I’ll share a little experience, in case it’s useful to someone)

I recently encountered this problem - I mean, I’m driving, I’m driving, I put it in neutral at a traffic light (or I’m squeezing the clutch), and my revs start to drop, the car practically stalls. This bullshit bothered me for quite a long time. That is, then no, then no again) In short, periodically my brain began to float. And then the singles disappeared completely. That's all! At least shit yourself. Whatever I tried, I couldn’t find the reason. Well, I think that's it, turn off the lights. We've arrived.

It's all up to chance, so to speak) I don't know why the hell I removed the terminal from the idle speed sensor, but when I put it back on, I noticed an interesting concept)) If I touch the contact on the sensor with the tip of the terminal, the idle ones appear, and if I put the terminal on, then disappear.

SHAITAN. Well, that's how it is! How the fuck?! In short, I pressed the contact, and everything worked again) Now, when some kind of crap starts with the electrics, I first move all the contacts))) What an adventure))

And also, I don’t know, whether it’s on the website or not, here’s a way to check the sensor: minus from the battery to the sensor body, plus to the sensor contact. If you hear a click, it works) If there is no click, replace it. And I think I even heard that it is better to buy a sensor with a red rubber band, and not with a black one. Better quality. But I don’t know for sure, I haven’t tried) So far the old one is shy)

The VAZ 2107 is not the best model among cars in its class when compared with foreign equivalents. However, thanks to its low price and accessible service, the car has been popular throughout the post-Soviet territory for many years. The car was produced from 1982 until 2014. That is, the oldest model is more than 30 years old. During such a period of operation, the owner will be able to encounter all types of faults and investigate most of the causes of problems.

After several years of operation, the VAZ 2107, as well as the almost identical model 2105, begins to show a new character with changes not for the better. Malfunctions associated with the power unit and its body kit are of a different nature, but are symptomatic:

- the engine stalls periodically;

- does not maintain stable speed;

- unstable operation at idle;

- hard to start;

- insufficient power;

- increased fuel consumption.

All malfunctions appear for two reasons: violation of adjustments or wear of parts.

Unstable operation of the injection engine

Usually expressed in a spontaneous change in engine speed. Observed while driving and at idle. The most common reason for low speed in VAZ2107/2105 injection units is the failure of the mass air flow sensor (mass air flow sensor).

This device controls the amount of air entering the engine. Based on this data, the ECU regulates the supply of a combustible mixture with the optimal fuel-to-air ratio under different engine operating modes. Accordingly, in the absence of this balance, engine speed begins to depend on the amount of incoming oxygen. That is, the wind blew - the speed increased, the speed died down - it decreased.

It is quite simple to make sure that it is the mass air flow sensor that is faulty. Disconnect the device connector and the ECU will switch to emergency mode. In this mode, fuel supply is controlled by the throttle position. If the car begins to behave more adequately, then the MVR is faulty. You can drive like this, but the power will drop slightly and fuel consumption will increase.

A failed mass air flow sensor cannot be repaired, except for contamination, so you can try to clean it.

Cleaning algorithm for DMVR VAZ2107/2105:

- Remove the sensor along with the protective casing.

- Unscrew the two screws and pull the sensor out of the base without touching the surfaces of the active element (straight, bent wire).

- Wash the casing with any dishwashing liquid.

- Using a bottle of cleaner for DMVR or for carburetor, based on alcohols (without acetone), carefully clean the surfaces.

- Pour generously 3-4 times, the liquid should drain.

- Dry the device.

- Reassemble the block in reverse order.

If the problem persists, you will have to buy a new device.

How to check the strainer

This is done as follows. Use manual fuel pumping and fill the float chamber with fuel, after which you will be able to see the shut-off valve close. Then move the top filter cover and remove the valve. It must be thoroughly washed in solvent, then dried using compressed air.

When the engine behaves incorrectly during loads, there are dips or loss of power, or the car “reacts poorly to the pedal,” most likely you have a problem with the fuel supply. In addition, often the cause is a faulty strainer.

Important! It is strictly forbidden to wipe the bottom of the float chamber using a fluffy or any other rag, since after such cleaning, invisible fibers may remain on the bottom of the chamber, which will clog your jets during operation.

The float chamber is cleaned using a rubber bulb and then dried with compressed air.

Unstable operation of the carburetor engine

The nature of the unstable speed of the VAZ2107/2105 engine with carburetors is the same as that of an injection engine, in the uncontrolled supply of air or fuel into the combustion chamber.

But in this case, the carburetor is responsible for preparing the combustible mixture. This is a completely mechanical device that is responsible for the optimal ratio of fuel to oxygen for different operating modes of the power unit.

Despite the fact that there are filters at the fuel and air inlets, they may not work efficiently, usually due to a long service life exceeding that specified in the maintenance standards. As a result, the carburetor jets become clogged with small particles.

Drivers with great experience do not stand on ceremony, they throw the VAZ2107/2105 carburetor into a bucket of gasoline for a day, then blow it out from all sides with compressed air and the carburetor seems to work normally. This is a normal solution, but flammable. Among the causes of engine malfunctions that are caused by carburetor failure are:

- displacement of the position of the adjusting screws due to shock or vibration;

- increase in the diameter of the jet holes due to wear;

- wear of the damper axis, limiting its travel;

- clogging of jets;

- failure of the float seal.

