options for the occurrence of this phenomenon will be discussed below.

The most harmless is detonation, which occurs with a sharp increase in speed. If at 1000 rpm

sharply depress the gas pedal, accelerating the work to 4000-5000 rpm

, you can hear a brief detonation. This is quite a common occurrence. There is no need to be afraid of this; in this case, detonation will not lead to dire consequences. The reason is a sharp increase in the fuel supplied to the engine; the amount of air initially remains at the same level, this causes premature oxidation of the fuel, which is accompanied by explosions. The only way to combat this phenomenon is to avoid a sharp increase in speed.

But sometimes detonation can appear during normal operation of the power unit. In such cases, it is necessary to identify and eliminate the malfunction as quickly as possible. Otherwise, it will lead to engine repair. So, detonation may have the following reasons:

- Incorrectly set ignition timing. As this indicator increases, the point with maximum pressure during fuel combustion shifts to TDC. Because of this, increased pressure occurs in the cylinder, and accordingly engine detonation occurs. If you experience unexplained knocking noises, be sure to check that the ignition is working correctly;

- Error in the operation of the engine control unit. If the fuel consumption sensor fails, the on-board computer may give erroneous commands. As a result, the engine begins not only to twitch, but also to detonate;

- Almost all modern cars are equipped with a knock sensor

. If you observe the phenomenon regularly, then check the condition of this small device. If necessary, you need to replace it; - Low octane number

. Each car has its own compression ratio; accordingly, this indicator is calculated based on the fuel that will be used in the engine. The higher the compression ratio, the higher the octane number should be. If you fill the tank with fuel with a lower rating, an uncontrollable reaction will occur in the cylinder. If, in order to save money, you have filled with lower quality gasoline, then it is advisable to drain it and fill with fuel with a suitable octane number. Sometimes, a similar phenomenon can occur when refueling with bad gasoline.

How to eliminate engine detonation

So, having considered the main causes of engine detonation and understanding what it is, you can move on to how to get rid of this phenomenon. Let's start with old internal combustion engines. At first, you should exclude overheating of the engine, as well as refueling with low-quality or unsuitable fuel, and check the spark plugs.

The solution is temporary, since it is impossible to drive for a long time with a low ignition angle (the exhaust valves will burn due to an increase in the temperature of the exhaust gases), but it is quite possible to get to the service on your own.

However, while driving, it is necessary to constantly ensure that there are no characteristic “sounds” in the engine. Even on an old internal combustion engine, you can install a so-called electronic octane corrector to avoid manipulation of the distributor. Let us also add, as practice shows, many owners of carburetor cars prefer to install electronic ignition.

As for more modern engines, injection units are usually used to avoid or minimize the risk of detonation. This is an engine knock sensor (DE), which detects its occurrence. The corresponding signal is then sent to the ECU.

Then the control unit independently adjusts the ignition timing taking into account the data received from the DD. In this case, the possibility of such adjustment amounts to an average angular shift of 2-5 degrees. If detonation cannot be eliminated in this way, the ECU corrects the error and writes it into its memory, the “check” on the instrument panel may continue, the engine goes into emergency mode, and so on.

It becomes clear that in this case the driver must initially start by checking the knock sensor, and also read errors from the ECU memory. This can be done as part of computer engine diagnostics. You can also check this yourself (if you have a special diagnostic scanner adapter in the OBD connector and a smartphone/tablet or laptop with pre-installed software).

How to check engine performance using spark plugs. The main signs of engine malfunction are the appearance of black, gray, red and white carbon deposits on the spark plugs.

Marks for determining the correct setting of the ignition timing. Consequences of an incorrectly configured OZ, methods for setting the ignition.

Purpose and design of the knock sensor. The main causes of detonation, types and principle of operation of the sensor.

Why does the fuel-air mixture explode in the combustion chamber? Reasons causing detonation. Consequences of fire during fuel detonation in internal combustion engine cylinders.

Why does the engine overheat? What to expect as a driver and what damage may occur if the engine overheats. What to do if the internal combustion engine overheats.

Common malfunctions of the engine cooling system: water pump, thermostat, radiator, cooling fan and others. How to determine the reasons for yourself.

Jerking if you press the trigger sharply

The main reason for this is the “triple” of the engine. That is, a situation when only three of the car’s four cylinders are working. If the engine stalls, it simply does not have time to react in time when you sharply press the gas pedal, and jerking occurs. This problem applies to all types of engines. Here are the main reasons for its occurrence and ways to eliminate it:

- The oxygen sensor is not working properly. Solution: check with a multimeter, replace if faulty.

- The engine's valve timing has shifted. Solution: Adjust according to the vehicle's operating instructions.

