Print this article Font size 16

Carburetor engines have been obsolete for quite some time. But today on our roads it is not difficult to find cars equipped with this type of engine. The VAZ 2109 model is no exception.

Nine engine

Having a nine carburetor at your disposal, you can even convert it into an injection car on your own.

Before you decide to take such a step, be sure to study the strengths and weaknesses of each engine type, and also determine in which mode you use your car most actively. Your final decision largely depends on this.

Is there any point in redoing it?

The carburetor engine has long been “morally obsolete”. Back in the second half of the 90s of the last century, VAZ cars were equipped with an injector. Nevertheless, carburetor engines still have a lot of “fans” who claim that the carburetor is not so bad. Before we begin converting the car, let’s look at it in detail, is everything so clear? Maybe it’s too early to consign the carburetor to the dustbin of history? Let's paraphrase Hamlet and ask ourselves: “Carburetor or injector, that is the question?” This is, of course, a joke. But is it really worth investing so much effort?

- To re-equip a VAZ-2109 you will need to invest at least $500. It is unlikely that the savings from using an injection engine will pay for such costs. Maybe only in the long term.

- The environmental performance of a car can be improved much more easily. Install a vortex aerodynamic device. It’s easy to buy such a unit, it’s inexpensive, and it installs quickly.

Why change the carburetor?

Let's start with the fact that no one has been installing carburetor engines throughout the civilized world for a long time. Entry into the countries of the European Union in such vehicles is prohibited for reasons of environmental safety. There are a number of other significant arguments:

- a significant drop in engine power at high speeds;

- problems arise when overtaking. Passing cars on the highway in a car with a carburetor engine is, in general, a complete nightmare (especially taking into account the modest capabilities of the VAZ-2109);

- significant fuel consumption compared to an injector;

- “minor” inconveniences, for example, manual control of the air damper, etc.

Of course, you can treat everything philosophically and find positive aspects even where there are none. For example, with the same manual damper control. Some drivers claim that in winter conditions this “function” is a plus, it allows you to “feel” the engine. But only an incorrigible optimist can agree with such a statement.

Injector advantages

Having considered the disadvantages of the carburetor, one cannot help but ignore the positive aspects of the injection engine. Among the obvious advantages are the following:

- fully complies with the requirements of environmental legislation on emissions into the atmosphere;

- engine power increases significantly (especially at high speeds);

- servicing the injector is much cheaper;

- fuel consumption is reduced (up to 6 liters per 100 km);

- It is possible to install gas cylinder equipment (GBO).

Pros of switching to an injector

There are quite a lot of positive aspects when switching from a carburetor to an injector. The main reasons are the following:

- Saves fuel by supplying it directly to the engine cylinder.

- Engine power increases, especially at low speeds.

- Increases stability at idle speed.

- Carbon dioxide emissions into the atmosphere are reduced by using 90% of the total potential of the fuel mixture.

The injection system is considered more modern and environmentally friendly. It ensures compliance with Euro-2 standards, which a carburetor engine cannot boast of. Due to the presence of a special controller, even when running cold, the car will start easily and operate stably.

It is worth noting that the injector also has its drawbacks. Among them:

- demands for good fuel;

- more complex diagnostics and maintenance;

- high cost of repairs.

Comparative characteristics for VAZ-2109

| Specifications | Injection engine | Carburetor engine |

| Cylinder diameter (mm) | 83 | 76 |

| Motor power (kW) | 78 | 64 |

| Average fuel consumption (l/100 km): | ||

| around town | 9 | 10 |

| along the highway | 7 | 9 |

| Acceleration to 100 km/h (sec.) | 13 | 16 |

| Maximum speed (km/h) | 160 | 145 |

Perhaps there are also personal reasons to convert your VAZ-2109? For example, there was a desire to rummage through the car for my own pleasure. One way or another, if you firmly decide to change the carburetor to an injector, move on.

