The appearance of the car, among other things, depends on the wheels installed on it. Stylish alloy wheels can transform the simplest and most unprepossessing car, giving it originality. VAZ car owners have access to a wide variety of rims:

- stamped;

- cast;

- light alloy.

For each type you have to buy suitable bolts to securely fix the wheel. These fasteners are made from numerous materials:

- black metals;

- nickel alloys;

- metals with the addition of zinc or chromium;

- alloys with molybdenum, etc.

When choosing wheel bolts, be guided not only by their appearance and strength, but also by their dimensions: length, head type, thread size and pitch.

Types of fasteners

Here are the types of fasteners needed for alloy wheels:

- Bolts are metal rods with a screw thread at the end. Used to connect detachable elements.

- Nuts are round-shaped parts designed to fasten elements by screwing a metal die onto threaded rods.

Steel, aluminum or titanium alloys are used to produce products.

Titanium bolts are distinguished by high quality indicators. Black bolts for alloy wheels are made from steel with the addition of molybdenum or steel with a chrome or nickel coating.

Other parameters of VAZ 2115:

| General parameters of wheeled $iden VAZ 2115 | |||

| Drawing General schematic drawing of wheel bolts | Quantity (pcs) Number of fasteners per hub for VAZ 2115. | ||

| Size(mm) Metric Fastener Size: Thread M14 x 1.5 means: M14 – thread diameter 14 (mm); 1.5 — thread pitch (distance between adjacent threads). | Type Wheel mounting type: To fasten wheels or disks, 2 main types of fasteners are used: - wheel bolts; -wheel nuts. | ||

| (bolt drawing) | 4 things) | M12x1.25 (mm) | Bolt |

| Wheel size tables $iden VAZ 2115 | ||||

| Year Number of fasteners per hub for VAZ 2115. | Quantity (pcs) Metric Fastener Size: | |||

Thread M14 x 1.5 means:

M14 – thread diameter 14 (mm); 1.5 — thread pitch (distance between adjacent threads).

Caution: the above data are the official figures of the manufacturer, however, please note that the information is for reference only and does not guarantee absolute accuracy.

Characteristics of bolts and nuts

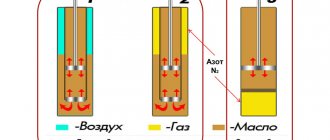

Bolts and nuts differ in design features, so the choice is determined by the type of disk. The stamped disc is made from a durable type of steel. Moreover, it has a small thickness at the point of attachment to the central part of the rotating part. For an optimal connection, the bolt and nut must have a flat surface. The composition of cast wheels includes relatively light alloys. They have reduced reliability characteristics. The fastening system of the products is made in the form of a cone.

What are these wheel mounts?

Wheels are fastened with both bolts and nuts; the second option is less common among us than among the Americans or Japanese, so today we will talk about wheel bolts, not nuts. Bolts can have different shapes, sizes, configurations and colors; in addition, bolts from different manufacturers can differ in threads and the composition of the metal from which they are made. As a rule, bolts are made of metal, less often titanium or aluminum. As for color, chrome-plated wheel bolts or nickel-plated analogues are most often popular, however, both of them are not particularly resistant to corrosion.

How to measure yourself

Measurements must be as accurate as possible, since the indicators differ in close values with a distance of a couple of millimeters, for example, 98 and 100 or 110 and 112, and they are not interchangeable. To eliminate errors, it is recommended to use a caliper or ruler.

Adjacent holes

Here's how to determine the distance between bolt holes. The dimensions of the circle on which the holes are located are taken. The diameter is determined using compatibility tables or by measuring using a ruler. The resulting distance between adjacent fasteners should be multiplied by a factor that depends on the number of holes. The circumference of a VAZ is 9.8 cm, and that of passenger cars is 139.7 millimeters.

Far holes

A simple measurement method is carried out on models with an even number of recesses - for 4, 6, 8 fasteners. Parallel Hole Distance – PCD.

And here’s how the far holes of disks with five bolts are measured: the calculation is made between non-adjacent recesses, the resulting figure should be multiplied by 1.051.

Hub window diameter

Indicative data for the central hub window are indicated in the table and in the complete bolt pattern formula. In the absence of information, readings are measured with a ruler or caliper. The diameter of the hub area on the VAZ 2110 = 58.6 mm.

The bolt pattern is carried out taking into account the relative size of the vertical axis of symmetry of the disk to the area adjacent to the hub.

Product types

The variety of vehicles leads to a wide range of accessories. For this reason, not all models are created equal and will not fit every vehicle. Each nut has a special design.

How do wheel bolts differ from each other?

- Carved. The most common models are with diameters 12-14, with a pitch of 1.5 mm. Tighten in such a way that the number of revolutions is at least 8 for strong fastening.

