Don't panic

This is a signal to the driver that a breakdown has occurred in the anti-lock braking system. Many people panic and are afraid to travel. Sometimes the car is dragged on a tow truck or on a cable, and the reason is that the ABS light is on.

No need to worry, because the brakes on the car work. Check to see if the brake fluid has leaked, try pressing the brake pedal. The car is slowing down, only the ABS system has failed. This means that on the way to the repair site you should not brake sharply so that the wheels do not skid.

How to modify the design

To protect the wiring harness from the environment, you can use a D-shaped seal. We lay the wires in it and wrap it with electrical tape. We put everything in the corrugation. We glue the cover covering the ABS sensor connector around the perimeter with the same sealant. This will prevent moisture and dirt from entering the area where the sensor and connector are located.

Attention! If the ABS fails, the brakes remain operational, but the braking efficiency is reduced, which is especially dangerous on some surfaces. See why.

An anti-lock braking system is installed in almost every modern car, and it greatly helps drivers avoid wheel locking. Cars with ABS provide maximum efficiency of the braking system, which allows you to reduce the braking distance. To diagnose the operation of the anti-lock braking system, the driver has a special indicator on the instrument panel. When it lights up, the car's computer systems warn the driver that the ABS is not currently working, and wheel locking is likely if the brake pedal is pressed too hard. The anti-lock braking system, if the car is equipped with it, must be maintained in working order, and besides, there are not many reasons why the ABS light is on.

How does ABS work?

The electronics regulate the brake force on all wheels, preventing them from locking when braking, but allowing the car to stop quickly. By braking sharply, the car will not lose stability.

If the system is out of order, or it is not installed on the car at all, then the wheels will lock during sudden braking. A strong skid may occur, especially in winter, or when turning. If the ABS is working properly, this will not happen. Even when turning, you can press the brake pedal sharply - there will be no skidding.

If the ABS light is on, the reason is a system malfunction. This is easy to check - accelerate to a speed of 40 km per hour and sharply press the brake pedal to the floor. If there is no pedal vibration and the wheels are skidding, then the ABS is not working.

If the system is working properly, you can sharply press the brakes and try to go around the obstacle. In this case, no skidding will occur. If the anti-lock braking system fails, the car will skid and hit this obstacle.

Causes of ABS error

The main possible reasons for a constantly burning ABS light on the dashboard:

- the contact in the connection connector has disappeared;

- loss of communication with one of the sensors (possibly a wire break);

- The ABS sensor has failed (the sensor needs to be checked and then replaced);

- the crown on the hub is damaged;

- The ABS control units have failed.

After inspection and, it would seem, elimination of the cause, it is very easy to check the operation of the ABS; you just need to accelerate to 40 km and brake sharply - the vibration of the pedal will make itself felt and the icon will go out.

Causes and their elimination

If you have repaired the ABS problem yourself, in most cases the light will go out after a few trips with the brake pressed. If everything is in order, the system will see this and turn off the lamp.

This is all the information related to self-diagnosis. It’s unlikely that you’ll be able to find anything else on your own. A good car service center will connect a scanner to your Lada Granta, which will be able to read the system and identify the cause. Most often the sensors or control unit are to blame. Subscribe, good luck to everyone on the roads, look forward to many more interesting things!

Source

Let's sum it up

Problems with ABS are not very pleasant incidents in any case. It is better to stay away from various problems and try to operate the car according to the requirements and advice of the manufacturer. But sometimes this turns out to be impossible, so it is necessary to have a good service in mind that can help in different situations. By contacting an official service center with this problem, you may become a victim of an overly scrupulous approach to diagnostics and incur huge repair costs.

However, sometimes the problem with the ABS sensor and the light on this system can be solved independently. Use the tips described above in the publication to understand all the features of a particular troubleshooting method. We warn you that it is impossible to completely disable ABS yourself. The on-board computer will either simply not allow the car to start, or will begin to behave inappropriately, producing new diagnostic system error codes each time. Have you encountered incorrect operation of ABS sensors and a constantly burning light?

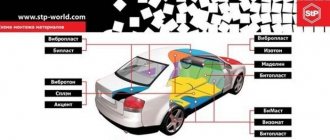

The ABS system is an important element of the entire car design, without which safe movement is indispensable. According to statistics, the reason for a large number of road accidents is that drivers do not use the braking system correctly. In most cases, this problem occurs in winter, when the road surface is very slippery. Let's take a closer look at the components of the ABS system, and also give advice on what to do if the ABS light comes on.

