Installation of a turbine on an 8 valve VAZ 2114 engine

Installing a turbine is the most common way to improve the power characteristics of VAZ cars. Atmospheric modification of the engine with a cylinder head bore, a sports exhaust system and sports shafts will be more affordable, but it is limited to a limit of 120-130 hp. Proper turbocharging allows you to remove more than 200 horses from a car.

When choosing between turbocharged and naturally aspirated engines, proceed from the tasks assigned to the car. Refinement of the naturally aspirated engine allows you not to get lost in city traffic among more powerful foreign cars. Turbo is better for racing.

In addition, it is almost impossible to legalize a turbo engine in a VAZ in Russia.

INSTALLING A TURBO ON A VAZ 2114: WHERE TO START

Installing a turbine on any car begins with a thorough examination of the hardware. You can’t just go to the store and buy a ready-made kit. And even if it is possible, the system will still have to be modified.

Turbocharged engine VAZ 2114

If you take on this task, consider the following:

- A number of stock units of the VAZ 2114 are unsuitable for a car with a power of over 150 hp. It will not be possible to do without re-equipping the suspension and brakes, installing wider wheels with a turbo engine.

- Tuning foreign cars is partly easier if the model being tuned has “bigger” brothers with turbo engines. Tuning usually comes down to searching, purchasing and adjusting ready-made factory units. It’s more difficult with Togliatti-made cars - VAZs don’t install turbines. Fortunately, in large cities there are tuning studios that develop and produce tuning parts. True, their products are mostly unlicensed, so there will be problems with legalizing changes.

- The correct choice of turbine is the key to successful turbo tuning. Before realizing your dream, we recommend that you read brief descriptions of the turbines used to modify the VAZ.

TURBINES FOR VAZ CARS

There are many options for installing a turbine on the 2114 model. Theoretically, anything can be adapted, but the following models are best suited for an 8-valve engine:

- Garret 1752;

- Mitsubishi TD04 (installed on Mitsubishi Lancer EVO, Subaru Impreza WRX, and some other models);

- IHI VF10 (this model was equipped with the 1st generation Subaru Legacy cars), as a variant of the VF11-20 (stock for the 2nd generation Legacy);

The list can be expanded with dozens of positions, including more powerful turbines TD05, TD06, VF23-30.

Moreover, if there is not enough money for new equipment, it is not difficult to find used kits in decent condition due to the transition of their owners to more powerful equipment

TURBO KIT GARRET 1752

Turbo kit Garret 1752

Turbines from Garrett are consistently among the most popular among VAZ owners.

Among the reasons for this:

- sold as a ready-made set, there is no need to assemble individual elements using spare parts at car dismantling yards;

- relatively low cost (a new set will cost 30-35 thousand, used ones can be found in the range from 15 to 25 thousand);

- without any special modifications, you can remove the boost from the car to 0.5 bar, increasing power to 120-130 hp. and torque up to 180-200 Nm;

- with additional modifications to the boost system, the boost can be increased to 1 bar, power – up to 170-200 hp, and torque – up to 240 Nm.

The boost kit from Garret is optimal for novice fans of turbo tuning. By setting the boost to 0.5 bar, you can get a good increase in power without reducing engine life. For serious “rides,” this option is not suitable due to its limitations.

Why Center Turbin?

Each client who contacts us is provided with qualified assistance in selecting power equipment. Website visitors can use online consultation and ask the manager all their questions. We have established ourselves as a successful and reliable company with great development potential. We sell original products from world-famous brands. Here you can find a turbocharger for any type of transport:

- cars;

- special equipment and agricultural machinery;

- commercial transport.

All turbochargers come with a one year warranty. In addition, we guarantee:

- new spare parts with factory parameters;

- prompt and high-quality work;

- excellent level of service.

It is very easy to purchase a turbine from us. On the page of the selected product, click the “Buy” button, then go to the electronic shopping cart and provide all the necessary information. For customer convenience, we offer several delivery and payment methods. Well-established courier services will allow you to receive the necessary goods in the shortest possible time.

TURBINES BASED ON TD04 TURBO-COMPRESSOR

Turbine TD04L with actuator

The Mitsubishi TD04 compressor and its various invariants (TD04H, TD04L, TD04HL and others) are one of the most common Japanese turbo systems in Russia. Installed on Mitsubishi Lancer Evolution IV-V generations, turbodiesel Mitsubishi Pajero, as well as many Subaru models of the mid-1990s.

The advantage of this compressor is that in the factory version it made it possible to extract a solid 280 - 340 Nm and 280 hp from 1.6 - 2.0 liter engines. In addition, it is compactly placed under the VAZ hood.

High-performance turbos like the Garret GTX30 (installed on the Toyota Chaser or Mark II and German BMW e39 cars) are more difficult to place under the hood. There are precedents, but doing it on your own is not easy.

The build quality of the Japanese turbine is higher than the Chinese Garrett, and the resource reserve allows you to purchase even well-worn equipment. A distinctive feature of the turbine is its flat torque level. Peak performance varies depending on the type of compressor and additional equipment.

For racing where acceleration is of paramount importance, it is better to consider other turbos. On tracks with long straights, where it is possible to fully use the maximum revs of 4 - 4.5 thousand, the TD04 can compete with more productive models.

TURBINES BASED ON IHI VF10 COMPRESSOR

Turbocharger VF22

Subaru has experimented with turbo engine configurations more than other manufacturers. On the same WRXs you can find Garretts, and the famous Apexi, and Mitsubishi. Not the last place in this series is occupied by the American manufacturer IHI, whose superchargers were installed on legendary cars like the Chevrolet Camaro.

VAZ is equipped with many variants of turbines from IHI, including:

- VF22

- VF23

- VF24

These are classic drag racing turbos that boost extremely quickly, already at 2800-2900 rpm.

The VF10 is less powerful than either of these options. Peak power is about 250 horses (rarely, with very professional tuning and a strong reduction in resource - up to 300). By comparison, the 20th and 30th numbers are capable of developing up to 325 or more horses. But for the VAZ engine, the “ten” (as well as the VF11-20 turbines similar to it), according to many turbo experts, is optimal.

