Comments: no Published: 01/06/2016

Rating:

Tags:VAZ 2108/2109/21099Replacement spar

The problem of a spar failure on a VAZ 2108/2109 is an unpleasant situation, but this does not mean that it cannot be corrected. There are many ways to fix the problem: replacement or welding, do-it-yourself repair or in a workshop. You will learn further how to make the right choice.

When is it necessary to repair or replace the spar on a VAZ 2109

The decision to straighten or replace a side member on a damaged car depends largely on the length of the deformed zone, the degree of deformation, and also on the qualifications of the repairman. If there is slight deformation of the spar over a long length, even if there is a small fold, does not need to be replaced . Using a jack or square, you can restore the original shape and position of the spar while maintaining its characteristics. On the other hand, if there is significant deformation, the spar must be replaced, since straightening will cause a change in the metal structure and strength, which will lead to a change in the characteristics of the body itself.

If the metal is rotten, then the side members (front and rear) cannot be repaired or restored. Even if you weld, the rot will continue around it. In addition, welding on soft metal can disrupt wheel alignment, tires will begin to wear out faster, transmission parts will begin to break, and body deformation may occur. Such repairs will be enough for a couple of weeks.

During welding, spacers are placed on the spar to prevent it from being pulled to the side. Otherwise, the body may become deformed.

If possible, it is always better to purchase a new part, which costs more than temporary repair work. But, even with a limited budget, in some cases you cannot save. Therefore, replacement is much cheaper, but if the crack is the result of an impact or collision with a VAZ, welding will be sufficient.

When repairing a spar, you should never lose sight of the fact that it is a reinforcing element of the body and largely determines its rigidity. At the same time, it is not recommended to strengthen the spar during partial replacement , mainly in the front and rear parts of the body, since this increases the strength of the area intended for crushing, i.e. for depreciation. If the depreciation of this zone turns out to be insufficient, then in the event of an impact, the deformation of the body will pass further, to the car cabin, which should not be deformed.

Typically, a crack forms after an accident only if the body has also become deformed. Then it will be necessary to first level it, and only then begin welding work.

Design Features

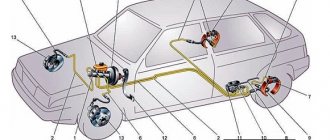

So, we figured out that the spar is a simple pipe with a rectangular cross-section. Depending on the engineers’ ideas, they:

- are located in front and behind the car.

- extend along the entire length of the housing structure.

Due to the fact that various forces are constantly pressed on the side members, they must withstand serious loads: this includes the weight of the engine, the weight of people in the car, as well as a host of other automotive parts. Also, this part is constantly subject to shock load, which is transmitted from car wheels while driving.

If you look at the photo of the inside of the car, you will see that the frame frame looks like a ladder frame, similar to the letter "P", including the rear one. Ladder frames are commonly used for SUVs, crossovers, and trucks. Passenger cars are most often equipped with a load-bearing body structure.

Where to repair the VAZ 2109 spar

Remember, you can only repair a VAZ yourself if you understand body work and know how to work with a welding machine. When you encounter it for the first time, you are unlikely to be able to perform high-quality repairs. And all of the above problems may follow.

Straightening and repairing the body can also only be done in a car repair shop. If you do not have the skills and special equipment, it will be difficult to cope with the task.

Replacement procedure

- We drill out the attachment points of the power element, and if this fails, then the remaining points need to be cut off using a chisel and a hammer.

- After dismantling the old spar, it is necessary to thoroughly clean the area for the replacement part purchased, install it and, if necessary, adjust it to the required size.

- A new part is being prepared for welding. This must be done in the same places where factory welding was used. A minimum of three welding points will be required for initial fixation.

- The prepared part is secured to the place to be installed using removable clamps.

- We sequentially weld the spar to the body according to previously prepared marks, after which we evaluate the correctness of the design.

- The final stage of installation is the final welding of the part. In this case, the structure is strengthened by applying additional strength elements.

- After completion of the work, the welding areas must be processed by cleaning with a grinding machine. Finishing is mandatory.

This stage involves thoroughly cleaning the welding areas from scale and other foreign contaminants. The surface is thoroughly degreased, coated with primer and anticorrosive. Epoxy resin can be applied to the weld areas to permanently protect them from spot corrosion. The final step is to reinstall the suspension parts and secure the beam. The interior elements are installed, the car is completely cleaned, put on wheels and rolled out of the garage.