Lada Granta Red Luxury Mechanics › Logbook › Granta and ABS - a surprisingly successful tandem

The brakes themselves on the Grant are ordinary; there aren’t enough stars in the sky. At reasonable speeds they are quite effective, especially on good tires.

But what is quite above average on Grant is ABS. What is ABS anyway? This is a system that, when the brakes are fully applied, seeks a balance between efficiency and controllability. This is how all ABS work, but the details are very important.

You can't comprehend the details without a glass. I'll try to explain it on my fingers)).

What types of ABS are there? Three types - 4s/2m, 4s/3m and 4s/4m. It is likely that the first two types of ABS were used previously, although I have not studied the issue and I won’t lie. I will only talk about four-modulator ABS.

ABS is a blessing. To understand this fact, I recommend taking a ride in FF2 or Logan in trim levels without ABS. There is a pressure limiting valve in the rear axle (much simpler and more reliable than the VAZ regulator), but once and for all configured in such a way that it actually deprives this axle of brakes.

For those who like exact numbers, about 50 kg of force on the rear alone is allowed. While on wet asphalt, for example, you can realize at least 200 kg. This is all done so that the rear will not be blocked before the front at all and on any surface, including the Olympic bobsleigh track.

On cars with ABS, the problem of advanced locking of the rear axle is not so acute, although, contrary to the opinion of many, it still exists. This is true, by the way.

Modern ABS 4S/4M is a subtle and vicious thing. You can configure it so that each wheel will implement the maximum possible braking force at a given time.

It's not hard to see what this will lead to in mixed doubles. Let's say the left wheels are driving on dry asphalt, and the right wheels are driving on the icy side of the road.

And then I had to brake sharply. At a minimum, there will be a sharp departure from the course towards the wheels with more grip (towards the oncoming lane). Or even a simple and vulgar spread with a flip and/or other goodies.

Tuning for a “weak” wheel is also not the optimal solution, because then the braking efficiency drops significantly.

Therefore, they achieve some average, optimal, compromise response. Due to the fact that finding this compromise is difficult, expensive, requiring roads, machine hours and very skilled man hours, it has become fashionable to do most of the work on the computer. The result is a little predictable.

About a year ago, there was a series of articles in the AR about severe bugs in the ABS operation of Polo sedans and Tiguans. There, in certain circumstances, the ABS began to think that there was some kind of crap under the wheels, such as ice, and the brakes disappeared almost completely. www.autoreview.ru/_archiv…_ID=69757&SECTION_ID=1991 www.autoreview.ru/_archiv…ID=123939&SECTION_ID=6991 www.autoreview.ru/_archiv…ID=130174&SECTION_ID=7344 www.autoreview.ru/_archiv…ID=128368&SECTION_ID =7279 As for our Soviet cars, due to poverty, we have not yet learned how to properly work on computers and do a lot of things the old fashioned way, on the road.

The result, I admit, is worth it. ABS Grants, if not the ideal of such a system, are then a very close approximation to such an ideal. Nothing can turn her away from the true path - not a mix, not a turn, not a bumpy road. It works late, allows the wheels to slide a lot, and doesn’t seem to be prone to “hanging” when the brakes are released. In the debate between braking and handling, efficiency clearly wins. This makes me very happy.

Even more gratifying is that Granta happily escaped the Nigerian problems from the links above.

It is clear that with such a balance, ABS in the direction of brake efficiency, on mixed doubles, pulls quite a bit to the side. But if there is an electric steering wheel and the driver is willing to not count crows, everything is within the limits of the rules and common sense.

And the fact that it will be difficult to drive around an obstacle on bare ice with such ABS is right; if you don’t jerk around the steering wheel on black ice, less people around you will suffer.))

Source

Replacing the front wheel ABS speed sensor wiring

Procedure for removing the front wheel ABS speed sensor wiring

- Disconnect the negative battery cable.

- Disconnect the brake system controller connector.

- Remove the corresponding contacts from the connector:

- Right sensor - pins 4 (WHITE) and 5 (GRY).

- Left sensor - contacts 6 (BOR) and 7 (GOL).

- The harnesses for both sensors branch off from the ABS harness immediately at the ABS connector. The right sensor harness runs along the top of the bulkhead and goes to the right fender. The left wheel sensor goes directly to the left fender.