When compared with the TD04 and even the TD05, the VF10 will be faster at the bottom, but the turbo lag will be more noticeable. A VAZ 2114 with such a turbine will feel better on drag or in circuit racing with a minimum of long straights.

TURBINE INSTALLATION: PURCHASE OF PARTS

Assembling a turbo car is a creative process; much (if not all) depends on the construction kit you assemble.

It is impossible to give unambiguous advice here - all answers are only specific.

In the VAZ store you will need to purchase:

- new pistons (usually Niv ones are used);

- rings (the higher quality the better);

- cylinder head gasket (iron, suitable from Kalina for 8 valves);

- fuel regulator at 2.5-3 bar;

- throttle;

- vacuum tubes, tees, bends, etc.

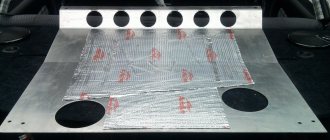

Simple turbo kit for VAZ 2114

If you buy a ready-made turbo kit, everything is simple. We order and receive. If not, online stores, Japanese car dismantling yards and other e-bay are available. You will need:

- turbocharger (from the above or whichever you like);

- gaskets (pipe, downpipe, oil drain);

- inlet receiver;

- exhaust manifold (there are ready-made solutions for Garrett and TD04; for other turbines you will have to assemble it yourself);

- a set of pipes, clamps and other small things (ready ones available);

- intercooler (you can start without it, it gives an additional increase of up to 10 hp);

- fuel pump (with a capacity of about 250 l/h, the better the quality, the better);

- injectors (budget option - from Volga, more productive - from Subaru or Mitsu Evo);

- blow-off (bypass valve for excess air pressure in the turbine, deserves a separate discussion);

- boost controller (for the VAZ 2114 it is better to use a mechanical one, it is simpler and cheaper, however, you can install an electronic one);

- absolute pressure sensor (ABP), air temperature sensor (ATS), turbine pressure sensor (TP).

The budget can start from 40-45 thousand rubles and tend to infinity, depending on the cost of components and the amount of work performed in the tuning studio.

INSTALLATION: PROCEDURE

Turbocharging an engine is a lengthy process. Plans to “turban for vacation” are practically impossible. Plan your time in advance. If the car is your main one, it makes sense to think in advance about purchasing a temporary means of transportation.

Most turbocharging features are unique to different models of compressors and other equipment. The description below is average and schematic.

Stage 1. Preparing the motor . The engine is disassembled, a complete inspection of the cylinders, crankshaft, connecting rods, liners and oil pump is carried out, and the block is polished. Pistons are purchased after preparing the cylinders (boring may be required).

The cylinder head is checked (if necessary, the cylinder head is ground), hydraulic compensators and valves can be used as standard.

Stage 2. Assembly of attachments. New injectors are installed and the fuel pump is replaced. VAZ 2114 engines with 8 valves have a number of advantages compared to 16-valve engines. Firstly, there is no need to be clever with the return. Secondly, it is much easier to connect the fuel pressure regulator.

Next, installation of the receiver, installation of the exhaust manifold, fitting of the turbine. If you purchased an intercooler, we find a place for it and install it. We install piping and blow-offs. We are preparing the oil and cooling supply to the turbine. We remove the air flow sensor and install the DBP and DTV system.

Stage 3. When everything is assembled and secured, there is confidence that nothing is leaking anywhere, the most difficult part begins - setting up. All horsepower, Newton meters and fuel consumption depend on the skill of the tuner. There are good turbo specialists in large cities - do not spare money on their services, otherwise a much larger sum will go down the drain.

A good boost is the result of intellectual work and skill. For the results to justify themselves, remember: there can never be too much information. Study the question thoroughly - the result will amaze you.

Why is a turbo engine needed?

When installing a turbocharger on a car engine, compressed air enters the engine cylinders. It occupies the same volume as before installing the turbine, but due to compression, its specific mass increases. It becomes possible to proportionally increase engine power.

Fuel consumption does not increase when installing a turbine. This is achieved by increasing the density of the air as it cools in the engine cylinder. Emissions of combustion products are also reduced.

The most commonly used compressor is exhaust gas powered. It is driven by the flow of exhaust gases to the compressor drive. As a result, fuel and engine energy are not wasted additionally, as with a mechanical compressor drive.

A little theory

Toyota Sera 1.5 turbo 4WD Serafima Logbook MythBusters FHE connecting rods

Such improvements can be carried out more effectively by those who have a clear understanding of their own actions. To do this you need to understand the theoretical part.

So, the car’s power and fuel consumption depend on the properties and degree of enrichment of the fuel-air mixture entering the cylinders, as well as on its volume.

The fact is that an ordinary engine, when operating, pumps air into itself due to the vacuum created by the piston. In a turbocharged power unit, this work is done by a turbocharger. At the same time, the air is compressed earlier, which allows you to pump in a larger volume. In other words, you can burn a larger volume of fuel. The result is an increase in engine power in relation to engine volume and fuel consumed.

One fundamental point: air, as is clear, heats up under strong compression. Secondly, it will heat up during compression in the combustion chamber. With all this, detonation may occur. And, in addition, due to heating, the air density in the cylinder will decrease, which will naturally reduce the efficiency of the entire system. To remove these bad phenomena, intercoolers are used - air coolers from the turbine. They are a radiator.

As already mentioned, there are two types of compressors:

- A turbocharger that operates by using the energy of exhaust gases. The processed gases enter the impeller and spin it, which is why air is pumped;

- Mechanically driven compressor. It is powered by a motor drive. With all this, efficiency decreases and fuel consumption increases compared to the first version of the compressor, because the mechanical supercharger takes away part of the power from the internal combustion engine.