The body will have to be thoroughly disassembled

Despite its apparent simplicity, before starting work, you need to assess your own capabilities. After all, redoing it is more difficult than doing everything right in the first place. Mistakes that can be made during poor-quality installation can lead not only to the rejection of the new spar, but also to a violation of the geometric shape of the car or its incorrect behavior while driving. Thus, replacing the rear side members is a process that can be done independently, but a responsible approach to the work is required.

Rear spar repair kit 2108-09

The rear spar repair insert allows you to replace only part of the body part, which simplifies the repair and makes it cheaper. The repair kit is a reinforcing element located on a bend; it is believed that this particular place on the body is subject to intense rusting.

In practice, it is not always possible to use a repair insert, since both the rear beam fastening in the side member (the main problem of 2109) and the jack often rot. The average cost of a repair insert in auto stores is 700-800 rubles, catalog numbers are 2108-5101372 and 2108-5101373 (right and left sides).

Replacing rear side members on a Nine in a car service center

Replacing rear LPs is a labor-intensive and quite complex job that requires care, metalworking skills, and the ability to use welding. Not every car owner undertakes to carry out such repairs on their own, so quite often the owners of front-wheel drive VAZs turn to professional technicians. The cost of replacing the rear spar 2108-09-099 can vary significantly, it depends on various factors:

- the location of the auto repair company, usually in the metropolitan region and large cities, repairs are more expensive;

- car service level;

- general technical condition of the car.

If the car body is heavily rusted, not all craftsmen agree to repair such a vehicle. I would also like to note that many auto repair shops fundamentally refuse to hire VAZ-produced cars, preferring to engage in more profitable repairs of foreign cars.

The average cost of replacing one rear spar 2108-09 is from 3,500 to 5,000 rubles; of course, car owners consider such prices to be simply extortionate. The price of body work, including materials, is sometimes a third of the cost of the used car itself, which cannot be considered normal. Private auto repairmen in garages have more affordable prices (from 2000-2500 rubles), but there are pitfalls here:

- a good repairman is not easy to find, and it is difficult to get to him, since due to high demand, repairs are carried out by appointment;

- among private traders working at low prices, there are many outright hacks;

- in garage conditions there is not always everything necessary for high-quality repairs;

- the work is carried out by repairmen with insufficient experience, technology is violated.

When replacing rear LPs, it is important to weld the body part exactly in place; if the spar is shifted to the side, the geometry of the body will be disrupted, the rear beam will “move” to the side, and the car will drive sideways with all the ensuing consequences.

Recommendations for replacing the rear side members of the VAZ-2108-09

- When replacing a LP, many craftsmen cut off the old body element with a gas cutter, but it is better to drill out the part.

- When installing a new spar, it is very important to find the control points correctly and not to disturb the geometry of the body, otherwise the work will have to be redone and problems will arise.

- It is recommended to grab the spar at three or four points; before thoroughly welding the part, it is recommended to try on the rear beam - the fasteners must match the studs.

- Before installing the body element, the seat must be thoroughly cleaned of rust and well primed; if the metal is rusty, new plates must be welded.

- You cannot weld with a continuous seam, this will weaken the metal of the body.

Replacing rear side members is not an easy job, if you are not confident in your abilities, you should not take on it, it is better to use the services of professionals.

Preparatory work for replacing the VAZ 2109 spar

Since spar replacement and repair are carried out using the same technology, the set of tools will also be the same.

Please note that it is better to purchase spars complete with other parts. This way you will be sure that they will fit each other perfectly and will not spend so much time installing them.

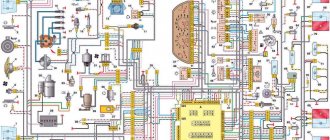

If you nevertheless decide to repair the side member on a VAZ 2109 yourself, first you will need to acquire the following tools for the job:

- welding unit (the most convenient and simplest option would be semi-automatic welding);

- grinder and discs, hard metal brush for the grinder;

- a set of new side members and connectors for the VAZ 2109;

- grinding tool;

- electric drill;

- metalworking tools;

- packaging of automotive mastic;

- 2 medium-sized paint brushes;

- can of primer;

- bottle of solvent.