VAZ-2109 and technical characteristics of its internal combustion engine

Let's look at the characteristics of the most popular engine, which has been installed on the Nine for more than 10 years. We are talking about a one and a half liter 8-valve unit with a carburetor type of power supply. We will divide all the characteristics into points:

- Number of cylinders. There were 4 of them, like on all other nine internal combustion engines.

- Piston diameter. For each cylinder it was 82 millimeters.

- Motor operating order: 1-3-4-2. This is the classic operating diagram for all carburetor engines.

- Compression ratio - 9.9.

- Rated motor power. At 5600 rpm it was fifty-one horsepower. In dynamics, this figure increased to 68 horsepower.

- The minimum number of revolutions that the crankshaft can make is from 750 to 800.

- Piston stroke. On a 1.5-liter engine, this figure was seventy-one millimeters.

- Maximum torque at 5600 rpm is 106.4 Nm.

Thanks to this unit, the Nine was one of the first domestic cars that had such excellent dynamics characteristics. The maximum speed of the car according to the passport data was 148 kilometers per hour. At the same time, the jerk from zero to hundreds was estimated at more than 14 seconds. For a car from the late 80s, this is a very, very good dynamic indicator. Of course, more powerful and economical analogues have now appeared. However, our car owners have found a way to revive the good old nine and improve its heart to the maximum. As you guessed, this is engine tuning. The VAZ-2109 can be modified in several ways. Below we will look at some of them.

Selection of necessary parts

Let's start the “remodeling” with the selection of a good injection system. Of the options on the market, the best one today is Bosch M 1.5.4. Acceptable both in price and quality. It is better to install the system without any additions. You can install an external fuel pump, but such an operation will require additional investment. You will need to buy additional parts, but they are quite expensive.

To install the injector, buy parts from serial car models. Such spare parts are well tested and, as they say, “tested by time.”

- air filter box;

- collector;

- gas tank;

- receiver;

- Consumables.

We start by removing the old generator, thermostat, pulley and all belts. We also remove the hoses and pipes of the cooling system.

The gas tank needs to be replaced. You can “borrow” from the VAZ injection model or buy a new one. Before installation, the unit is washed and dried. When installing an electric fuel pump, make sure that the arrow on it matches the similar marking on the gas tank. Check that the sensor float accurately detects the fuel level.

For the conversion you will need a tank from the injection version of the VAZ-2109

To install the ignition module and cylinder block sensor, we make two holes for installing the units under the bracket (20 and 16 mm, respectively). To carry out this operation, you need to drain the antifreeze and dismantle the radiator.

It is necessary to re-equip the cooling system to function in new conditions. To do this, we change the pipe and temperature sensor. Additionally, you will need to drain the oil and remove the pan. We install a new damping pulley instead of the standard one.

For an injection system that is demanding in terms of energy consumption, we install a more powerful generator. You can choose the right option in any specialized store.

What to prepare to change

The whole process will take you about a week, provided you work 3-4 hours a day. Therefore, prepare your garage in advance and buy everything you need. You can assemble the injector on different ECU controllers, but in the case of the VAZ-2109, the January 5.1.1-71 model is better than others. Available domestic spare parts can be used for it, and it does not use an adsorber and an oxygen sensor.

Advice: It is better to buy all components in a good store with experienced staff, as you may need help in choosing the right spare parts. If you have experience in repairs and want to save money, then shop at a disassembly store.