The entire system, not counting the turbine itself, contains several more fundamental components that need to be kept in mind during installation:

- a control valve that maintains this pressure;

- a bypass valve, which ensures that compressed air returns back to the compressor inlet pipes if the engine throttle valve is closed;

- a bleed valve that releases compressed air into the atmosphere when the throttle valve is closed;

- air pipes;

- oil pipes (serve for lubrication and cooling of the turbine).

Hi all ! In this video I will talk about the design of a turbo engine in our implementation. Enjoy watching.

Refinement and modernization of the carburetor. The main shortcomings of the carburetor injection system and methods for eliminating them, settings. Intake manifold tuning.

Advantages and disadvantages of the turbine

As a result of using a correctly selected turbine, engine characteristics, including those on the VAZ 2114, are improved:

- Fuel consumption is reduced compared to other ways to increase engine power.

- The ratio between the weight of the engine and its power is optimized.

- A turbocharged engine is quieter than an engine with the same power without a turbocharger.

The disadvantages of using turbines include:

- The need to change oil and filters more often. In this case, only special oils can be used.

- Short service life of the turbocharger, the need to replace it.

- The effect of an “air hole” or “turbo lag” when starting the engine is due to low crankshaft speeds and a small amount of exhaust gases, which are not enough to start the turbine.

Mechanical supercharger for VAZ - pros and cons

The larger the engine and the more cylinders it has, the higher its power. This is the very first conclusion when observing motors and machines. But this is not always the case. The more fuel burned in the engine cylinders, the more power it can produce. But the cylinder volume is finite, and I want to have increased power. This is where a mechanical air blower comes to the rescue.

The principle of its operation is extremely simple and works on any car, including the VAZ 2107, 2106, 2114, 2112 family - it provides additional air to the engine, resulting in:

- the purging of the cylinders increases, and they are better freed from the remains of burnt fuel;

- more fuel enters the engine cylinders, which ensures more power;

- The compression ratio increases, which also gives an increase in power.

This approach is almost similar to the turbo mode used on diesel engines. Only there, for these purposes, a turbocharger is used, driven by exhaust gases, and in this case, a mechanical air blower, which is connected to the engine crankshaft by a belt. This approach is much simpler, the air supply depends on the engine speed, the higher it is, the more air is supplied; and also does not require ensuring the operating modes of the turbine and can be done with your own hands on any VAZ car.

Do not forget that you are boosting a VAZ engine, be it any of its models 2107, 2106, 2114, 2112, the work must be carried out comprehensively, and only then is it possible to obtain the expected result. However, this is not such a big price to pay for the increase in power.

Turbine for VAZ 2114

The choice of turbine for a VAZ 2114 8 valve has its own characteristics. First of all, this is due to the fact that the AvtoVAZ plant does not produce turbo engines.

Therefore, it is necessary to select turbines from foreign manufacturers that are suitable for an 8-valve engine:

- Garret 1752 turbines (made in China) - most often used when installing a turbo on a VAZ 2114 8 valves. Their advantages:

- sold as a ready-made set - there is no need to assemble all the components separately;

- reasonable price compared to other manufacturers;

- do not require complex modifications to the engine to achieve power of 120-130 hp;

- upon modification, a power of 170-200 hp is achieved, and torque increases to 240 Nm.

- Mitsubishi TD04 and different variants of this compressor:

- has compact dimensions;

- large resource of work;

- high build quality;

- without modifications it is capable of accelerating the engine to 280 hp. power and torque 280 – 340 Nm.

- IHI VF is a turbocharger made in the USA (previously it was equipped with Subaru Legacy I). For VAZ you can use IHI VF10, VF 20-24. Their advantage is high peak engine power (from 250 to 325 hp depending on the turbine model). The disadvantages include noticeable turbo lag when starting the engine.

Important ! The factory suspension and braking system of the VAZ 2114 are unsuitable for using a high-power engine (more than 150 hp). Therefore, when installing a turbo system, it is necessary to further tune them. It is also recommended to increase the width of the wheels.

How to make a turbo engine for a VAZ 2114 yourself

There are various ways to increase the power of a naturally aspirated engine: by boring the cylinder head, installing sports shafts or improving the exhaust system. This is a budget option, but makes it possible to increase power by no more than 130 hp. Installing a turbine allows you to reach 200 hp. This option is more suitable for racing.

Some nuances of turbo tuning

Before you begin work on upgrading the power unit on the VAZ 2114 model, you should study its system and choose the most suitable option, taking into account the capabilities of the engine, design, your own technical knowledge and experience in repair work.

Some components of the VAZ 2114 do not allow the installation of an engine with a power exceeding 150 hp. For a turbo engine, you will need to upgrade the brakes, suspension, and install wider wheels. Foreign brands are easier to modify, since they include a turbo engine in the range of models. Therefore, to modernize a foreign car you just need to buy the necessary components.

The situation with VAZ cars is more complicated, since the plant does not produce them with turbines. In big cities there are workshops that develop and produce tuning parts. But they operate without a license, which is fraught with problems for legalizing modifications.

Having decided to increase the power characteristics of the engine by installing a turbine, you need to study the existing options for turbo installations, which ones are better suited for VAZ cars. The right choice will make the car more powerful with minimal costs and modifications.

Selection of turbine units for VAZ

The car market has a fairly wide selection of turbines that can be used for tuning the VAZ 2114. The main problem is the number of modifications. The following models are suitable for an eight-cylinder engine:

- TD04:

- Garret 1752;

- IHI VF10.

The listed models are the most common, they can be repaired, and have a low cost. On the market you can find a used turbine in good condition, the owner of which has acquired a more powerful system. This will save money. You can consider other options for turbines with higher power, but modernization in this case will be more expensive.

Japanese compressor TD04 from Mitsubishi

Turbines with this compressor and analogues are widely used among VAZ owners. At one time, these were installed on Mitsubish turbodiesels, in particular on Pajero and Lancer EVO, as well as on various Subaru models.

The advantage of this installation is that it allows you to increase the power of 1.6-2.0 liter power units to 280 hp. In addition, the compressor does not take up much space and is easy to place in the VAZ engine compartment. High-performance turbines from other manufacturers are more difficult to place under the hood; they were placed in the body.

