Last updated May 28, 2022 at 10:40 am

Starting with the third version of gas equipment, the function of supplying fuel (methane, propane-butane mixture) to the combustion chambers of the engine began to be performed by special mechanical injectors. 4th generation HBO gas injectors are on a completely different level. Thanks to electronic control and fine-tuning, it has become possible to more efficiently use gas systems in cars.

A gas kit for installation on a car is often assembled from a set of parts from different manufacturers. Which injectors are better to install and how to choose them, as well as install them correctly, we will tell you in this article.

General concepts

LPG or gas equipment (approved abbreviation - LPG) is additional equipment for a car, the purpose of which is to store and supply fuel in a gaseous state to the internal combustion engine.

This type of fuel includes methane and a mixture of butane and propane. There are six generations of gas equipment. Differences between HBO generations in gas supply and regulation systems (injector, carburetor). 4th generation HBO injectors are an equipment unit that is used in parallel or distributed sequential injection of a mixture into an engine. Its task is to dose the fuel.

HANA (Korea)

The body of HANA 2000/2001 is made of metal alloys, which is much better for increasing the structural strength. High accuracy of dosing of the mixture is ensured by the needle valve introduced into the design. The design allows for installation both individually and on a ramp. There is no possibility of replacing the jet - a certain cylinder power requires the use of a certain type of valve for the horsepower ranges:

from 20 to 30 are marked in black;

from 26 to 39 – red;

from 33 to 50 – green;

from 40 to 60 – in blue.

HANA 2000/2001 are one of the fastest valves: the armature response time has been increased to 2 milliseconds. Other advantages include low noise level and increased resource.

Maintenance consists only of thorough bench washing. Solenoid failure or mechanical failure automatically leads to replacement. Hence the increased demands on what types of fuel are used, frequent replacement and the use of expensive filter elements.

Operating principle

The gas unit is responsible for controlling the operation of gas injectors, which processes the signals from the gasoline electronic unit for gasoline injectors. The volume of gas for supply to the internal combustion engine (internal combustion engine) is calculated based on the temperatures of the gas and the reducer, the pressure of the gas mixture and other parameters.

Injection technology using an HBO gas injector intersects with the idea of gasoline injectors. An electromagnet (solenoid valve) is required that moves a part (rod) to open the flow of fuel from the reducer, which evaporates the mixture, to the intake manifold. The nature of the fuel affects the cross-section of the injector channels - for gas the cross-section is larger, because the volume of the gas mixture exceeds the same dose of gasoline (about 250 times) and greater throughput is required.

To ensure such tasks, the gas injector of the HBO has a reduced electrical resistance. Gasoline injectors have a resistance of 16 - 17 Ohms, while for gas it is 1 -3 Ohms.

It is important that to ensure the speed of operation of a gas injector, electromagnetic coils of greater power are needed than for gasoline injectors. There are other design differences. The petrol injector opens with a 12V pulse. Applying such voltage in the case of a gas mixture will disable the opening element. Therefore, the 4th generation HBO injector opens due to the action of a short-term pulse, the interruption speed of which is quite high. As a result, the winding of the part does not overheat and does not burn out. This method is called pulse width modulation.

Signs of malfunction

The fact that the injectors have begun to work incorrectly can be noticed by every motorist who has at least a little experience in using gas equipment. Externally, problems in their work appear as follows:

- unstable engine operation;

- no idle speed;

- lack of traction;

- increased fuel consumption;

- deterioration in engine performance, etc.

All these signs indicate that gas injectors need immediate cleaning. The reason why they become clogged may be improper maintenance of gas equipment, the use of low-quality filters for the vapor and liquid fractions of fuel, or the use of cheap liquefied gas of inadequate quality to refuel a car.

Malfunctions in the gas injection system

The LPG gas injector, if there is a malfunction in the injection system, is completely repairable. But for this you need to have a repair kit of gas injectors on hand.

Since the correct and coordinated operation of the entire LPG system is determined by the injectors, you need to learn how to diagnose their malfunctions.

It could be:

- nozzle contamination;

- imbalance of the rack;

- open circuit;

- coil short circuit;

- electronic problems.