- Disconnect the wheel speed sensor harness from the wiring harness.

- Remove the electrical connector from the clamps and disconnect it from the sensor.

Front wheel ABS speed sensor wiring installation procedure

- Install the front wheel speed sensor connecting harness.

- Connect the front wheel speed sensor connector and secure the harness with clamps.

- Connect the sensor harness to the ABS harness.

- Install the contacts into the connector in the same order in which they were removed:

- Right sensor - pins 4 (WHITE) and 5 (GRY).

- Left sensor - contacts 6 (BOR) and 7 (GOL).

- Connect the brake system controller connector.

- Connect the negative battery cable.

Source

ABS system on a Lada Granta car

The principle of operation of the system is simple: receiving data from the rotation speed sensors of all wheels and from the vehicle speed sensor, the control unit controls the rotation of each wheel and, if the wheel locks during braking, reduces the pressure in the corresponding brake circuit.

The ABS system ensures full control of the car during emergency braking, but does not lead to a reduction in braking distance.

Therefore, you need to maintain the correct distance.

On vehicles with an ABS system installed, a four-channel system is used.

The channels are connected according to a diagonal pattern.

The executive element of the anti-lock braking system is a hydraulic modulator. This is a complex assembly in which a hydraulic pump and solenoid valves are built in.

It is installed in the engine compartment.

The operation of the hydromodulator is controlled by an electronic unit installed on the hydromodulator.

The control unit also monitors the health of all elements of the ABS system.

Wheel speed sensors are installed in the front and rear brake mechanisms.

Why does the ABS light come on?

Based on the ABS device, we can come to the conclusion that the system malfunction indicator may light up for the following reasons:

- Problems with sensors installed on wheels;

- Malfunctions in the ABS system control unit;

- The cables between the elements that transmit information about their status are faulty;

- There are problems with the crown on the hub.

All the described malfunctions can appear while driving. For example, vibrations on rough roads often lead to wire breaks. When driving off-road, dirt may stick to the sensors or sand may become clogged with them, which will not allow them to transmit the correct information to the system control unit, and it will indicate a malfunction by turning on the ABS light on the instrument panel.

Inductive type sensors

To operate the sensors installed in the front brake mechanisms, gears are made on the housings of the external hinges of the front wheel drives.

To operate the sensors, master discs are installed in the rear mechanisms under the brake drums.

Rice. 4. Rear wheel speed sensor

Pulse signals from the sensors enter the control unit.

When one of the wheels is blocked, the hydraulic modulator, at the command of the control unit, limits the pressure in the corresponding channel.

If a malfunction is detected, the control unit informs the driver using a warning lamp on the instrument panel.

The problem can be determined by the fault codes.

An ABS malfunction may be caused by a failure of the wheel rotation sensors or a malfunction of the hydraulic valve block itself.

If the ABS fails, the braking system remains operational, but braking efficiency is reduced.

Removing the ABS hydraulic unit

We install the car on a lift or inspection ditch.

Disconnect the plug block of the wires from the hydraulic unit.

We disconnect the brake pipes going to the brake mechanisms from the hydraulic unit of the anti-lock braking system. We install plugs on the tubes and holes in the hydraulic unit.

Disconnect the primary and secondary circuit pipes of the master cylinder from the ABS hydraulic unit.

Using a 13mm socket, unscrew the two bolts securing the hydraulic unit bracket to the front side member.

Remove the hydraulic unit with the bracket assembly.

Using a 10mm wrench, unscrew the hydraulic unit from the bracket.

Hydraulic unit installation

We install the hydraulic unit on the bracket and secure it with nuts. The tightening torque of the nuts is 7 – 10 Nm.

We install the hydraulic unit with the bracket assembly on the car body and tighten the two bolts with washers securing the hydraulic unit to the left side member.

We remove the plugs and attach the tubes to the ABS hydraulic unit. The tightening torque of the tube fittings is 15 – 18 Nm.

Attach the plug block. Install the battery. We bleed the brake system.

Removing and installing the front wheel ABS sensor and rotor

We install the car on a lift or inspection ditch.

Disconnect the front wheel speed sensor harness connector from the front wiring harness.

Using a flat-head screwdriver, remove the speed sensor harness block holder from the hole in the car body.

Remove the sensor harness from the brackets on the front suspension strut and the car body.