The service life of turbines of this type is impressive, which allows the use of equipment that has traveled many kilometers. The quality of the Japanese assembly speaks for itself; it is much higher than its Chinese counterparts. The compressor is distinguished by a flat torque shelf. Maximum performance depends on the type of turbine and installed equipment.

If acceleration is important, for example for racing, then it is better to choose a different type of turbine. On routes with a predominance of straight roads, where you can make the most of 4-4.5 thousand rpm, the TD04 can outperform models with higher efficiency.

Turbo kit GARRET 1752

This type of turbochargers occupy leading positions in the car tuning market for owners of Togliatti models. This happens for a number of reasons:

- is sold as a kit, which eliminates the need to search for individual components from different car disassembly sites;

- relatively low price, you can save additional money by purchasing a used kit;

- With minor modifications, the car receives improved characteristics; with significant changes, the performance doubles.

The GARRET kit in question is more suitable for beginner tuning enthusiasts. Installing a compressor with a boost of 0.5 bar allows you to increase power quite well. To obtain more powerful indicators, this option is not suitable, since the capabilities are limited.

Turbocharger from IHI VF10

Subaru, more than others, installed turbine configurations from different manufacturers on its models: Mitsubishi, GARRET, Apexi, as well as products from the American company IHI, which were equipped with Chevrolet Camaro models.

For VAZ cars, various modifications of IHI turbines are used. These are traditional turbo tuning setups. They achieve the required pressure in the turbine as quickly as possible, starting from 2.8 thousand revolutions. The performance of the IHI VF10 is lower than the listed options.

Maximum power is achieved at 250 hp, in rare cases up to 300 hp, but with a significant reduction in engine life. Many specialists in turbocharged engines consider IHI turbines of the VF10 and VF11-20 types to be optimal for the VAZ 2114. The car behaves briskly at low speeds, however, the turbo lags are felt more. He feels great on circuit races, on long straights.

How to make a turbocharged engine correctly: step-by-step instructions

The set of spare parts for assembling a turbo engine depends on the designer, which is assembled by the car owner himself. At the auto store you need to purchase:

- it is better to take a gasket for the cylinder head from Kalina;

- quality rings;

- throttle;

- new pistons, suitable from Niva;

- fuel regulator 2.5-3 bar;

- fastening material;

- vacuum tubes, etc.

It is advisable to purchase a turbo kit, which contains all the necessary parts. Otherwise, you will have to look for Japanese spare parts from car dismantling yards. It is necessary to purchase the following components:

- turbocharger;

- an exhaust manifold in which the turbine is located at the bottom;

- gaskets between the manifold and turbocharger;

- inlet receiver;

- front intercooler;

- fuel injectors are suitable from Volga, but from Subaru and Mitsubishi EVO are more productive;

- boost controller;

- gasoline pump;

- sensors: turbine pressure (TD), air temperature (DTV), absolute pressure (DAP);

- bypass valve;

- exhaust flange;

- oil supply;

- blanks and air line connectors.

The list of parts depends on the desired result that you want to get after modernization, and on financial capabilities.

The process of turbocharging an engine takes a long time. First you need to prepare the power unit and make all the necessary modifications. Each type of turbine and attachment requires its own set of actions.

In general, the installation consists of the following main steps:

- Engine preparation. We disassemble the unit and carry out a full check of the connecting rods, oil pump, cylinder-piston group, liners, and crankshaft. If necessary, we carry out grinding of the cylinder head. First you should prepare the cylinders, and then buy the pistons. Standard valves and hydraulic compensators are suitable.

- We install attachments. We are replacing the fuel pump and installing new injectors. 8-valve engines have advantages compared to 16-valve engines, since it is easier to attach a fuel regulator to them and there is no need to bother with the return line. Next, we install the exhaust valve, receiver, and try on the turbopump. If you purchased a front intercooler, install it in a free space. Next, install the bypass valve and painting. We provide cooling and oil supply to the turbine. We dismantle the mass air flow sensor and install the air pressure sensor and air pressure sensor.

- After final assembly, we check the reliability of the fastenings and the presence of leaks. We eliminate detected defects. Now that the turbo system is completely ready for operation, we configure it. The newly acquired engine power characteristics and fuel consumption depend on the quality of the tuning. It is better to turn to highly qualified specialists to justify the financial investment and get a turbocharged car.

To achieve the best result, you need to thoroughly study the vehicle equipment requirements for installing a specific turbine model and take them into account during assembly.

Installation of a turbine on a VAZ

How to install a turbine on a VAZ 2114

Installing a turbine on a VAZ 2114 requires preliminary preparation.

You need to purchase spare parts for VAZ in the store:

- new pistons and rings (possibly from Niva);

- cylinder head gasket;

- fuel pressure control;

- throttle valve;

- vacuum tube system.

If the turbo system is not supplied as a kit, but only a turbocharger is available, you need to buy:

- intake receiver and exhaust manifold;

- fuel pump - preferably with a capacity of 130 liters per hour. Submersible gasoline pumps from various manufacturers are suitable for injection-type engines. When selecting, you need to focus on the desired engine power;

- fuel injectors with the ability to supply a larger volume of fuel - possible from Volga or Subaru;

- overpressure relief valve;

- boost controller – a controller for regulating turbocharger pressure. It can be mechanical or in the form of an electromagnetic valve;

- pipes, clamps, gaskets, etc.

Be sure to purchase new sensors - absolute pressure and pressure in the turbine, and air temperature in the intake manifold.

Next, it is necessary to inspect the engine - disassemble and fully inspect its key mechanisms (cylinders, valves, crankshaft, oil pump, etc.). If necessary, replace with new ones. Spark plugs and ignition system wires may also need to be replaced.

Sequentially install all components of the turbo system. To adjust the operation of the turbo engine, it is advisable to seek the services of a specialist.

Thus, installing a turbocharger on a VAZ 2114 can significantly increase engine power and improve vehicle performance. The main thing is to choose the right turbocharger and components, and take a responsible approach to installation and configuration issues.