To determine the malfunction of the VAZ2107/2105 carburetor, and it will most likely be complex, start by checking the tightness of the float. To do this, remove it from the top carburetor cover (it needs to be removed). If there is gasoline in the float, throw away the float; if there is air, check in a bowl of water for bubbles. Let's say it passed the exam, then it is necessary to check the gap.

Lift the carburetor cover vertically. The gap between the float chamber and the carburetor wall should be 6.5 mm.

Install the carburetor cap and run the engine for 30 seconds. Remove the cover. The gasoline level should exactly coincide with the middle of the conical surface of the carburetor body. If this does not work, you should slightly bend the corner of the float rod.

Over time, air and fuel jets either become clogged or wear out. In the first case, they need to be cleaned and blown out. In the second case, you should check the throughput of the jets using a tank of water installed above the measured jet by 1 meter. They are connected by a tube. A volumetric flask is installed below. Measurements take place in units of cm3/min. Depending on the marking of the nozzle, the volume of liquid collected per minute in a volumetric flask should correspond.

It is much easier after 7-10 years of carburetor operation to buy a set of jets and replace them.

Those who use gas installations should know that a carburetor is not used when driving on gas. Over time, oxide forms inside dry jets, which clogs the fuel supply holes. A gasoline car may not start. It is recommended to use gasoline periodically.

Problems with Solex carburetors

In addition to all of the above, engine speed drops if the fuel level in the carburetor (float chamber) is incorrectly adjusted. As a result, there is either not enough gasoline in the fuel mixture or too much of it. When adjusting the VAZ 2107 carburetor, it does not need to be disconnected from the engine.

Follow these steps:

- remove the air filter housing by unscrewing all fasteners;

- remove the carburetor cover;

- check the position of the floats. To do this, separate and bring them together to achieve the correct location.

It is necessary to achieve such a position of the floats so that they move freely without clinging to the walls of the chamber in which they are located. It will not be superfluous to measure the distance from the protrusions on the floats to the paper gasket. The distance should be within 0.75–1.25 mm. Use a feeler gauge to measure.

What to do if it is far from normal? In this case, you need to adjust the height of each of the floats.

As we have seen, there are many reasons why the engine stalls. To start the engine correctly, you need to check and eliminate all the above faults. Afterwards, if the problem is not resolved, you will have to contact specialists.

Didn't find the information you are looking for? on our

forum

If you find an error, please select a piece of text and press Ctrl+Enter.

Carburetor adjustment

Adjusting the carburetor involves several steps:

- Adjust the position of the float as described above.

- Check and set the “quality” and “quantity” screws to the initial state. Screw them all the way and unscrew them 2-3 turns for the “quality” screw and 3-4 for the “quantity” screw.

- Connect a tachometer or auto tester to the “K” terminal of the ignition coil, and the second probe to the housing.

- Start and warm up the engine to a temperature of 90°C

- Use the “quality” screw to set the maximum idle speed. The gasoline supply increases when the screw is rotated counterclockwise.

- Use the “quantity” screw to set the speed higher, approximately 80-90 rpm.

- Using the quality screw, we determine whether these speeds are maximum; if not, then we repeat the procedure.

- If the position of the quantity screw does not affect engine speed, tighten the quality screw so that the speed drops by 800-900 rpm.

This carburetor adjustment may not be entirely accurate, but does not require special equipment.

How to set the ideal settings yourself

To work, you will need the usual set of tools that are found in almost every garage. To eliminate fuel overflows, you need to correctly set the float in the chamber. This operation can be done using a special template. Experts recommend not using this template, since the number and thickness of gaskets in carburetors do not always match. Fans of various improvements often replace factory gaskets with better ones. It happens that the factory settings of the template do not suit everyone. Although Solex carburetors are the same, the fuel pump can deliver gasoline differently. A lot also depends on whether the return line is plugged, so specialists use a different method.

- The mixture quality adjusting screw is tightened by hand until the end;

- Next, unscrew it back five turns;

- Turn on the engine, remove the choke and use the mixture screw to bring the engine speed to 750 rpm;

- By turning the quality screw, we bring the engine speed to the maximum;

- Using the quantity screw, reduce the speed to 800 rpm;

- We tighten the quality screw a little until instability appears;

- We unscrew the same screw back one turn;

- We turn the quantity screw until the idle speed reaches 800 rpm (in winter they can be raised to 900).

It is worth remembering that adjusting the carburetor not only eliminates floating engine speeds. A well-tuned carburetor will consume a minimum amount of fuel at stable idle speeds.

Various problems may arise with this adjustment.

It happens that when unscrewing the quantity and quality screws, the engine practically does not react. This happens when a large stream of gasoline flows from the idle hole and the screw is unable to influence it. It is possible that the valve is poorly closed or the jet is deformed. It happens that when replacing jets, they mistakenly choose a larger diameter than required. The plug may be loose. It is worth conducting a thorough inspection of all carburetor elements, this will help avoid such problems. When cleaning, the jets must not be cleaned using abrasives.

If the solenoid valve malfunctions, unscrew it and check for deformation. The mounting hole may also be deformed. If the thread of the mounting hole is torn off, you will have to replace the carburetor cap with a new one. If no defects are found, simply lubricate the O-ring before screwing in the nozzle.

