Today you can find various types of internal combustion engines on cars, ranging from low-volume 3-cylinder units to powerful V8 or V12. At the same time, the vast majority of cars under the hood have conventional 4-cylinder engines.

If previously such power units were installed on entry-level and middle-class models, now the 4-cylinder engine can be seen even in the premium segment.

The fact is that boosting, increasing the number of valves per cylinder, introducing variable valve timing systems, installing turbocharging and other improvements made it possible to achieve the required power and efficient output from such engines.

The most affordable solution for increasing efficiency turned out to be a design that involves a greater number of valves per cylinder. In the simplest version, engines can have 2 valves (intake and exhaust). In more technologically advanced versions, the timing belt receives 4 or 5 valves.

In this article we will talk about the difference between an 8 valve and a 16 valve engine, as well as which engine is better, 8 or 16 valve. Next, we will try to figure out what advantages and disadvantages a larger or smaller number of valves in an engine has, taking into account the repair and maintenance of such internal combustion engines.

8 valve engine design

Such engines are used mainly on models in the entry-level price segment. Here there are 2 valves per cylinder: 1 for intake and 1 for exhaust.

Another important feature of such power plants is that only 1 camshaft is needed, which controls the gasoline injection and exhaust gas exhaust system. To operate it, a simple belt or chain mechanism is sufficient. Such a system is much easier to maintain and repair compared to complex timing belts of more expensive cars. And such an elementary design significantly affects the final cost of the car.

As an example, we give a diagram of the design of an 8-valve VAZ-2114 engine.

1) generator drive pulley; 2) oil pump; 3) timing belt; 4) coolant pump timing belt; 5) front cover of the timing mechanism drive; 6) tension roller; 7) camshaft toothed pulley; camshaft drive rear cover; 9) camshaft oil seal; 10) cylinder head cover; 11) camshaft; 12) front camshaft bearing cover;

13) pusher; 14) valve guide; 15) oil separator mesh for the crankcase ventilation system; 16) exhaust valve; 17) inlet valve; 18) rear camshaft bearing cover; 19) fuel pump; 20) housing of auxiliary units; 21) ignition distributor sensor; 22) cooling jacket outlet pipe; 23) cylinder head; 24) spark plug; 25) crankcase ventilation hose;

26) flywheel; 26) flywheel; 27) crankshaft rear oil seal holder; 28) rear crankshaft oil seal; 29) cylinder block; 30) oil pan; 31) oil level indicator (oil dipstick); 32) crankshaft; 33) piston; 34) connecting rod cover; 35) connecting rod; 36) crankshaft main bearing cover; 37) front crankshaft oil seal; 38) crankshaft toothed pulley.

What are they doing?

When extracting motive power from gasoline inside an engine, the intake and exhaust of air and fuel is probably the most important thing you need to worry about. Forget about the spark, you have to think about air intake. When you pump air, there will always be one big limitation - a bottleneck. A place where there are enough problems and this will be the critical place you need to work on to make sure the air and fuel are flowing. In the case of an internal combustion engine, this location is at the bottom of the cylinder head.

Pros and cons of an 8 valve engine

This engine design, despite its venerable age, has many advantages:

- simplicity of design - an 8-valve engine has significantly fewer wearing parts, and accordingly, its repair will be easier and cheaper;

- lack of hydraulic compensators - motors of this type simply do not need them, so the design is further simplified and cheaper;

- less demanding on oil characteristics - 8-valve engines allow the use of lower quality lubricant, which is noticeably cheaper;

- less sensitivity to the quality of gasoline - most of the 8-valve valves used today were developed at a time when there was no better fuel than 92;

- small size - one camshaft takes up much less space, so such engines are more compact than their 16-valve counterparts, and this makes access to attachments easier.