Using a TORX E8 socket, unscrew the bolt securing the speed sensor to the bracket on the steering knuckle and remove the sensor.

Installing the front wheel speed sensor

Before installation, apply AZMOL LSC-15 lubricant to the mating holes. Install the sensor in reverse order. The tightening torque of the sensor mounting bolt is 6 – 9 Nm (0.6 – 0.9 kgcm).

If it is necessary to replace the ABS rotor of the front wheel, then replace the drive assembly: (right front wheel drive part. 11180-2215010-10, left front wheel drive part. 21700-2215011-00) or the outer hinge assembly (part 11186-2215012 -00).

Removing the speed sensor and rear wheel rotor of Lada Granta

We install the car on a lift or inspection hole.

Disconnect the rear wheel speed sensor harness connector from the wiring harness.

Using a flat-head screwdriver, remove the speed sensor harness block holder from the hole in the car body.

Remove the rear wheel speed sensor harness from the mounting brackets located on the rear suspension arms and vehicle body.

Using a TORX E8 socket, unscrew the bolt securing the speed sensor to the bracket.

Remove the rear wheel speed sensor.

Before installing the speed sensor, lubricate the mating parts with grease.

The tightening torque of the sensor mounting bolt is 6 – 9 Nm.

Removing the rear wheel rotor

Place the car on a lift and remove the rear wheel.

Using a 7mm socket, unscrew the guide pins securing the drum.

We insert the pins into the threaded holes of the brake drum and screw the pins in sequence. Thus, compressing the brake drum.

Removing the brake drum

Removing the rear wheel rotor

In the rear block of a car with an ABS system there is a hole into which the tip of the speed sensor fits.

Installation

Apply grease to the hub seating belt, install the brake drum and tighten the guide pins. The tightening torque of the pins is 7 – 15 Nm. Install the wheel.

Reviews

“Using a 7-head socket, unscrew the guide pins securing the drum.”

Using a 7-head socket, we unscrew the guide pins of the wheel rim, which are also used to secure the drum.

Source

What you can do yourself

Like I said: no need to panic. Let's look point by point at what you can do yourself.

- Open the hood and disconnect the battery. The electronic control unit is located under the hood, usually in the same housing as the hydraulic modulator (brake force distributor). An article on the ABS device. You can recognize it by the large number of brake pipes suitable for the block (usually 6) and a bundle of wires with a connector. So, disconnect this connector and carefully inspect for water or mechanical damage to the contacts. If there is moisture, blow and dry.

- Check the fuses, this should have been done first. Well, never mind, wipe your hands and move on. The ABS system can be supplied with several fuses, which are usually located in the engine compartment mounting block.

- Well, then it’s a little more complicated. If there is a car lift, then look at it. If not, you can lift it with a jack. Your task is to inspect the wires that go to the wheel sensors (usually screwed into the hub) for damage. Because often these wires fly off the mounts and rub against the wheel.

- Wheel sensors are designed with a wire and a connector at the end. The length of the wire can reach 1 meter. Your task is to find these connectors and check the quality and presence of contact. Make sure there is no moisture or rust.

- If everything is in order, but the abs light is still on, then you have a direct route to a car service center. Moreover, it is not always possible to clear an error in the locking system by simply removing the battery terminal.

But in most cases, after eliminating the malfunction, you should drive the car a little and brake once or twice. The abs light goes out.

Everything written here concerns independent searches. A good service center will connect a scanner to your car, which will tell you exactly what is broken.

What is vehicle stability control system?

Modern Lada cars can have up to six different active safety systems. Such correction and driving assistance systems are highly likely to prevent accidents. Let's look at what exchange rate stability systems are available on Lada cars and how they work.

Lada cars (Priora, Granta, Kalina, Vesta, Niva, Largus and others), depending on the model and configuration, can be equipped with the following electronic stability control systems:

When to change the CV joint, signs of malfunction

As was said, the external grenade fails after about 40 thousand mileage. This is evidenced by crunching, creaking and knocking sounds in the area of the drive shafts. To determine which side of the CV joint requires replacement, you need to turn the steering wheel all the way and drive off. In 90% of cases, a worn drive will manifest itself as a crunching sound. For control, you can turn it first in one direction, and then in the other direction, and turn it back. If the CV joint is worn out, a crunching sound will be heard immediately.

This is the case when there are no visual signs of wear:

- Lubricant leaks near the outer joint.