You can determine whether the carburetor needs adjustment by the engine's response to pressing the gas pedal. An engine receiving a balanced fuel mixture responds to pedal pressure without hesitation, in a split second. The speed should be smooth at idle. There should be no jerks or failures. If the engine runs smoothly at idle, but when you press the accelerator it begins to act up, you need to tighten the quality screw, enriching the mixture.

The quality screw directly affects CO emissions into the atmosphere. Drivers are familiar with the situation when, before going for a scheduled inspection, they need to tighten the quality screw. The emissions become smaller and the car easily passes inspection, after which the position of the quality screw returns to its place. Some people are perplexed why their neighbor’s car consumes less fuel, although both have identical models. It's all about the settings and adjustments of the quality screw.

If the car responds to pressing the gas pedal late, the problem is in the accelerator pump. You can replace it, or change only the spout. When it comes to the spout, the fuel mixture is supplied over-enriched. The problem is solved by replacing the spout. If you decide to install a spout of a different diameter, do not forget to select the appropriate jet for it.

Setting up a carburetor is a rather complicated procedure. Don't expect everything to work out the first time. It may take a couple of weeks to complete the full cycle of eliminating all deficiencies. It is better to listen to the engine, quickly respond to the slightest interruptions in its operation and carry out regular carburetor flushing. The main thing when washing is not to use nameless Chinese-made cleaning products. And if you refuel with high-quality fuel, the carburetor will thank you for years of trouble-free operation.

If the car stalls

An engine that suddenly stops not only creates an inconvenient driving experience, but also poses a safety hazard to the driver and passengers. There are several reasons.

Stalls at idle:

Stalls while driving:

- interruption of fuel or air supply due to a dirty filter;

- fuel pump malfunction;

- clogged carburetor jets;

- engine overheating.

When diagnosing a car whose engine stalls in the most unexpected places, it is better to start by checking the idle speed sensor.

It's easy to check its functionality. Dismantle the device without removing the contacts, or connect them after dismantling. Hold the device in your hands, place your finger on the cone needle and ask a friend to turn on the ignition. If you feel shocks, then install the device back. The idle speed sensor is OK.

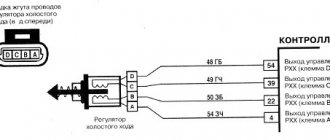

Checking the IAC electrical circuit.

What can you do yourself when checking the electrical circuit of the idle speed control of a VAZ 2107? Measuring the voltage at the connection block to the control unit and measuring the resistance of the regulator motor windings. To measure you need to have a tester. The diagnostic procedure is given below:

- Disconnect the block with the wiring harness from the regulator. It is located on the throttle assembly.

- Turn on the ignition.

- Set the tester to voltage measurement mode in the range from 0 to 20 volts.

- Connect the probe from the tester with a minus sign to the ground of the car.

- Connect the probe from the tester with the “plus” sign in turn to terminals “A” and “D” on the harness block. The voltage between ground and terminals should be 12 volts. If there is no voltage, the controller may not be corrected.

- Next, move the tester to the resistance measurement position. Measure the resistance of the first winding between terminals “A” and “B”. Measure the resistance of the second winding between terminals “C” and “D”. There should be 52 ohms on both windings. In other variations of measurements between the terminals, the device should indicate an open circuit. If the tester shows the opposite, then the electric motor is faulty.

IAC malfunction.

The electric motor is not the only component in the regulator that can break; there are a number of other breakdowns:

- oxidation of connector contacts, broken wires;

- contamination of the rod, preventing movement;

- the o-ring is torn;

- wear of the screw thread on the rod.

Of the above breakdowns, the most common is contamination of the rod. If during operation the throttle assembly has not been maintained for a long time, carbon deposits on the regulator rod are possible. To remove dirt, you need to remove the IAC and rinse with acetone.

The stem needs to be cleaned periodically. Otherwise, the load increases, which can damage the ECU. Then you will have to contact service station specialists.

Problems in the mass air flow sensor - mass air flow sensor.

The mass air flow sensor is located in the air duct between the throttle valve and the air purification filter. It shows the volume of air entering from the atmosphere into the suction manifold. Based on these data, the control unit calculates the amount of fuel required for the current operating mode of the internal combustion engine.

If the sensor is faulty, the “Check Engine” light on the panel lights up. In parallel with this, a number of signs of failure are possible:

- Fuel consumption has increased.

- Idle speed is increased.

- The dynamics of the car are disrupted due to a decrease in power.

- It is impossible to start the internal combustion engine, even when “hot”.

- The speed changes at any throttle position, even under engine load.

Such sensors are not repaired, but replaced. Therefore, you need to make sure that this is the reason. Often the cause may be contamination of the platinum thread inside the device; it can be cleaned. Or the cause of air leakage through a damaged air duct.

Air leaks through cracks in hoses and seals.

There are many places where excess air can enter the suction manifold, bypassing the mass air flow sensor. The fuel mixture becomes leaner, the speed decreases, and the power drops. The ECU tries to correct these errors. A failure occurs in the system, the speed and “thrust” do not correspond to the specified parameters. The "Check Engine" warning light on the dashboard does not light up. The conclusion from this is that the sensors are working, but the internal combustion engine is sucking in air somewhere.