Tasks of spars

The spar in a passenger car serves as a reinforcing part for the underbody, mudguards and luggage compartment floor. In large cars it acts as the main strength element of the body. In addition to its reinforcing task, the front spar acts as additional shock absorbers - it is located in the deformation absorption zone. After all, in order for the part of the car body where people are located to receive the least impact while driving, it is necessary to soften the impact - and this impact is taken by the front side member.

To ensure that vibration spreads evenly throughout the body, engineers create “deformable” zones in its front parts. In the longitudinal direction they have a weak force structure. Now passenger car manufacturers are trying to make it as thin as possible: they reduce the thickness of the section or walls, create special holes in the “safest” places where less load is applied. Designers also use folds when stamping parts. They are needed so that during an accident the spar folds into an accordion and does not break. In a collision, the side members take the brunt of the impact, which is why they are often deformed. But such a sacrifice is justified: due to the absorption of kinetic energy, the force of the impact on the cabin is reduced. In trucks, both the rear and front side members suffer.

In what cases does the spar need to be changed?

The decision to repair or replace the spar is made based on the degree of damage. Most often, side members are damaged during an accident. In addition, the reason for partial or complete replacement may be corrosion, as well as the appearance of cracks during the operation of the car.

If the damage after the accident is smooth, without sharp corners, then the spar must be repaired; if the damage has sharp corners (pressures with an angle of less than 90 degrees) in a small area, cracks, tears or corrosion that are difficult to remove after pulling, then the spar needs to be partially or completely change. The metal structure of the spar with such damage changes, as do its characteristics.

Spars with significant damage, made of ultra-high strength steel (UHSS-Ultra High Strength Steel) most often need to be replaced, as they are very difficult or impossible to repair. Heating significantly weakens the strength of such steel.

Installation process

Let us describe the process of replacing the front side member on VAZ 2108/2109 cars:

- Using a plasma cutter, in the absence of which you can use a hand hacksaw for metal, you need to cut off a new spar. Its size must be identical to the size of the damaged VAZ part.

- Once you have everything you need to make the repair, you can begin installation. The spar is connected to other parts, using guide templates, you can achieve precise installation.

- Now you can start welding parts 2108 / 2109, but first you need to check everything carefully. Only after this will it be possible to secure the part in several places. She welds the joint to the joint using arc welding.

- Fix the side member on the front panel of the VAZ. The method of spot or through welding is used here. Please note that if you replace the spar, the second option is more reliable.

- All you have to do is go over the welding areas with a grinding machine. It will be enough to tap the new contact points between the spar and the wheel arch with a hammer to secure the result. Finally, apply primer, soundproofing and sealant to 2108 or 2109.

Problems related to spars

Under the influence of loads, the side members still deform over time, especially the front one (the load from the engine and its systems) suffers. Just like the front ones, the rear ones can crack and get tired. The word “get tired” implies the initiation of a crack, which over time grows throughout the entire part. Of course, an accident can also leave a significant mark.

What does operating a car with damaged side members entail? Some parameters of the car are violated: slightly, but the position of the doors, connectors of body parts, and the position of the power plant changes. The suspension geometry also suffers. Due to all these shortcomings, the car's handling is reduced. Therefore, if the body is damaged, you need to take the car for diagnostics - this decision will be correct.

If the spar completely bursts, then the entire body structure will be completely destroyed. It is because of this that after an accident, experts look at the degree of deformation of these elements. The position in which the side members are in the car also plays an important role.

Statistics: Approximately 90% of all work associated with this part occurs on the front spar. Such damage can be resolved quickly only with a frame spar - there it is simply replaced. As for the supporting body, sometimes the spars simply cannot be replaced. Let's say it was slightly dented in an accident: such damage can be corrected using a special carolin stand. For example, on the stand there are front left and rear side members - using a convenient location, mechanics measure all the parameters necessary to correct the problem.

It happens that the side members of a car are in such a state that the only option left is replacement. Changing parts entails a significant change in the properties of the entire body. After all, the shape, material and weight are calculated by the manufacturing company - in automotive centers you have to improvise. When the main parts of the spar are in good condition, a partial replacement is performed using arc gas welding.

When making repairs, you must insist that the new spar is no larger in size and weight than the old one. Some people prefer to harden a new one, but one must remember that such a decision may lead to a loss of shock-absorbing properties upon impact. Constant blows will lead to more serious consequences. Do not forget that in the event of an accident, the side members are checked first, and then everything else.

Forget about fines from cameras! An absolutely legal new product - Traffic Police Camera Jammer, hides your license plates from the cameras that are installed in all cities. More details at the link.