However, there are also many significant disadvantages:

- less power - intake and exhaust through 2 valves significantly limits the amount of fuel supplied to the cylinders and the total engine power;

- slightly higher fuel consumption - the reduced throughput of 1 pair of valves forces the engine to put more effort into pushing exhaust gases into the manifold, and accordingly more energy is spent on this;

- noise at high speeds - the pushers wear out during engine operation, gaps form, which is why the engine begins to make noticeable noise;

- the need for more frequent valve adjustments - if this is ignored, engine performance will drop, and fuel consumption, on the contrary, will increase.

What should you choose?

We bring to your attention 5 engines that we consider the best:

Ford 1.0 EcoBoost

The 1.0 EcoBoost engine was introduced in 2012 and found its way into most Ford models, from Fiesta to Mondeo.

Customers could choose from versions developing 100, 120, 125 and 140 hp. Despite considerable effort, the device turned out to be durable. Before 2013, the cooling system was a problem. In some vehicles, leaks were found in the pump and water channels. The subject of the service action was a hose susceptible to cracking between the expansion tank and the turbocharger.

Mercedes 2.0 CGI

Mercedes had a lot of supercharged engines. Due to characteristics and historical events, the concern used compressors more readily than turbochargers.

After all, even in Stuttgart, turbo was considered the only true way. The new four-cylinder engine was not built from scratch. Engine code M271 (2002-2011) with direct injection was used and the compressor was replaced with an exhaust gas turbocharger. As a result, the engine became economical during quiet driving and developed 156-204 hp.

The change in supercharger concept also solved one of the main problems of the old engine, namely the compressor problem. However, with high mileage, it is worth preparing to replace a worn timing chain - a single-strand chain that is not very durable.

Opel 1.4 Turbo

For many years, Opel offered supercharged petrol engines that could cope with the need to drive a poorly regulated gas setup without the need for frequent oil changes.

To keep up with competitors, Opel had to update its engine range. One of the new era engines is the 1.4 Turbo, introduced in 2010 (also found in Chevrolet). It produces 120-140bhp and in some models it has been fitted with an LPG unit from the factory which works very well thanks to indirect fuel injection and hydraulically compensated valve timing which is not available on naturally aspirated 1.6 engines for example.

Fiat 1.4 T-Jet

The 1.4 T-Jet series engine is designed for long-term operation. With proper maintenance more than 300,000 km.

Properly installed LPG and even tuning attempts, which Fiat often used when creating subsequent versions of the Abarth 500 / Punto, do not harm it. In top versions, the 1.4 T-Jet developed 190 hp. Its base variants produce 105 hp, which proves how versatile the engine is.

Renault 2.0 Turbo

Depending on the version, the engine offers 165-275 hp.

Thanks to its high torque (at least 270 Nm), it allows you to enjoy smooth driving even in basic versions. To keep the engine running for a long time, the driver must remember to change the oil and timing belt.

Petr Alekseev

Regular author of articles for the magazine rating cars.

16 valve engine design

In such 4-cylinder engines, each cylinder already has 2 pairs of intake and exhaust valves. To operate such a system, 2 camshafts are required. And for their coordinated work, a much more complex gas distribution mechanism is used. At the same time, 2 intake valves allow more fuel to be supplied to the cylinders per stroke - and hence a significant increase in power and efficiency. At the same time, fuel consumption is reduced thanks to the presence of 2 exhaust valves.

Hydraulic compensators are often used to press the valves against the shaft in such engines. Unlike 8-valve valves with mechanical pushrods, this system operates smoother and quieter. It also provides an additional increase in power and additional fuel economy.

Another specific feature of 16-valve engines, which becomes especially relevant against the backdrop of ever-tightening environmental requirements, such engines, due to more precise operation of the gas distribution mechanism, are safer for the environment.

For example, here is a diagram of the design of a 16 valve VAZ 2112 engine.

