The thermostat is a key component of the cooling system, which is responsible for high-quality engine warm-up by timely redirecting coolant flows in a small or large circle.

Failure of this unit inevitably leads to a number of problems - overheating of the power unit or the inability of it to reach the desired temperature.

That's why a car enthusiast needs to know how to check the thermostat and what malfunctions of this device exist.

Common Causes of Thermostat Problems

During the operation of the car, the following thermostat breakdowns and the reasons for their occurrence are possible.

- INCREASED HEATING TIME OF THE POWER UNIT. The engine operates unstably (for example, troits), which leads to excessive vibrations of the device valve and damage to its seat. Due to exposure to strong vibration, damage to the temperature-sensitive element occurs. The result is that coolant gets inside the unit (wax comes out), which leads to a malfunction of the device, which stops opening or closing the valve when the required temperature level is reached.

- THE OPENING OCCURS EARLIER OF TIME. The cause of such a breakdown may be the ingress of coolant into a special element that controls the temperature level of antifreeze in the system. The result is an increase in the total volume of filler and premature opening.

- THE THERMOSTAT OPENING IS DELAYED. The reason is the appearance of a leak of a special filler that allows the device to respond to temperature changes. Changing the volume of this element downward will require more heating to open. The result is that the thermostat operates with a certain time delay.

- THE ENGINE OVERHEATS REGULARLY. For example, there may be situations where the thermostat allows coolant to pass through on time, but the engine still overheats. The reason is that the fluid is not passing through the main radiator, but is being discharged through the return line back into the engine.

- THERMOSTAT IS NOT COMPLETELY OPEN. The reason is mechanical damage. The result is a small volume of liquid entering the radiator, and, as a result, overheating of the power unit.

- NOT COMPLETELY CLOSED. This is possible when coolant “sneaks” into the working element. Due to the increase in the volume of the working element, the valve disc cannot close completely.

- INCORRECT OPERATION OF THE DEVICE. For example, opening and closing it ahead of time. This is possible in case of failures in the factory settings and excessive overheating of the cooling system of the power unit.

- DESTRUCTION OF RUBBER SEALING. Due to a breakdown, oil gets into the coolant. The latter acts as a solvent for the rubber seal (rubber simply cannot withstand aggressive influences).

Which thermostat is better to choose and install on your VAZ-2107 if the old one has failed

In recent years, manufacturers of parts for VAZ have been rapidly multiplying. And not all of them offer high-quality products; most sell consumer goods that won’t last even a month. It is better to change the thermostat in the winter, unless it is so broken that it cannot be delayed.

- Judging by the reviews of VAZ owners, the factory device works for a maximum of 3-4 years, and it begins to jam on a large circle, which is not so fatal, but also not good for the car.

- Polish WEEN products are recommended by almost everyone who has dealt with them. They keep the antifreeze temperature at any time of the year, but their operating period is 2 years from the manufacturer, but sometimes they cannot withstand more than 1.5 during intensive use of the car.

- PRAMO ThermostATO from Russia has a bad reputation because the thermoelement is poorly regulated, which does not open completely or late, turning on the fan at each stop. It often jams on a small circle, which is fraught with damage to the engine.

- BAUTLER from China is not an option when spare parts from the Land of the Rising Sun are better than domestic ones. The motor temperature does not rise above 85º C. Suitable if you remove it for winter and use it only in summer.

- PRAMO with a Polish thermoelement, made in Russia, is excellent in operation and easy to adjust. The valve does not turn on even in traffic jams, but after a long drive during the day it can remind you of itself. Warms up the engine quickly and runs for a long time in any season.

Ways to solve problems

Possible solutions to the problem include:

1. If the coolant temperature exceeds the norm (provided the thermostat is working and it is correctly selected), it is necessary to replace the device, but with a higher opening temperature. As a rule, this step is recommended for motorists who operate cars in the mountains and in regions with hot climates.

2. When opening the thermostat late, it is important to ensure that there are no plugs and that the system is completely filled. If the problem is caused by a plug (coolant stagnation), then the best solution is to make a small hole in the plate (2-3 mm). As a result, the coolant flow around the thermostat is normalized, and the engine warm-up time increases.

3. Early opening of the thermostat is possible due to excessive pressure in the system. Zones of different pressure often appear around the device, which leads to its early operation. There are several reasons:

- failure of the cooling system;

- The thermostat spring has weakened;

- The engine runs at higher speeds during the warm-up period.

4. The engine takes too long to warm up.

Causes:

- incomplete closing of the thermostat;

- violation of the integrity of the valve plate (for example, a gap has appeared);

- Incorrect position (possibly changing the location of the air valve).

5. The engine heats up above normal even in a situation where the thermostat is fully open:

- traffic jams or low coolant level;

- failure of the radiator (clogging of its cells);

- failure of the cooling pump or fan;

- contamination of the cooling system.

What will you need for replacement?

Before starting work, you need to make sure you have:

- New working part.

- Wrenches or socket heads with a ratchet and an extension “10” and “13”.

- Phillips and slotted screwdrivers (depending on the bolt heads of the worm clamps used).

- Containers with a volume of about 10 liters for coolant, preferably low and wide; a basin is perfect for this role. If you plan to reuse antifreeze, the container must be clean.

