Over its five-thousand-year history, the wheel has gone through a tremendous evolutionary path from a wooden disk to a rubber tire. A wheel is a component of a vehicle that is fixed and freely rotating on an axle, allowing the body to roll. Currently, numerous tire sales points offer products from different brands. There are two types of tires: radial and bias-ply. We suggest you understand the differences between these two types of tires.

Differences between bias and radial tires.

How the tire is made

Before considering the design of a radial-type product, let's look at their general structure:

- frame - serves to give and maintain shape, as well as for strengthening;

- breaker - ensures a smooth transition to the outer part, accepts, distributes, and compensates for loads from the rim;

- cord - polymer and metal threads that play a reinforcing role;

- tread is an outer covering with a specific pattern that is in direct contact with the road.

This design is considered optimal and is still relevant today. On the one hand, the wheel has nothing extra that could add to the overall weight and negatively affect the speed and maneuverability of the vehicle; on the other hand, manufacturers take utmost care of the reliability and durability of the product.

Additional tire marking parameters

- Winter - winter tires.

- A pictogram in the form of a snowflake - tires are marked for use in harsh winter conditions.

- Aqua, Rain, Water, Aquatred, Aquacontact, etc. (or umbrella pictogram) - indicates that the tires are effective on wet roads.

- AS, All Season or AGT (All Grip Traction) - designation of all-season tires

- AW or Any weather - all-weather

- M+S (Mud+Snow) or M&S - mud and snow, winter or all-season tires are specially designed to improve vehicle handling when driving in mud or snow (in slush, not to be confused with winter use - for this it is better to choose tires marked 3SMPF ( details below).

At the end of the marking there may be an “ E ” - studded tires.

- If the tire sidewall does not have the above-described markings, then this tire is intended for use only in summer conditions.

- All-Terrain is a designation for all-terrain tires with universal properties intended for SUVs.

- Max pressure — The maximum permissible pressure, measured in kPa.

- Max Load - The maximum permissible load on a tire, measured in kg (or British pounds).

- ROTATION with a directional arrow – applied to tires with a directional tread pattern, indicating the direction of rotation of the tire.

- FRT = Free Rolling Tire: This tire can only be installed on a trailer axle or free rolling axle and cannot be installed on a steering or drive axle.

- HCT = Hot Climate Technology: A tire with specific characteristics for working in countries with hot climates.

- DOT – compliance with US standards. The US Department of Transportation requires tire manufacturers to evaluate tire quality [Tire Quality Classification], with the exception of winter tires. This code identifies the company and factory, soil, batch, and production date (2 digits for the week of the year plus 2 digits for the year; or 2 digits for the week of the year plus 1 digit for the year for tires made before 2000).

- E in a circle - tires that meet ECE (Economic Commission for Europe) requirements are marked. The number indicates the country of approval.

- Reinforced (or the letters RF at the end of the size) - indicate that the tire is reinforced, used for vehicles with increased load capacity, and has 6 layers. The letter C in the size designates a truck tire with 8 layers.

- XL (Extra Load) – reinforced tire.

- Radial – tire of radial design. The same as the letter R in the standard size. Steel (steel belted) - this means that the tire structure contains a metal cord.

- Outside, Side Facing Out – the outer side of a tire with an asymmetric tread pattern. During installation, the word Outside must be on the outside of the machine.

- Inside, Side Facing Inwards - the inner side of the tire with an asymmetric tread pattern. During installation, the inscription Inside must be located on the inside of the machine.

- Retread - restored;

- Plies – tire design features – Tread area: – tread layer composition; Sidewall: – composition of the sidewall layer.