- Cracks, tears on the boot.

- Lost or misaligned clamps.

- There is obvious play when turning the suspended wheel.

If there are visual signs of wear, we replace the CV joint on the Grant as soon as possible.

ABS function

The anti-lock braking system prevents the vehicle's wheels from locking when braking. The main purpose of the system is to ensure optimal braking efficiency (minimum braking distance) while maintaining vehicle stability and controllability. However, when braking on a road with uneven or loose surfaces (gravel, sand, unpacked snow), a slight increase in braking distance may occur compared to braking under the same conditions with locked wheels.

Braking, controlled by ABS, begins at speeds above 5–8 km/h and is accompanied by slight pulsation of the brake pedal and characteristic noise of the actuators. ABS stops regulating when the vehicle speed drops to 3–5 km/h.

When braking in an emergency, press the brake pedal as quickly and as hard as possible and do not release it until the end of braking. When changing direction while braking, do not release the brake pedal.

Warning ! Intermittent braking (releasing and pressing the brake pedal again) with ABS working will increase the braking distance.

The ABS status is indicated by the “ABS” indicator. The indicator lights up yellow when the ignition is turned on and goes out after the engine starts (self-test mode).

ATTENTION ! In all other cases, when the warning light comes on, this indicates an ABS malfunction, which must only be repaired by dealers.

If an ABS malfunction occurs, the operation of the hydraulic brake drive is not disrupted, and braking remains possible as on a car without ABS.

General issues

Let's figure out when you need to change the pads and what to choose from components.

When to change rear pads

Rear pads on Grant are changed at the following indicators

:

- the wheels make noise - rattle - vibrate when braking;

- 1.5 mm (or less) left on the pads;

- the pads have delaminated, causing the wheels to periodically jam;

- stopped holding the handbrake;

- You recently changed the front pads, but haven’t touched the rear ones yet.

As always, the obvious point: we change the pads as a set along the axes! You cannot replace only the right or left wheel and leave the other with the old brakes.

Even with severe wear on the pads, the car can slow down, but this is dangerous and unacceptable.

Selection of components for Grants

We have compiled a table of articles for spare parts

to replace brakes.

Here it is (can be used to search and order online): List of article numbers for all spare parts that may be required for work.

For example

:

Search results for pads in one well-known online store.

– the same in another well-known online store.

There are never too many options.

ABS allows you to shorten braking distances and maintain maneuverability when braking.

EBD function

The brake force distribution system is a continuation of the development of the ABS system. The fundamental difference between the system and basic ABS is that they help the driver control the car all the time, and not just during emergency braking.

EBD provides an optimal ratio of braking forces between the front and rear wheels of the vehicle during unregulated ABS braking and in the event of an ABS malfunction. The EBD status is indicated by the “Brake Failure” indicator. The indicator lights up red when the ignition is turned on and goes out after the engine starts (self-test mode).

Warning ! The simultaneous lighting of the “ABS” and “Brake failure” indicators, with the exception of the self-test mode when the ignition is turned on, indicates a malfunction of the ABS and EBD. In this case, when braking, the rear wheels may lock prematurely and the vehicle may skid dangerously. The fault must be repaired by dealers as quickly as possible.

Front Wheel Speed Sensor Installation Procedure

- Insert the sensor harness into the hole in the wheel arch, insert it into the rubber bushing and secure the bushing in the hole.

- Secure the harness using the bushing fasteners and clamps to the wheel arch.

- Install the wheel.

- Lower the car.

- Connect the front wheel speed sensor connector.

- Connect the negative battery cable.

ESC and TC function

After starting the engine, ESC and TC are switched on automatically.

To turn off ESC and TC when driving in difficult road conditions (mud, sand, deep snow), press and hold the “ESC” switch button pressed for 0.5–1 seconds. Disabling functions only works when the vehicle speed is less than 50 km/h. The functions are activated by briefly pressing the “ESC” switch button or automatically when the speed reaches 50 km/h.

The operation of ESC and TC is accompanied by a characteristic noise of the actuators. The activation of ESC and TC indicates that the limit of tire adhesion to the road surface has been reached. To avoid losing control of the vehicle, you must adapt your driving style to the actual road conditions.

