The VAZ 2110 (or Lada 110) is a four-door sedan with front-wheel drive and an original design. Serial production of the five-seater Lada 110 began in 1996 and continues to this day (the car is currently assembled under the Bogdan 2110 brand at the LuAZ plant in Ukraine). Since 1996, the production of several modifications of the VAZ 2110 has been launched, among which you can find models with both 8-valve and 16-valve engines (on later versions). Such technical characteristics of the VAZ 2110 as the type and displacement of the engine (four-cylinder petrol with a volume of up to 1596 cc), as well as the maximum speed of the Lada VAZ 2110 (170 km/h for an 8-valve engine and more than 180 km/h for a 16-valve engine) valve engine) make this front-wheel drive sedan ideal for use in urban environments to this day.

Among the distinctive features of the VAZ 2110, which is classified in the upper price segment of LADA cars, one can also note the presence of an immobilizer, a gasoline vapor recovery system and a special on-board control system (diagnostic unit). There was the possibility of installing electric windows (in fact, they were installed), as well as power steering.

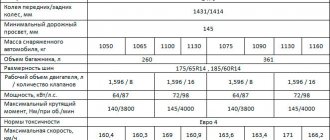

Dimensions of VAZ 2110

Technical data VAZ 11183 1.6

- VAZ 11183 1.6 is a four-stroke gasoline engine, the four cylinders of which are arranged in one row.

- Power supply of the power unit, injection, distributed fuel injection.

- The cylinder block of the Lada Kalina internal combustion engine is made of especially durable cast iron. The gas distribution mechanism is single shaft, has 8 valves. The timing mechanism is driven by a toothed belt from the crankshaft pulley.

- The engine piston has a stroke less than the cylinder diameter of 75.6 mm and 82 mm, respectively. The compression ratio of the internal combustion engine is 9.6. The fuel used is AI 95. It is permissible to use AI 92, for which you need to change the ignition timing.

- Power VAZ 11183 1.6, at 5200 rpm min., 81 l., sec. Torque at 3000 rpm, min., 125 Nm.

- Environmental compliance standards: Euro 2, Euro 3.

Fuel consumption

Fuel consumption when driving around the city is 8.8 liters per 100 km, mileage. When driving on the highway 6.2 liters. Total consumption is 7.6 liters per 100 km, mileage.

Oil consumption

The permissible consumption of motor lubricant is 50 grams per 1 thousand km. Types of oil used: 5W40, 10W40, 5W30, 15W40. The volume of engine lubricant in the VAZ 11183 1.6 engine is 3.5 liters. When changing, fill in 3.2 liters. Manufacturers recommend changing the oil every 15 thousand km.

Resource

Engine operating life according to factory data is 150 thousand km. In reality, in the right hands, the VAZ 11183 1.6 can last up to 300,000 kilometers.

Transmission and suspension VAZ 2110 8 valves injector

Lada 21102 has a built-in five-speed manual transmission (MT).

This box is used on all versions of the 2110 line. It has good noise insulation, the lever stroke is comfortable, and the smoothness of switching is much better than that of Zhiguli and Samara. The body (casing) of the box is made of aluminum alloy. Inside the casing there is a primary (drive) and secondary (driven) shaft. The shafts are combined with the differential and final drive. The five forward gears are equipped with synchronizers, which improve smooth shifting. Gear ratios: 1st gear - 3.636, 2nd - 1.95, 3rd - 1.357, 4th - 0.941, 5th - 0.784. For reverse gear - 3.5. The final drive ratio is 3.7. The operating instructions state that you need to change the transmission oil every 75 thousand km.

Mitigating the impact of the chassis on the body, as well as ensuring stability and smoothness, is carried out by the front and rear suspension of the Lada 2110. An independent design is used on the front axle.

Each wheel has an independent coil spring, inside of which a MacPherson strut is placed. Each strut has its own hydraulic shock absorber. The lower control arms are attached directly to the steering knuckles, and the anti-roll bar is attached to them. Levers help reduce wheel roll (rotate it around the longitudinal axis). When the car makes a turn, the wheel, which is turned “inside the body,” can move away from the axis of rotation. The stabilizer prevents this from happening by twisting. Thus, the front suspension of the Lada 2110 allows you to maintain the stability of the car when cornering. The rear suspension

is a rigid structure, the main element of which is the transverse beam. Since the rear wheels do not rotate, there is no need to provide maneuverability, but rear stability must be at a high level. Therefore, this design was used. The beam consists of trailing arms attached to each wheel and a connector that welds the arms together. The wheels on the rear axle are also equipped with hydraulic shock absorbers to soften impacts. The Lada 2110 is equipped with 175/70 radial tires. Ventilated disc brakes are used on the front wheels, and drum brakes on the rear wheels.