1) engine oil pan; 2) front crankshaft oil seal; 3) crankshaft; 4) crankshaft pulley; 5) oil pump; 6) generator drive pulley; 7) timing belt; front cover of the timing mechanism drive; 9) coolant pump pulley (pump); 10) tension roller; 11) camshaft toothed pulley; 12) rear cover of the timing mechanism drive; 13) camshaft oil seal;

14) exhaust camshaft; 15) hydraulic pusher; 16) valve spring; 17) valve guide; 18) exhaust valve; 19) receiver; 20) camshaft bearing cover; 21) guide pipe; 22) cylinder head cover; 23) plastic cover; 24) spark plug; 25) intake camshaft; 26) inlet valve; 27) cylinder head; 28) coupling;

29) fuel rail; 30) crankcase ventilation hose; 31) nozzle; 32) intake manifold; 33) flywheel; 34) crankshaft rear oil seal holder; 35) rear crankshaft oil seal; 36) cylinder block; 37) oil dipstick; 38) piston; 39) connecting rod; 40) connecting rod cover; 41) crankshaft main bearing cover.

Crankshaft

The crankshaft is located at the bottom of the cylinder block. It is cast from cast iron, consists of eight counterweights and nine journals, five of which are main (located on the same axis) and four connecting rods. Behind the main journals, through the bearings on which the crankshaft rotates, it is attached to the block with non-interchangeable covers (they are marked accordingly). On the middle main journal there are grooves machined for the support half-rings, the rear one is metal-ceramic, and the front one is an alloy of aluminum and steel. These half rings prevent axial play of the crankshaft. Oil channels are machined inside the crankshaft, performing a dual function:

- Cleaning oil from mechanical impurities (due to centrifugal force);

- Oil supply from the main journals to the connecting rods and their lubrication.

During an engine overhaul, and during any removal of the crankshaft, these channels must be cleaned, and the channel plugs must be replaced. A flywheel is screwed to the rear of the crankshaft with six bolts, onto which the ring gear is pressed. The starter gear engages with the ring splines, causing the engine to start. And the flywheel itself performs several functions. Firstly, due to the accumulation and subsequent release of kinetic energy, it removes the piston from the so-called “dead spots”. Secondly, it stabilizes the crankshaft speed, smoothing out torque irregularities and dampening engine vibrations. Well, actually through the flywheel the rotational energy is transferred to the transmission.

Flywheel

At the front of the crankshaft, two pulleys are mounted in series: the camshaft drive and the generator drive, respectively.

Pros and cons of a 16 valve engine

So, here are the main advantages of 4-cylinder engines with 16 valves:

- significant increase in power, increased maximum speed and dynamics;

- lower fuel consumption and environmental friendliness;

- much lower noise level;

As you can see, the advantages of such engines are significant. But they also have significant disadvantages:

- hydraulic compensators are very sensitive to oil quality, it is recommended to use only synthetic oil;

- for efficient operation of the “four” with 16 valves, you need high-quality gasoline, ideally not lower than AI-95;

- Structurally, such engines are much more complex, in particular, replacing the timing belt here, as a rule, costs several tens of thousands of rubles;

- The motor itself is larger, which makes access to attachments more difficult.

Piston group

Steel connecting rods of an I-section (in the shape of the letter H) move on four connecting rod journals; the connecting rod caps, as well as the main bearing caps, are not interchangeable (the number of the corresponding cylinder is stamped on each connecting rod and its cover). The pistons are cast from aluminum alloy, with three grooves machined into them for the rings: two compression and one oil scraper. Compression rings prevent the penetration of gases into the crankcase, and oil scraper rings remove oil from the cylinder walls to the piston bosses, due to this the pin is constantly lubricated. The pistons are attached to the connecting rods through piston pins freely floating in the holes (bosses); they are secured in the bosses on both sides with retaining rings. The pistons of the eight-valve one and a half liter engine have a recess, which protects them from meeting these same valves in the event of a timing violation (in other words, if the timing belt breaks, the valve does not bend, as was the case on the 1.3 engine).