There can be many reasons, but if you ignore them and do not react in time, you can limit yourself to not just replacing parts of the injection mechanism, but say goodbye to the entire power unit. Therefore, if in doubt what exactly the fault is, it is better to take the car to an electronic stand, where mechanics will describe the breakdown in detail.

It might end up figuring out how to clean your gas injectors, or maybe you'll need an advanced repair. But, in any case, this is more profitable from an economic point of view than replacing the entire engine.

Although the new generation of gas equipment is already equipped with systems that themselves monitor and diagnose problems. But still, if the car is retrofitted with a gas installation, inspecting the system itself is absolutely not an unnecessary manipulation. It happens that during the investigation, minor little things come to light, which, however, can lead to serious damage.

Also, when purchasing injectors, you need to read reviews of the manufacturer and compare prices for such parts, since cheap parts can cause big problems. It is best if you have any questions regarding HBO, contact the station, where specialists can advise on the operation of the HBO system.

On our website there are articles about gas injectors from companies:

- Lovato;

- Valtek;

- AEB;

- Barracuda;

- OMVL.

Do-it-yourself cleaning

Having discovered obvious signs of clogging, many car enthusiasts try to clean gas injectors themselves. The process of their cleaning consists of several stages:

- Close the supply valve located on the gas cylinder. This must be done to prevent gas from entering the engine.

- Use up all the fuel remaining in the line. When the gas runs out and the car switches to gasoline, you need to force the switch to gas several more times so that all the remaining gas is used up.

- Mark the wires going to the coil and the ramp with injectors differently. This way you will avoid any tangles in the wires when they are reinstalled. It is convenient to use electrical tape or markers of different colors for marking.

- Remove the ramp with injectors, unscrew the calibration jets.

- Remove the corkscrew rings and spool, unscrew the guides.

- Remove the rods, springs and O-rings. In this case, you must remember from which injector this or that rod is removed.

- Remove dirt and deposits from the rods, avoiding getting the rubber seals wet.

- Clean the inside of the nozzle body. A rag is best for cleaning, since using it does not leave fabric lint on the parts.

- Restore the arrangement of all parts in reverse order.

After all the injectors are returned to the ramp, all that remains is to install it in its original place and connect the wires correctly. Before using the equipment, be sure to check the system for leaks

To do this, apply a soap solution to all connections and turn on the flow valve. Bubbles will appear in places where gas will escape. These places need to be additionally fixed.

Disassembling gas injectors

The first step to removing the ramp from the car is to shut off the gas supply to the LPG line by closing the flow valve on the gas cylinder.

- Exhaust all the gas from the line; to do this, start the car with the valve closed and wait until it switches to gasoline, then force the system to switch to gas two or three more times.

- Before disconnecting the wires and removing the ramp, be sure to mark which wire belonged to which of the gas coils. This can be done using a marker or multi-colored electrical tape. When assembling, you must accurately determine whether the wire belongs to one or another coil.

- Unscrew the fasteners and remove the ramp. When unscrewing the clamps, you will hear residual gas escaping - this is a normal situation.

- Using a 12mm wrench, unscrew the calibration jets.

- Remove the corkscrew rings, carefully folding them so as not to lose them. Remove the coils. If you made marks on the coils with a marker, mark which coil was in which place so as not to confuse them during assembly. If you made marks on the ramp itself, the order of installing the coils may not be followed.

- Using a 14 key, unscrew the guides and carefully remove them. If one rod is being replaced, during disassembly, it is imperative to mark the rod-seat pair so that they are not confused during reassembly. If all parts are replaced, the order may not be followed. Remove the rods and springs from the guides.

- Conduct a visual inspection of the rods and rubber bands, determining whether you need to use a repair kit or not. If the rubber band is completely worn out, metal comes into contact with metal, resulting in a characteristic “clicking” sound.

- If the rod itself has a satisfactory appearance, you can replace only the rubber band and the spring (also in case of wear); to do this, remove the old rubber band from the rod with a sharp object (an awl) and place a new one in its place. If the mileage of the injectors is significant, the rod should also be replaced.