- Absolutely legal (Article 12.2);

- Hides from photo and video recording;

- Suitable for all cars;

- Works through the cigarette lighter connector;

- Does not cause interference to radios and cell phones.

Content

Replacement or welding

Removing the rear side member

Installing the rear side member

Front spar

Removing the front side member

Installing the front side member

From the author

About 1.4 million copies of VAZ-2109 cars were produced and it, along with classic VAZ models, became a truly people's car. Not least of all, this was achieved thanks to the high maintainability of the “nine”. In this article I would like to dwell on such an important problem as replacing side members on VAZ-2109 and 2108.

Replacing side members on a VAZ-2109

Replacement or welding

Welding of the spar is used in two cases:

- When fatigue cracks started to appear. Then it makes sense to put a patch over the crack and weld it using semi-automatic welding.

- When there are small pockets of corrosion. In this case, the metal is cleaned, treated with a rust converter and primed. If necessary, small patches are applied.

Welding the spar is possible even if it is destroyed, but this will only be a temporary repair, and driving such a car is dangerous.

If the car was involved in an accident in which the side member was significantly deformed or rotted, then a complete replacement would be advisable. It is necessary to understand that you need to repair the spar if you have sufficient skills in body work and welding. For an inexperienced person, this process will be quite complicated, so if you are not confident in your own abilities, then it is better to trust the professionals.

Required tool:

- Semi-automatic welding.

- Bulgarian.

Semi-automatic welding

- Electric drill.

- Wire brush.

- Spars for VAZ-2109.

- Mastic, primer, solvent.

Removing the rear side member

Dismantling of the spar must be carried out on a slipway or with the machine turned over on its side. In addition, you need to completely remove all the trim and soundproofing of the trunk. After this, we clean the weld seams. Next, we will need to find all the resistance welding points of the spar and drill them out using a 7-mm drill. At the end of this process, we need to completely cut off the old spar. We clean the place of its attachment from rust and paint. This is done using a metal brush on an angle grinder and a rust converter. If necessary, we cut out the rotten body elements and put patches in their place.

Removing the rear side member

Installing the rear side member

Before installation, the mounting area is degreased and primed. The new spar also needs to be cleaned of transport soil, primed and holes made in it for welding points. If everything is done correctly and the geometry of the body is not damaged, then the new spar will fit into its seat without any problems. We weld the spar at the welding points to the body and cross member. At the end of this process, coat the seams with automotive mastic.

Front spar

The front spar is more loaded than the rear. This is because it bears the entire weight of the engine and gearbox. If we add to this operation on bad roads and aggressive driving, then its service life will be only about 4-5 years. In some cases, a special repair insert, which is welded into place of the damaged fragment, can save you from the labor-intensive process of completely replacing the spar.

Just as when replacing the rear spars, replacing the front ones must be done on the slipway. Otherwise, you can break the geometry of the body.

Before you begin replacing the side member, you need to remove the entire front suspension and engine and partially disassemble the interior. When disassembling the front part of the car, pay attention to the condition of the remaining body elements, such as glasses, radiator frame (most likely, the frame will have to be changed along with the side members, since it serves as a structural reinforcement), mud flaps. It is possible to partially replace the front spar. In this case, the old one is cut off, and a new one is welded in place of the cut out part. However, next we will look at the process of completely replacing the front side member.

Possible faults

For the manufacture of spars, only special aluminum or titanium alloys are used. The strength of the structure is very important, since the elements are subject to constant loads.

Over time, such exposure can lead to their deformation. During operation, microcracks may appear on the metal. This effect is often called metal fatigue. Damage, bends and cracks can affect changes in body geometry and many other parameters of the car. For example, the wheel alignment angles will change, an incorrect gap will appear when closing the doors, various kinds of squeaks in the cabin, and so on.

Also, these important elements can be deformed during an accident. These are the most common cases. Bending of the side members threatens serious repairs, or even complete disposal of the body. Cracks and gaps appear, and the geometry of the body is disrupted. In this case, it is unsafe to operate the car. Even repairs do not always give the desired result. Due to geometry violations, tire wear will most likely increase and the factory steering settings will be disrupted.

Deformation zone of side members

On the other hand, side members also belong to passive safety elements. They have zones of programmed deformation. In the event of an accident, the part will bend exactly in this place, taking away part of the impact energy.