Main differences between 16 and 8 valve engines

We have figured out the features of these types of engines, now we will specify the differences between them.

8-valve engines are much simpler in design, which has a positive effect on the price of the entire car, its maintenance and repairs. However, they are significantly inferior in power to 16-valve analogues with the same displacement - on average, the difference in power here is 15-25 hp. Because of this, engine response, acceleration dynamics, and maximum speed suffer.

At the same time, 4-cylinder engines with 8 valves are much simpler and more affordable to repair. There are significantly fewer elements that can break, and if something does break down, the breakdown can be repaired with less effort. And spare parts for such engines are usually cheaper.

With efficiency, everything is not so clear. Yes, 8-valve engines consume more fuel - but at the same time, they can be filled with lower quality, inexpensive gasoline. Oil may not be the most expensive either. Another controversial point is the use of hydraulic compensators. They are installed on 16-valve engines and eliminate the need for systematic valve adjustment. At the same time, they sometimes fail, and replacing them will cost a pretty penny.

One more important point should also be noted: in 16-valve engines, the piston and valves can jam together - and this inevitably leads to costly repairs, and sometimes to a complete replacement of the engine. In principle, 8-valve patients do not have such a disease. However, such jamming occurs, as a rule, on Russian and Chinese cars, which by default are inferior to the Western and Japanese automobile industry.

Eight or sixteen

We have said a lot here, but it is still not completely clear what is better - 16 valves or 8. Let us draw conclusions and the picture will become clearer. In any case, you need to focus on your wishes for the car and the features of future operation.

- Are dynamics and efficiency indicators at the forefront? Then the choice should definitely fall on a 16-valve engine. But the car should only be serviced at a professional service station.

- When dynamics are not so important, and power can be sacrificed, then you can save money and choose an 8-valve engine. In addition, it will not require professional maintenance, which will further reduce costs.

Think about what is of utmost importance to you personally and make choices accordingly. It is not always worth chasing technical innovations. Often old and proven mechanisms turn out to be better than their improved counterparts.

Which is better 16 valves or 8

So, let's try to determine which option and in which situation will still be preferable. New cars with 4-cylinder engines offered in showrooms are almost always equipped exclusively with 16-valve engines; such engines have already displaced the outdated 8-valve design from the market. However, some manufacturers, usually from the lower price segment, still have such simplified options. Their main advantage is just a more affordable price.

But, if you have the opportunity to pay extra, the car is chosen for personal, not commercial use, and you are not going to service it yourself, then it would be more reasonable to buy a car with a 16-valve engine. It will delight you with higher power and dynamics, as well as efficiency and reduced noise.

In a situation where the car is taken from hand, 8-valve options may be preferable. The fact is that they are structurally simpler and more unpretentious in the choice of fuel and oil, respectively, here the chance of getting a car with a “live” and peppy engine will be higher than in the case of more sensitive 16-valve engines.

It is impossible to say unequivocally which option is better. It is necessary, first of all, to take into account your own goals and objectives, financial capabilities, and the conditions in which the car will be operated. If your primary requirements are reliability and unpretentiousness, then it makes sense to take a closer look at the 8-valve modifications. If speed and power are important to you, then it is better to choose 16-valve engines.

Valves

You need a strong, durable valve to hold the blast in the cylinder. You also want it to be smaller than the surface area of the piston. And you need one to let the air in and one to let the air out again.

For decades, most engines had two valves. One for intake, one for exhaust. Simple, easy, effective. But there were limits. You see, you can make a valve so large that it fits into a piston, cylinder wall, or other valve.

And even when they approach this maximum size, air can no longer flow around them without opening the valve. This is called high lift, named after the camshaft lobe that raises the rocker arm, which opens and closes the valve higher than normal.