The ESC and TC status are indicated by the “ESC” and “ESC OFF” indicators. The warning lights light up yellow when the ignition is turned on and go out after the engine starts (self-test mode). Triggering of ESC and TC is accompanied by flashing of the “ESC” indicator. When the functions are disabled using the “ESC” switch, the “ESC OFF” indicator lights up with a constant light.

Attention ! In all other cases, the lighting of the “ESC” indicator indicates a malfunction of the ESC and TC, which must be repaired only by dealers.

Attention ! To avoid limiting the performance of ABS, EBD, ESC and TC, do not install tires of different sizes on the vehicle.

How the vehicle's stability control system works is also shown in the video:

What kind of malfunctions can there be?

If you hear a cracking noise when you press the brake pedal, this is normal. This sound appears when modulators operate. If ABS is faulty, the indicator on the instrument panel lights up after turning on the ignition and does not go out, and continues to light when the engine is running.

There are four ABS fault conditions:

- During the self-test, an error is detected and the ABS is deactivated. The reason may be an error in the controller unit or the presence of breaks in the wiring of the rear right abs sensor, or any other sensor. No angular velocity measurement signals are received.

- After switching on, ABS successfully undergoes self-diagnosis and turns off. The reason may be broken wires, oxidation of contacts, poor connection at the contact points, broken power wire, short circuit of the sensor to ground.

- After turning on, the ABS undergoes self-diagnosis and detects an error, but continues to work. This can happen if there is a break in one of the sensors.

Information about the angular speed of the wheel comes from an additional device. The cause of this malfunction may be due to different tire pressures and tread patterns. If one tire is flat, or one wheel has a rougher tread than the others, the wheel will slow down. The same effect will occur if the car is equipped with tires with different degrees of wear.

- ABS doesn't work. The reason may be a break in the wires, the wire near the sensor may have broken off, the wheel bearings may have worn out, there is play or there may be breaks in the wheel sensor rotor.

To correct problems, you need to check the play, tire pressure, and the condition of the wheel sensor rotor (comb). If the comb is chipped, it must be replaced. Check the condition of devices and wires that connect to them. If these measures do not help, then the problem is in the electronics. In this case, for accurate diagnosis you need to get the code.

HHC function

Prevents the car from rolling away when starting on an incline. When stopping on an incline greater than 4%, depress the brake pedal with sufficient force to keep the vehicle stationary. When you subsequently release the brake pedal and press the accelerator pedal, the HHC function maintains hydraulic pressure in the brakes until the vehicle starts, but for no more than 2 seconds, which prevents the vehicle from rolling away.

The operation of the HHC is accompanied by a characteristic noise of the actuators. HHC does not operate when the parking brake is applied, the driver's door is open, or the ESC malfunctions.

Let us remind you that other reviews of Lada cars can be found in this category.

Source

The need to replace the device

Malfunctions in the ABS system are indicated by a warning lamp located on the dashboard of the car. In normal mode, the indicator lights up when the engine starts and goes out after 3–5 seconds. If the controller behaves incorrectly - it turns on while the engine is running or blinks chaotically when the car is moving - this is the first sign of a sensor failure.

The ABS indicator should go out 3-5 seconds after starting the engine

Also, a possible device malfunction is indicated by:

If any of these problems occur, the device should be fully diagnosed. It is not at all necessary to trust this question to highly paid car service technicians - checking the ABS sensor yourself takes little time and is done without expensive equipment. If diagnostics reveal that the device is broken, it will have to be replaced with a new one.

Braking system design Grants

Before you start adjusting and checking, you should find out what the Lada brake system is like and what its features are. The design includes the following parts:

To ensure efficient and safe braking, Grant has a double-circuit (diagonal) pipeline system. The tasks of the first circuit include blocking the left rear and right front wheels. The second circuit is designed to block the left front and right rear wheels. The front wheels have disc brakes, and the rear wheels have drum brakes.

The process of controlling the master cylinder on the Lada Granta is carried out using a vacuum amplifier. This device is designed to improve controllability of the brake system. To do this, you need to press the appropriate pedal. It is necessary to take into account that an anti-lock braking system may be included in the Lada Granta, or ABS will be absent. The Lada Granta system under consideration is equipped with a hand brake that blocks the rear wheels by spreading the corresponding pads in the drums. These parts are moved through levers and by moving a steel cable located inside the vehicle.

The vacuum amplifier is a diaphragm. This element shares the rarefied atmosphere of the vacuum booster with external pressure. The pressure difference helps to reduce the effort exerted on the corresponding pedals. When the brakes are released, the atmospheric and vacuum chambers are connected to each other using a special valve.