General design features of internal combustion engines

The VAZ 11183 1.6 engine is a modified version of the already well-known carburetor power unit VAZ 21083. Most of the design elements are borrowed from this model. The cast iron cylinder block also has four in-line cylinders. But the aluminum cylinder head is adapted for distributed fuel injection. It has an overhead camshaft. The valves are driven by fists through pushers. Hydraulic compensators are not provided on this engine model. Because of this, periodic adjustment of the valves is required. Which you can do yourself by selecting the required number of steel washers.

The 11183 1.6 engine block is very similar to the VAZ 21083 power unit block. The only thing that has changed is the height of the cylinder block. As a result of these changes, the stroke of the piston group increased. It became 75.6 mm, instead of the previous 71 mm. Accordingly, engine capacity increased from 1.5 liters to 1.6 liters.

Owner reviews

VAZ 2114 continued the tradition, and like its predecessor, it became a truly people's car. At one time it was the most affordable offer among non-mileage vehicles. This allowed it to become widespread and take its rightful place among other popular VAZ models.

Maksim. Lada 2114 1.6 l. 8th grade, 2010 180,000 km

I bought a car in 2015. The mileage on this example was quite decent, but the condition is good. I settled on the version with an 8-valve engine. Power is not so important for me, but they are considered much more reliable.

In general, this is confirmed so far. I only let you down once. When the temperature dropped below 30 degrees in winter, the battery died. But in fairness, it’s not entirely correct to make claims against the car itself.

Among the repair work, I did the replacement of the master brake cylinder and vacuum booster. We also had to change almost all the hoses under the hood. I recently had to replace the heater radiator. The rest is just consumables. I change the oil every 6-7 thousand, I only use synthetics. Many people do this on much higher mileages, but I like to play it safe. Moreover, given the quality of our fuels and lubricants, this will not be superfluous.

Among the shortcomings, we can note the quality of spare parts. Original spare parts from the factory do not serve flawlessly, but they have some margin of safety. Among the new ones there is a lot of different rubbish and defects. And this despite the fact that I try to buy the highest quality possible and not save. However, their “life” is very short. This is very frustrating and stressful. So I started thinking about selling.

Andrey. Lada 2114 1.6 l. 8th grade, 2008, 150,000 km

This car came to me unexpectedly. I was looking for a temporary second car for the family and settled on this option. I thought it wouldn’t be for long, but it turned out that I drove it for five years. All because I had to sell my main car. When purchased, the mileage was about 65 thousand.

There is not much to say about the ownership experience. A simple and unpretentious car. There are minimal amenities, but it doesn’t cause any trouble either. There is a minimum of electronics and electrics, and as a result it is quite reliable.

I didn’t have any breakdowns that would make it stand up straight on the road. I changed the clutch, replaced the timing belt and rollers three times (at my own request). Nothing more serious. I went for diagnostics a couple of times because the engine was not running very smoothly. Once we cleaned the throttle, and the second time we had to clean the injectors. I also replaced a rotten muffler.

Perhaps I would have kept it as a second car just in case, but it was starting to rot very actively. If not for this shortcoming, I would have given it a solid A. And so only four plus. For those who need a simple work machine for every day and are not too demanding, this is a very good option. The main thing is to find a specimen that is not killed or rotten through and through.

Nikolai. Lada 2114 1.5 l. 8th grade, 2006, 120 00 km

I purchased it in 2011 with 30,000 miles. The mileage is truly original, despite its age. I can say this for sure, since a friend had the car and was in plain sight all the time. I traveled for three years and did not know grief. I only changed consumables and all sorts of small things. But after the mileage exceeded 100 thousand, breakdowns began to appear.

First the stove stopped heating. Well, I thought it was a common thing: a thermostat or a faucet, but it’s not that simple. The antifreeze was slowly decreasing, but I thought it was coming from under the clamps somewhere, so I just added it little by little. Everything turned out to be much more serious. The temperature sensor was broken and was giving incorrect readings. That is, it showed normal temperature, but in fact it was overheating. It wasn’t actively boiling, but just a little bit at a time. Accordingly, the antifreeze gradually disappeared. As a result, such regular overheating gave me headaches. And minus the cylinder head gasket.