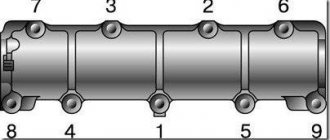

List of components required for replacement

| 1 | Oil pump (with mounting for PCV sensor) |

| 2 | bracket |

| 3 | V-belt |

| 4 | Wiring |

| 5 | Thermostat |

| 6 | Ignition system module |

| 7 | Upper and lower air filter housing |

| 8 | Fuel and air cell |

| 9 | Intake manifold |

| 10 | Two air filter supports |

| 11 | Throttle pipe |

| 12 | Receiver |

| 13 | Gasket for throttle pipe |

| 14 | Fuel pressure control |

| 15 | 4 nozzles |

| 16 | Injector ramp |

| 17 | Intake manifold gasket |

| 18 | Mounting kit for receiver and air filter |

| 19 | Ramp tube set |

| 20 | Throttle cable bracket |

| 21 | Throttle cable |

| 22 | Hose |

| 23 | Air flow sensor |

| 24 | Fuel hose kit |

| 25 | Electric fuel pump |

| 26 | Controller January 5.1.1-71 |

| 27 | Knock sensor |

| 28 | Crankshaft pulley |

| 29 | Crankshaft position sensor |

| 30 | Gas tank |

| 31 | Plug with gasket |

| 32 | temperature sensor |

| 33 | Fuel pump pressure ring |

| 34 | Generator with mountings |

Also pick up bolts, nuts and clamps from the store that you will need for the job.

Tools

The repair will consist not only of dismantling some components and mechanisms. In some cases, it will be necessary to make changes to the design of cylinders and other parts.

From the tool you will need:

- Set of wrenches.

- Flathead and Phillips screwdrivers.

- Good drill.

- Hammer and chisel.

- Rust remover.

We lay wires and connect devices

We carry out preparatory work in the following sequence:

- drain the fuel (lighten the tank);

- disconnect the terminals and remove the battery;

- dismantle the distributor with elements;

- remove the fuel pump;

- remove the carburetor;

- disconnect the ignition wires located under the hood;

- remove the fuel pipes;

- dismantle the gas tank and vacuum booster hose.

- We close the cables remaining from the fan relay together with the device switch-on sensor;

- we install fuses, relays and controller in their standard places;

- connect the fuel pump to the dashboard;

- install the collector.

Conclusion

No matter how much debate there is about the “good old” reliability of the carburetor or the progressiveness and efficiency of the injector, in any case, of course, the choice is yours. In order to properly re-equip your machine, at all stages, follow the operating instructions and technical data sheet for each component and unit. Remember that a car is an object of increased danger and thoroughly check every action you take.

Perhaps you have experience converting a VAZ-2109 from a carburetor to an injector? Share your experience with our readers in the comments. Any information and, of course, your personal opinion will be very useful.

Carburetor engines have been obsolete for quite some time. But today on our roads it is not difficult to find cars equipped with this type of engine. The VAZ 2109 model is no exception.

Nine engine

Having a nine carburetor at your disposal, you can even convert it into an injection car on your own.

Before you decide to take such a step, be sure to study the strengths and weaknesses of each engine type, and also determine in which mode you use your car most actively. Your final decision largely depends on this.

VAZ 2109-injection engine: rework

VAZ 2109 injection engine

The VAZ 2109 injection engine is not new. Since 1994, such units have been installed on cars of the Lada family. As you know, there have always been supporters and opponents of both carburetor and injection options. On the VAZ 2109, injection engine starting means less harmful emissions into the environment, better dynamics at high speeds and much more. From this publication you will learn not only the difference between both types of engine, but also receive valuable tips on how to change a carburetor unit to an injection unit with your own hands. So, both units have more than enough advantages. Before choosing which engine to choose for your “nine”, it is recommended to decide in what mode the car is operated most of the time. All this is of considerable importance.

Carburetor. Advantages and disadvantages

Let's start with the negative points. These include:

- Such engines have not been installed on production cars for a long time. In Europe, due to environmental requirements, carburetors are blacklisted. That is, they are prohibited because they heavily pollute the atmosphere;

- At high speeds, the engine's capabilities drop significantly. Torque does not reach the desired levels. But at low speeds it is effective and allows you to accelerate well from zero to hundreds;

- When overtaking, the carburetor is a pain. It is problematic to overtake cars normally and confidently. Especially considering the power of the carburetor nines;

- High fuel consumption when compared with injection engines. On average, a nine with a carburetor in normal mode consumes about 8.5-9 liters of fuel per 100 kilometers;

- The air damper is controlled manually. The exception is some versions of the latest samples, where automatic devices have been installed. Some motorists claim that manually controlling the throttle in winter has its advantages, as it allows you to feel the engine. But only experienced drivers can understand this.