Purpose of the ABS sensor and operating principle

The ABS sensor is one of the three main components of the system, which also includes the control module and hydraulic unit. The device determines the moment of wheel locking based on its rotation frequency. When this undesirable event occurs, the electronic control module receives the sensor signal and forms an effect on the hydraulic unit installed in the line immediately behind the main brake cylinder.

ABS sensor with wire and connector

The block reduces or even stops the supply of brake fluid to the locked wheel cylinder. If this is not enough, the solenoid valve will direct the fluid into the outlet line, relieving the pressure already in the master cylinder. When wheel rotation is restored, the control module removes the pressure from the valves, after which the hydraulic line pressure is transferred to the wheel brake cylinders.

Each wheel of the car is equipped with an ABS sensor.

ABS brake bleeding process

In order to efficiently complete the task, it is advisable to carry out bleeding with an assistant, starting with pumping the brake system from the front wheels, then the rear wheels (right and left).

Pressure is released by discharging the pressure accumulator. To do this, turn off the ignition and press the brake pedal about 20 times. And then to proceed to the next stage of bleeding the brakes, disconnect the connectors on the brake fluid reservoir.

General principle of how to bleed ABS brakes

Sequence of removing air from the vehicle

We start pumping the brakes from the front right , and then the left. The procedure takes place with the ignition turned off (position at “0”) and the terminal on the TJ tank removed.

The rear wheels are pumped with the ignition on in key position “2”.

To properly bleed the ABS brakes on the rear left wheel, the sequence of actions needs to be slightly changed.

Procedure for removing the front wheel speed sensor

- Disconnect the negative battery cable.

- Disconnect the front wheel speed sensor connector.

- Raise the vehicle and place it on the supports provided for this purpose.

- Remove the wheel. Cm.

- Turn the steering wheel so that the wheel speed sensor is accessible. The sensor is located at the rear of the steering knuckle near the steering linkage.

- Remove the mounting bolt and the sensor itself from the steering knuckle.

- Remove the rubber bushing from the wheel arch through which the sensor wiring harness and hydraulic drive tube are passed. Remove the wiring harness from the rubber grommet so that the connector can fit through the hole in the wheel arch.

- Release the sensor harness from the bushing fasteners and clamps and pull it through the hole in the arch.

Connector for hydraulic unit ABS 2190, 21901 with wires

Dear customers, in order to avoid errors when sending connector 1928405167R for the ABS hydraulic unit 2190, 21901 of a new type with wires, in the “Comment” line indicate for which ABS unit, your car model, year of manufacture.

Contact carrier 1928405167R with wires for connection to the ABS control unit (hydraulic unit) 21900-3538010-00 / 21901-3538010-01 is used in Lala Kalina, Priora, Granta cars and their modifications and for flashing control units. Can be used to make your own firmware cable for an ABS unit or another. The contacts are already crimped onto the wires (wire length 100 mm) and inserted into the connector according to the pinout sufficient for programming the ABS unit. Can be installed on a car.

Hydraulic unit (ABS) ABS 2190/21901 Bosch for cars with manual transmission and automatic transmission, is most often replaced by the following terms: stability control unit, ABS control unit, ABS brake hydraulic unit unit, anti-lock brake system unit. Therefore, if you hear these terms, then know that we are talking about the same thing.

If you brake hard on a slippery road, problems may arise. The anti-lock braking system (ABS) takes over this action and saves your nerves.

Bosch unit 21901 is part of the vehicle's stability control system with automatic transmission. Structurally, it consists of an electronic control unit (ECU 0 265 242 344), a hydraulic modulator and containing electromagnetic valves (EMV), a return pump and a return pump electric motor (ERM).

Based on received commands, the hydraulic modulator, by turning on or off the solenoid valves, reduces, increases or permanently fixes the pressure of the brake fluid in the wheel brake cylinders, thereby ensuring the best adjustment of the braking forces. When the pressure decreases, excess brake fluid is pumped by the return pump into the main brake cylinder.

The anti-lock braking system (ABS) is part of the vehicle's working braking system and is designed to mechanically regulate the degree of wheel slip in the direction of their rotation during braking due to the metamorphosis of brake fluid pressure in the working brake cylinders with the intention of preventing loss of control and stability of the vehicle and increasing braking performance.