Body repair is a harsh thing, or use a chisel to “CHISEL”

For everything about garage welding of rotten cars, see the new book on car repair from Khoma

In August 2009, a nice young lady approached me with a small request - to weld a hole in the side member of a VAZ-21093 car, in common parlance - “chisels”, they say, the husband is a diagnostician, “fumbles” with engines at 10c plus, but there is no one to do auto body work.

Well, helping your neighbor is a sacred thing, I thought and invited them to the show. The initial examination raised a lot of questions, ranging from year of birth to:

WHERE IS THE CAR'S FLOOR? Brief questioning of the owner revealed the following: the car was produced in 1996, stupidly stood in a pit for three years, after which it was bought outbid, hastily patched up, coated with various mastics and successfully sold off to the current owners, and since the diagnostician husband figured out that the engine was in good condition, he didn’t bother with the condition of the body…..But in vain!

The young lady was offered the following options:

– replace the floor, sills, rear side members

– completely change the body (the engine is excellent)

– cover it up again and sell it off to other less fortunate buyers at an even lower price (there was no recycling program at that time).

Ultimately, the decision was made - COOK!

Disassembling the interior took two hours, they opened the Shumka and “rejoiced”:

the floor of the car was practically destroyed by corrosion (see photos 1, 2, 3) The place of the “happy” driver, who almost ran along the “path with his own legs” (photo 4) looked especially impressive

Since the floor tunnel miraculously survived, only the “trough” was replaced

After cutting off the rags, cleaning off mastics and other offal, drilling out resistance welds on the side members, and carefully marking them, welding of the floor began.

By the way, everything was cooked using a domestic carbon dioxide semi-automatic PDG-165.

Next in line were the rapids.

After opening the outer panels, a view appeared no less gloomy than the appearance of the floor (photo 9, 10)

In order not to take risks, stretchers were installed in the body for rigidity (see photo 26, where the car looks quite naked) and this measure, I think, was not unnecessary - it’s better to be overdressed than underdressed.

The remains of the side members and jacks brought tears to my eyes... (photo 11, 12)

Having mercilessly chopped off pieces of old metal with a grinder and a chisel, we got to the living metal of the body. We welded in the amplifiers, connectors and front jacks. Buy a new book on auto repair from Khoma. We decided to wait a while before installing the doors to install the external sill panels in order to prevent the appearance of unnecessarily large gaps.

Finally, the turn came to the spars. This “hole” was what the sweet girl wanted to seal (photo 14)

The same photo shows that the edges of the wheel arches still have the same deplorable appearance. Removing the rear bumper and examining the trunk for integrity forced me to take up the camera again:

The left trunk well (see photo 21) and the rear panel (see photos 15, 32) also suffered from terrible rot. For further repairs, we had to remove the gas tank and the rear beam (photo 28). While they were filming, the soured brake pipes were told to live to death for a long time (see photo 23). There was no time to mourn for them, so the chisel, grinder and drill were used again. The edges of the arches were trimmed, the side members were drilled out, and the rear panel was cleaned down to bare metal. First, new spars were installed, and then new edges freshly cut from millimeter sheet metal were welded to them by spot welding, as well as parts of the rear panel (see photos 24, 25, 27, 16). At this point, the welding work was completed, but the owner expressed a desire , taking the opportunity to “make noise” of the interior, and treat it with anticorrosive... No sooner said than done, especially since the customer supplied the materials himself, with the exception of body iron.

So, the hidden cavities were treated with Movil, the interior was glued, the bottom was treated with bitumen mastic (the rear panel, of course, also got it) see photos 18, 19, 20.

Washed down the spar — Lada 2110, 1.6 l., 2005 on DRIVE2

Well, I haven’t written anything so useful for a long time and many people have probably lost interest. Well, I began to do something further with the car) when the right drive was heavily underestimated, it hit the side member, the knock is not pleasant, I’ll tell you, from -100 and those who use pneuma will understand me. I started drinking almost a week ago, namely on August 16, 2013. I thank my friend Rodriguez102 very much, namely Oleg and Anton and the whole family) I won’t write much, just the key points) They said if you go down and stop by, we’ll do it) in the end I got there, went down and everything is ok)

We started somewhere around 10-11 o'clock and finished at 18:00

The first problem was to remove the stand; there are elongated studs on the support and they broke off and did not unscrew. They cut it off, then the spruce armor was removed, because the ears bent and tightened the nuts, it was unfortunate, but we took it off) and then we did everything slowly and in between times and helped them with the housework myself) Well, let's start, we took the grinder, marked what needed to be cut and away we go)