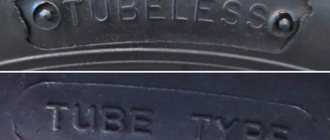

Tubeless or TL – marking of tubeless tires. The absence of this marking indicates that this tire can only be used with a tube. Tube Type, TT or MIT SCHLAUCH - the tire must be used only with a tube. Parameters reflecting the quality of tires, according to the American UTOG tire quality classification system: Traction A, B or C - the coefficient of adhesion to the road surface or the tire’s braking ability. Takes on the values A, B, C. Coefficient A means the highest value of adhesion in its class. Temperature A, B or C is an indicator characterizing the heat resistance of the tire. Possible values are A, B and C. Indicator A is the best Treadwear 200 - wear resistance coefficient, determined in relation to the base tire (it has a value of 100) of a particular manufacturer. Obtained as a result of standardized tests in the USA. TWI (tread wear index) or TWID - indicates the location of the projector wear indicators, protrusions at the bottom of the tread grooves. When the tread wears down to the level of these indicators, the tire is considered unsafe to operate and it is time to replace it. Date of manufacture of the tire (four digits, enclosed in an oval or rectangle with rounded corners) - the first two digits indicate the serial number of the week in the year, the next two the year of manufacture. DA (stamp) - minor manufacturing defects that do not interfere with normal operation are indicated. The tire also indicates: • Trademark, manufacturer's name • Trademark (tire model). • Made in... – name of the country of the tire manufacturer. FB – (Flat Base) – marking of tires without rim protection. FR – (Flange pRotector) – marking of tires with rim protection. Green X, Reduces CO2 - designations for tires with low rolling resistance, indicate fuel savings due to the use of such tires. RunFlat, RunOnFlat, HP, SSR, SST - designations indicating that these are emergency tires, making it possible to continue driving even when the tire is flat. RPB (Rim Protection Bar) or MFS – (Maximum Flange Sheild) – protects the rim from damage from curbs and sidewalks.

Tire features

Both bias-ply and radial tires for passenger cars are made of special rubber, which is made from rubber (artificial or natural). In this case, the base is made of cord fabric - tightly twisted threads of textile, polymer, or metal material, most often located longitudinally and responsible for strength.

There is a breaker on the outside - a guarantee of rigidity and shock absorber. It is covered with a tread, which is responsible for the quality of adhesion to the road surface. For better contact, a pattern is applied to the surface of the rubber; it forms a pattern of grooves and checkers to effectively remove dirt and water.

An important element that both radial and bias-ply tires have is the bead, which ensures a fairly tight fit to the rim.

The visual perception of a tire depends mainly on the tread pattern. If the pattern is identical in appearance, both options will be similar in appearance. How can one not confuse them, especially for a beginner? This is exactly the situation when you need to look at the marking and look for R (in 90% of cases) or D in the article. This will give you an idea of the nature of the cord. Let's figure out why this point is fundamentally important.

Structure of a tire

Tires can be tubed or tubeless. The first type consists of the following components:

- a chamber that is filled with air and gives the wheel the necessary elasticity;

- tires - the outer part of the tire, which has a multi-layer structure and protects the inner tube from damage.

Thus, the tire is just the outer part of the tube tire. It in turn consists of:

- frame (cord) made of metal threads, polymers and textiles;

- layers of breaker, which is located between the frame and the tread, gives rigidity to the central part of the tire and protects the tire from through damage;

- a tread that has a specific external pattern and provides traction with the road surface when the vehicle is moving;

- beads that allow the tire to be placed on the wheel rim;

- side parts protecting the side sections from mechanical damage.

With tubeless tires, air is pumped directly into the cavity between the wheel rim and the top rubber. Therefore, there is no need for a camera there. Thus, we can say that tubeless tires consist of one element - an improved tire. Of course, in order for such a tire to not go flat, it must be sealed. This is ensured by the presence of additional sealing elements on the sides and rim of the wheel.

Returning to special equipment, it is worth mentioning that various types of “shoes” of different sizes and characteristics are used for it: from 10-16.5 tires for mini loaders to 18.4-26 for excavators. Choose the option that suits you.

General information

A tire is an elastic shell that fits the rim of a wheel. Designed to absorb vibrations transmitted to the wheel during vehicle movement. In addition, the tire provides optimal traction between the wheel and the road surface, reduces the noise generated when the vehicle is moving, and softens the destructive impact of the wheel on the road. Part of some tires is the tire

Comparison

To better understand the difference between a tire and a tire, let’s pay attention to some details. So, in terms of its design, a tire can belong to one of two categories: tubed and tubeless. The design of a tube tire includes a tire. It is located outside and is a kind of rubber cover. In this case, it is the tire that is responsible for the reliable adhesion of the wheel to the road surface and performs a protective function. Under the tire, this type of tire contains a chamber that holds compressed air.

A tube tire is a suitable solution for those vehicles for which no other option is possible. However, the wheels of modern cars have long been equipped with tires of a different type - tubeless, which have a number of undeniable advantages. There is no camera as a separate element in such a tire. It is replaced by a special sealing layer. And the side zone acts as a tire in its own way.

