VAZ 2107 is the latest model of the Zhiguli, available with rear-wheel drive. In essence, this is the “Five”, which has increased engine power, improved design and exterior. The car was produced with various engine sizes, ranging from 1.45 to 1.7 liters. Until 2006, the “Seven” had a carburetor engine, but during the transition to Euro-2, the designers developed and installed a forced fuel injection system, i.e. injectors.

With the introduction of injection engines, car enthusiasts felt positive changes in the operation of these cars.

All mechanisms are subject to wear and tear and fail over time. The forced injection system is no exception; during operation it acquires a number of malfunctions.

In VAZ 2107 cars, the engine sometimes stops working while idling. It happens that the engine stalls, but after starting it works properly. After some time this happens again. This means that the breakdown exists and will still have to be fixed. The reason is most likely in the throttle assembly, or more precisely in the idle air controller (IAC).

Purpose and design of the idle speed controller.

The idle speed regulator is designed to regulate the amount of atmospheric air entering through the bypass channel (bypass) into the suction manifold when the engine is idling. The main channel is closed by the throttle valve.

The regulator is a DC electric motor. It has two windings on the stator and a rotor with permanent magnets. The rotor is connected to the rod by a lead screw. At the end of the rod there is a valve that closes the hole in the bypass. Power is supplied either to the first or to the second stator winding. At the same time, the rotor rotates in one direction and then in the other, extending or retracting the rod and the valve with it using a screw.

Location of the sensor on the VAZ 2107

In injection engines, the sensor is located on the intake manifold in the throttle block.

In carburetor engines, the control solenoid valve is located in the unit block.

Operating principle of IAC.

SPVT (Forced fuel injection system) has its own “brain”, which receives all the information from the sensors, processes it and issues commands to the actuators for the optimal functioning of the internal combustion engine (ICE). This “brain” is called a controller or ECU (Electronic Control Unit). IAC refers to the actuators controlled by the controller.

At the moment of start-up, the regulator opens a hole in the bypass. Air enters the suction manifold through it. The engine starts running. As the engine warms up, the valve closes, reducing the air supply. The speed is stabilized to a minimum.

When the throttle valve is opened, the main flow of air is supplied to the engine through the main channel. In this case, the regulator closes the hole in the bypass. To smoothly control the idle air control, the ECU receives additional information from sensors: throttle position, air flow, crankshaft position and tachogenerator.

When additional loads on the engine arise (turning on a radiator fan, heater, etc.), the regulator opens a hole in the bypass. This makes it possible to maintain power and prevent engine failures.

The cause of a stalled engine is the spark plugs

In 50% of cases, the problem is due to the fact that the spark plugs simply do not produce a spark. This failure occurs as a result of 3 reasons:

- contacts become clogged;

- plaque forms along the entire contour of the candle;

- malfunction when supplying voltage to the spark plug.

However, the most popular is still black carbon deposits on the spark plugs, which prevents the spark from appearing or causes it to work periodically.

If you see dirt on the surface of the contacts, this indicates the need to replace a low-quality type of fuel or check the serviceability of the oil supply systems. It is the oil supply adjustment sensors that can splash the spark plugs with it if there is a problem. Also, oil that appears on a set of spark plugs may indicate serious damage to components in the engine cylinders. Be sure to check the engine at a car service center. Otherwise, further operation may lead to expensive replacement of jet rods and even the entire set of pistons.

If you systematically use low-quality gasoline samples, you may find a red-brown coating on the contour of the spark plug. In this case, cleaning will not help - it is better to immediately replace the entire set after a new refill. If you find that the car periodically turns off at full speed, but starts easily even with clean spark plugs, then the problem lies in the electrical wiring.

spark plug

Unstable operation of the injection engine.

Engine instability can be due to a failure in any system. Either:

- ignition;

- fuel supply;

- electronic control unit

- wear of moving parts and engine components.

To understand this, it is necessary to check the performance of systems using the elimination method. Let's look at an ECU as an example.

The engine is warmed up, but vibration and increased speed are felt during operation. Perhaps this is an accumulation of errors in the controller memory. To reset them, you need to turn off the engine and turn off the “mass” for 15 minutes. After that, start the engine. If there are no changes in engine operation, then the reason is in the ECU sensors.

When any of the sensors does not work, the ECU has to rely only on the data from the working devices. This is not enough for normal management of SPVT. The engine does not work correctly:

- Unstable crankshaft speed.

- Increased gasoline consumption, highly enriched mixture.

- There is black smoke on the exhaust.

- Soot or soot on spark plug electrodes.