- Carefully inspect and replace worn parts with new ones on all injectors, then reassemble the ramp in reverse order.

It is imperative to adjust the gas injectors before installing them on the car.

Read about how to do it yourself here!

Gas injector repairs have been completed. If you have any questions during the repair process, ask them in the comments to the article and we will be happy to answer them.

Options

The main characteristic for a gas injector is its performance, which is measured in horsepower per cylinder. Various factors are responsible for this parameter.

The 4th generation gas equipment does not use high-precision atomizers. Because the gas supply to the opening part is already in an evaporated state (gas in liquid form evaporates on the gearbox). For this reason, a fitting (an element resembling a bushing, essentially part of the exhaust pipe) is installed on the exhaust manifold near the gasoline injector. The fitting allows for finer tuning depending on the specific engine. Therefore, it is very important to select parts of the appropriate size in combination with all elements of the equipment.

For example, the accuracy of the dose of the gas mixture will be affected by:

- The angle at which the fittings are installed in relation to the angle of air flow

- Length of hoses between the supply fitting and the 4th generation LPG nozzle

- The place where the fitting is installed depending on the cylinder head

The next factor influencing performance is the linearity of the structure. This means that the volume of gas that passes through the valve increases by the same amount as the opening time of the element in milliseconds increases.

When there is a deviation in linear performance, a loss of power occurs, a disturbance in the temperature regime of the engine, and uneven gas consumption. For correct operation, it is important that the nozzle valve closes as soon as possible after the pulse is given. The exact response of the injector to the signal affects the quality of the system as a whole.

Malfunctions in the gas injection system

Gas equipment of any generation, no matter how carefully it is installed and adjusted, is susceptible to breakdowns. At the most inopportune moment, the emulator may fail and the gas supply may be interrupted. Failures of fuel injection mechanisms also occur.

The main indicators that the injectors require repair or replacement are:

- uneven engine operation, unstable speed;

- the engine does not develop the required power;

- there is no automatic gas-gasoline switching;

- increased gas fuel consumption;

- There are failures in the operation of the internal combustion engine when the speed is suddenly increased or decreased.

It is best to contact the station where the gas equipment was installed or serviced if these types of symptoms occur. The same should be done if the injection mechanisms knock and there is a noticeable gas leak in the seals.

What can cause malfunctions and breakdowns in LPG systems? There are not many reasons, and in most of them the car owner himself is to blame. Lack of proper maintenance and care of injectors, the use of gas mixtures of improper quality or composition, gross violations of operating rules are the main prerequisites for the fact that the service life of even expensive injectors will be significantly reduced.

The occurrence of injector malfunctions has nothing to do with the type of power system and does not depend on the generation of gas equipment. Whether it is single injection, distributed or direct injection, second generation or fourth generation equipment is installed - compliance with the rules is necessary.

Material

An important parameter is the material of the product. The operation of all equipment is carried out in various temperature fluctuations: from -200C with a cold engine to +1000C after warming up. The gas fuel itself contains impurities (for example, paraffin or oil), which lead to contamination of parts.

Under these conditions, the metal will deform, which is not acceptable. For example, one of the elements of an injector is a plunger that creates fuel pressure. It makes translational movements, with a stroke length of 0.5 mm. Any change in physical dimensions will affect the performance of the system. Therefore, it is desirable that the material has a minimum coefficient of thermal expansion.

In budget versions of injectors, it is possible to reduce the plunger stroke to 15-20%. This shortens the life of the injector, increasing its wear.

RailIG3 Horizon

This type of injector is widely used due to the possibility of being assembled into a structure, increased productivity, high response speed, and the ability to be installed on a single injection. Greater performance of the Rail IG3 Horizon is ensured by the valve seat diameter increased to 3.5 mm. Increased performance and speed of response to an electrical signal make it possible to integrate this brand of valves into gas equipment for engines equipped with turbocharging and a turbocharger, with high power per cylinder.

Flaws:

- very noisy work;

- low mean time between failures;

- susceptibility of plastic elements to temperature deformation;

- fear of pollution;

- high cost of the kit.