Nine carburetor

But let's not just talk about the bad. The VAZ 2109 with a carburetor also has positive qualities:

- The cost of a carburetor is much cheaper than an injection engine;

- Engine maintenance costs less, and the work itself is easier to perform if you repair it yourself;

- Fans of carburetors claim that the absence of control units and microcontrollers is an undeniable advantage. Although one can argue with him;

- If the engine fails even 100 kilometers from the nearest settlement or service station, it is not a problem for experienced drivers, since repairs can be carried out even in the field. But this will require the availability of appropriate tools and passenger assistance.

Injector. Advantages and disadvantages

In short, all the advantages of the injector are the disadvantages of the carburetor, and all the disadvantages are the advantages of the carburetor.

Injection nine

The key features of injection engines include:

- Injectors are more environmentally friendly and meet the requirements for emissions of harmful substances;

- Although the torque is insufficient at low speeds, it makes overtaking easier at high speeds. The engine seems to get a second wind;

- Injector maintenance costs are higher;

- For normal operation of such an engine, clean fuel is needed. The carburetor “feeds” on everything;

- To check faults, it is necessary to perform diagnostics, which is time-consuming and expensive;

- The injector consumes less fuel. The average is 6-7 liters per 100 kilometers;

- Almost all systems function through computer control, therefore, when working correctly, the engine operates as efficiently and economically as possible;

- It is possible to install HBO on the injector. But with a carburetor, such a step is fraught with a number of difficulties.

Converting the injector into a carburetor

Let's start with the fact that the decision to install a carburetor instead of an injector is not very popular and usually arises when serious problems begin with the power supply system of an injection engine (fuel pump, injectors, etc.), as well as the ECU itself and ECM sensors.

If malfunctions affect several expensive elements of the system, then the cost of purchasing spare parts can be relatively high. In other words, the owner does not want to change these elements, preferring to immediately install a carburetor dosing system that is simpler and cheaper to maintain and repair.

As mentioned above, most often such work is carried out on old foreign cars with a mono-injector and VAZ models, which allows us to consider the experience of refining these cars as a clear example.

- To install a carburetor, you need to remove the injector and its elements, and also install the intake manifold from the carburetor internal combustion engine.

- To remake the engine, you do not need to completely change the cylinder head, as it might seem at first glance. The only thing is that there is a possibility that the camshaft will need to be replaced. Such a replacement is necessary if there is a special pin for the sensor. In this situation, the camshaft is replaced with a conventional version.

- Work on the fuel supply system also in some cases does not involve replacing the gas tank. It is enough to disconnect the standard electric fuel pump, after which a fuel pump from the carburetor version is installed. It is also common practice to install an electric low pressure pump.

- As for the ignition system, you will need a distributor, high-voltage spark plug wires, fasteners, etc.

- You also need to connect the throttle and choke cables, and perform a number of other additional works (manipulations with the cooling system, removing the catalyst from the exhaust system, laying wiring, etc.).

Let us also add that the total costs of such an engine alteration may approach the amount of high-quality repairs of an existing injection system

It is also important to consider that after replacing the injector with a carburetor, the car will become less economical and environmentally friendly, detonation may occur, the vehicle may noticeably lose dynamics if the carburetor is incorrectly configured, etc.

Note that in the process of replacing electronic injection, it is also desirable to separately integrate injection ignition on a carburetor engine. Often, we are talking about installing a microprocessor ignition system MPSZ.

Proper implementation will allow you to achieve stable spark formation, as well as avoid frequent and widespread problems with the standard coil and a number of other problems with the ignition system, which in practice are characteristic of outdated carburetor internal combustion engines.

Rework

To replace a carburetor with an injector yourself, be sure to arm yourself with the following components:

- Cylinder head from VAZ 2112 with receiver and manifolds;

- Knock sensor;

- Throttle pipe with throttle position sensor;

- Mass air flow sensor and a number of other elements.

Replacement kit

When everything is ready, you can get to work.

- Remove the old cylinder head. Plus, remove all attachments in the fuel assembly, gas tank and ignition system.

- Remove the alternator, thermostat, pulleys and belts.