This occurs due to a lack of data entering the control unit, such as:

- air flow;

- amount of oxygen in exhaust gases;

- throttle position;

- crankshaft position;

- temperatures;

- speed;

- or IAC failure.

To check the functionality of the sensors, you need to disconnect the wire connectors one by one and observe how the internal combustion engine operates. If there are no changes, then the device that is turned off has failed.

Most often, malfunctions occur in the idle air regulator.

The best

look at the fuel pressure in the rail, if there is a return line, see if gasoline is flowing from it, if it doesn’t, then there is no fuel pressure in the rail, look at the main relay, the fuel pump relay, the fuses, right the caps with it from them and look, maybe the main thing clicks for you and immediately hangs up or doesn't turn on at all,

see if the immobilizer is sewn into the firmware, flash the firmware from the ECU to the table and look, or replace it with another ECU, look for errors with a scanner,

look at the readings of the mass air flow sensor and the IAC (the latter can be checked by slightly opening the throttle valve)

Why does a VAZ injector car immediately start and stall?

Situations when a VAZ injector starts up immediately and then immediately stalls appear quite often. And all the rest due to the accounting fuel injection system (forced type). To correct this situation, car owners often use a heating plug, but this is not a solution to the problem, but only a temporary measure. If a VAZ 2107 starts and stalls immediately

after turning the key in the ignition, this almost always indicates a problem in fuel delivery (the fuel pump is clogged or not working correctly), or the quality of the fuel used is not sufficiently developed, and the injectors are simply clogged. And the car starts only with the remaining fuel in the cylinders.

Signs of IAC malfunction.

There are several of them. They are all noticeable.

- Unstable engine speed at idle.

- Floating engine speed.

- When the engine is loaded, power drops sharply.

- Until you press the gas pedal, the internal combustion engine will not start.

- When you release the gas pedal, the internal combustion engine stalls.

- High idle speed.

The above symptoms may also occur in case of malfunctions of other SPVT equipment. To be convincing, it is necessary to confirm the inoperability of the IAC by conducting diagnostics at a service station, or independently.

Preparing the machine

The preparation operations are not complicated and standard for any repair, but your personal safety, the time spent on maintenance and repair, as well as the quality of the work largely depend on their implementation. We prepare our VAZ2107 car for replacement as follows:

- We do car washing

- If possible, it is advisable to wash the outside of the car before work (you will get less dirty while working), including the bottom if necessary

- If the work (as in our case) is to be done in the engine department, then it should be washed there too

- The operation associated with washing the engine compartment is best performed in a non-automated car wash.

- Here, the engine compartment of your car will be washed by hand, having previously treated the outside of the body and the engine compartment with specific cleaning compounds.

- They will also remove dirt stuck in the wheel arches, as well as from the bottom of the body, using a directed jet of water under pressure, with drying completed.

Warning: When washing the engine compartment, you should protect the pads, sensors and other actuators of the fuel injection system from getting water. You should also avoid getting water on the starter and alternator. The sensors and contacts are wrapped with insulating tape or tape, the generator and starter are covered with plastic bags and the bags are secured so that they do not fly off. In any case, washing the engine compartment involves disconnecting the terminals from the battery. After washing, the above components and parts must be thoroughly dried; to do this, blow them with a stream of compressed air.

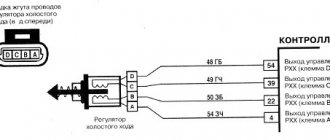

Checking the IAC electrical circuit.

What can you do yourself when checking the electrical circuit of the idle speed control of a VAZ 2107? Measuring the voltage at the connection block to the control unit and measuring the resistance of the regulator motor windings. To measure you need to have a tester. The diagnostic procedure is given below:

- Disconnect the block with the wiring harness from the regulator. It is located on the throttle assembly.

- Turn on the ignition.

- Set the tester to voltage measurement mode in the range from 0 to 20 volts.

- Connect the probe from the tester with a minus sign to the ground of the car.

- Connect the probe from the tester with the “plus” sign in turn to terminals “A” and “D” on the harness block. The voltage between ground and terminals should be 12 volts. If there is no voltage, the controller may not be corrected.

- Next, move the tester to the resistance measurement position. Measure the resistance of the first winding between terminals “A” and “B”. Measure the resistance of the second winding between terminals “C” and “D”. There should be 52 ohms on both windings. In other variations of measurements between the terminals, the device should indicate an open circuit. If the tester shows the opposite, then the electric motor is faulty.

IAC malfunction.