There are several places for air leaks that you should pay attention to, these are:

- the manifold with its gaskets, all kinds of joints, gaskets under the equipment attached to the manifold;

- vacuum brake booster and its hoses:

- throttle body;

- vacuum pipes.

After eliminating these shortcomings, the power unit will operate normally.

Other reasons.

A car is a complex engineering structure. During operation, its units, components, systems, and blocks are subject to wear. And it is impossible to describe all combinations of breakdowns.

Here are some reasons for the internal combustion engine not working properly:

- The ignition system has many of its own “sores”.

- Nozzles requiring professional care.

- Low quality gasoline.

- Presence of water in the fuel tank.

- Fuel and air filters are clogged.

- Other.

In each case it is necessary to understand, identify cause and effect. If you can’t do it yourself, you should contact a service station specialist.

In this article, “Why do idle speeds fluctuate on a VAZ 2107 injection engine,” the emphasis is on the breakdown of the XX Regulator. If it is broken, it can hardly be repaired. It's better to change it. It’s not difficult to do it yourself, having a new IAC and a minimum of tools.

Not enough air

Often the car starts up well and runs on choke, but as soon as the choke is turned off, the engine stalls. This indicates only one thing - lack of air. Most likely the air jets are clogged. They need to be unscrewed and cleaned. Then check that the car should not stall without suction.

There are an incredible number of reasons for poor performance of car components with similar symptoms, but only a specialist with a set of professional diagnostic tools can figure them out. But if you feel confident in yourself, go for it, VAZ service centers are already waiting for you.

What to do if the idle speed of a VAZ 2107 jumps, is there any panacea for this? The fuel system causes a lot of trouble for owners, but one thing needs to be taken into account - it is not always to blame. For example, in carburetor engines with a classic ignition system, there is a high probability of contact group failure if there is instability in the idle speed. But with injection engines everything is somewhat simpler. And now about everything in more detail.

Checking engine systems

The car engine runs on gasoline; the composition and quality of the fuel does not always meet the standard requirements. A clogged carburetor can lead to unstable engine operation. Depending on how clogged the carburetor is, this can manifest itself in different ways, even to the point that the engine may stall.

Reasons for unstable idling of the VAZ 2107 car:

- the air filter is clogged;

- the strainer, jets and their channels are clogged;

- incorrect fuel level in the float chamber;

- difficulties or limitation of valve travel in the EPH;

- air suction through tubes, membranes or damaged gaskets;

- incorrect gap between contacts or their burning;

- bad candles;

- incorrectly adjusted ignition.

Before you start adjusting the idle speed, you need to eliminate the problems listed above, if any, otherwise you will not be able to achieve the result.

Why is the engine speed unstable?

When it comes to the carburetor, there are several reasons:

- The carburetor is clogged, the movement of air and gasoline becomes impossible.

- The operation of the solenoid valve is disrupted - the winding is burned out or the nozzle is clogged.

- Fuel or air filters are clogged.

- Incorrect carburetor adjustments on VAZ 2107.

In most cases, the culprit is the solenoid valve. Its appearance is shown in the photo. It is necessary in the power system for the following purpose - it opens the fuel supply when the ignition is turned on and closes it when it is turned off. Consequently, the engine stops immediately after turning off the ignition.

The VAZ 2107 carburetor solenoid valve is a small device consisting of the following elements:

- Frame.

- Winding (one end connected to a metal body).

- A rod that acts as a valve that opens and closes the fuel supply at idle.

- Copper jet with holes. Please note that the jets are marked; there are several sizes.

The solenoid valve operates only when the ignition is on. If suddenly there is a break in the power circuit, you can temporarily connect the central wire of the device to the positive terminal of the battery. Just try to carry out repairs as soon as possible.

EPHH carburetors Ozone 2105, 2107

Carburetors Ozone 2105-1107010 (VAZ 2101, 21011, 2105 with 1.3 l engines), Ozone 2107-1107010 (VAZ 2107, 2104 with 1.45 and 1.6 engines) are equipped with a forced idle economizer system (EFI). It allows you to block the supply of the fuel mixture through the carburetor idle system at forced idle (FID). Let's consider the features of its device and principle of operation.

Purpose of EPHH Ozone carburetors

The forced idle economizer system of carburetors 2105, 2107 Ozone is designed to forcibly stop the supply of fuel to the engine through the carburetor idle system in forced idle mode (when braking the engine with the gear engaged and the gas pedal released). This is necessary to achieve fuel efficiency and improve combustion processes in the cylinders, as well as to prevent engine operation after the ignition is turned off (“dieseling”, glow ignition).

Location by car

An economizer with a needle is installed instead of a screw for adjusting the “amount” of the carburetor fuel mixture. In addition to it, an EPHH microswitch is installed right there on the carburetor, on a special bracket, on the throttle valve block. On the left engine splash guard there is a control unit for the EPH system, on the right there is an electro-pneumatic valve from which there are tubes for supplying vacuum to the fitting on the intake manifold and the fitting on the economizer in the carburetor.

EPCH Ozone device

EPH system of carburetor 2105, 2107 Ozone consists of several elements.