How to install an air blower yourself

There are several approaches that allow you to install a mechanical air blower on VAZ family cars with your own hands. This means making a device yourself that provides turbo mode or boosting the engine, or using a ready-made KIT kit.

Homemade supercharger for VAZ

With this approach, the mechanical air blower will be decisive. The entire future design depends on it. The main thing is to find an air supercharger from an imported car that meets the requirements, or you will have to use a homemade one. This is also possible, and in this case suitable parts and components from completely unexpected devices, for example, a vacuum cleaner, are used.

When making such a homemade air supercharger, you need to take literally everything into account - dimensions, weight, placement in the engine compartment, how and where the drive pulley and belt will be located, the performance of this device, operating modes (short-term or long-term), the possibility of lubrication and much, much more. Once the compressor becomes clear, it is necessary to calculate the implementation of the turbo mode for the engine.

Even the far from complete list of questions shown shows that making a homemade air supercharger for a VAZ of any family, be it 2107, 2106, 2114, 2112, is quite difficult, but possible. An example would be a photo showing that such work has been successfully completed. True, this is not a VAZ, but the fact itself is important - it is possible to make a homemade air compressor in which its drive unit is connected to the engine crankshaft.

Do-it-yourself drive supercharger - from a KIT kit

Yes, there are such kits on sale that allow you to implement the turbo mode in VAZ 2107, 2106, 2114, 2112 cars with your own hands. As a rule, it includes everything needed to assemble and install such a device on a car - the compressor itself, belts, drive unit , brackets and air ducts. What such a kit is like can be seen in the photo below.

As an advantage of implementing the turbo mode in this way, it is worth noting that it is tailored specifically to VAZ cars of one model or another (2107, 2106, 2114, 2112). The advantages of this approach also include the fact that under some conditions, when the level of additional pressure created is not more than half a bar, no intervention is required in the vehicle’s fuel system.

Turbocharging for a VAZ, who cares

Turbocharging on a VAZ is certainly exotic. But the power advantages of turbo engines over “aspirated” ones themselves encourage the emergence of more and more cars that received a turbine. And not all of these cars are foreign cars...

Theory

Let's start with the theory. There is simply supercharging (mechanical supercharging, charger) and there is turbocharging. In both cases, the boost is created by a turbine installed between the air filter and the intake manifold. The difference is what exactly drives it.

In the first case, the engine itself turns the turbine. One of the advantages is the direct dependence of the turbine speed (the pressure created by the turbine) on the speed, i.e. no delayed reaction (turbo lag). The downside is that the engine spends part of its power spinning up the turbine.

Turbocharging is more complicated because consists of 2 turbines. One pumps more air into the engine and is driven by another turbine, which is installed immediately behind the spider (exhaust manifold). Thus, the chain looks like this: exhaust gases rotate one turbine, which is connected to a second turbine that forces air into the engine. The advantage of turbocharging is that it has greater efficiency because does not require engine power to rotate it. Minus turbo in the presence of the “turbo lag” effect. What does it look like? You sharply press the gas to the floor and wait for an instant response from the engine. And in order for a turbo engine to produce maximum power, it is necessary to sufficiently spin up the turbine, which “comes to life” only when the engine reaches 3000-3500 rpm.

Turbines can be conditionally divided into 2 groups: low pressure (up to approximately 0.2-0.6 bar) and high pressure (up to 1 bar and above). If a high-pressure turbine requires a fairly serious modification of the engine, then for a low-pressure turbine you can leave almost everything factory, but more on that later.

In fact, the main goal is to get the maximum possible number of horses. Well, at least for those who like to drive so precisely J With the same displacement, a turbocharged engine can have almost 2 times more power with approximately the same fuel consumption. So, small-displacement turbo engines have recently come into fashion. Fiat has been building small city hatchbacks with turbo engines and the dynamics of a sedan with a 3-3.5 liter engine for quite some time. A simple example of this is the Fiat Grande Punto with a 1.4 turbo engine with a power of 120 to 150 horses, and in some modifications up to 180. However, similar engines appeared in VW.

How can you boost a turbocharged engine?

The specificity of these engines is such that if some improvements give practically nothing on naturally aspirated engines, then on turbo the results obtained are simply amazing. A simple example is forward flow. Many people have the opinion that with it the engine “breathes” and spins easier, our forum is proof of this. But these are only subjective opinions. If in the case of a naturally aspirated engine the power is given more by the sound than the forward flow itself, then with a turbo, with the correct intake and exhaust you can achieve very good results.

The picture is the same with such a popular modification as chip tuning. If this procedure gives an aspirated engine no more than 10% of power, then a turbo will easily give up to 25%

Installation of turbocharging on a VAZ

Let's consider a more budget-friendly option, in terms of modifications, with a low-pressure turbine and a VAZ 21083 engine with distributed injection.

The cylinder block, crankshaft and connecting rods can be used as standard. Camshaft and valves too. The difference may be in the pistons and cylinder heads because... installing a turbine requires reducing the compression ratio. And this can be achieved either by enlarging the combustion chamber, or by using special pistons. Although you can leave the original pistons and limit yourself to just the head.

The exhaust is also different - there is now a turbine between the exhaust manifold and the exhaust pipe. The resonator and muffler can be used as standard ones, although a direct-flow exhaust can be installed to obtain more power.

The injection needs a larger receiver and a non-standard control program. The lubrication system will also require minor changes.

Low pressure turbine - at your discretion and capabilities. In the case of a VAZ, the turbocharger is mounted above the right wheel drive between the exhaust manifold and the exhaust pipe. The compressor is supplied with 2 air pipes. The first is connected to the air filter, and the second to the receiver.

Thus, the most expensive and scarce part is the turbine itself.

Remember also that in addition to the engine, you will also need to modify the brake system and, quite possibly, the transmission.

How to Install a Turbine on a VAZ 2107 Carburetor

Turbine for VAZ 2107

According to tuning specialists, the turbine on the VAZ 2107 is not a business that appreciates, from the category of those about which they say “the production work is not needed.”