The electric motor is not the only component in the regulator that can break; there are a number of other breakdowns:

- oxidation of connector contacts, broken wires;

- contamination of the rod, preventing movement;

- the o-ring is torn;

- wear of the screw thread on the rod.

Of the above breakdowns, the most common is contamination of the rod. If during operation the throttle assembly has not been maintained for a long time, carbon deposits on the regulator rod are possible. To remove dirt, you need to remove the IAC and rinse with acetone.

The stem needs to be cleaned periodically. Otherwise, the load increases, which can damage the ECU. Then you will have to contact service station specialists.

Problems in the mass air flow sensor - mass air flow sensor.

The mass air flow sensor is located in the air duct between the throttle valve and the air purification filter. It shows the volume of air entering from the atmosphere into the suction manifold. Based on these data, the control unit calculates the amount of fuel required for the current operating mode of the internal combustion engine.

If the sensor is faulty, the “Check Engine” light on the panel lights up. In parallel with this, a number of signs of failure are possible:

- Fuel consumption has increased.

- Idle speed is increased.

- The dynamics of the car are disrupted due to a decrease in power.

- It is impossible to start the internal combustion engine, even when “hot”.

- The speed changes at any throttle position, even under engine load.

Such sensors are not repaired, but replaced. Therefore, you need to make sure that this is the reason. Often the cause may be contamination of the platinum thread inside the device; it can be cleaned. Or the cause of air leakage through a damaged air duct.

Air leaks through cracks in hoses and seals.

There are many places where excess air can enter the suction manifold, bypassing the mass air flow sensor. The fuel mixture becomes leaner, the speed decreases, and the power drops. The ECU tries to correct these errors. A failure occurs in the system, the speed and “thrust” do not correspond to the specified parameters. The "Check Engine" warning light on the dashboard does not light up. The conclusion from this is that the sensors are working, but the internal combustion engine is sucking in air somewhere.

There are several places for air leaks that you should pay attention to, these are:

- the manifold with its gaskets, all kinds of joints, gaskets under the equipment attached to the manifold;

- vacuum brake booster and its hoses:

- throttle body;

- vacuum pipes.

After eliminating these shortcomings, the power unit will operate normally.

Other reasons.

A car is a complex engineering structure. During operation, its units, components, systems, and blocks are subject to wear. And it is impossible to describe all combinations of breakdowns.

Here are some reasons for the internal combustion engine not working properly:

- The ignition system has many of its own “sores”.

- Nozzles requiring professional care.

- Low quality gasoline.

- Presence of water in the fuel tank.

- Fuel and air filters are clogged.

- Other.

In each case it is necessary to understand, identify cause and effect. If you can’t do it yourself, you should contact a service station specialist.

In this article, “Why do idle speeds fluctuate on a VAZ 2107 injection engine,” the emphasis is on the breakdown of the XX Regulator. If it is broken, it can hardly be repaired. It's better to change it. It’s not difficult to do it yourself, having a new IAC and a minimum of tools.

The procedure for returning the car to “life”

Let's say you find yourself in circumstances where the injection engine starts poorly or refuses to do so at all. There is no need to hesitate in such a situation - it is advisable to immediately begin resuscitation procedures. If you don’t have time to figure out the exact reason why the car doesn’t start well, then you should quickly carry out the following algorithm of actions:

- First of all, we check the availability of gasoline and battery charge. Is there something missing? Fill it up and light it up. Let's try to start. If there is no result, proceed to the next step;

- Next, we quickly analyze under what circumstances the car malfunctions. If it takes a long time or is difficult to start when hot, we first check the spark plugs for overheating (light carbon deposits) and the functioning of the fuel system. Otherwise, when the car malfunctions both cold and hot, a more comprehensive approach is required. As a rule, the following procedures are sufficient: checking spark plugs, wiring the ignition system, assessing the operation of the injector and fuel system;

- Note that most motorists manage to solve the problem, so to speak, with little loss, that is, by implementing the actions described above. If you are not one of the lucky ones and your car still takes a long time, starts poorly or refuses to work at all, you will have to act globally. Here it is better to take the car to a service station or a convenient garage and check the compression, timing adjustment, clean the injector, assess the condition of the fuel system and ignition devices. If there are any malfunctions, they must, of course, be eliminated.

Replacing the idle air control.

In addition to the tool, you need to prepare some consumables. First of all, the regulator itself. Throttle assembly gasket and rubber ring for idle air control. 300 milliliters of coolant (you will have to add it) and a rag. To change the IAC, you must:

- Raise the hood, turn off the ground.

- Disconnect the accelerator drive from the throttle.

- Disconnect all wires leading to the regulator and throttle.