- Depth and width of the well for fastening.

- Length. This indicator should be calculated so that when screwed into the hub, the steel product sticks out from the reverse side. In this case, you will get a reliable connection.

- Material from which the product is made: black iron or steel.

- Top coating: molybdenum, chrome or nickel.

Depending on the shape and size, the following types of automotive bolts are distinguished:

- Spherical. The hat has a round shape.

- Conical. They have a classic cone shape with a mounting angle of 60 degrees.

- Short. Used for “stampings”.

- Long. Used for casting.

On a note! A separate category includes secret and eccentric models. They have unique shapes and designs.

Full and abbreviated bolt pattern formula

Manufacturers provide detailed wording that reflects all important meanings. Motorists use abbreviations that do not fully describe the product.

Abbreviated

PCD (Pitch Circle Diameter) is a short formulation that includes two parameters. It is indicated: 4×98 – wheel bolt pattern on a VAZ-2110. The number of four indicates the number of bolt recesses. The number 98 was obtained as a result of the transverse method of measuring their circumference.

Full

Let's look at an example: the full bolt pattern formula is indicated on the rim: 7.5 J×15 H2 5×100 ET 40 D 54.1.

Decoding of alphanumeric groups means:

- 5 JX 15 – rim width 7.5 inches and diameter 15 inches;

- X – indicates that the disc is made by casting or forging;

- J – it is recommended to use the product on single-wheel drive vehicles;

- JJ – marking of all-wheel drive models;

- H2 – the number of protrusions that secure the tires. Models with one protrusion - H1. Absence of protrusions - marking AN;

- Hump - indicates high-quality rubber retention; this feature eliminates depressurization.

Preparing for adjustment

Most often, the VAZ 2110 camber and alignment are installed at a service station, but you can do it yourself. First of all, check whether there is play in the bearings and whether the steering is loose. At the same time, check the diameter and absence of deformation of the disks, air pressure in the tires, and tread wear.

VAZ 2110 front suspension assembly diagram

Naturally, if a wheel is loose, action will need to be taken, and one with improper tread wear may need to be replaced. Wheels standing on the ground need to be pulled relative to the vertical. If you find any play, have a helper apply the brake and check the play again.

If it disappears, the bearing needs to be replaced. If after this the size of the play not only does not disappear, but only decreases slightly, the suspension needs to be checked, repaired, and sometimes replaced.

Front wheel hub diagram

After this, hang the wheel and check the play again. It is possible that the play has disappeared, but the wheel turns jerkily or is simply difficult, then you need to slightly expand the diameter of the bearing installation site.

If you hear a grinding noise, the bearing needs to be replaced.

Consequences from another bolt pattern

Using inappropriate bolts is a safety hazard. When a bolt pattern occurs, an axial displacement of the entire wheel relative to the hub occurs. At high speeds, the wheel spins unevenly, the car will shake, which is accompanied by a beating in the steering wheel.

When installing wheels, car enthusiasts often encounter such a problem as a discrepancy in the diameter of the fasteners. In this case, eccentric bolts with a movable conical part are suitable, which will eliminate discrepancies in size.

Compatibility table

The diameter of the bolt holes is a key factor when looking for wheel bases. Buying wheels without taking these indicators into account is a big risk, since the fasteners affect the condition of the car's chassis. Even minor discrepancies lead to damage to the suspension and steering.

Tightening fasteners on alloy wheels

Before installing the bolts into the mounting recesses, it is recommended to treat the hardware with graphite lubricant. As a result, when it comes into contact with the disk, the head of the bolt or nut will rotate and make full contact. This will prevent blocking during starting power due to friction between the disc and the mounting system. Bolts are produced that compensate for minimal deviations in fastener dimensions. A loose connection will lead to cyclical failures in the fastening system; the bolts and nuts will begin to unscrew themselves.

Locking bolts for alloy wheels

Secret bolts for alloy wheels are another subtype. If you install locks, car tires will be protected from theft. You won't be able to remove the wheel with a regular wrench. To unwind the secrets, you will need a key that comes with them in one set.

When selecting fasteners for wheels, you should remember that cast products are relatively thick. Accordingly, longer bolts are selected for them than for stamped discs.

Car wheels perform not only basic operational functions. It’s hard to imagine the stylish appearance of a vehicle without well-groomed and pleasing wheels. The choice of products on which tires will be installed must take into account a number of factors.

Tuning decisions should in no way be made to the detriment of the technical characteristics of the car. The selection of wheels for a VAZ-2107 will be successful if you take into account a number of technological and design features of the model.

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Throughout the entire period of mass production, the VAZ 2107 was equipped with stamped wheels with a diameter of 13 inches (R13) for standard 175//70 R13 tires. Export versions, as an exception, were equipped with light alloy models of the same size.