Tire types

Among the main advantages of a tubeless tire are the absence of the risk of a quick flat tire in case of a puncture (unlike a tube tire), less heating and comparative lightness. It is also important that in many situations you can repair a tubeless tire without removing the wheel.

But let's return to the main question and try to guess why there is confusion with the name of the outer element of the wheel. Probably, from old memory, from the times when car wheels and tires were still produced. Perhaps the concepts are changed because the tire still covers something, namely the rim.

In any case, you should not verbally simplify the meaning of the tire by applying a different name to it. Knowing the difference between a tire and a tire, it would be more correct to use the terms according to their definitions.

Radial tire design

All the threads of its frame run parallel to the profile from the sidewall - they do not intersect in any of the layers. It is this feature that you should pay attention to; it is key and affects the performance characteristics of the tire (which we will discuss separately below).

Let us clarify: the abbreviation will not necessarily be indicated on board. Some manufacturers write the entire word Radial, as well as TUBELESS. This is done in order not to confuse the consumer, because the markings next to the letter R usually contain dimensions, and the letter is visually lost. For example, the code 195/65 R15 tells us about the current 195 mm width, a height of 65% of this figure and a fifteen-inch wheel diameter.

Advantages of radial tires over bias tires

The described embodiment provides:

- Relatively long service life, even in harsh temperature and climatic conditions.

- Better removal of heat generated by friction due to a small number of breaker layers, which reduces abrasion during high-speed driving.

- Low rolling resistance has a positive effect on vehicle handling.

- Less weight, resulting in economical consumption of fuels and lubricants and reduced load on the transmission.

- Safety in the event of damage - if radial tubeless truck tires are punctured, the tire pressure will quickly drop. This will allow you to get to the service station without additional risks.

- A wide contact patch, due to which the tread, regardless of pattern, more reliably adheres to the road surface (even snowy, wet or icy ones). As a result, the car's behavior on the track is less dependent on weather conditions.

That is why in 90% of cases we will see the letter R on tires.

Our production

Truck tires

Tires for special equipment

Tires for agricultural machinery

Disadvantages of this type of tires

For the sake of the most objective assessment, we will consider not only the positive aspects, but also the disadvantages:

- The sidewall is usually not very well protected from accidental cuts and does not tolerate short-term significant overloads, so falling into a hole while driving at high speed or carelessly running over an approaching curb can become a problem. These situations are fraught with pressing down to the disc, concomitant destruction of synthetic fibers and the appearance of a “hernia”.

- Products marked D are more expensive, even though there is no shortage of them today and most manufacturers widely present all sorts of variations.

- Almost every damage results in a replacement and is difficult to repair.

What is a radial tire?

A radial tire consists of a single-layer cord, which is pulled from one side part to the other so that the threads present in its structure do not overlap with each other. They are located at an angle of 90 degrees. The top layer of the carcass of this tire is covered with a special belt made of durable rigid cord (usually steel, sometimes sewn from fabric).

Radial tire

Most often, radial tires are classified as tubeless. A radial tire is usually equipped with 1 bead ring.

The fact that the tire is a radial is indicated by the letter R on its side. Sometimes the words Radial or Belted are nearby.

The main advantages of radial tires:

- high wear resistance;

- long service life;

- reduced rolling resistance (due to this, it becomes possible to use fuel more economically);

- ensuring good handling and stability of the car;

- ensuring good grip on asphalt (this is due to the large contact area of the tire surface with the road);

- ease;

- ability to withstand high loads;

- high thermal conductivity of the frame.

However, the types of tires under consideration also have disadvantages. Among them:

- vulnerability of the side part to mechanical stress;

- relatively high price.

Radial tires are considered the most common in the automotive industry. In turn, on the wheels of special technical equipment, as well as, of course, many cars, you can often find diagonal tires. Let's study their features.

What is the difference between a radial tire and a bias tire?

The main difference is in the execution of the cord layers. Usually there are an even number of them, they do not run in parallel. Adjacent threads intersect approximately in the middle of the tread due to the fact that they are placed at an angle of 35-40 degrees. They can be made from any material, but the most common are nylon and nylon options.

This structure makes it possible to provide an internal chamber for air and install two side rings at once instead of one. And this is an exclusively “internal” moment that determines the configuration; it is not visible externally.

The advantages of this arrangement of carcass threads:

- reduces the cost of production, and therefore the final cost of tires from category D;

- provides comparatively higher lateral protection.