- Incorrect spark plug heat rating. Solution: check the heat number in the instructions and install a new set of spark plugs with the correct number.

- The injectors are clogged. Solution: remove them, install them on a stand that simulates engine operation, and wash them with a special solvent.

- In addition, in carburetor cars, jerking when you sharply press the gas may occur due to the fact that the accelerator pump in the carburetor is not working correctly. Solution: the pump is removed, its nozzle is checked, then the diaphragm and valve channels. If they become clogged, they should be thoroughly blown out with compressed air.

You can find out more about other possible reasons here.

Finding out why the engine suddenly began to twitch is not an easy task. To make an accurate “diagnosis,” it is necessary to answer three questions: when the jerking occurs, how long it lasts, and on what type of engine it is observed. Only with this approach does the car owner have a chance to quickly identify the cause of the problem and eliminate it. Read

Chip tuning specialists and studios in the region

Car owners often notice that the car jerks when accelerating. Such dips mainly appear at low and medium speeds. They are characterized by the following:

- Failure from 2 to 9 seconds;

- With a jerk of 1–2 seconds;

- Jerking - a series of jerks;

- Rocking - a series of failures.

Few people like this kind of car behavior. If the car stalls when accelerating, you have to press the pedal harder, which increases fuel consumption. This is also a matter of safety for the driver and passengers. When overtaking, a quick reaction to the gas is required, but the car “thinks for a long time”, which is why you may not have time to complete the maneuver. With such thoughtfulness of the gas pedal, the ride becomes uncomfortable.

Symptoms of sensor malfunction

You can determine whether the sensor is broken without a dashboard. But this will require experience and a special approach to your car. You need to know him very well. We list the signs by which you can understand that the device is broken, from here it will be immediately clear what the knock sensor affects:

- Fuel efficiency will drop. This may not be noticeable right away, but over time the driver will definitely notice it.

- Also, as the throttle increases, the engine detonates longer than usual. The knock sensor affects the acceleration of the car.

If you determine the breakdown yourself, then it’s not far to independently diagnose the sensor, as well as replace it yourself. In principle, this is not difficult, but it requires some understanding of the process.

Decarbonization of engine piston rings. - there is more useful information here.

If it requires replacement, then it is necessary to purchase a new device and install it as soon as possible. All car enthusiasts are primarily interested in the price of a new device. It is low and depends on the make of the car and on the country in which the part was manufactured.

Replacement can be done in several ways, the easiest way is to contact a specialist and pay money. On average, all this will cost 2000-3000 rubles.

You will be interested in this article - Flushing the injector, cleaning the injectors with your own hands.

You can carry out the replacement yourself when the engine has cooled down by disconnecting the negative terminal of the battery. It is necessary to achieve the most convenient access to the sensor so that it can be removed. The fact is that it also depends on the car model.

You can remove it with a 12 mm wrench; to do this you need to unscrew the bolt. Before you pull out the faulty device, unplug it. A new sensor is installed in the same place, and everything is repeated, but only in reverse order.

Thus, the knock sensor is a simple device, yet very useful for an electronic control system. It is not difficult to determine its malfunction; you can check it yourself, even in rural areas.

It will also be inexpensive to replace the sensor. It doesn’t matter whether this is done by a specialist or independently.

People, help out! How to overcome detonation? Detonation is always present, as soon as you press the trigger, in any gear! Firmware stock. I only use 95th gasoline: I tried all (!) gas stations, I filled it with “premium” and “euro” and 98th, with zero results! It did not arise suddenly, but gradually, somehow a little more and more. If you don’t accelerate too much, but pick up speed smoothly like a pensioner, then detonation will not occur. There is also a feeling that the pulling has become worse, somehow at speeds the engine is a little heavy and there is a kind of growling sound under load. Computer diagnostics did not find any problems, they said that all parameters were ideal.

Comments 67

Detonation? Maybe hydrikam kirdyk. It happened to me too, you press the gas, for example up a hill, and detonation appears. A neighbor advised me to look at the hydraulics. I took it apart and 10 out of 16 can be pressed with my fingers without any effort at all. Changed it and everything went away

I had the same problem, detonation appeared as soon as the engine warmed up... The diagnostics also showed nothing, all indicators were normal. Cured by rewiring the brain))))

Detonation on injection engines can mainly occur from glow ignition and a malfunction of any sensor. Glow ignition occurs on a warm engine from hot, unburned carbon particles on the piston, valves, cylinder head, and spark plugs. D. - a consequence of engine overheating, bad fuel, coked CPG, poor cooling, bad oil, hardened valve stem seals, bad spark plugs... there can be many reasons, right down to the engine temperature sensor constantly changing the engine temperature readings due to a malfunction (I heard about one such car on diagnostics). In short, I suggest starting with diagnostics.