Then the ECU burned out. For some unknown reason. There is an opinion that the firmware is simply crooked. In the end I had to replace it. It cost, as they say, a pretty penny.

Well, little things somehow started to fall apart. And the quality of spare parts is absolutely poor. At least buy it in advance and rearrange everything around. Therefore, I sold it at 120 thousand. Perhaps I just came across an unsuccessful copy, because many people can easily ride for 200 thousand. But we need to clarify how much is being invested in repairs. I wasn’t happy with such fixed costs, so I decided to sell.

Judging by the mileage of 100 thousand, then everything is quite worthy, with the exception of corrosion resistance. Afterwards there is a big lottery. The car is suitable for those who love and know how to tinker themselves. The services turn out to be very expensive.

Design features of the VAZ 11183 timing belt

The camshaft of the gas distribution mechanism is driven from the crankshaft pulley using a toothed belt. Belt tension, unfortunately for drivers, is manual and brings a lot of trouble. Therefore, the belt often has to be tightened manually. A very important and pleasant point for owners of such an internal combustion engine is that when the timing belt breaks, the pistons do not meet the valves. This is possible thanks to the special design of the pistons, which has a recess in the upper part.

Modifications of the internal combustion engine VAZ 11183 1.6

This engine underwent a major modernization in 2011. On the new model, the receiver has been enlarged, and the throttle valve has received an electronic control system. The type of throttle control is called E-gas. The new engine acquired its own VAZ 11183-50 index, and its power increased to 82 hp. What is also important is that the VAZ 11183-50 began to comply with European compliance standards Euro 4.

It should be noted that in parallel with the VAZ 11183 engine, the VAZ 21114 engine was produced. By and large, this is the same engine. Most systems, components and mechanisms are identical.

However there are some differences:

- in the power system of the VAZ 21114 engine they used a completely different generator 5132.3771 for 90 Amp hours;

- a new fastening method was used to mount the generator;

- To drive the generator, a new belt with a thickness of 882 millimeters was used. The mechanism for tensioning the belt has also been changed.

All other components, systems and mechanisms of the engine are completely the same, despite the fact that the motors were produced in different production shops.

Recommendations for servicing the Lada Kalina engine

The service life of any engine depends on proper maintenance from the very first days of operation; the VAZ 11183 1.6 engine is no exception to the rule.

The manufacturer recommends servicing this engine in the following order:

- During the first kilometers of driving, the entire car undergoes grinding in of parts, including the engine. The grinding-in period is called the running-in period. It lasts about 1.5 thousand kilometers. After it expires, you need to replace the engine lubricant and the oil filter element.

- The next stage of maintenance must be performed after a mileage of 10 thousand kilometers. The engine oil and oil filter must be replaced. Also, at this stage it is necessary to change the air filter, measure the compression in the cylinders and adjust the valves.

- After 20,000 kilometers, it is necessary to diagnose all mechanisms and systems of the internal combustion engine. Naturally, you need to change the engine oil, since it must be replaced every next 10,000 kilometers.

- After 30 thousand, you only need to change the engine lubricant and filter element

- After a mileage of 40 thousand km, many engine elements and parts must be replaced:

- replacing the air flow filter element;

- replacing the fuel filter element;

- replacing the timing belt and roller;

- replacing the alternator belt if necessary;

- replacing the pump at the slightest play in the fuel pump pulley;

- replacing the valve cover gasket;

- other parts requiring replacement;

- In addition to replacing parts, during this period of operation the valves should be adjusted and diagnostics of the internal combustion engine systems should be carried out.

Subsequent maintenance must be carried out in accordance with points 2 and 5. The exception is motor oil and filter. They need to be replaced every 10 thousand kilometers.

Oil change video

Gas distribution mechanism and cylinder head

The cylinder head (cylinder head) is made of aluminum alloy. Its centering is done using two bushings. Attached to the block with ten bolts. A disposable metal-reinforced gasket is installed between the head and the block. When disassembling and reassembling it is replaced with a new one. Also during installation, the fastening bolts are checked. If they extend more than 135.5 mm, they must be replaced. The instruction manual indicates the order in which the bolts should be tightened using a wrench. 5 camshaft supports are located under the head roof.

The timing belt of the Lada engine consists of:

- camshaft;

- valves;

- rocker arms;

- springs;

- intake and exhaust manifolds.

