Simply put, when unusual sounds appear in the engine that were not previously heard, the intervention of experienced professionals is required, and the first thing they should do is conduct a thorough diagnosis of the car’s power unit at a car service center. The problem, most often, lies in the connecting rod and piston group, and in this case a major overhaul of the car will be required. The reason for the knocking sound is engine crankshaft play.

More common causes of excessively loud engine idling include:

- The electronic engine control unit increases speed to prevent engine stalling.

- Increased clearances are also one of the reasons for the increased noise of a running engine. Such increased gaps between the surface of the cylinders and pistons contribute to increased load on the units and, naturally, noise. When the parts heat up while the engine warms up, the gaps decrease and the noise subsides.

- If the car has a significant mileage of over 100,000 km, the cause of the unusual sound may be hydraulic compensators. Coking of the channels can become an obstacle to the operation of the oil pump and the flow of oil into the engine. At the same time, a characteristic “clatter” is heard, which decreases as the engine warms up and then disappears.

An increase in the engine speed of a cold engine occurs by enriching the fuel mixture. This compensates for unburned fuel, the cause of which is the reduced engine temperature. In addition, increased speed is necessary for stability of operation and sufficient lubrication of the rubbing surfaces of parts, since, due to the increased viscosity of the oil at low temperatures, the operation of the oil pump is difficult.

An increase in the number of revolutions during warm-up is also necessary to quickly achieve the optimal temperature of the catalyst and reduce the toxicity of exhaust gases.

As the engine temperature rises, the control unit reduces speed and the noise becomes weaker. Reducing noise after warming up also helps to reduce clearances and reduce oil viscosity. Therefore, increased noise when the engine warms up is not a sign of a car malfunction.

Faults that increase engine noise

When unnatural sounds appear in a running engine, the driver tries to understand their cause and, when he comes to a certain conclusion, seeks to fix the problem on his own or involve his friends who have the necessary experience.

The most significant malfunctions that cause unusual noise in a running engine:

- Use of low quality oils and fuel;

- Malfunctions of the lubrication system;

- Inappropriate temperature conditions;

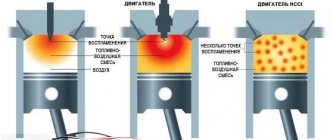

- Problems with the ignition system;

- Worn timing belt;

- Malfunction of hydraulic compensators;

- Problems in the timing belt;

- Unstable operation of the idle speed controller;

- Malfunction of electrical systems.

So many malfunctions that are caused by extraneous or more powerful noises from the power unit can only be sorted out by a car service specialist, and that is where you should go.

Delay in this case will result in serious damage and the need for an expensive overhaul of the engine,

Lubrication system problems

An insufficient amount of lubricating fluid in the system leads to a drop in pressure. As a result, the rubbing surfaces of the parts will be without sufficient lubrication, which will lead to their premature wear. It is also unacceptable to use low-quality oils or those that do not correspond to the type of engine, the viscosity of which will not allow high-quality lubrication of the mechanisms. In this case, the increased load on the engine will be accompanied by an increased noise level of its operation.

Another reason for a loud engine is insufficient lubrication of engine parts, which increase in size as the temperature rises and begin to noisily come into contact with other mechanisms and parts of the power unit without lubrication.

The entry of coolant into the lubrication system leads to dilution of the oil and loss of its necessary lubricating properties. At the same time, engine wear significantly exceeds established standards. If coolant gets into the lubrication system, it is necessary to immediately change the oil, filling in the required type for this engine.

How to determine the source of strange sounds in an internal combustion engine

At the initial stage of the occurrence of the described problem, it is important to understand where exactly the unfortunate knock comes from. To do this, there are a number of applied techniques that do not require the use of special equipment.

Let's consider various options for the presented phenomenon, taking into account certain operating modes of the engine.

Cold engine

On a cold engine, knocking in the engine area can be a consequence of various malfunctions in the operation of related components.

As a rule, a knocking sound on a cold internal combustion engine indicates that the standard clearance values for the CPG elements and liners have been exceeded. To make sure that this is the reason, just wait until the engine warms up to operating temperature. If the knocking stops as the engine warms up, it is highly likely that the liners are wearing out.

It is worth noting that in some cases, to get out of this situation, it is sometimes enough to change the oil to a more viscous one.

Pistons

A knock in the CPG area can indicate various kinds of circumstances. As a rule, among them are:

- increased engine heating;

- water hammer;

- wear of the working elements of the CPG.