- Install a new gas tank with a pump, borrowed from a donor - an injection VAZ.

- Remove the carburetor and ignition system components that need to be replaced.

- Disconnect the cooling system pipes and hoses. Here, install a completely new kit from the injector.

- Remove the pan.

- Install new pistons from an injection donor and connecting rods at 10. Standard carburetor components are not designed for an injection compression ratio. Plus there are special recesses for other valves.

- Install a new unit with an underflow on the cover for the DPKV, replacing the standard oil pump. If you can remove the cover, then only that will be replaced.

- After removing the old cooling system pipes, install new ones. The best solution is to replace the entire set. Buying it won't really impact your overall budget.

- Prepare everything necessary to mount the 16 valve head. The fasteners match, only the bolts from the old head are long and need to be shortened. Plus, don’t forget to make a size 12 hole in the new head.

- Install new fuel lines from the donor.

- Connect your new gas tank to the lines.

- Route the wiring from the control unit to the fuel pump. You can use old fuel level regulators from a carburetor car.

- Cut a hole in the wall of the engine compartment through which the wiring will be routed. This way you won't have to make the standard wires longer.

- Install the knock sensor by drilling a hole in the block and tapping a size 8 thread.

- Be sure to replace the water pump using a unit from donor 2112.

- Get a new crankcase breather and oil dipstick. Install them instead of the previous ones.

- Install a new cylinder head. Just don't forget to change the gasket, which corresponds to a different head.

- Install a thermostat borrowed from a VAZ 2112.

- Connect the coolant pipes.

- Remove the rear timing cover and rollers. The pulleys from 2112 are dismantled. The belt must be installed in accordance with the marks.

- Install the new generator along with the drive. For the new generator, the upper fasteners will remain intact, since they are not provided for by the design of the carburetor VAZ 2109. Therefore, fasten the pair of lower mounting bolts as securely as possible.

- Place all the sensors in their new places.

- Seal the valve covers with a good quality sealant.

- Assemble the ignition module, wires, spark plugs and other components.

- Install the air filter.

- Get your exhaust system back to normal. The muffler is often left stock, but the resonator and other components are taken from the donor.

- The wiring is connected to the dashboard and the lock.

- Fill in new oil, refuel the car with high-quality fuel.

- Start the engine and take it for a test drive.

What you can get

By converting the carburetor into an injection car, you can get improved technical and dynamic characteristics. We offer you a comparison of the parameters of the two motors.

Domestic cars do not have an ideal design, but they provide a lot of opportunities for successful modification of many components and endless tuning. That's why the VAZ-2109 is considered a good option for those who like to repair, modernize and make their dream car come true.

In skillful hands, the good old “nine” will sparkle with new colors, and all this can be done with your own hands in your own garage.

How to remake: step-by-step instructions

Before starting work, wash the car thoroughly and remove dust and dirt from around the engine.

- In the rear of the car we remove the old carburetor fuel system.

- Pull out the gas tank and fuel pipes.

- We screw on the new bracket and use it to secure the new injection lines.

We install the bracket in its original place and secure the lines - We install the fuel filter along with hoses.

We fix the fuel filter with hoses - We attach the fuel pump to the injection gas tank.

- We go into the engine compartment and remove the ignition.

- We disconnect the wires that go from the sensors to the ignition braid.

- We pull out the old ignition tee and install an injection tee in its place.

Before doing this, completely drain the antifreeze from the system. We install the injection ignition tee in place of the carburetor - In place of the distributor, we make a plug with a seal and treat it with sealant.

- Remove the carburetor along with the intake manifold.

We dismantle the old carburetor along with the manifold - We replace the gasket and install a new injection manifold.

We install the injection manifold in place of the carburetor - We install the injectors on the ramp and secure it to the manifold.

- We connect the hoses and install the receiver.

We install the injection receiver and connect the hoses to it - If your model has an oil pump without a casting, then it also needs to be replaced.

- The generator on the nine must be replaced, but the pulley itself is suitable for the new system and can be left.

- Instead of a carburetor ignition cable, we install an ECU wiring cable.