- Loosen the clamps and remove the coolant inlet and outlet hoses.

- Loosen the clamp on the breather hose and disconnect the hose.

- Disconnect the air supply pipe from the throttle body.

- Remove the fuel vapor exhaust hose from the throttle body.

- Unscrew the nuts securing the throttle assembly to the manifold.

- Remove the throttle assembly from the studs.

- Unscrew the screws securing the regulator.

- Remove the regulator.

Thus, the IAC is removed. To install a new regulator, all steps are performed in reverse order. It is better to take new gaskets and sealing rings.

Do not start the engine immediately after replacing the regulator. It is necessary to turn on the ignition, wait 20-30 seconds, turn off the ignition. This time will provide an opportunity to calibrate the IAC in the ECU. After this, you can start the engine.

As a rule, when starting, the speed of a cold engine will be increased, around 1500 rpm, and when warmed up, it will drop to 800 rpm.

The video clearly shows how you can eliminate one of the reasons for floating idle speed on an injection VAZ 2107:

Repair

Of course, it is not in all cases advisable to repair the IAC device. More often, it requires a complete replacement with a new one. But, as they say: trying is not torture. First of all, the device must be completely dismantled. Next, disassemble it and wash it completely using carburetor cleaning fluid. The next step is to clean the contacts, both on the sensor itself and those to which it connects. Also, be sure to clean the needle and the place where it is located. After the work done, the IAC will most likely work properly.

To be more sure, you can carry out an additional inspection of the regulator. There may be a solder break on it. If this malfunction is detected, correct it by soldering the wire back. Now the device can be assembled and installed back. If, after checking, the sensor does not start working, then only replacement will help.

Carrying out diagnostics

The simplest method is to measure the voltage at the block to which the regulator is connected. These are terminals D and A. When the ignition is turned on, a voltage of 12 V should be present on them. If the voltage is less than this value, it is worth looking at the battery and generator. It is quite possible that the battery is undercharged. In the same case, if there is no voltage at all, it is necessary to check the entire power circuit of the device and diagnose the ECU.

Set the multimeter to resistance measurement mode. Between pairs of terminals A and B, C and D, there should be a resistance of approximately 53 ohms. Remove the IAC and connect (with the ignition off) to the block. Then turn on the ignition and look at the behavior of the needle - it should extend completely when voltage is applied. If this does not happen, we can judge that the IAC is broken.

Sometimes simply cleaning the regulator helps. To do this, you can use sprays, of which there are sufficient quantities in stores. But in some cases, only replacing the device will help. Of course, this is not a DAAZ carburetor, the cost of the IAC will be many times lower, and there will be no problems with replacement. If, even after the replacement, the engine does not idle, it is necessary to fully diagnose the injector.

The VAZ 2107 idle speed control is removed to replace it with a new one if the old one fails as a result of any mechanical damage. Before removing the regulator, it is recommended to test it with a performance tester; the test comes down to simply measuring the voltage at the terminals of the block, and after removing it, measuring the resistance at the same terminals. To check, you will need a multimeter with voltmeter and ohmmeter mode, as well as a standard set of tools.

The procedure for checking and subsequently replacing the idle air regulator is as follows:

- Connect the negative terminal of the voltmeter to engine ground and turn on the ignition on the car.

- Disconnect the block from the regulator; the terminals will be marked on its body.

- Connect the positive terminal of the Vols and then to the “D” terminal. The voltage at the terminals should be 12V. For any significant deviations from the norm of more than one volt or a complete absence of voltage, the cause may be either a weak battery charge, faulty power wiring or a malfunction of the electronic control unit. After measuring, turn off the ignition.

If the voltage at the terminals is normal, but the regulator does not perform its direct functions, then it must be changed. Removing and replacing the regulator looks like this:

- It is necessary to remove the throttle body, for more information about this, see Replacing the throttle body of a VAZ 2107.

- After that, use a Phillips screwdriver to unscrew the two screws securing the regulator to the damper body and remove it.

- A rubber sealing washer will be installed between the regulator and the housing. Replace it if cracks or other damage is found.

After the idle speed regulator of the VAZ 2107 is removed from the car, it must also be tested with a tester in ohmmeter mode. For this:

- Switch the tester to ohmmeter mode and measure the resistance between terminals A-B and C-D, it should be about 52-53 Ohms. Next, measure the resistance between terminals A-C and B-D, the resistance should tend to infinity or be large enough. If there are any deviations from the norm, replace the regulator.