If there was overheating, there is a possibility that the rings in the pistons were simply stuck. This situation will inevitably lead to the fact that the piston begins to “walk” in the cylinder, producing a characteristic sound.

When operating a vehicle, it also happens that, as a result of water hammer, the alignment of the CPG elements is disrupted. As a result, extraneous noise occurs, characterized by knocking in the area of the cylinder block.

In addition, if the car has a high mileage, it can be assumed that the elements of the CPG have simply worn out, as evidenced by unwanted jingling in the engine area.

Video of Lada Priora piston knock

The presented video material will allow you to get acquainted with the nature of the noise of the engine CPG, using the example of the Lada Priora engine.

Fingers

The piston pins can also make noise. This happens when there is increased wear and tear. The fact of poor-quality assembly after a major overhaul of the internal combustion engine should not be ruled out.

Article on the topic: Connection diagram for a car trailer socket

Despite the established norms and standards, situations arise when it would seem that the stated requirements do not meet. Therefore, when replacing a CPG, you should not believe what is written on the box. It is best to take your own measurements or contact a specialist.

Crankshaft bearings

Crankshaft liners, like any other working element of an internal combustion engine, have their own resource, after which they simply cease to fulfill their intended purpose. In addition, they can lose their function long before the due date.

This may be due to improper operation of the car and the use of inappropriate fuels and lubricants. The knocking sound of the crankshaft liners is characterized by a systematic increase as the engine speed increases.

Connecting rod bearings

In most cases, connecting rod bearings are subject to less wear than main bearings. However, they too can make themselves felt.

Connecting rod bearings, as a rule, emit a metallic knock that gradually increases with increasing crankshaft speed..

Video noise in the Kia Sportage engine

The video clip presented below will allow you to determine the characteristics of the noise and the nature of the engine malfunction using the example of a Kia Sportage car.

timing belt

A rustling or “strumming” sound can come from the timing belt or chain. Thanks to the characteristic uniform “tinkling”, this knock is difficult to confuse with something else.

When diagnosing a car by ear, in this case you can do without a stethoscope. This noise has a number of characteristic features unique to it.

valves

Increased wear of the working elements of the distribution mechanism can cause valve knocking. In addition, incorrect adjustment of the valve clearances may also be to blame. This knock is expressed by a characteristic jingling sound in the valve cover area.

Camshaft

Another element of the gas distribution mechanism, the camshaft, also often makes itself known publicly. As a rule, this phenomenon manifests itself on a cold engine, when the lubricant has not yet had time to pass through its channels to the rubbing surfaces. The knock has a dull, barely noticeable sound.

Video of how the VW Polo Sedan engine knocks

For a more detailed understanding of the problem of engine knocking, we bring to your attention a video that clearly demonstrates engine knocking in a VW Polo Sedan.

Cooling system

The cause of premature detonation may be exceeding the permissible engine temperature due to damage to the thermostat. With such a malfunction, coolant will not flow into the radiator in sufficient quantity, which will lead to engine overheating.

If the thermostat breaks down, it is also possible for excess coolant to enter the radiator, which leads to an increased noise level of its operation. This malfunction can be eliminated by cleaning the thermostat or replacing it.

Muffler malfunction

The exhaust system of a car consists of many parts, and noise suppression starts from the engine. The more mileage a car has, the more wear and tear it wears on its exhaust system. Most often, the gasket between the muffler and the engine fails. For this reason, the noise level increases. To eliminate a malfunction of the exhaust system, in most cases it is necessary, having established the cause, to eliminate it by bringing the muffler into working condition, welding the defects, or replacing the gaskets or muffler.

Wheel bearing - metallic monotonous sound

If any bearing fails, there will be a constant monotonous hum, which intensifies at speed. The wheel bearing is the most common type of failure of these structural elements of a car. On poor roads and under high loads, such parts do not work for too long. Installing non-original bearings does not guarantee durability at all. Replacing a wheel bearing is quite difficult:

- first you need to determine whether it is the wheel bearing that is really humming;

- To do this, it is enough to jack up the car, place the stops and spin the wheel in fifth gear;

- a spinning wheel will hum after turning off the engine if the bearing is broken;

- Next, you should remove the wheel, disassemble the block of brake elements, unscrew the hub nut;

- after this, the bearing is knocked out, its seating area is cleaned and lubricated;

- in the last stage, a pre-lubricated new wheel bearing is installed;

- all systems are carefully assembled back without any changes in design;

- After installation, the bearing is checked in the same way as the old one was checked.