Economizer

It consists of a housing, a shut-off needle that blocks the fuel outlet from the idle system, connected to the diaphragm needle, and an adjusting screw for the “amount” of the fuel mixture.

Microswitch

It sends a signal to the control unit whether the throttle valve of the first carburetor chamber is closed or open. It is turned on or off by moving the lever on the throttle axis of the first chamber. There is a groove in the lever that provides some free play, within which moving the pedal does not cause the throttle to open. Therefore, the driver, pressing the gas pedal, first closes the contacts of the microswitch (sending a signal to the control unit to start opening the throttle), and then moves the throttle. Read more: “Microswitch EPHH carburetor Ozone.”

Electropneumatic valve

Vacuum from the engine intake manifold passes through it into the economizer housing. After turning on the ignition, the electro-pneumatic valve is energized and allows vacuum from the intake manifold to enter the economizer housing. At the IAC, the control unit de-energizes it and thus closes the supply of vacuum to the economizer, the needle of which closes the outlet of the IAC. The central fitting of the pneumatic valve is the outlet to the intake manifold, the side one is to the carburetor economizer.

Control block

Receives a signal from the ignition coil about the crankshaft rotation speed and from the microswitch about the position of the throttle valve of the first carburetor chamber (closed - open). Based on the data obtained, it de-energizes or energizes the electro-pneumatic valve, through which vacuum is supplied to the economizer housing.

Parts EPHH carburetors Ozone 2105-2107

The EPHH system economizer has a shut-off needle connected to a diaphragm. After starting the engine, a vacuum is constantly supplied under the diaphragm from the intake manifold through an electro-pneumatic valve, which keeps the needle open - the idle system works. By rotating the adjusting screw for the “amount” of the fuel mixture, you can adjust the needle stroke, thereby providing more or less fuel supply at idle.

Preparing to adjust the idle speed

If you do not plan to clean and disassemble the VAZ 2107 carburetor, then one of the tools you will need is a screwdriver. A device for measuring the speed (tachometer) is installed in the dashboard. But it’s worth getting a mixture quality indicator. With its help you can create an air-fuel mixture in ideal proportions. This article will talk about adjustment using this device.

Before starting work, you need to warm up the engine to operating temperature. Let us remember that this is a temperature of about 90 degrees. You also need to put the air purification filter in place to simulate normal engine operation. Make sure the float is adjusted correctly. The fuel level in the chamber must always be stable.

There are also many requirements for ignition and gas distribution. Be sure that all clearances must be correct, and the ignition timing must be adjusted for the gasoline used. And most importantly, open the air damper completely while making the adjustment. That's all, the preparation work is briefly summarized, now you can begin the idle adjustment procedure.

Now let's look at how the carburetor works, ensuring the distribution of the fuel-air mixture:

- Acceleration pump.

- Econostat system.

- Maintains constant fuel level.

- Idle support.

- Support for engine starting and warming up.

- Jets (air and fuel), diffuser, VTS atomizer, well and emulsion tube are located in the main metering chamber.

The carburetor is adjusted after cleaning and assembly. Before you start disassembling and cleaning, I suggest you remember the main saying of any auto mechanic - “Don’t make a fuss while it’s quiet,” meaning that you shouldn’t get into a place where everything is in order or disassemble something that has nothing to do with the breakdown.

Setting the idle speed of the VAZ 2107

Carefully inspect the carburetor, there are several screws on it - the quality of the air-fuel mixture and quantity. It is with their help that we will now try to adjust the carburetor. Of course, not every driver has such a device as a gas analyzer. However, not everyone cares about the level of CO in the exhaust. For convenience, it is advisable to have a digital or dial tachometer. You can find how to connect it correctly in the corresponding article on our website.

So, start the engine and turn the quality screw. Listen to the engine, you need to stop at the moment when the crankshaft speed is at its maximum. After this, you begin to rotate the quantity screw and achieve a frequency of 1100. And the last step is to set the frequency to 800-900 using the quality screw. Please note that if necessary, the idle speed adjustment must be repeated.

What carburetors are installed on the VAZ 2105

All carburetor installations equipped with the VAZ 2105 are focused, first of all, on minimizing fuel consumption. Of course, AvtoVAZ engineers throughout the history of the “five” experimented with the equipment of the car in order to identify the most effective mechanisms.

Over the years, various modifications of carburetors were installed on the VAZ 2105. All of them had both their advantages and disadvantages, which the drivers themselves often had to identify while driving.

Modification of DAAZ

The Dimitrovgrad Automobile Unit Plant (DAAZ) has launched the production of carburetor units under license from Weber. The main quality of DAAZ products is ease of operation and repair. The production of all parts necessary for repair and replacement was established, so if necessary, the driver could easily buy the necessary components and independently carry out the work of adjusting the carburetor.

DAAZ carburetors provided the car with increased speed characteristics, since the new nozzle system made it possible to react as quickly as possible to an increase in speed and supply the required amount of fuel to the engine.

A significant drawback of the Dimitrovgrad Automotive Unit Plant carburetor can be considered fuel consumption. In the combined cycle, the device required at least 10–14 liters of fuel per 100 kilometers.