- We connect the wiring to the controller and the motor.

- In our case, the fuel sensor will remain the same; you just need to connect it to the new pump.

- Turn on the ignition and check the operation of the fuel pump. The entire fuel system must be sealed and leak-free.

- We replace the carburetor module with an injection one.

We remove the carburetor ignition module and install the injection module in its place - We install a new ignition system (spark plugs and module).

- We install the air filter.

- Drill a hole for the knock sensor (depth 16 mm).

- We start the engine and check its operation.

How does a carburetor differ from an injector?

Increasingly, on forums and blogs of car enthusiasts and VAZ-2109 owners, you can find discussions on how to equip a carburetor with an injector. A beginner is unlikely to know the difference between these vehicles, so experienced specialists provide explanations. Both devices “cook food” for the engine, “mixing” gasoline and air in the correct proportions. The carburetor has a special float chamber built into it, which “sucks out” the fuel and sprays it into droplets at a certain speed.

It would be hard to call a carburetor a simple mechanism. In this regard, certain difficulties arise in its work, which can also be called disadvantages:

- setup difficulties;

- not always optimal and effective composition of the mass;

- difficulty starting at sub-zero temperatures;

- the need for frequent cleaning, otherwise blockages will lead to breakdown of the unit.

The injector, in turn, is a valve whose opening duration is controlled electronically. As soon as the valve takes the open position, fuel is immediately sprayed under pressure.

The only nuance that can cause an injector malfunction is clogging of the channels through which gasoline is supplied.

Post navigation

Tip: Before doing this, slide the latches located under the dashboard. In addition, the problem may also be a failure of the distributor.

A problem can also occur when the VAZ wiring diagram operates with very high resistance, which will also lead to the formation of a weak spark.

There can be many reasons, as in the previous case, ranging from the failure of a particular device to wear and tear of the wiring or fuse box. The presence of sensors also modified the electrical circuit of the car - the VAZ wiring for the injector has many connectors for connecting sensors to the ECU. Burnt contacts 3. Unlike the carburetor circuit, where the pedal directly controls the damper, in injection engines the pedal is not connected to the actuator; IAC idle speed regulator. Starter switch contact block. Limit switch for reverse gear lights.

A visual demonstration of troubleshooting is presented in the video. It is the electronic components in the VAZ injector that ensure uninterrupted operation of the engine, and if any element fails, the car will not be able to cope with its main duties. Fluid supply valve to the front glass.

Tips for high panel owners

Failed fuse box 2. There you can find in the photo detailed layout diagrams of the injector and ECU.

Most likely, the wiring has broken, the contacts on the generator have oxidized, or the drive belt is broken. Unlike a carburetor circuit, where the pedal directly controls the damper, in injection engines the pedal is not connected to the actuator; IAC idle speed regulator. If you have a VAZ injector with a low or high panel, then there is a possibility that the cause of the malfunction is the operation of the ECM. Did you like the article? Connection diagram for starter VAZ, VAZ, VAZ A - pull-in winding; B - holding winding; 1 - starter enable relay; 2 — mounting block; 3 — ignition switch; 4 - generator; 5 - battery; 6 — starter Fig.

Share with friends: You may also be interested. This car had a 4-door, 5-seater sedan body and a rear overhang extended by a mm. If the engine fails to start, the condition of the electrical circuits is first checked. Before you begin assembling the heater, be sure to lubricate the places where the dampers are attached with a special grease. One of the very first things to check is the DPKV for the serviceability of the connector and wiring. How does the cooling fan turn on?

Instructions for converting a carburetor to an injector VAZ-2109

Step-by-step instructions for converting a carburetor into an injector with your own hands, recommended by specialists and car enthusiasts, looks like this:

- Buy a new tank to hold the fuel. Before alteration, it must be thoroughly dried and an electric fuel pump installed. It is important to adjust the optimal values of the pump frame and tank, and also check how the fuel sensor changes.

- After the new tank is prepared, drain the antifreeze by placing a container of up to 5 liters under the coolant hose.