The idea of a turbine in itself is not bad, and with its implementation you can significantly increase engine power (for example, a 2-liter engine up to 700 hp) and torque on almost any model. It is only on VAZ vehicles that this is problematic.

The features of a classic carburetor engine are such that installing a turbine is quite difficult, troublesome and expensive. When installing a turbine on VAZ models, it is necessary to have an intercooler (to cool the air heated by the turbine), which still does not give the expected effect. Then. The turbine on the VAZ 2107, like other classics, is unsafe for installation, unlike the compressor. There is a great danger that the exhaust manifold cannot withstand the high pressure created by the turbine. What does this mean? no need to explain. Having decided to install a turbine on your forward-thinking (or overlooked) VAZ 2107, sooner or later, you will have to change (or change) the engine to an injector.

All this will take hundreds of hours and tens of thousands of money. The question is in the name of what? It's clear that you are a greedy tuner and decided to get something like this:

(1.7 liter engine from Niva, turbine, 5-speed manual transmission, front brake discs with perforation, rear discs, rims.R15, Goodyear Tire F1 tires 195x50, body kit, rear lighting neon lining, JOM leather sports seats, salon equipment)

https://youtube.com/watch?v=5yyMEMSvleI

VAZ 2107 turbo carburetor!!!!

VAZ 2107 volume 1.6 l carburetor. turbine from skyline!! completely fucked up.

DESIGN REVIEW VAZ 2101 1.6 turbo carburetor 2014 / turbo carburetor review

Hi all! In this video I will talk about the design of the turbo engine in our design. Enjoy watching.

And if you want, like any driver, to improve engine performance even at traffic lights, and not accelerate by 20 seconds and at least 8-10, take an interest in the “Kit-kit” (0.5 bar compressor, increases power to 45-50%). Drive pump installation kits have been developed for all domestically produced models. They are characterized by their small size, low noise level in operation and high reliability.

Structurally, the supercharger consists of two parts: a centrifugal compressor and a high-speed multiplier.

Drive is via a poly-V belt from the engine crankshaft pulley. The compressor is not serviced during operation

When installing on foreign cars, you can orient the direction of the cochlea head relative to the position of the air duct.

The outer diameter at the compressor inlet is 74 mm, at the outlet. 62 mm with a coil diameter of 195 mm. The high-speed multiplier is assembled on rolling bearings of a special high-speed series. Replacement is carried out every fifty thousand kilometers of the car. Torque is transmitted by a PJ series polypropylene belt. Replace every fifty thousand.

The supercharger is almost silent during operation. Oil and coolant are not supplied. When installing a supercharger, there is no need to make any changes to the engine design, with the exception of pressure parameters above 0.5 bar.

Pay attention to how to determine the wear of the cross on a VAZ 2106 and VAZ 2107

Turbo VAZ - instructions for turbocharging

Instructions for installing a turbo on a VAZ

Through the efforts of specialists, we decided to write instructions for beginners on how to independently install a turbine on a VAZ car for dragging.

The very first and most important question is where to start?

First of all, when you buy a car (especially if it’s used), I advise you to pay attention to its condition. If you understand this or want to become better acquainted with the machine and its structure, I advise you to disassemble it to the ground. Only when we strip everything down to the body will we be able to see the scale of the problem.

The most important problem we may encounter is rust. Most often, the bottom, fenders, and sills rust heavily. The “TV” is also a problem area for the “chisels”.

You must understand that a car made by VAZ has very thin metal, and such metal is not intended for high loads (the metal will simply tear), and rusty metal will “die” even earlier than usual, which is very dangerous for us and those around us. Therefore, we take a welding machine, fresh iron and replace all the rotted metal with fresh metal, or we drive the car to a service station.

We replace almost all of the metal in the engine compartment with stronger iron. Have you fixed all the metal jambs? Is the body like factory? Well done! Let's continue.

Now you need to put the car in order and make it move at least in stock. We change the wiring, put the engine in order (or immediately change it to a “gear”), gearbox, brakes. This is our starting point in turbocharging.

If you have returned your car to its original condition, and you still have the desire to turbocharge it? Let's continue.

Which engines are easier to turbocharge?

The simplest thing is to take a VAZ 16-valve engine. It is easy to repair and tune, and what is most important for us is that it can provide us with power suitable for motorsport without huge costs, effort and modifications to the car. A 16-valve valve is initially more powerful than any VAZ engine.

Let's look at other VAZ engines.

— Old carburetor engines cannot be turbocharged. — An 8-valve injector could be suitable, but we are building a racing car and every horsepower is important to us. — The 16-valve engine is our choice for drag!

When considering the option of an engine from a foreign car, you must understand that it will cost us quite a large sum and will also require large modifications. The foreign engine is more complex in design than the VAZ engine, and without a specialist you are unlikely to understand it. Our choice is “shesnar”.

What is needed to build a turbo engine?

For people who want to get 200+ hp. It is advisable to obtain a “Kalinovsky” block, since it is higher (+2.3mm). A dozen or more will do, but we are building a car for racing and every horse is a victory, so it requires a “Kalinovsky” crankshaft with a crank diameter of 75.6 mm.

We select forged pistons and machine a recess for the desired compression ratio (it is better to contact a specialist or buy in specialized stores).

Turbocharger

The small one works at low and medium speeds, but stops at high speeds, therefore the large compressor does the opposite.

- TD04L – Subaru. Boost at 3k rpm. 200-250 hp

- TD05 – Mitsubishi. Boost at 3k rpm. 250-300 hp

- IHI VF10 is a much larger turbine than the Subarov one. 250+ hp

- IHI VF22 – drag turbine. The largest of the series.

- Turbines are also good, but they are expensive and you need to wait until your order arrives.

- There are also many Chinese turbines on our market. The quality is weak, but the price does not bite. T3, T4 – 300+ hp

Turbo engine cooling

Everything is simple here. We need a new copper double-row radiator (2110) as it is much more productive than any VAZ radiator.

Intercooler.