The first VAZ 2105 cars were equipped with DAAZ carburetors

Modification "Ozone"

The Ozone carburetor is considered a modified version of the device that was assembled at DAAZ under license from Weber. "Ozone" is a more advanced version of the old "DAAZ". This carburetor has higher environmental friendliness, and also significantly reduces fuel consumption per 100 kilometers.

However, not everything is so good in the Ozone design. After numerous complaints from VAZ 2105 drivers, the designers identified a major drawback of this type of carburetor. The device is equipped with two chambers, but a pneumatic valve takes part in the operation of the second chamber. It was because of this that drivers had problems, since even with the slightest contamination the valve began to work incorrectly.

What about the injector?

Everything is a little simpler here, since no adjustments are needed. The reason is that a smart on-board control system is responsible for everything. And specifically for idling - the regulator (IAC). Some may call it an idle speed sensor, but this concept is completely wrong. The fact is that there are two types of devices on injection cars - sensors (reading) and actuators. The idle air control is a stepper motor; it does not measure anything, but on the contrary, it opens and closes the air supply through a special channel.

A breakdown of the IAC can only be determined by external signs, and then only relatively. The fact is that the control lamp on the dashboard will not light up if the regulator suddenly fails. But if you feel unstable revolutions, or they have disappeared completely, and the engine jerks and stalls, then first of all, of course, it is worth checking the performance of the IAC. It is worth noting that sometimes the “Check” can light up when the IAC is faulty. This happens if the engine detonates. The knock sensor signals a malfunction to the electronic control unit.

Methods for solving the problem

Before proceeding directly to the process of solving the problem, you need to understand that diagnostics and repair of these components should be performed only with knowledge of the matter. Also, it is worth separately noting that for a carburetor and injection engine there will be different diagnostic methods, but the principle of the causes is the same.

So, it is worthwhile to consistently understand the diagnostic and repair work that will eliminate high idle speed.

IAC sensor

It is not often possible to find an idle air control sensor on carburetor engines. This is usually done using a quality and quantity screw. To normalize high idle speeds, you should not carry out the process cold. First, you should warm up the engine to operating temperature, and only then begin adjustments. If after making the adjustments the speed remains high, then the reason is different.

TPDZ

The wrong amount of air entering the combustion chamber can cause the ECU to over-idle. If the throttle position sensor is faulty, it must also be checked. This can be done with a multimeter or oscilloscope. If it is discovered that the TPS is faulty, it is worth replacing it.

Throttle valve

A stuck throttle can cause a large amount of air to enter the engine. This fact will force the electronic control unit to increase the amount of fuel injected to balance the mixture. This will increase the fuel consumption and accordingly.

In order to solve the problem, it is necessary to dismantle the unit and clean it using special means. If cleaning does not give the desired result, the throttle must be replaced, but you should be prepared that this will not be cheap.

Motor temperature sensor

A failure of the temperature sensor can lead to many problems. One of these will be an increase in idle speed. Typically, as practice shows, this sensor is the most vulnerable and most often fails because it is exposed to temperature changes.

First, it’s worth diagnosing the health of the unit. This can be done using a multimeter and an oscilloscope. If the unit is faulty, it should be replaced. After this, it is recommended to reset all ECU errors.

Collector

Often, due to the use of the vehicle, the intake manifold becomes deformed or the gasket wears out. Thus, an increase in idle speed may indicate that there is an air leak in the manifold. To treat the malfunction, you will have to dismantle the part, which is quite problematic, since almost the entire injection system and several components of other systems are attached to the manifold.

It is worth examining the manifold gasket in detail; the presence of damage may indicate not only problems with speed, but also other malfunctions. Also, deformation of the cavity can cause excess air to enter the combustion chambers. This can affect warming up, engine starting and other factors.

To fix the problem, you will have to grind the surface of the collector until it is smooth. In car services, this is done using a special machine. Of course, you can carry out the process in a garage, using a special stone, but this is not always possible for car owners.

Electronic control unit

Repeatedly high idle speed is a consequence of incorrect operation of the electronic control unit. So, to troubleshoot a problem, you will have to connect to the “brains” and fix the problem at the software level. To complete the process you will need a special cable and software.

But simply resetting errors does not always help; you often have to change the software in order for all the problems to finally go away. It is recommended to trust this process to masters who are professionals in their field.

Along with replacing the firmware, you can increase the power characteristics, which is also recommended to be entrusted to specialists. As practice shows, most car enthusiasts, when independently tampering with the ECU, end up in a car service center to eliminate the consequences of their own modifications.

IAC breakdowns

If you have a VAZ 2107 with an injection engine, then pay due attention to the condition of the vehicle systems. If the speed on an injection engine fluctuates, then you need to look first at the idle speed control. The fact is that the breakdown of such a mechanism as the IAC can lead to very sad consequences, including a traffic accident. Here are the main signs by which you can independently determine whether the regulator is broken:

- The engine begins to “live its own life” - the crankshaft rotation speed is constantly changing, sometimes decreasing, sometimes increasing. Consequently, the tachometer needle constantly floats.

- When you start a cold engine, the crankshaft speed does not increase, it fluctuates within a certain range.

- If you turn on powerful electrical appliances (for example, a car radio, low or high beam), the speed decreases and does not return to the set level.

- When you engage the neutral gear, the engine begins to stall if you do not apply the gas pedal from time to time.