But there are also disadvantages to this option, especially with constant and intensive use of rubber in the changing Russian climate and often broken roads. In practice, there is a significant difference between a radial and bias-ply tire. The last one, for example:

- wears out faster during intense driving;

- lasts less, even if used less actively;

- more seriously resists rolling, which negatively affects the maneuverability of the vehicle;

- weighs more, puts more stress on the transmission;

- does not increase the quality of grip on the road surface;

- it dissipates heat worse during friction, which results in wear;

- withstands relatively less physical pressure.

Thule Wingbar Edge - the ideal luggage system: features, dimensions, reviews

Radial analogues are more in demand because they have better consumer properties and are ready to offer current advantages. When it comes to the issue of bias-ply tires, they are classified as tube tires that have 2 bead rings. There is a fairly reliable frame, which is based on a multi-layer cord. Moreover, the layers always have an even number. Most often there are from 2 to 8 layers.

Their location is diagonal, that is, directed from one side to the other side. Here the crossing of adjacent threads occurs, which gives the cord a multilayer structure.

The threads themselves are made on the basis of various synthetic materials. These are mainly nylon and nylon.

Advantages and disadvantages

A list of objective advantages can be given in favor of bias-ply tires.

Among the most significant advantages, experts highlight the following:

- high strength;

- reliability of design;

- good performance characteristics;

- indestructibility;

- adaptability to complex and difficult conditions;

- an excellent solution for off-road driving;

- noticeable reduction in shock load;

- difficult to damage the product;

- low price;

- simple repair.

Bias tires are mainly valued for the last 2 advantages. But still they are not as good as they might seem at first glance.

Mostly diagonal products are used on trucks, they are installed on special vehicles, etc. In terms of equipping passenger cars, everything is not on the side of diagonals.

As for the shortcomings, the list of them is also impressive. But also more significant, which forces consumers to choose radial analogues. The disadvantages here are:

Why do people buy D-tires?

So, we have radial and diagonal tires. It seems clear what the difference between them is, which one is better is also clear. So where do those 10% who choose D models come from? Naturally, such tires are purchased not out of ignorance or mistake, but for certain reasons. The list of main reasons:

- budget deficit - you have to choose cheaper solutions, even if they are designed for a shorter service life;

- forced frequent driving on roads with deep holes - when it is necessary to protect the wheels and transmission;

- periodic impacts of foreign objects on the board are expected or observed, and profiles with the strongest possible side part are needed;

- maintainability is important for those who do not want to buy new tires after the first problems.

Popular goods

How to choose the right one?

When considering the types of tires, remember the general rules that should be followed at the time of purchase:

- It should be determined taking into account seasonality, that is, depending on the operating temperature, preference should be given to winter, summer or all-weather tires. The first is designed for frost, snowy and icy roads, the second has good grip on the road surface, but loses these positive properties at +7℃ and below. Still others are universal and focused on weather from +6…+11℃.

- It is worth paying attention not only to the nominal size, but also to the tread height, which is higher for studded versions.

- It is not recommended to install diagonal models together with radial ones - the tires of the car both front and rear must be of the same type.

- Availability is not the main thing. Remember: the cheaper the rubber, the worse the composition of its mixture and the structure of the cord, which entails unpleasant consequences.

- You should opt for a product with a directional pattern if areas of frequent travel traditionally experience significant precipitation.

- Tires with high tread are designed for unpaved and fairly sticky roads.

- For high-speed and aggressive driving, choose an option with a small number of horizontal slats.

- Keep in mind that the thicker the layer of abraded coating, the more noise, and vice versa.

What's better

Radial tires are best. Although they are more expensive and weaker to side cuts, they are more durable. Such tires can withstand heavy loads, their tread does not change shape when the car moves, which means that the contact patch of the wheel with the road does not decrease. Less wear and longer tread depth.

Good handling at all speeds and types of surfaces. Resistant to frontal puncture, less weight, which means fuel economy .

Therefore, tires with radial cords are more popular. They have even found application in agricultural machinery. Thanks to their design, they redistribute the weight of the vehicle over the entire area of the wheel without damaging the root system of plants.

To Contents...

