Without an engine and body there is no car. This old driver's saying has a point. Replacing a rotten or dented body is always expensive, and without a working engine the car will stop working. The most important sign of imminent engine death is an extraneous sound from under the hood.

In this article we will tell you in detail about knocking in the engine and what it means.

Most often, the characteristic dull sound under the hood occurs due to a gap between the parts inside the engine. If you hear a loud knock, then the permissible distance between parts has been exceeded by 2 or more times. The louder the sound, the more the gap “grows” and the faster the wear of the insides of the unit.

Why the knocking appeared and what changes await the engine depends on the quality of the parts and operating conditions. In any case, the consequences are sad:

- excessive loads and increased detonation;

- constant heating of the working mixture and loss of its qualities, which causes engine parts to wear out faster.

Diagnosis of engine knocking

Checking the condition of the motor when knocking occurs is carried out according to several parameters.

- According to the nature of the sound: constant, rare or episodic - the frequency of tapping depends on the type and degree of malfunction.

- By tonality: determining the tonality of a sound is not an easy task. Only an experienced technician can understand that the loud knocking sound of an engine in a Korean car and the muffled sound of a higher-power engine in a German car mean essentially the same thing - a faulty crankshaft bearing. The fact is that structurally different engines can sound differently, regardless of condition.

- By location: to obtain the most reliable data, specialists use a stethoscope, but if the device is not at hand, you can make a listening device from scrap materials. For example, from a tin can and steel wire.

Engine knocking is inextricably linked to the operation of the crankshaft, which ensures engine speed. Accordingly, the faster the crankshaft rotates, the more often the knocking sound is heard in the engine. Depending on the operating mode of the internal combustion engine, the sound may be louder or quieter. It is important to accurately establish the relationship between the increase in engine speed and sound intensity.

During the diagnostic process, it is necessary to check at what point in operation the engine knocks louder. It often happens that at high temperatures in the system (at the moment when the engine oil is most liquid and increased in volume), the power plant knocks loudly. In some cases, knocking is heard precisely when the engine is cold, and after warming up the noise completely disappears or becomes almost unnoticeable.

Why is the engine knocking?

There can be many possible reasons for engine knocking. In the list of the main ones, experts note wear of parts inside the internal combustion engine, as well as detonation knocks. The degree of wear and a number of other factors will determine the nature of the knock, which can be from quiet and muffled to distinct metallic knocks inside the engine. After the engine starts when cold, a knocking noise in the engine becomes audible, which, when warmed up, can:

- disappear completely;

- become less noticeable;

- stay at the same level;

- increase with increasing temperature and load;

Causes of engine knocking

If immediate action is not taken, the knocking noise in the engine may intensify. In the systems of the gas distribution mechanism, cylinder-piston group and crank mechanism, knocking can occur:

- piston in cylinder;

- piston pins;

- camshaft in the block head;

- directly the crankshaft in the cylinder block;

- the so-called rocker arm, as well as the axis of the valve mechanism;

- valve and valve guide;

- valve and cylinder head (cylinder head).

If timing parts (chain or belt), made of hard and sufficiently durable materials, are worn out, the knocking noise can continue for a long time. The destruction of the softer elements that function in tandem with the metal bearings and liners will cause the sound to begin to intensify.

to “Why does the engine knock when it’s hot and when it’s cold.”

I do not agree with the author. Hitting the road with a knocking engine is absurd, unless we are talking about valve knocking, which you can adjust yourself. A knock in the engine is a sign for the driver. In most cases, this indicates a serious engine malfunction. In any case, the motor must be disassembled to fix the problem. True, there were cases when a car owner filled in bad oil and the engine began to knock. The issue was resolved by replacing it with high-quality oil and the client left happy that he had avoided major engine repairs. A knocking noise may occur due to a clogged oil receiver. This occurs after flushing the lubrication system with solvents. Resins and dirt after this procedure settle in the pan and clog the oil receiver. At high speeds the knocking does not appear - the oil pressure is enough to lubricate the parts, but at idle the engine begins to knock as the oil pressure drops. The problem can be easily solved. The pan is removed and the oil receiver is washed.

The most dangerous causes of knocking

1. Pistons are knocking in the cylinders.

The knocking of the piston, distinguished by a dull tone, is clearly audible in the cylinder block and is sometimes accompanied by a kind of clicking sound.

The engine knocks and clatters as a result of thermal expansion of the piston, usually “in the cold,” at low engine speeds, as well as when the gas is suddenly released while driving. A knock occurs as soon as the gap becomes larger than 0.3 mm. 2. The piston pins are knocking.

The sound of the piston pins knocking is “metallic”, high-pitched and slightly ringing. This sound is clearly audible if you over-throttle or press the accelerator hard to accelerate. The place where the sound occurs is considered to be the cylinder block; the gap is about 0.1 mm.

The malfunction can also be determined by unscrewing the spark plug. Without a spark plug, the fuel in the cylinder does not burn, which means there is no load on the piston.

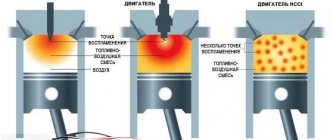

Detonation often occurs due to the use of fuel that is unsuitable for this type of engine, as well as during extreme overloads (steep uphill, long descent).

3. Main bearings and crankshaft liners are knocking.

The metallic knock of the engine, characteristic of this case, is a little muffled and is heard from the crankcase. Knocking elements are especially audible at low speeds of a “cold” engine during acceleration and at the moment of releasing the gas. The size of the gap between the neck and the liner is equal to the minimum 0.1-0.2 mm. A drop in oil pressure to a critical level makes the sound louder, regardless of the operating mode.

Often, valve knocking is caused by the use of low quality motor oil, or one that does not match the type of power unit.