This completes the repair work. Install the new regulator in the reverse order of removal. Before installing the regulator, measure the length of the valve needle protrusion; it should not protrude more than 23mm. To measure, use a caliper or any suitable ruler. Before measuring, it is necessary to extend the needle to the maximum distance; to do this, apply voltage from the battery to the valve, connecting the positive pole to terminal “D” and the negative pole to “C”. The regulator solenoid valve works slowly, so touch the wires repeatedly until the needle reaches its maximum length. Measure with a ruler and if the needle protrudes more than 23mm, replace the valve.

A malfunction of the idle speed regulator (aka sensor), or its unstable operation, manifests itself as follows: the car engine periodically stalls at idle, when starting the engine, or in a traffic jam, or at a traffic light. Replacing the idle speed sensor on a VAZ 2107 is not a complicated procedure, requiring a minimum of tools and a minimum of knowledge of a repairman, so any owner of a VAZ 2107 can easily replace the regulator with their own hands.

We identify the cause and fix the problem ourselves

The car has stopped and will not start. There is a spark, gasoline flows, contactless ignition. The starter turns, but doesn't even engage. I replaced the starter, started sneezing into the carburetor and pouring smoke out of it, but it still doesn’t work. Please tell me what is the reason and how to fix it. (Vladimiro)

Hello, Vladimiro. We understand your question, we will try to answer in more detail.

VAZ 2107 car

Content

Open

[Hide]

Why won't the car start?

As you understand, there may be many reasons why your VAZ 2107 does not start. Starting from the battery and ending with the perforated head gasket. But we will look at them all in turn:

- Battery failure. We know this is nonsense, and since you can repair or replace the boot yourself, you probably checked the battery first. However, we recommend that you double check the charge.

- The carburetor is clogged. It is possible that the device’s injector is simply clogged, as this is often the reason why your car “sneezes.” It is necessary to disassemble the device and thoroughly blow it with a compressor. If this is the problem, it will disappear after cleaning.

- The fuel filter is clogged. Look at the filter: does it contain gasoline? Otherwise, most likely, it is simply clogged and will not be able to perform its functions. Try simultaneously squeezing the pipes leading to the filter and shaking the fuel pump. If the hoses are clogged, a small amount of gasoline will flow into the filter when compressed.

- The reason is the fuel pump. Sometimes the reason for this behavior of the car is the fuel pump. When regularly refueling a car with low-quality fuel, there is a high probability of condensation appearing in the fuel pump. In this case, starting the engine will not be possible. The fuel pump must be removed and cleaned or replaced with a gasket.

- The worst result is a perforated cylinder head gasket. If you see that white smoke is coming from the exhaust pipe, while the car is very strong, power is lost, and antifreeze may boil in the expansion tank, then know that this is most likely the reason. This can be checked using candles. If antifreeze gets into the oil, the spark plugs will always be flooded.

First, let's look at the most common problems.

- Without gasoline (diesel). As paradoxical as it may seem, drivers often forget to monitor the fuel level in the tank.

- On diesel engines (especially in winter), frozen fuel can cause the car to start and stop almost immediately (but, as a rule, diesel VAZs are very rare).

- The quality of gasoline at gas stations is often alarming, so when refueling a car with low-quality fuel, you may encounter the problem of a stalled engine. If there is not enough bad gasoline, you can dilute it with good gasoline. But if the tank is full, it is best to drain the surrogate so as not to cause harm.

- Worn wires and old (faulty) spark plugs are also very common causes.

- Engine compression, or rather the lack thereof, can cause a situation where the engine barely has time to “recover.” But this is already a very serious breakdown, the appearance of which is accompanied by a host of other symptoms, which are simply impossible not to notice while operating the car.

An interesting article about biofuel from ordinary sawdust, more details.

Carburetor adjustment

Carburetor adjustment consists of several stages:

- Adjust the float position as described above.

- Check and tighten the “quality” and “quantity” screws. Screw them in until they stop and unscrew 2-3 turns for a “quality” screw and 3-4 turns for a “quantitative” screw.”

- Connect a tachometer or auto tester to the “K” terminal of the ignition coil, and the second sensor to the body.

- Start and warm up the engine to 90°C

- Use a “quality” screw to set the maximum speed to the minimum. Gasoline consumption is increased by turning the screw counterclockwise.

- Use the "amount" screw to increase the speed by about 80-90 rpm.

- Using a high-quality screw, we determine whether these speeds are maximum; if not, we repeat the procedure.

- If the position of the adjusting screw does not affect the engine speed, tighten the quality control screw until the speed drops to 800-900 rpm.

This carburetor adjustment may not be entirely accurate, but does not require special equipment.