The 2111 engine is equipped with a cast iron camshaft. It is driven into rotation by a toothed belt, which is pulled together with the crankshaft. The correct installation of the shafts relative to each other is carried out according to the marks on the pulleys.

There are 8 rotary cams on the camshaft, which push the valves and open the combustion chamber from one side to the other. When the intake valve opens, air is sucked in from the manifold and the injector pumps fuel. After ignition, the spent mixture exits through the outlet valve into the corresponding manifold. The valves are cast from steel, and the outlet is made of special heat-resistant steel, since its operation is associated with high temperatures.

The valve bushings have oil reflective caps made of special rubber. The valve closes under the action of springs.

Possible malfunctions of VAZ 11183 1.6

The VAZ 11183 engine is an improved version of the VAZ 21083. Most of the possible malfunctions for these engines are similar:

Flow sensor

For cars, a number of VAZ models, including Lada Kalina and Lada Granta, stopping the engine while driving is popular. Experienced drivers know that the culprit of the breakdown is the sensor responsible for mass fuel consumption. When replacing this sensor, the engine will start without problems.

Oil leaking

A popular problem is engine lubricant leaks. Oil can leak through the valve cover gasket, gaskets and seals. Sometimes a leak can be so critical that complex repairs cannot be avoided. Critical failures include oil leakage through the crankshaft seals.

Overheat

Overheating of the VAZ 11183 power unit occurs due to the thermostat. Unfortunately, the quality of domestic spare parts leaves much to be desired. A newly installed thermostat may not work. The motor may overheat, or on the contrary, it may not heat up.

Engine knock

Knocks in the power unit are a real problem for many VAZ cars. It is necessary to take into account the fact that the engine knocks when cold. If the engine has already warmed up and the valve clearances have been adjusted, the problem may be more serious. To determine the problem, you will need to diagnose the internal combustion engine.

ECU

The control electronics on the VAZ 11183 1.6 engine is one of the sore spots. Most drivers have encountered its replacement. There may be several reasons for this. For example: increased fuel consumption, the engine cannot develop full power, idle speed failure.

Engine tripping

If the engine starts to stall, you need to check the spark plugs. If the spark plugs are OK, then the ignition coil has failed. Very rarely a valve can burn out.

The revolutions are floating

If the engine speed fluctuates, then with a high probability it can be said that a dirty throttle valve is to blame. Often the cause may be a failed electronic sensor.

Crankshaft bearings

If, when accelerating, you can hear the sound of metal in the engine, then there is a high probability that the crankshaft liners are rattling. Further operation of the vehicle is not advisable until the problem is resolved. Otherwise, scuffs may form on the crankshaft journals.

As can be seen from everything described above, the VAZ 11183 power unit has many weak points and possible malfunctions. However, given the simplicity of the engine design, drivers fix most internal combustion engine problems themselves. Here, it must be said that spare parts for the VAZ 11183 are low in cost. Thanks to these circumstances, many domestic drivers fell in love with this engine. They consider it a reliable, easily repaired power unit.

Acquired deficiencies

The crankshaft of the 1.6 engine is quite modern, it is fully counterbalanced, that is, on the extension of each shaft cheek there is a counterweight (eight in total). Imported motors often have only four counterweights. They save.

“Weight loss” is visible everywhere. The thin rod of the connecting rod merges into a smaller lower head. The piston is lightened to the limit. The area where the piston rings are located and two small “tongues” are left, replacing the previous full skirt.

“Weight loss” is visible everywhere. The thin rod of the connecting rod merges into a smaller lower head. The piston is lightened to the limit. The area where the piston rings are located and two small “tongues” are left, replacing the previous full skirt.

A short piston skirt is in the spirit of modern automotive engineering, but this solution does not have the best effect on engine life. Not only is the piston bearing surface small, but also shifting (lateral vibrations) is more possible than with older, tall pistons.

The connecting rods of the current modification of the engine have become noticeably thinner compared to the old ones, with the index 2108. A high-tech break-off connecting rod cover has also appeared, but the width of the connecting rod bearing has been significantly reduced. Yes, the mass of the connecting rod was reduced a little in this way. But this definitely increased the load on the bearing. At the same time, the width of the neck on the shaft remained the same. It would be quite possible to install a connecting rod with a “wide” lower head.

You can clearly see how narrower the lower connecting rod head is than the crankshaft journal.

You can clearly see how narrower the lower connecting rod head is than the crankshaft journal.