Motor 126 and 127: working life, differences

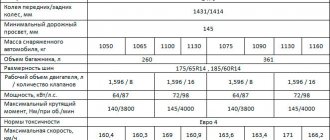

These engines on Priora had a displacement of 1.6 liters (or 1596 cm3). Optimal for city sedans, the engine size of the Lada Priora gave a good combination of dynamics and consumption: along with very decent acceleration, fuel consumption does not exceed sky-high numbers. Both engines received good marks, because the car behaved perfectly in the city and on the highway.

127 motor - looks like this

In fact, the 126 Priora engine became the first sixteen-valve engine for this model, and the 127 is a modified version, “overclocked” by AvtoVAZ designers. In addition to the same engine displacement, they have other identical characteristics. The in-line type of arrangement of four cylinders provides a simplified design that can be repaired on your own.

The distributed multipoint injection system is involved in creating a good, rich fuel-air mixture (a lean mixture can lead to breakdowns). The cylinder diameter is 82 mm, the piston stroke is 75.6 mm, the compression ratio is 11. The “engines” fall under the Euro 4 standard, they are powered by gasoline with an octane rating of 95.

The 126 engine for the Priora received the following characteristics: 98 hp. (72 kW at 5600 rpm), acceleration to 100 km/h in 11.5 seconds (with manual transmission), city consumption 9.1 l - 100 km (manual transmission), maximum torque - 145 Nm.

The 127 engine for the Priora was upgraded to the following figures: 106 hp. (78 kW at 5800 rpm), acceleration to 100 km/h in 11.5 seconds (with manual transmission), city consumption 8.9 liters per 100 km (with manual transmission), maximum torque – 148 Nm.

The difference may not seem so noticeable, but this is a very small but strong step in design on the part of AvtoVAZ (this is where the change to sixteen-valve “engines” with a volume of 1.6 liters ended). For a car of the Lada Priora class, the engine power was sufficient.

In the same block it is necessary to say about the operating temperature. An absolutely normal operating temperature is considered to be between 90 and 95 degrees Celsius. Further, when the car is being pushed in a traffic jam, is basking in the sun, or for some other reason, but can still work - from 97 to 110 degrees. The engine is slow in places and wears out a lot, but you can still get to your destination. A temperature below 90 degrees is a direct sign indicating that the car has not yet warmed up, and it is better to wait in place until the arrow points to the coveted 80-90 mark.

Operating a car at temperatures above 110 degrees is dangerous because the service life of the engine is noticeably reduced - hot parts undergo very severe wear, overcoming the force of friction.

In general, the service life of the Lada Priora engine with a normal driving style and careful treatment is 200,000 km - after this mark the time comes when the “engine” requires major repairs. AvtoVAZ mentioned the timing belt separately as a recommendation, saying that it needs to be checked every 100,000 km (many car enthusiasts talk about the figure of 50,000 km).

All Lada engines have a problem, and it is related to the valves, which will be discussed further.

Signs of the need for internal combustion engine repair

The reasons why the operation of the engine is disrupted are arranged in a small list, starting with refusal to start and ending with floating idle speed (this problem was removed on the 127 “engine”). Not all breakdowns end in capital damage - sometimes it’s enough to add oil, sometimes it’s enough to adjust the ECU settings.

Compression reduction

A decrease in cylinder compression below 16 atmospheres is a bad sign. Such a high limit corresponds to a compression ratio of 11.

If the compression decreases (or vice versa increases), then the “engine” will have to be rebuilt.

Knocks in the engine

Engine knocks can come from several points. These could be hydraulic compressors, timing belt rollers or pins. The knocking noise could also be caused by low oil level. The answer to the question will be given by a thorough detailed inspection of all parts of the unit and checking the oil level.

Blue smoke from the exhaust pipe

The blue smoke that comes from the exhaust pipe appears when oil enters the combustion chamber. It can leak either from the valves or from under the piston. The result is the same: the oil is eaten up and blue smoke pours out of the chimney. Once the leak is located, half the problem will already be solved.