What is an injector emulator

For 2nd generation gas internal combustion engines, an electronic device is installed to simulate gasoline injectors. This device is called an LPG injector emulator. For the 3rd and 4th generation it is integrated into the electronic gas control unit.

Emulators depend on the number of engine cylinders because it is necessary to read the signal to supply the appropriate fuel to each cylinder using a switch on the dashboard. This device allows you to set the interval for switching from gasoline to a gas mixture. You can set the delay in the range of 0-5 seconds.

The task of the emulator, when turning off the gasoline injectors, is to transmit signals to the control unit that simulate the operation of the injectors.

Rail (Italy)

Rail SPA injectors are a world-famous Italian company producing components, replacement and consumable parts for gas equipment, in particular gas valves that can operate on both a mixture of propane and butane and methane.

Rail IG1, without exaggeration, is the most common brand in Russia. The operating pressure ranges from 0.5 to 2 bar, the maximum is 3 bar. Until 2010, they were produced with a valve seat diameter of 4 mm; after modernization carried out in 2010, its diameter is 3 mm. The operating temperature range declared by the manufacturer is from -20 CO to +120 CO.

The Rail IG1 fire rate at idle is 3.3 milliseconds with an accuracy of +3%. Experts recommend setting such a gas pressure and selecting the diameter of the nozzle opening so that the response speed when lifting the armature 0.6 mm is within 4 - 4.5 ms.

The massive aluminum body ensures quiet operation of the valves; they are not demanding on the quality of the gas mixture. The average service life before repair or replacement is about 50,000 km.

Types by manufacturer

Which LPG gas injectors are better? The choice is up to the car owner. There are cheap options, and there are more expensive ones. Each model has its own pros and cons. Injectors from different manufacturers differ in their designs. Let's look at some of them.

Rod gas injectors

The most common and budget-friendly are rod gas injectors. Their representatives:

- Rail Type 30,

- Valtek Type 30,

- Rail IG1-IG5-IG9.

Advantages of this model:

- Price

- Work even with deviations in the stoichiometric ratio of the gas mixture

- To be repaired

The basis of the product is a solenoid valve. The design involves supplying gas to the rod through a hole located close to the seat, perpendicular to the locking part. As a result, it is not possible to blow through the solenoid rod; it is subject to temperature loads and can easily be coked with dirt.

At the same time, the rods are relatively heavy, which leads to faster wear of the rubber bumpers. At the same time, the valve opening speed is at least 2 milliseconds, which is low performance.

Such injectors need repair after 20-50 thousand kilometers and wear out after 70 thousand. There are isolated cases of longer work, but this is not a common occurrence.

Repair

The procedure for repairing LPG rod injectors is simple:

- The ramp needs to be removed and disassembled

- Clean from the inside

- Replace elements (rubber bumper, rod)

- Assemble the structure

- Calibrate the rod stroke to 0.45 mm using a micrometer

However, it is recommended to carry out diagnostics at a service station. It is not always possible to immediately determine what exactly needs to be repaired in the injector. For example, the cause of excessive consumption of the gas mixture can be either overheating of the fuel, which affects the physical parameters of the parts, or carbon deposits on the injector.

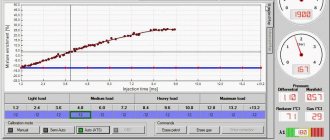

The injector can only be cleaned on a stand in a special pressure environment. When washing directly in the engine compartment, there is a high risk that all the contamination will remain on the cylinders and other parts. Correction of the rod stroke occurs along with diagnostics of all equipment components. The repair results are checked at the stand. In this case, the operation of each node is recorded. A more advanced model is OMVL. The design is made lighter through the use of composite plastic. The rod responds better to magnetic impulses due to a special alloy. This made it possible to more accurately dose fuel injection. The service life of such injectors reaches 100 thousand kilometers.

Needle nozzles

Another type is needle gas injectors. Such elements, for example, are produced in Japan by Keihin, in Korea by Hana, and in Poland by Barracuda. These injectors are expensive and cannot be repaired. Their wear resistance is affected by timely replacement of phase filters for the vapor state of gases (approximately every 10,000 kilometers).