4. Connecting rod bearings are knocking.

The sound of faulty connecting rod bearings is similar to signs of main bearing problems, but is more distinct. If the sound intensity increases, repairs must be made urgently. Operation of both gasoline and diesel engines with unsuitable connecting rod bearings is prohibited - the engine may “seize” at any time.

When starting from cold

If a knocking noise starts when you start the engine at a cold temperature, this is due to the viscosity of the oil on a cold engine, especially for this reason the noise of the expansion joints occurs.

If the driver changed the oil, he heard knocking noises in the engine when starting up. This is a normal phenomenon, since the oil was drained during replacement, and the new oil has not yet had time to completely enter the lubrication system. For some time the engine runs with oil starvation, as a result. To speed up the oil filling process, all engine lubrication systems are filled with oil before changing a new oil filter.

When the oil level in the crankcase decreases, an incomprehensible noise also appears in the engine, gradually increasing as it warms up below. When hot, it intensifies with increasing speed and these are signs of oil starvation of the connecting rods and piston pins.

Engine repair tips

If a distinct knocking sound appears in the engine, be sure to check the engine oil level; its drop in the lubrication system can lead to malfunction of the entire internal combustion engine system. If the level is optimal, determine where the sound is located. At this stage, you need to make sure that the following are in working order:

- fuel system;

- drives;

- attachment pulleys.

The next step is to determine the characteristics of the knock. If a “loaded” engine knocks more strongly, most likely, problems have appeared in the crank mechanism or in the cylinder-piston group.

If you notice that the knocking frequency does not coincide with the crankshaft rotation speed (it differs by about 2 times), then the probable problem must be looked for in the timing system. The fact is that the crankshaft rotation speed is 2 times higher than the camshaft rotation speed. When the engine warms up, the knocking noise usually gets worse because the clearances in the valve mechanism become larger as the engine heats up. The gas distribution mechanism, on the contrary, is not related to the operating mode of the engine. As an exception, we can recall cases of hydraulic compensators knocking under load.

Increased knocking can also occur due to heating and subsequent expansion of the engine oil, which indicates a problem with the bearings of the crankshaft mechanism.

The specialists of the official FAVORIT MOTORS service center will help you troubleshoot any engine design.

The experience and professional knowledge of our specialists can quickly and inexpensively return your vehicle to good condition using original spare parts, consumables and modern equipment. All work is carried out with a guarantee and in accordance with the manufacturers' recommendations. Sign up for service Service center contactsAsk a question

Determining the causes of sound

Modern cars are equipped with engines in which the clearance is adjusted automatically. When looking for an answer to the question why a valve is knocking on a foreign car, the answer is most likely not in adjusting the clearance. All modern internal combustion engines are equipped with hydraulic compensators. But with domestic cars and other foreign cars that do not have a similar system, the issue of adjusting the gap is relevant. On many foreign cars, the procedure for adjusting or checking the clearance is a complex topic. As a rule, the engine should be checked for violations of the gap by specialists. On an old engine or domestic units, you can check why the valves are knocking as follows:

Other causes can only be identified through a professional inspection of the engine, or in some cases, during its disassembly.

Starter operating principles

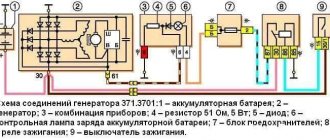

A starter is an electric motor whose main task is to spin the engine so that it starts working on its own. To do this, a special control device is installed on the starter - a solenoid relay. But after starting the engine, the rapid rotation of the flywheel can destroy the starter mechanism, so a special overrunning clutch called a bendix is installed on it. The starter operates in several stages:

- After turning the key to the start position, voltage is applied to the solenoid relay. Its coil is magnetized and attracts the core, which moves.

- The fork, attached to the core, moves the bendix with the gear to the gear or flywheel ring, and at the end of its stroke it closes the contacts to the starter motor.

- Current is supplied to the armature, it begins to rotate in the magnetic field of the stator, simultaneously rotating the overrunning clutch, flywheel and crankshaft.

- After the engine starts, the key turns to the operating position and the current stops flowing to the solenoid relay. Under the influence of the spring, it returns to its original position, returning the bendix to its place and opening the contacts to the electric motor, as a result of which the starter stops working.

How to fix a rattling starter

The method for troubleshooting depends on what is causing the problem. If the starter cannot work normally due to a discharged battery, it is enough to charge it to the required parameters. Typically, charging is carried out with a current of 0.1C, where C is the battery capacity in ampere-hours. At the same time, highly discharged current sources and calcium batteries should be charged with low currents (1-2 A) to at least 25% charge (this parameter is controlled by the density of the electrolyte). The gentle mode will take more time, but will protect the battery from many negative aspects.

Note! Often, when the battery is discharged, car owners try to start the engine “from a tow”. Note that this method is only suitable for the simplest power units, but not for injection engines. Launching the latter “from the pusher” often leads to a failure of the electronic control unit software.

In this case, the ECU begins to behave unpredictably - for example, request permission to start from a disabled immobilizer. The situation can only be corrected by reflashing the “brains”, and this, as you yourself understand, is an additional and completely unjustified expense.

In the case where the cracking of the solenoid relay occurs due to poor contact with the vehicle ground, it is enough to simply restore the electrical connection. To avoid problems in the future, it is recommended to remove the tire that connects the engine to the body and clean the contact pads with sandpaper. A thin layer of technical Vaseline or VD-40 universal lubricant will help prevent their oxidation.

If the source of the malfunction is the retaining winding of the starter solenoid relay, then try to repair it. If this is not possible, then a decision is made to replace the solenoid relay assembly. As you can see, even a novice driver can cope with finding the fault that is causing the starter to crack.

Video: Why the starter cracks. Useful advice from an auto electrician.

Source