Comparison of tire designs, radial and bias

For clarity, we present all the main differences in table form.

| Property/Option | R | D |

| Number of cord layers | one | some |

| Threads | run parallel | intersect at 35-40° |

| Number of side rings | 1 | 2 |

| Wear resistance | big | small |

| Lifetime | long | almost 2 times lower |

| Effect on handling | improved due to a wide contact patch | do not have any positive effect |

| Rolling resistance | insignificant | significant |

| Load resistance | strong | weak |

| Availability of camera | No | There is |

| Comparative weight | easier | heavier |

| Thermal conductivity of the base | high | low |

As you can see, there are quite a lot of nuances, but we want to draw attention to the key feature of the structure. Since the carcass threads in a radial tire are parallel, it is more suitable for high-speed driving. That is why R-category tires are used to equip Light Truck class vehicles, while D-category tires today are installed primarily on excavators, tractors and other special-purpose vehicles that, due to the nature of their activities, do not have to move quickly.

Diagonal tires - advantages and disadvantages of the model

To make a bias tire, a frame is built. As a rule, fabrics made of viscose, nylon and metal are used, in which the main cores are located at an angle of 45°-55°. One layer is 1 strip of fabric with left or right direction of threads. 1 belt is made from 2 fabrics, stacked on top of each other through a layer of rubber. The more layers, the stronger the tire.

The diagonal cord construction has been used for many decades. It is shock-resistant and softer in motion. Rubber is easy to repair. Even after a side cut, the retreaded tire can be used under load as before the damage.

!Radial tires after side cuts are recommended to be installed on the rear axles or used as a spare wheel!

What other features does a bias tire have?

- Advantages: low cost;

- ease of repair;

- durable sidewalls;

- off-road efficiency.

- wear out quickly;

Bias tires are used today in the construction or mining industries. They are installed on loaders, tractors, wheeled excavators and other types of special equipment. They are mainly used with a camera, so they are marked TT (Tube Type).

How to install an R-tire: nuances and features

- Mount directional models (and even roll them into the garage) according to the vector of their movement, which is indicated by the arrow on the side.

- Place the spare tire on the assumption that, if used, it will most likely be located on the right side, as statistics suggest.

- Place asymmetrical ones so that the inscription Inside is on the outside.

We looked at what diagonal and radial tires are, how they differ from each other, now we’ll talk about their common features. Both the first and the second need to be looked after regularly - periodically inspected, paying special attention to the condition of the tread and side parts. If you find any visually noticeable defects, you should immediately contact a service station to have the tire examined by specialists. The presence of damage is also indicated by a change in the behavior of the car while driving - if the car moves to the side during maneuvers, then there is definitely a problem.

Wheel in galoshes

In 1910, the American company BF Goodrich Company began adding highly dispersed amorphous carbon or simply soot to the rubber mixture to increase strength. The rubber abraded less, but the elasticity of the wheel immediately decreased. Therefore, engineers decided to make the tread and tire as separate elements.

Back then, tires were made from natural raw materials and were white or beige. And the tread with carbon soot inside turned out to be black. As a result, the lower black casing of the tires looked like galoshes. A disposable tread was installed on reusable tires and the wheel was used much longer than usual. Such black and white tires can still be seen on restored vehicles, as well as in films of the twenties.

Removable tread was used for some types of tires until the sixties. In the sixties, similar composite wheels were produced by the Yaroslavl Tire Plant for GAZ trucks. However, as speed and load increased, this design turned out to be ineffective.

To avoid slippage of the removable tread and its failure, they began to make a monolithic tire. The tread was welded on top, like other layers of rubber. The rudiment of these technological processes is now the so-called vulcanization, in which old truck tires are given a new tread.

Marking

When purchasing, be sure to pay attention to the inscription on the board - the symbols will show you what this or that model is. The article contains all the data: type, what a radial tire means, direction of tire installation, main dimensions, and so on. But how to read it?

Let's say you see 225/70R15. Here 225 is the width in millimeters, 70 is the height, expressed as a percentage of the previous value, 15 is the diameter in inches, well, you already know what the letter R means.

The recording format may be different, without the “/”, for example, 185R14. This only indicates full-profile performance. Some manufacturers are increasingly beginning to indicate all parameters in millimeters, and then the marking takes the form of 265/790R540.

Please note: on D-group tires, all sizes are often written in inches, without letters or separators, please take this into account.

So, we have looked in detail at how to distinguish a radial tire from a diagonal one, even if outwardly both of them look almost the same - look for the coveted letter R in the article number.

Popular models of summer radial tires

Many manufacturers offer their products, from which the best models can be selected so that they meet all the necessary requirements and last a long time.

All car tires have their own distinctive characteristics. The use of a particular type of tire for transport depends on its purpose and operating conditions. The radial tubeless tire is currently the most popular tire used on passenger cars.

Source