A very large intercooler can cause so-called “turbo lag” problems. Turbo lag is how long we have to wait for boost pressure after we open the throttle. And the small one will not have time to cool the air.

Blow-off valve

An important part of a turbo engine, its function is to release part of the compressed air after closing the throttle valve. Otherwise, excess pressure may break all rubber connections. There are a huge number of options on the market, from stylish ala Lamborghinis to almost homemade ones.

Westgate valve

It is needed to allow part of the compressed air to bypass the turbine to maintain a given pressure in the turbo system. There are also a large number of executions.

Fuel system for VAZ turbo engine.

The fuel system must have a return line and a fuel pressure regulator installed in the rail. It is permissible to use an external fuel pressure regulator, but it must be connected with a vacuum hose to the throttle receiver, because In order for the injectors to overcome excess pressure in the throttle space, the pressure in the ramp must also increase.

Fuel pump

. The stock one is not suitable, its performance is too low. We take either from Volga or Walbro - 255 l/h.

Injectors

. Stock again won’t work, we need 350cc or more. DEKA 630cc injectors are suitable for us, for 200 hp engines. BOSH will also fit.

Everything is installed without any problems. You can do everything yourself (except perhaps for the firmware and configuration). If you have no time/too lazy/don’t want to tinker, then you can give everything to the service. There are no complicated parts or connections in what we need to get, everything can be done by yourself. Spare parts for attaching to the engine are usually included with the part. And if you have to buy more, it won’t be too difficult.

Exhaust system for VAZ turbo engine.

The exhaust system releases exhaust gases from the engine. This is a very important part, we don’t want to change the engine ahead of time, do we?

The temperature of the gases leaving the engine is enormous, about 900 degrees, when leaving the cylinder. In the case of turbocharging, these exhaust gases must not only be removed, but directed to the turbine wheel for spin-up.

You've all probably heard of the "spider". "Spider 4-2-1" is a system in which gases enter four pipes, are then collected into two, and then into one. The system is effective at medium speeds, a good choice for driving on the streets and rare “bullets” from traffic lights. “Spider 4-1” is a system where gases from 4 pipes are immediately combined into one. Effective for high speeds. Our choice.

Suspension for turbo VAZ.

Suspension affects handling. Therefore, for a car that plans to overtake everyone and everywhere, it needs to be modified. I advise you to modify the suspension thinking about your own safety, because if at full speed something falls off due to old age, the car may become uncontrollable, which can lead to an accident. Let's consider suspension options.

1) Soft suspension

: Pros: smooths out potholes, rides smoothly and comfortably Cons: poor maneuverability, rolls when cornering, skidding.

2) Rigid suspension

: Pros: turns like a glove, maneuverability, instantly reacts to steering wheel turns. Cons: It will be rough on the bumps!

Clutch and transmission for turbo vaz

The choice of clutch must be approached thoroughly. The clutch must be selected taking into account the engine power and torque. The stock clutch is designed for a quiet ride! We have several options:

a) budget: basket with increased downforce (there are different options). This option firmly holds the driven disk and increases the force on the pedal (pump your legs otherwise, you will lose a split second at the start). b) not budget: ceramics. It can withstand the stress of motorsports. Our choice.

Gearbox for turbo VAZ

A stock box is a box designed for quiet movement, standing in traffic jams and stirring up dirt in the countryside. The stock box has a very short first speed, only up to 40 km/h. Short first means that we will have to waste time and torque when switching to second.

To solve this problem we must choose a range of gear ratios. The optimal choice for turbo engines 103 series. The main pair reduces the speed transmitted from the engine to the wheels by about 4 times. The higher the gear ratio, the better the acceleration and the lower the maximum speed. Our choice is 3.7 or 3.9

Tuning a VAZ turbo engine

All this is done using a “wastegate”; the less pressure is released into the atmosphere, the greater the pressure in the system.

There are several ways to adjust the pressure, the best of them is a boost controller. You need it to set the pressure you need right from the cabin. It works simply, it prevents the safety valve on the manifold from releasing pressure, which contributes to a temporary increase in pressure.

Firmware

The standard control unit program requires significant adjustments. A properly tuned turbo engine will be more powerful, run smoother and be less voracious in terms of oil and fuel. The most reliable option is to find a specialist in your city (or in a neighboring one) who is not doing this for the second time in his life. You don't want to overhaul the engine every two days, do you? Therefore, firmware is a crucial moment.

What other improvements are needed?

The stock engine is not designed for racing loads, so most of the components and spare parts are replaced with more efficient and durable ones. This applies to pistons, rings, pins and connecting rods...

Also a prerequisite is the modification of the cylinder head channels; we need to make the timing system more efficient. 40% of success depends on the “head”.

We must remember that we are building a 70 hp production car into a 200+ hp race car. Stock and life-killed components are not designed for this, so you must understand that when the project is ready, there will be nothing left in the car from the stock, you will have to go through the entire car down to the bolt.

How to refuel a turbo engine

?

You need 95 or 98 gasoline. 98 is preferable for those who like “gas to the floor.” 92 in no case, you will destroy the turbine ahead of schedule and without getting a decent result from the speed, since low-quality gasoline increases the combustion temperature, which negatively affects the turbine blades and the engine as a whole.

What oil to use

?

The 16-valve engine has hydraulic compensators and for their best performance you need to choose synthetics. Yes, it’s not a budget, but we demand the best results from a car, right? So for this we need to give her the best.

Contents Turbocharging on the VAZ 2114: Part 3 - Assembling the cylinder blockWe have the engine ready (the cylinder block is assembled with the head), it’s time to do the wiring - let’s start with the exhaust and other little things. The TD04L turbine sits on a turbo manifold with equal pipe lengths. The manifold is welded from black carbon and sandblasted in Stinger. The product looks very good, can't complain.

But you can and should find fault with the stretching of the front struts. Planting this “product” on the glasses of the racks took a lot of time. This time was spent fine-tuning the holes - drilling, grinders, cutters - everything went into action. The thin plates securing the additional engine mounts do not withstand not only criticism, but also operation - they simply tear off. That’s why you need to make reinforcing scarves for them.

