In the official technical manuals of most cars, there is usually not a word about warming up the car before starting at sub-zero temperatures. This is because manufacturers are not interested in ensuring that the car operates for as long as possible; it is quite enough to ensure that the engine operates perfectly within the warranty period.

But with the arrival of winter, the question increasingly arises of whether it is necessary to heat the oil in the crankcase before starting

. Let's try to figure it out.

Oil thickens in the cold, and the lower the temperature, the thicker the oil will be. A cold start means that the frozen oil is not pumped through the pump and it remains in the sump. In this case, the engine runs partially without lubrication, because what has been pumped is not enough. Warming up the oil in the crankcase in winter will eliminate startup loads and will facilitate rapid pumping of fluid through the lines.

Is it necessary to warm up the oil in the engine crankcase in winter before starting?

Drivers

It is clear that the interest in how to warm up the oil in the engine before starting is not caused by empty talk. How else can you take a lecture from a respected professor who compares 5 seconds of cranking at -20°C with three-digit mileage. The average equivalent is no more or less – 200 km. The dry theory does not specify specifically whether in the city or on the highway, but the essence is clear - the oil system is not in rhythm at the start-up stage.

The physics is simple: oil is a liquid, and it thickens in the cold. Scientifically, as the temperature decreases, the low-temperature viscosity increases. To what extent is not clear: automotive lubricant manufacturers keep thematic diagrams secret. It is easier to teach information according to the SAE classification: the fewer details, the more convenient it is for marketers.

Soviet mineral water tests bring clarity. Let's take the most liquid mineral oil M8. Temperature gradient – from room temperature to -5°C. The result is a tenfold deterioration in viscosity characteristics. Modern synthetics, of course, do not thicken as intensely, but the hint was taken.

For whom the theory is an empty argument, we present the facts. The thick oil composition prevents the rapid rotation of the crankshaft and is poorly pumped, which is why:

- The life of the starter is reduced.

- The load on the battery is increasing.

- Oil starvation occurs in the first minutes of work.

General recommendations

Universal advice is to study the section on technical fluids available in the owner's manual for a specific vehicle. A table linking the viscosity of oils with their operating temperature limits will give you the idea that it would be a good idea to fill in something like 0W-40, 0W-30 for the winter.

The share of starting wear will decrease, but it is far from reaching summer values. Yes, and not all car manufacturers give the green light to the use of the super-fluid variety, but you shouldn’t violate the instructions - you will run out of lubrication and the seals will leak. Hence the question - how can you heat the engine oil in winter in pre-start mode.

Another option is to not allow the oil composition to cool down before the next start. Obviously, after a forced stop for 15-30 minutes or after the “Start-Stop” system has been activated, the starting conditions are equivalent to summer ones. Almost all modern alarm systems can automatically start and stop the engine. The function is called autostart based on engine temperature.

Conclusion

Warm up engine oil in winter

- This is a necessary procedure. The choice of warming up method depends on your budget and the characteristics of the car: from installing an autonomous heating element or heating element with a thermostat to conventional mechanical warming up. Before purchasing a heater for heating a car engine, consult with specialists to choose the most suitable option.

Let's be honest: the manufacturer does not care about the maximum service life of the motor. The task is to ensure impeccability for the first three years, and then at least it’s scrapped. Just judge by the official recommendations: change the lubricant every 15,000 km and drive off immediately after starting the power plant. And the choice of equipment: stitching and interior gadgets, not a word about the technical aspects. Meanwhile, it’s winter outside, and our engine is not happy.

Briefly about the main thing

An electric probe, a heated drain plug, a heating element and a heating plate - with these simple means you can safely heat the oil inside the engine in winter before starting. In fact, you don’t need to invent anything - each of the four options is available for purchase on many trading platforms.

In terms of power supply, there are no difficulties: a wire and a plug or a simple electrical circuit based on a relay and a toggle switch. Another question is whether it is necessary. The answer is short and advisory in nature: it is necessary, especially in cold weather worse than -10°C.

Many motorists are forced to think about how to heat the engine sump with their own hands due to the weather conditions in winter, which affect the normal starting of the engine. Some drivers mistakenly believe that in winter it is difficult to start the power unit due to weak battery power. In fact, the problem is caused by a change in the lubricant, which becomes very viscous, making it difficult to start the engine and the functionality of the crankshaft.

Ineffective lubrication in the initial minutes of engine start leads to excessive wear of the piston unit. These troubles can be avoided by heating the crankcase and eliminating excessive oil viscosity.

Crankcase warm-up safety basics

When using any method of heating the engine, it is important to remember safety precautions. The fact is that the design of the car does not initially imply a system for preheating the oil in the crankcase (unless this is provided for in the technical specifications). Therefore, it is necessary to take into account basic safety requirements.