These are the main signs that the regulator is faulty. In fact, any interruptions in the idle level are the first sign of a breakdown or minor defect in the IAC. But the time has come to diagnose it. It won't be difficult to do this.

Dosing unit device

Carburetors installed on walk-behind tractors have a general operating principle and design. They have four main nodes:

- Float chamber. This is where the gasoline needed to run the engine comes from. When its level reaches a certain point, the float cuts off the fuel supply.

- Mixing chamber. It saturates the air with fine gasoline dust, which is formed due to the rarefied atmosphere in this unit. Due to the reduced pressure in the chamber, fuel is drawn into it from the float system. It passes through the nozzle, turning into fine dust.

- Throttle valve. It is she who regulates the rotation of the crankshaft and meters the flow of air from the cylinder. If the engine speed of the walk-behind tractor fluctuates, then at a minimum, you should check the condition of the cable on the handle of the cultivator, which regulates the position of the damper.

- Idle speed regulator. This screw is a support for the throttle valve drive. By screwing in the regulator, the engine idle speed is increased.

Carrying out diagnostics

The simplest method is to measure the voltage at the block to which the regulator is connected. These are terminals D and A. When the ignition is turned on, a voltage of 12 V should be present on them. If the voltage is less than this value, it is worth looking at the battery and generator. It is quite possible that the battery is undercharged. In the same case, if there is no voltage at all, it is necessary to check the entire power circuit of the device and diagnose the ECU.

Set the multimeter to resistance measurement mode. Between pairs of terminals A and B, C and D, there should be a resistance of approximately 53 ohms. Remove the IAC and connect (with the ignition off) to the block. Then turn on the ignition and look at the behavior of the needle - it should extend completely when voltage is applied. If this does not happen, we can judge that the IAC is broken.

Sometimes simply cleaning the regulator helps. To do this, you can use sprays, of which there are sufficient quantities in stores. But in some cases, only replacing the device will help. Of course, this is not a DAAZ carburetor, the cost of the IAC will be many times lower, and there will be no problems with replacement. If, even after the replacement, the engine does not idle, it is necessary to fully diagnose the injector.

Setting the Ozone carburetor trigger

A situation often arises when a VAZ-2106 car has difficulty starting in cold weather; the main reasons for this problem are an unregulated starting system or a broken diaphragm. Here you need to know that when the choke is extended, the air damper is completely closed, but when starting, under the influence of vacuum, it opens slightly to a certain angle.

On DAAZ carburetors of models 2105, 2107, for cold starting, a pneumatic valve is installed, which provides a starting gap for the air damper, and this valve has an adjusting screw closed with a special plug. If the throttle angle of the screw is set incorrectly, the proportion of the fuel mixture of a cold engine will be disrupted and starting problems will arise.

There are several ways to adjust; it can be done with the carburetor removed by closing the damper and simulating the vacuum force by pressing your finger. In this case, the gap between the housing wall and the lower edge of the “air” should be within 5-5.5 mm; for measurement, you can use probes, drills or other objects of certain diameters. Also, the starting gap is set between the throttle valve (lower part) and the carburetor body, its recommended value is 0.7-0.9 mm, and the adjusting screw is located at the bottom.

Causes of “triple tripping” of a VAZ car engine

Incorrect timing of ignition installation Air leakage in the vacuum brake booster system Malfunction of the spark plug Breakdown of the high-voltage wire Malfunction of the capacitor Loss of tightness in the area of the intake manifold (intake manifold, carburetor) Burnout of the valve, piston Breakage of the piston rings Incorrect adjustment of the valves Destruction of wear of rockers (valve levers) Breakdown of the gasket Cylinder head Wear, hardening, destruction of oil seals Very low fuel quality Incorrect carburetor adjustment Wear of the distributor shaft, rotary plate bearing Loss of tightness of the membrane of the vacuum ignition advancer Use of spark plugs that are not suitable for the engine and other “faults” I do not take into account

Perhaps not all the reasons, but what I could remember, if you have anything to add, then write in the comments.

Well, now let's talk about each of the reasons in more detail.

Incorrect ignition timing. With this option, I personally know not a tripping, but a seemingly slamming of the engine (missing), which is accompanied by “bouncing” of the entire engine. This is especially noticeable at idle; as the speed increases, the skips disappear. Most likely, your ignition is set too early; this may also be indicated by jerky cranking of the engine by the starter when starting. Quite often, the cause of engine tripping in a VAZ of all models (except for the VAZ 2101, which does not have a vacuum brake booster) is a loss of tightness in the hose, diaphragm, or valve. As a result, excess air appears in the intake manifold, which leads to over-leaning of the mixture and misignition of the mixture in the cylinder, as a result of which the spark plug may become wet and stop igniting the compressed mixture. A faulty spark plug is one of the most common causes of engine misfiring.