There are also no complaints about the downpipe (pipe from the turbine to the resonator) - it is made and welded perfectly. The turbo manifold and downpipe are in place - there is less and less space in the engine compartment. The compartment is very cramped - many tubes and wires run closely. All this will have to be rearranged and redone. If the Tyaplyapovites would turn a blind eye to this, then we would not, although this is another waste of time.

We open another box. Here we have a Chinese turbine TD04L . The price of this device is only about 10 thousand rubles . Against the background of total costs, this is a good saving of money, because the original snail costs about 5-7 times more. There was a long debate with the client about the turbine from the very beginning. I won’t describe them in detail, but there were many doubts not only about the snail’s resource, but also whether it would provide the required “pressure”. The client was generally against the Chinese turbine. Tolyatti did not provide any guarantees for the snail - return due to a malfunction was impossible. However, the price was tempting. We didn’t want to take larger snails (for example, TD05) - the car had to be civilian, and we wanted to get supercharging in the zone of as low revolutions as possible. Yes, and it was necessary to find and understand the starting point for further work, so to speak - the “reference point”. Initially, the ultimate dream was 160-180 horsepower , which would have suited the client quite well, so we had no ambitions for large turbines. Stinger responded very vaguely about the reliability of Chinese snails - they say, “we sold them recently, everyone takes 05s, there were a couple of problems, but now we don’t even remember.” Allegedly, one buyer did not like the gap between the housing and the impeller (the author also looked at the gaps with doubt - were they too big, would this turbine provide adequate boost?), the second “had something, but I can’t remember what.” Additionally, we bought gaskets for the flanges - what was included in the kit could be immediately thrown away. One wastegate control tube is already torn - well, let's replace it. As a result, the client was persuaded to choose the Chinese; the decisive factors were the low price and small dimensions, which was very important for Samara. It looks like it was made from “factory China” (in Dmitry’s words); traces of balancing are visible on the impeller nuts. Let's hope that the Chinese will not let you down!

To attach the hot part of the turbine to the exhaust flanges, you need to use bolts of increased strength class. Regular bolts cannot be used. Strength classes are indicated on the bolt heads. The bolts are located in very inconvenient places, and to make removing the turbine easier in the future, all bolts must be lubricated with copper paste. It would seem like little things, but the future operation of the car depends on it. We fasten the turbine and rejoice at the completion of a new stage of work.

The easy part is over - a stub of a downpipe hangs under the body - everything else about the exhaust needs to be welded and made almost from scratch.

“Tyaplyapovtsy”, who install turbocharging on a car in 3 days, this would be quite enough. But we don’t. Then the nuances begin, because of which Dmitry came to us, and not to Moscow or Tolyatti. These nuances monstrously inflate the work deadlines, but we cannot do without them (at least in our understanding). So, the turbo manifold with a heavy turbine actually hangs only on the head studs. What will happen when driving on bad roads? That's right - either the studs will break off, or the turbo manifold will crack. And it will definitely crack and fall apart if it is not reinforced with spacers - additional supports for the turbo manifold, connecting it into a rigid circuit, along with the engine. The author turns into “blacksmith Vakula” - in fact, we are forging spacers, using spacers from the manifold of an 8-cl engine as a basis. The first spacer rigidly connects the turbo manifold in the middle part to the cylinder block. The second spacer closes the U-shaped circuit of the turbo manifold with the engine, eliminating the breaking-bending moment that inevitably appears on such a manifold during engine operation. It would seem like nuances, little things, but it took a lot of time to adjust and forge the spacers, but it needs to be done!

The intake receiver was purchased from us - it is a “turbo receiver”, with pipes, manufactured by the same Stinger. Traditionally, we carry the receiver to the machine and grind the surfaces. The photo clearly shows how deformed the flanges are after welding. They are literally bent. Most installers don’t bother - they mold 2 gaskets with a kilogram of sealant, but we grind them. Stinger, again, ignores this problem. Well, what do you want for this money... Many copies were also broken regarding the receiver. The same laws apply to a turbo engine as to an aspirated engine - resonance (increased cylinder filling) on a short intake tract occurs at high speeds, and with a long intake tract - at low speeds. We didn’t want to install a short intake, especially since the client firmly insisted - “we need torque at low and medium speeds!” I don’t want a buzzer!” At the same time, we received a negative answer to the question about the sharp radiator frame. After trying on an aluminum intake and working on the issue of making a “custom intake,” we finally reluctantly installed a short intake. There was no other adequate option in a short time frame and reasonable money. The last hope was only for narrow-phase shafts with RS hydraulic pushers. High performance injectors were installed from Volvo. The ramp is an old model 2112, with a conventional pressure regulator. We refused to install a sports regulator - increasing the pressure would lead to an extra load on the fuel pump, the chipmaker made a calculation based on the performance of the injectors - the standard regulator was enough for us. The engine is gradually gaining fat, but there is still plenty of work to be done - the short intake requires moving the fan, there is simply nowhere to put it.

Deep engine boost raises the question of an additional radiator to cool the engine oil. You can, of course, do it in the “tippy” style, but if you do it wisely, you need to stage it. The oil filter spacer is screwed to the block. Oil will be taken from it to the turbine and oil will be supplied/returned to the oil cooler.

The strut spacer had to be removed again - the wastegate control membrane housing almost touches the pipe. Use a sledgehammer to make a dent in order to save the body. We strengthen the attachment of the additional support to the brace with two gussets. Stretching is needed for the next stage - installation of the exhaust tract requires final signage of the power unit on all supports.

How much has been done, and how much still needs to be done!

The next stage of work is installation of the exhaust system. We will devote a separate part of the report to this.

Turbocharging on the VAZ 2114: Part 5 - Exhaust system

Article written: March 22, 2014 Author of the article, photo-video materials: © Quasar Prohibited without the written permission of the author: reprint of the article in whole or in part, reprint and use of photo-video materials, as well as their modification and editing for the purpose of further publication on third parties sites.