The main one is the implementation of constant monitoring of the process. Even if the technical documentation for the heating element indicates the automatic operating mode of the unit, this should not be the basis for the uncontrolled use of the heating system. » alt=»»> Safety measures will never be superfluous: they will allow you to prolong the operation of the car engine and ensure the safest possible heating of the oil in the abnormally frosty Russian winters.

Electric heater

How to make a heated engine sump with your own hands,

Let's look at it further. There are several types of structures that differ in operating principles and technical characteristics. It is possible to make an electric crankcase heater at home.

The main advantage of this device is the fact that the elements and parts required to assemble the unit are available to most motorists at hand. The following materials will be required:

- A heating element. Any working spiral from old household appliances (kettle, electric oven) will do;

- Small metal container;

- Fitting. They can be purchased at any plumbing store;

- Junction box.

The simplest do-it-yourself heaters

You can start the engine in cold weather and warm up the oil in the crankcase using traditional methods that have been known for many years. The essence of this process is to use an open flame to heat the engine sump. The sources used are a blowtorch, a gas cylinder with a burner, or just a fire. The presented method requires caution and attention.

The whole procedure takes about 20 minutes. Although it is possible to warm up the oil and start the engine in this way, there are a number of disadvantages:

- Difficulties in performing the process itself due to the inconvenient location of the pallet;

- The need for preliminary preparation of special devices;

- High risk of fire.

A modernized mechanical method of warming up the crankcase involves using a special pipe with stops and a nozzle. Connected to a fire source, it makes it possible to warm up the engine oil more safely and purposefully. The pipe should be bent in two places (this reduces pressure and flame atomization). You can select a suitable part from old scraps or weld it yourself.

Mechanical methods

Mechanical (or external) methods of heating the oil in the crankcase include a cycle of work that is not associated with interfering with the design of the vehicle by installing additional equipment. These are the so-called ancient methods.

The most common type of such work that provides crankcase heating is the use of open fire. A fire built under the car where the crankcase is located, a blowtorch and other devices will allow you to effectively warm up the oil and start the engine.

However, this method also has significant disadvantages:

- infrastructural difficulties when carrying out preliminary and immediate work (working clothes, inconvenient location of the crankcase, etc.);

- the need for additional equipment and materials (heat sources);

- unsafe work performed (possibility of fire).

The second mechanical method is the use of special removable electrical equipment, which helps heat the entire engine. For example, a special tape equipped with electric heating elements operating from a standard electrical network. But this heating is not without its drawbacks, such as the need for such equipment and the complexity of the procedure for placing it around the engine (with mandatory subsequent dismantling).

Finally, a very effective way to ensure the oil warms up is to move the car to a warm, heated garage. But, due to the banality and cost (both resource and time) of such an algorithm for solving the problem, we will refuse to consider it in detail.

Autonomous heater

A fairly common device for warming up the engine sump. The autonomous version is capable of processing decent volumes of air, consumes little energy and is practically silent. The unit can be installed with your own hands, both in the power supply system and in the cooling circuit of the car, regardless of the engine type. The source of energy in this case is the gas tank.

The autonomous crankcase heating model is a small chamber containing a fuel-air mixture, which is ignited using a special pin. Coolant circulates stably in the walls of the tank, the heating of which is provided by the pump. The warm mixture enters the car's small cooling circuit, warming up the engine.

Installation of this unit consists of connecting the heat exchanger of the heater to the small cooling circuit of the car, and the electrical part of the device to a similar system of the car.

Aggregate method

Recently, the aggregate method has become increasingly widespread, which consists of installing additional equipment that allows the engine to warm up under standard conditions. In other words, to achieve the goal, there is no need to resort to any significant additional manipulations.

Modern manufacturers offer a wide variety of devices to heat the oil. However, despite the independent technical solutions, they all have one common operating principle and a single device, which consists in the use of electrical energy and a special heating element mounted in the engine crankcase.

The heating element (heating element) is located in the crankcase in such a way as to be constantly immersed in engine oil. Otherwise, the heating element will quickly fail. If necessary (lower temperature), before directly starting the engine, a direct or alternating electric current (12, 24 or 220 V) is supplied to the heating element, which helps warm up the oil and normal engine starting.

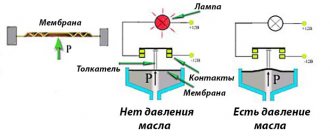

As a rule, heating elements have one drawback associated with the uncontrollability of the heating process. The temperature of the oil in the crankcase can reach a critical point and it will boil. This can be avoided by using a special thermostat, which is used in conjunction with a heating element to turn it off when the required temperature is reached. Some modern heating elements have a self-regulating operating algorithm, eliminating the need to use a thermostat.