Mode

Oleg in progress)

Then they took a 3-4 mm pipe, Oleg not only cut it, but also directly adjusted it in everything)

We adjusted everything to the pipe, and because... 3-component longe, it was decided to open one layer and boil it in all places where possible

Middle layer

Oleg cursed for such a low car, it was hard for him to cook)

In general, we welded everything we could and as best we could, it looks like this) in fact, very conscientiously, really) everything was done neatly without rushing) well, just like I did for myself)

Then they cleaned up the whole thing and went over it with Movil, now there is no knocking)

And yes, I took off one spacer, then another second) now the muzzle is lower, the front fender covers the tires by 2-3 cm, and the wings hurt terribly when turning inside out; I already solved the problem yesterday, I just rolled up the edge more tightly and clamped it, ph no, they had no time )

I thank Oleg and Anton and his entire family for implementing and helping to solve this problem) THANK YOU SO MUCH

!

I’m waiting for banal comments “Why are you doing this, you’re an idiot, you’re ruining the car” and in that spirit) and for those who finished reading, please like it, it’s not difficult for you, but it’s nice for me)

Rear spar repair kit 2108-09

The rear spar repair insert allows you to replace only part of the body part, which simplifies the repair and makes it cheaper. The repair kit is a reinforcing element located on a bend; it is believed that this particular place on the body is subject to intense rusting.

In practice, it is not always possible to use a repair insert, since both the rear beam fastening in the side member (the main problem of 2109) and the jack often rot. The average cost of a repair insert in auto stores is 700-800 rubles, catalog numbers are 2108-5101372 and 2108-5101373 (right and left sides).

Preparation for work

Considering the long-term use of the VAZ 21099 sedan, the condition of the vehicle’s structural frame may not be the best. Therefore, if you need to replace the rear side member of a VAZ 21099, you need to purchase all the necessary spare parts.

Replacing the rear beam

It is equally important to decide how the replacement will be carried out. If you do everything in a garage, you will need a lift and the necessary equipment. If you are replacing the rear side member yourself, you need to perform a number of preparatory work before lifting the car on the lift.

- Seats, carpets and interior floor coverings must be removed. This is done to comply with fire safety and maintain the quality of materials.

- Considering the welding work, it is advisable to dismantle (or at least protect with special material) the fuel tank with gasoline residues. And after the car is on the lift, be sure to disconnect the negative terminal from the battery.

Further operations are carried out in the following sequence:

- drive the car onto a lift, remove the wheels from the hubs;

- release the rear beam with suspension elements, otherwise it will be impossible to carry out work;

- clean the rear spar to determine the mounting points.

It should be borne in mind that the spar is usually secured by spot welding, so it is important to locate all such places. For better cleaning, use a wire brush. We clean the welding areas using an angle grinder.

Rear spar repair kit 2108-09

The rear spar repair insert allows you to replace only part of the body part, which simplifies the repair and makes it cheaper. The repair kit is a reinforcing element located on a bend; it is believed that this particular place on the body is subject to intense rusting.

In practice, it is not always possible to use a repair insert, since both the rear beam fastening in the side member (the main problem of 2109) and the jack often rot. The average cost of a repair insert in auto stores is 700-800 rubles, catalog numbers are 2108-5101372 and 2108-5101373 (right and left sides).

Replacement procedure if you decide to do it yourself

- Raise the entire car on a rack lift, or just the damaged side.

- The VAZ 2109 spar is attached using spot welding, it must be drilled out. Anything that cannot be drilled out, cut off with a grinder.

- If some elements of the part are inaccessible to you, then remove the suspension (the wheels will have to be removed in any case).

- If, after all that has been done, you still cannot remove the spar, cut it off with a chisel.

- Let's try on a new part. If it is larger, then we will cut off the excess part.

- In the new case, we make holes in the places where you will weld it.

- We attach the part to the body by welding.

- We clean the welded points with a grinding machine.

- We prime the new part and paint it in several layers.

- If desired, you can carry out anti-corrosion treatment.

As you understand, you can’t joke with the spar. And if you are not an expert in body repair, then all defects need to be repaired at an auto service center. Well, and lastly, a funny video of how our compatriots decided to quickly straighten the side member of a VAZ 21099.