Troit motor

Sometimes in the cold the engine may stall - don’t be alarmed by this, because it may simply be one of the spark plugs that fails. In this case, we advise you to simply restart the engine and it will stop running.

How much does it cost to overhaul a Priora engine - average price

Self-repair of a Priora engine with 16 valves costs an average of 16-20 thousand rubles. The cost depends on the severity of the breakdown and may be lower or higher than this average range. Repairing a Priora engine can be entrusted to the wrong hands, but then you will have to pay for the work - sometimes the cost of repairs reaches as much as 40 thousand rubles.

This is an unreasonably inflated figure, because, as practice shows, you can rebuild the engine on a Priora, working at a moderate pace, in just three days - and three days of work is definitely not worth that kind of money. Don’t be afraid of not being able to cope - your Lada is easy to repair, and using the advice and “tutorials”, you will conquer even such a task that is impossible at first glance.

About the technical component

Technically, engines with 8 and 16 valves are quite different. Although all the difference is stored at the top (engine block head) where the car's camshafts (camshaft) are/are installed. In fact, this is the main design feature, but what I want to note is that almost every engine can be made into either an 8 or 16 valve version. For example, on our VAZs, the engines are very similar, and hypothetically, on the same block, you can fit a different cylinder head, with one or two camshafts.

Main differences.

The 8-valve engine has a narrow cylinder head because it has a single camshaft. The candles are located on the block horizontally and at a certain angle. The camshaft controls the order of their opening - first it opens the intake, then the exhaust. The valve opens with the help of conical parts located on the camshaft, and closes with the help of springs located on it. In a four-cylinder engine, there are two valves for each cylinder of the engine - intake and exhaust. Actually, that’s why there are eight of them per power unit.

Advantages of an 8-valve engine:

- Initially, the design of the engine is relatively very simple and, accordingly, easy to maintain.

- The absence of hydraulic compensators undoubtedly simplifies the design of the power plant as a whole.

- Undemanding to oil.

Flaws:

- Power is less compared to a 16 valve engine. It is also impossible to achieve such high speeds - two valves per cylinder does not allow speeding up the intake and release of fuel and gases from the chamber. The process is happening slower than we would like.

- Increased fuel consumption. Due to the fact that the gas exits through one valve, which cannot let through more than it should.

- Such engines are, in essence, noisier, especially when moving at high speeds.

- The absence of hydraulic compensators requires adjustment of the valves as their precise synchronization is disrupted (even with slight deformation of the camshaft cam profile), in the worst case, a knocking sound appears.

16-valve engine and its significant advantages:

- More powerful. It accelerates better and therefore the top speed will be significantly higher than that of an 8-valve engine. More powerful. Accelerates better and therefore the top speed will be significantly higher than the 8-valve engine.

- It is also important that fuel consumption is noticeably less (should be).

- Engine noise is less.

- The valves are regulated by hydraulic compensators.

Flaws:

- The presence of hydraulic compensators requires a timely change of engine oil to avoid coking of the hydraulic compensators.

- Engine maintenance is more expensive. After all, the design of such an engine is an order of magnitude more complex than the design of an 8-valve engine.

A few words about another reason why valves should sit tightly in the seat. In addition to ensuring complete sealing of the combustion chamber, it should be taken into account that the valve discs operate under severe conditions of high heat. In addition, the plates must be in close contact with the seat, which is located on the cylinder head, which is cooled. After all, the heated plate transfers most of the heat to the saddle. This is especially true for the exhaust valve, since it is cooled only through the tight fit of the plate to the seat, and the intake valve is cooled when the incoming air-fuel mixture is in contact with the seat. If there is poor contact with the seat, no (even the most heat-resistant) valve will withstand such strong overheating. It will simply burn out and collapse, so its tight fit in the saddle is very important. Therefore, they are made from heat-resistant metal alloys. In addition, they do not have magnetic properties.