If the hum disappears, then the right decision has been made. But wheel bearings are quite tricky parts to diagnose. These elements in a modern car can hum just like other bearings in the structure. Also, a hum can occur due to wear on the wheel seats, and sometimes low-quality tires hum when they come into contact with an asphalt surface. So it’s simply impossible to make an unambiguous conclusion based on the sound from the front end.

Hydraulic compensator noise

At idle, an unheated engine makes noise most often due to hydraulic compensators. When replacing worn hydraulic compensators with lightweight new ones, the noise level increases, while gasoline ones make the same noise as diesel ones.

The eight-valve engine produced by VAZ does not have hydraulic compensators. For this reason, such an engine requires periodic valve adjustment. If this is not done, the specific noise during engine operation will increase significantly. The engine with adjusted valves runs almost silently.

Crunch when turning – CV joints and steering knuckles

CV joints are one of the most common reasons for car owners in Russia to visit a workshop. The turning mechanisms in the wheels of both foreign and domestic cars break down. The cost of replacement parts is quite high, so it is better to proactively check the reliability and quality of the CV joint when servicing vehicles and at every convenient opportunity. To check the performance of the CV joints, perform simple steps:

- turn the wheels completely to the right and examine the right boot of the outer CV joint for damage;

- then carry out the same procedure with the left boot and look at the mount;

- you can simply drive the car into a pit and look at the integrity of all rubber parts;

- then you can check the operation of the CV joint on the go; this will require a large platform;

- Turn the steering wheel as far to the right as possible and slowly accelerate the car in a circle;

- then depress the clutch and turn off the engine to hear the sound of the suspension;

- If at the same time a slight uneven or rhythmic crackling is heard, the CV joint fails.

As you can see, there are a lot of problems in modern cars. But this does not mean that you will spend a lot of money on repairs and maintenance. Most likely, you will be able to repair your car without any difficulties if you fix all the problems on time. This is the only condition for the normal operation of modern transport, which many drivers, unfortunately, violate.

Electrical system problems

Malfunctions of the vehicle's electrical system manifest themselves in unstable engine operation, the formation of a poor-quality air-fuel mixture, and interruptions in the functioning of the cooling, ignition and other systems. With all these malfunctions, the engine noise level exceeds normal, but they do not exhaust the reasons for the increased noise. In particular, such reasons may be worn-out engine mounts, as well as cylinder block gaskets.

Such malfunctions can be eliminated either on your own or by involving car service specialists.

Rumble and noise in the center in the front - gearbox

Transmission problems are not that uncommon in the modern world. Today, motorists can tell incredible stories about how expensive it is to repair a transmission at a service station, and this is really true. Just removing the gearbox turns out to be quite a difficult task, which makes you think about a possible change of car while the sounds are not too strong. In fact, the gearbox may not be the main cause of noise; it is worth examining the car as follows:

- put the car in first gear, then rest your hands on the front;

- push the car to the limit, then release and let it roll back a little;

- repeat this procedure to rock the car at speed;

- if the car’s range is too large, the gearbox is quite worn out;

- if knocking occurs in extreme positions, the problem may not be in the gearbox, but in the steering system;

- Often the cause of unpleasant sounds is also the attachment of the axle shafts to the box;

- After identifying the problem, you can easily replace the failed unit.

If the problem really is with the checkpoint, you will have to take the car for service; there are no other options. Repairing a gearbox in a garage is not only difficult, but dangerous. One missing small part can cause serious problems after assembly. It is better to trust this action to specialists who have sufficient experience and all the necessary professional tools.

Crankshaft fault

Increased noise levels in both gasoline and diesel engines can be caused by abrasion of the crankshaft bearings or journals, bearing wear, insufficient lubrication, or the penetration of antifreeze or water into the lubrication system.

To summarize, we can say that the main reasons for increased noise levels during engine operation are problems:

- exhaust system;

- gas distribution mechanism;

- generator, including wear of bearings or belt;

- other malfunctions in which the “engine knocked.”

The main thing is not to overdo it

Trying to somehow get out of the situation, owners increase the belt tension beyond the norm, which, in fact, does not solve the problem, but rather deepens it.

When the drive belt is tightened, the shafts (pump shaft, generator rotor, etc.) become distorted, which greatly increases the load on the bearings of the pump, generator, power steering drive, etc. The service life of the bearings is reduced several times with such excessive tension on the drive belt.

In such cases, worn pulleys must be replaced, except for pulleys that have a width adjustment (for example, ZAZ-968M), where a certain number of washers are either removed between the parts of the pulley or added depending on the situation.