In addition to diameter, there are a number of other parameters of car rims:

- width;

- bolt pattern;

- departure;

- centering hole.

The standard rim width of the VAZ-2107 of various models ranges from 5 to 5.5 inches. This size is of great importance for the directional stability of the car; the coefficient of adhesion to the road surface depends on it. Symbol: 5.0J or 5.5J.

The bolt pattern in production models is indicated by the symbols 4x98, where 4 is the number of holes for mounting bolts, 98 is the diameter in millimeters of the circle on which they are located. To put it simply, 98 mm is the distance between the central axes of opposite holes. Novice car enthusiasts underestimate another important parameter. The diameter of the hole itself affects the reliability of fastening the wheel to the hub; it must be taken into account when choosing mounting bolts.

Overhang is the distance between the plane of contact of the disk with the hub and the plane that conventionally cuts the rim in the center. There are positive and negative offsets. In the first case, the wheel is recessed into the arch, in the second it is moved towards its outer boundary or even protrudes beyond it. The standard offset of VAZ-2107 wheels is positive and amounts to 29 mm (ET29).

The centering hole for production models is marked with DIA 58.5. The numbers indicate the hub diameter in millimeters. The value of this parameter is important when choosing new disks; if the centering values do not match, a special sealing ring is additionally purchased. The tightness of the fit of the central hole of the disk to the hub is a determining factor; the correct operation of the tires and the absence of “runout” of the wheel depend on it.

Useful video

You can find more interesting information in the video below:

The appearance of the car, among other things, depends on the wheels installed on it. Elegant alloy wheels can transform the simplest and most inconspicuous car, giving it originality. VAZ car owners have access to a large selection of wheel rims:

For each type, you must purchase the appropriate bolts to securely secure the wheel. These fasteners are made from a variety of materials:

- black metals;

- metals with the addition of zinc or chromium;

- nickel alloys;

- alloys with molybdenum, etc.

When choosing wheel bolts, consider not only their appearance and strength, but also their size: length, head type, thread size and pitch.

Freelance options

VAZ-2107 cars are equipped with stamping, which has certain advantages and disadvantages. Stamped discs serve for a long time and reliably, bend and do not burst upon impact, and can be easily repaired even at home. Such models are easy to use, affordable, and do not attract the attention of intruders. However, the relatively large weight increases fuel consumption, makes acceleration and braking difficult, and creates inconvenience during installation and dismantling.

Innovative light alloy models are divided into 3 categories based on their manufacturing method:

Cast ones are made from alloys based on aluminum or magnesium, which allows them to reduce their weight by a third compared to standard versions. The fragility and inelasticity of the material upon impact leads to chips or even bursting of the wheel.

Forged products are distinguished by increased strength and lower density due to hot stamping technology. Deformation requires a lot of force, but the inflexibility of the material forces the suspension to take on the full force of impacts when driving on a bad road.

Prefabricated ones consist of 2-3 segments fastened with bolts. You need to pay special attention to the fastening material. Steel bolts rust quickly, titanium bolts do not corrode. Components can be manufactured using different methods and from different materials. This technological solution makes it possible to reduce weight, increase the interchangeability of parts and the maintainability of products.

Characteristic differences

Wheel bolts for stamped wheels differ in length and material. Usually good steel is used, which has several types of coating:

It must be said that any type of coating is only a top protective layer. Therefore, it cannot provide reliable protection against corrosion.

To give the stamped disc a more aesthetic appearance, chrome-plated bolts are ideal. If you properly care for your car and operate it normally, the bolts will never rust.

Selection principles

The selection of wheels is made taking into account the design features of the vehicle and operating conditions, assessing the impact of many factors.

The VAZ-2107 on 14 wheels looks more attractive than the standard version, but it must be taken into account that a new light-alloy version will lead to additional financial costs due to a change in tire size.

A car with 15 rims looks beautiful, but requires the use of low-profile tires, otherwise the tires will rub against the wheel arch protection. Operation in off-road conditions, maximum loading of the trunk with this option is fraught with negative consequences.

Wide wheels with a long offset increase stability, but tend to heavily pollute the car in bad weather conditions. The large curb weight of the car leads to friction between the tires and the fender liners.

The selection of accessories is carried out taking into account the correspondence of the parameters of the tires used to the standard sizes of the wheels. Dimensions of 13 inches exclude the use of wide-profile tires due to the small volume of the wheel arch.

Choosing non-standard wheels means replacing car tires. It is necessary to take into account the acceptable tire sizes for the VAZ-2107 recommended by experts:

- diameter 13-15 inches;

- width 165-185 mm;

- tire profile – 55-80%.