The design assumes the possibility of blowing the nozzle independently. In some cases, it is permissible to wash the injector on a gasoline stand. Needle injectors work for a long period. Wear occurs after 150 - 200 thousand kilometers. Engines using Hana parts have traveled more than 300 thousand kilometers.

Torelli Rapido produce injectors with a one-piece piston-type design. Thanks to the gas supply from above, the injector is self-cleaning. In addition to these features, strips have been added with which you can connect 3-4 nozzles together.

Product material – stainless metal. In this case, when a small current is supplied at the output, there will be an increase in magnetic induction. The result is good response time. Such an injector will open the valve in 1.9 milliseconds. It closes within 1.2 milliseconds. The manufacturer's warranty is 100 thousand kilometers.

Diaphragm gas injectors

The next type of injectors is membrane. Manufacturer: BRC. Such products cannot be repaired and are expensive. The membrane is damaged when an aggressive environment penetrates inside.

But the constructive idea of separating the electromagnetic part from the locking mechanism with a membrane leads to a longer service life (up to 200 thousand kilometers). This feature prevents incoming dirt from jamming the parts and sticking together.

OMVL (Italy)

OMVL gas injectors differ from analogues primarily in their body made of composite plastic and the possibility of two-way gas connection. The unused socket is either plugged or used to install a temperature sensor. The versatility of the injectors is ensured by the ability to install jets with different hole diameters and installation on a single injection.

Valve stems are made of ferroalloy, which has a positive effect on response speed, noise level and durability. OMVL mechanisms are suitable for repair, have sufficient service life, and are low in cost.

Installation

The installation of HBO injectors has a great influence on the stability of the system. The position in space depends on the specific model. This is due to the side from which gas is supplied to the rod. If the injector is not fastened correctly, dirt will accumulate, which will lead to loss of performance.

Another nuance is what to attach the injector itself to. Some experts allow fastening with plastic ties. This is not up to standard. Metal brackets are preferable. It is important to install the injector so that its ramp avoids excessive vibration when in contact with various parts in the engine compartment. Plastic ties can deform faster, which will affect the quality of the nozzle.

As mentioned above about non-repairable injectors, vapor phase filters are a necessary element in maintaining performance. Filters come in different types and are made from different materials. The most convenient are separator filters. In the settling tanks of such filters there are special channels in which the gas moves in a spiral. A centrifuge effect occurs, due to which heavy gas fractions are separated and remain at the bottom of the structure.

Barracuda (Poland)

The design of the Barracuda injection mechanism is of a needle type, which is superior to other designs. Gas flowing through the solenoid prevents the mechanism from clogging. A plunger pair lined with fluoroplastic works much better; it has a low coefficient of friction and is not subject to contamination and burning.

The response speed of 1.9 milliseconds, high quality manufacturing, original design solutions and long service life make Barracuda products one of the leaders when completing gas equipment installation packages.

That's when I encountered the problems of HBO.

The car is equipped with Lovato LPG with Matrix injectors. To be honest, I didn’t appreciate this package at the time, because... I was far from all this equipment and had never encountered it. Now I can already say that Matrices are cool injectors, although they are no longer produced.

Initially, the car switched to gas and because of the HBO, it was running. But after working a little, the engine began to work normally. The former owner of the car immediately made me happy, saying that the injectors needed to be changed, because... The gas at our gas stations is bad and it’s time for them to be replaced. When I went to the LPG service station, they immediately changed the filters (they really had some tar in them), and the master told me not to bother with replacing the injectors, but to drive until the LPG stops working completely. Well, that's what I did. Naturally, the further we went, the more problems there were with HBO.

When switching the LPG, the car was shaking and twitched while driving, but after a couple of hundred meters the operation of the LPG leveled out, and you could drive around calmly. Although due to the HBO, the revs fluctuated for some time.

So autumn passed unnoticed and winter began.

While warming up in the morning, the car switched to HBO and stalled. Although no. At first, she was Troil, specifically Troil. Well, a month later she was completely deaf. Only specific warm-up saved the day, and after a few kilometers, it was possible to switch to gas. But the HBO really didn’t want to switch, the car almost stalled.

Well, when the frosts came, you yourself understand what happened: I switched to gasoline.