The ABS control unit 2190/21901 continuously checks the locking of each wheel and controls each valve to regulate the brake fluid pressure if required.

The ABS control unit 2190/21901 also checks that the components are working properly and turns off the ABS if a fault is detected.

If the ABS control unit 2190/21901 is faulty, the brake system operates as a standard brake system.

Other article numbers of the product and its analogues in catalogues: 1928405167R.

Applicability: VAZ 2170, VAZ 2192, VAZ 2194, VAZ 21925, VAZ 2190.

How problems with the ABS hydraulic unit manifest themselves in a VAZ family car.

How to independently replace the ABS hydraulic unit on a VAZ family car.

When dismantling the hydraulic unit and pipelines, take measures to prevent brake fluid from spilling.

With the online store Discounter AvtoAzbuka, repair costs will be minimal.

Don't forget to share the information you find with your friends and acquaintances, because they may also need it - just click one of the social networking buttons located above.

The ABS light came on: what to do?

The surest way in such a situation is to use diagnostic equipment, which will allow you to determine from which sensor the signal is not transmitted to the control unit and what errors there are in the operation of the ABS. If it is not possible to check the car on a diagnostic stand, you can take the following actions:

Accelerate on a flat, straight section of the road to 40 kilometers per hour, and then sharply press the brake pedal. If the light goes out, it means that the anti-lock braking system has returned to operating mode, eliminating the temporary malfunction;- In the case when the ABS light comes on for a while while driving and then goes out, you need to carefully check all the wire connections that are part of the transmission of data on the operation of the system. Most likely there are problems with the wires and contacts;

- If the ABS problem lies in incorrect readings from sensors installed on the wheels, you need to check them. Often, when carrying out repair work, auto mechanics forget to connect the ABS sensor. There are often cases when it is simply clogged with dirt and needs to be cleaned. Also, incorrectly installed wheel can lead to problems with the indicators that go from the sensor on the wheel to the control unit;

- The most difficult problem is the malfunction of the ABS control unit itself. If a software failure occurs, you will have to contact a service center. It is worth noting that some modern car models display information about a problem with the ABS control unit on the on-board computer.

The ABS system is extremely simple in terms of its operating principle and self-diagnosis. There are not many reasons why it can fail, and most of them the car owner can detect and eliminate on his own.

( 476 votes, average: 4.53 out of 5)

Source

Replacing brake fluid

To complete the work, you will need an assistant, as well as a rubber bulb.

1. We prepare the car and the necessary equipment to perform the work.

2. Remove the tank cover

To prevent air from entering the hydraulic drive of the brake system, when replacing the brake fluid, make sure that its level in the reservoir does not fall below the MIN mark.

3. Use a blower to remove the working fluid from the master brake cylinder reservoir.

4. Fill the tank with new fluid up to the top edge of the tank.

5. We pump the circuits of the hydraulic drive system, starting with the rear wheels of the car.

6. We pump each wheel cylinder until new (lighter) brake fluid begins to emerge from the fitting.

7. After replacing the fluid in both circuits, we check the operation of the hydraulic drive and bring the fluid level in the master brake cylinder reservoir to normal.

Generations of anti-lock braking system

It took 14 years of effort from a huge number of engineers to create the ABS system. ABS has been produced since 1978, its creator is Bosch.

The first generation of the system (1970) was called ABS-1. This electromechanical product was not reliable and durable due to the thousands of analog components that were used in the ECU. Although the main function of ABS was fulfilled, the product was not suitable for mass production.

Second generation (1978). ABS-2 from Bosch first began to be installed as an option in Mercedes-Benz S-Class cars, and after some time in BMW 7 Series limousines. The number of components was reduced to 140, and the weight of the hydraulic unit was 6.3 kg.

In subsequent generations of ABS, Bosch engineers relied on improving the system and reducing its size. So, in 1980, ABS-2E was released, in which the mass of the hydraulic unit was already 4.9 kg, and the number of components was reduced to 40. In 1995, ABS 5.3 appeared with a mass of the hydraulic unit of 2.6 kg and 25 components. In 2003, ABS 8 was released, in which there were 16 components, and the weight of the hydraulic unit was reduced to 1.6 kg. Since 2010, Bosch has been releasing the 9th generation of the ABS system, which is distinguished by its compact dimensions and hydraulic unit weighing only 1.1 kg.