There is nothing special to tell here, it is important to remember and replace spark plugs regularly, and the presence of a spark on an inverted spark plug at atmospheric pressure does not indicate its full functionality, because ignition occurs under much more difficult conditions (Za Rulem magazine, dating back to Soviet times). At this point I will combine the breakdown of the high-voltage wire and the capacitor on the contact ignition system. A wire breakdown can be determined by replacing all wires, as well as the capacitor

You can also try to determine the breakdown of the wire by looking at them in complete darkness; if there is a breakdown somewhere, you will see flashes. Loss of tightness in the collector area, as a rule, does not occur on its own. More often this happens due to incorrect assembly or bad gaskets. I also had a case where they complained about trimming at idle. The reason was the elimination of the vacuum ignition advancer and the unplugged vacuum tube on the carburetor. As a rule, when a piston or valve burns out, the cylinder stops working altogether or does not work for a long time. It can only be determined by measuring compression and opening the engine. Breakage or sticking of piston rings is also not a very common occurrence, because a number of conditions are necessary for its occurrence. You can check it by measuring the compression; if it turns out to be low, then eliminate cylinder head malfunctions in a simple way - pour a little oil into the cylinder; if the compression increases, then there is a malfunction in the piston system. With incorrect valve adjustment, everything is already clear - any valve may not open or close completely. Proper valve adjustment can cure this problem. Rocker wear can cause a similar problem. The valve stops opening correctly and the cylinder stops working. Well, now let’s briefly go over the problems that may arise with the distributor. Quite often, on not new machines, wear of both the shaft itself and the bushings in which it rotates occurs, as a result of which it becomes impossible to establish an adequate gap between the contacts. The same thing happens if the swing plate bearing is worn out. Also, misfires can occur due to depressurization in the vacuum ignition timing advancer, where the membrane may fail.

Here I have written a few reasons why a VAZ engine may be tripping, if you want to notice or ask something, write below in the comments!

Maintenance and Troubleshooting

Routine work on systems that ensure engine operation should begin with a complete inspection. For convenience, the air filter housing is removed from the carburetor and all air tubes are inspected. There should be no cracks on them, and the material should remain elastic. If necessary, the carburetor is dismantled and completely disassembled with defect detection and replacement of faulty parts.

The next stage involves diagnosing, eliminating identified faults and adjusting the ignition system. It is recommended to clean the contacts in the distributor with fine sandpaper, replace the spark plugs and set the timing correctly. This can be done using a tester or a primitive test lamp. It makes sense to proceed directly to regulating the VAZ 2107 engine only if the carburetor and other systems are in order.

We go to the service station for service

Using low-quality fuel can also lead to serious engine damage. This may not only be problems with the fuel filter, but also general contamination of the injection system.

It should be said that such a breakdown can only be determined after computer diagnostics. Such diagnostics will allow you to identify existing problems with the injectors, after which it is necessary to replace failed spare parts under service conditions.

We would not recommend changing the injectors yourself. This kind of work is complex and can only be done by experienced workshop technicians on modern cars.

In some cases, the reason why the engine does not pick up speed and there are operational problems is the failure of the control unit. The engine's computer brains send the engine the wrong signals, causing the engine to shake and the engine to run rough.

Such a breakdown can also be determined only after computer diagnostics. Depending on the nature of the problem, it is necessary to either reprogram the control unit or replace it. In the latter case, the cost of repair work can be quite high, since such engine brains are expensive.

Retarded ignition is also a common reason why an engine runs rough. If the engine does not pick up speed, there is a pronounced shudder, the cause of the problem in this case may be late ignition. The fuel mixture entering the cylinders is simply not completely burned and continues to burn in the exhaust manifold.

As a result, the power unit operates unevenly, noticeable detonations appear, the engine runs intermittently, and the existing engine control unit begins to forcibly reduce engine speed.

When you turn on the heater, the engine temperature drops

As we said above, turning on the interior heater can affect the engine temperature. In short, many cars have a so-called heater radiator. The specified radiator is included in the general circuit of the engine cooling system, that is, the coolant heated from the engine passes through the radiator, giving off heat. The resulting heat then enters the car interior through the air deflectors. The intensity of heat extraction from the radiator is regulated by the speed of the heater fan and the position of the temperature regulator of the air supplied to the cabin.

It is quite obvious that when the outside air temperature drops, drivers prefer to turn the heater on to “maximum” to quickly warm up the interior space and further maintain comfortable conditions. At the same time, in winter, the engine often idles, operates at low speeds when driving, etc. It turns out that the unit burns a minimum of fuel and does not experience any special loads. In such a situation (taking into account the working stove and the “minus” outside), the heat generated by the engine is simply not enough to fully warm up the coolant and bring the engine to operating temperature.

For better heating of the interior and internal combustion engine, as well as complete warming up of the gearbox, it is enough to drive the car for several kilometers at medium speed (about 3-3.5 thousand rpm) in a low gear. Also, many drivers use the method of additional insulation of the engine compartment using felt, installing a cardboard or plastic damper on the radiator, etc.

This decision to insulate the engine for the winter is fully justified in cases where the car is operated in conditions of intense cold for a significant part of the time. With additional insulation of the hood and the engine itself, the engine does not cool down so quickly after stopping and warms up faster at idle and while driving. Consequently, the stove in the cabin also works better.

Finally, we would like to add that the quality operation of the entire cooling system depends on antifreeze/antifreeze and its quantity in the system. For this reason, it is necessary to monitor the condition of the coolant and regularly check the fluid level in the expansion tank. You should also monitor the tightness, avoid the formation of air locks, change antifreeze in a timely manner and flush the engine cooling system when replacing the working fluid.