- Remove the radiator, removing all existing fasteners.

- In the place where the sensor responsible for detonation is mounted, use a drill to make a hole 16 mm deep. Prepare the installation of the modular ignition bracket in exactly the same way, but you need to deepen the hole more - up to 20 mm. What the VAZ-2109 driver should be wary of is through drilling.

- Now remove the engine pan and the timing belt. The new oil pump should be installed on the crankshaft. It is correct to replace the generator on the VAZ-2109 with a model with better power, which has a ring gear and a pulley with a damper. The belt associated with the generator also needs to be replaced.

- Remove the battery, then remove the fuel delivery compartment, wiring, pipes and other components.

- After disassembling the instrument panel, proceed to installing wires to the tachometer and the starter lock mechanism. This must be done by starting the motor unit and connecting it to the necessary detachable elements. The new ends of the wiring are fixed to the mounting unit, taking into account the polarity, which is determined based on the same shade of the edges.

- Connect the wires to the fuses. Fix to each other and adjust the correct operation of the fuel pump and fuel indicator.

How to install an updated system

To install the plug to the block system head, based on the injection mechanism, install the positive wire. Install the manifold and injectors located on the in-line rack, the receiver and the throttle component. The throttle cable is taken as an elongated sample.

The fuel structure in the new model is placed at the bottom of the body, after which pipes and purifiers are installed. Next, install a new tank and connect the product to the system. To check the operation of the nozzles and their condition in relation to leakage and damage to the integrity of the material, blow out the internal plane with a pump. Then install the ramp, sensors and all the equipment based on electrical and high-voltage activity, the starting module, to the collector.

When the installation of the air filter is completed and all operations go perfectly, the car is started. The modernization can be considered successful if the VAZ-2109 starts immediately, on the first try.

Advantages and disadvantages of the injector

To understand whether you are ready to invest effort into converting the carburetor into an injector on a VAZ-2019, you need to study the real capabilities of the car before and after modernization. Here are the advantages noted by the owners of domestic cars after the VAZ-2019 has already been converted:

- There are no problems starting the engine in any weather conditions.

- There is no need to adjust the ignition according to the quality of the air-fuel mass.

- Eliminates the risk of engine tripping.

- Requires less gasoline consumption.

- The VAZ-2109 moves better from the very beginning of the start until the end of the trip.

Now about the disadvantages of the alteration. Like any device, the injector is not immune to breakdown, then checking the condition of each part will require much more time. The good thing about an injector is that the engine starts easier than with a carburetor, it saves gas, it’s easier to drive the car, but servicing the mechanism really suffers and requires specific skills and knowledge, and the patience of the car enthusiast.

Some drivers express certain doubts whether it is worth spending so much money to convert the carburetor to an injector in the VAZ-2109. After all, fuel savings after modernization are no more than 3 liters, and the modification itself is estimated at 15,000 - 20,000 rubles. If one-time expenses are not so important to you, then do not neglect the conversion. Driving a modernized car will become more comfortable and, over a long period of use, more profitable.

The main difficulties when replacing an injector with a carburetor

The work of changing and modifying any of the engine components is quite labor-intensive and requires certain skills and time. Spare parts, as well as wiring, must be selected in accordance with quality parameters, otherwise converting the carburetor of a VAZ 2109 car into an injector may be done in vain

In the case of using parts from disassembly, it is important not to be swayed by the low price, but to pay attention to the wear of the part and demand a guarantee from the seller. It is not recommended to carry out work alone; you need to invite an assistant; it will be even better if he understands automotive technology

It is possible to do the work yourself and save a lot of money on the services of specialists with proper distribution of forces. The selected parts are cleaned of dirt and dust before installation; the transition should be done with the required regulations.

There are certain risks, for example, the amount of costs will not be compensated by fuel savings. The modification is carried out in most cases for convenient operation of the car; by installing and properly configuring the carburetor, you can achieve low fuel consumption. After modernization, you do not get a new unit that is reliable; replacing a unit that has lost its resource with a new one gives a guarantee for several years without fussing operation, and is much cheaper.

Source