In most cases, up to three new clamps and at least 1–2 liters of antifreeze, similar to that poured into the car, will also be useful, because it is difficult to completely eliminate coolant loss when draining it. The following will help increase the convenience and efficiency of repairs:

- Socket wrench “7” or “8”, suitable for loosening and tightening clamps.

- Pliers that make it easier to remove the factory-installed band clamps on the Classic.

- A funnel for collecting coolant, for example, cut from a plastic bottle.

Often, replacing the thermostat on a Zhiguli is combined with pouring fresh antifreeze and installing new pipes or other parts of the cooling system. In this case, it is necessary to purchase the appropriate spare parts and coolant (total filling volume is 8.65 liters, that is, a little more than 9.5 kg).

Checking the Thermostat

The problems described above can appear at any time. To avoid engine overheating and damage, you need to know how to check the thermostat directly on the car and after dismantling it at home.

It is important to know that after starting the engine, the thermostat is still closed and the coolant flows through a small circuit (through the cooling jacket and the stove). This allows the power unit to quickly reach the desired temperature.

As soon as the required level is reached, the valve opens and coolant flows through the main radiator.

Understanding this principle is very important when checking the thermostat.

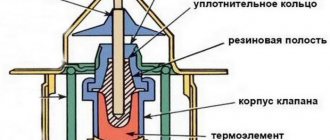

Therefore, we invite you to familiarize yourself with the diagram.

Let's consider two diagnostic options.

Without dismantling

The easiest way is not to remove the unit, but to check it directly on the car. The main condition is a cold engine.

The diagnostic process begins with starting the power unit and warming it up for 2-3 minutes at idle.

This time is not enough for the engine to warm up and the coolant to circulate in a large circle, so the radiator is not yet connected to the general cooling system.

To check that the system is working correctly, touch the pipe that goes to the top of the main radiator with your hand.

The pipe should be cold, which signals the passage of coolant in a small circle (only through the engine and stove).

Therefore, the valve of the device under test is in the closed position (as it should be at this stage).

Continue to monitor engine cooling system performance. As soon as the coolant warms up to 90 degrees Celsius (can be controlled by the sensor), touch the inlet pipe. The thermostat should be open at this moment.

In this case, the coolant is directed in a maximum circle (encompassing the radiator). In such a situation, the pipe that extends from the radiator will be well heated.

By the way, the lower pipe of the cooling system, extending from the radiator, will also be hot.

If the condition described above is not met, then we can talk about a breakdown of the thermostat and its incorrect operation (for example, the valve could be jammed). In such a situation, you need to check it and replace it if necessary.

The second option is also possible, when after starting the engine the tube leading to the radiator warms up almost immediately.

One of the reasons is the valve jamming in the open position and, as a result, the coolant moving in a large circle at once.

The result in this case is obvious - the power unit will not operate in normal mode due to the impossibility of reaching normal temperature conditions.

Such a malfunction is not dangerous for the engine, but can lead to increased fuel consumption.

Situations are possible when the valve “hangs” in the middle position, that is, it does not close or open fully. The problem is diagnosed by the long warm-up of the power unit.

It is more difficult to determine a malfunction in “field” conditions.

In this case, checking the thermostat can only be done by dismantling it.

Checking the functionality of the thermostat by removing

If it is not possible to determine the breakdown without dismantling, then proceed as follows:

- pour the antifreeze into a container prepared in advance. In this case, first install the vessel, and then unscrew the drain plug. To speed up the process of coolant release, unscrew the cap on the expansion tank;

- If there is no such plug, then place a container under the lower part of the radiator pipe. loosen the clamp that holds the pipe to the radiator and remove the pipe itself. Wait until the coolant is completely drained into the container, and then proceed to dismantle the thermostat;

- dismantle the outlet pipe;

- take the thermostat and go to the kitchen. There you will need a stove, a saucepan (or any other metal container) and water. Pour in the liquid and set the pan to heat. Then place the assembly in water so that the body part does not touch the walls of the container itself;

- install a special thermometer in the water and monitor changes in its readings, as well as the actions of the valve itself;

- as soon as the desired temperature is reached, the unit should operate and open. This is possible thanks to the precise operation of the device’s working substance (artificial wax). When heated, the wax expands and allows the valve to operate. If it still does not work at the required temperature, then we can draw conclusions about the unsuitability of the entire assembly (we will talk about the operation temperature below);

- remove the thermostat from the water and let it cool. If the node worked earlier, it should close after a while. Again, if this does not happen, then it needs to be changed.

Consequences of using a faulty thermostat

You cannot continue driving with a faulty thermostat. The engine will not warm up properly, and the flow of antifreeze will normally flow in large and small circles. This can cause a number of serious problems:

- overheating of the internal combustion engine with all the consequences;

- underheating of the engine, which will lead to worse fuel combustion and increased consumption, and the oil will grow a beard on the valves;

- antifreeze boiling in the expansion tank;

- failure of the entire cooling system, etc.

“One winter this happened to me. I’m driving home from a business trip, about 50 kilometers behind me. The track is flat, there is no snow, I move at a speed of 100-120 km/h. Well, I think why should it heat up, fifth gear, the fan cools it, that’s all. Suddenly I looked at the antifreeze reading arrow - below 40. This shouldn’t happen. It’s good that I stopped by the car service on time. The guys quickly determined the thermostat was faulty and replaced it with the original one. I also talked with the mechanics - they said that the open valve position is not so destructive for the engine, but fuel consumption increases and the valves become dirty. You’re lucky, they say it’s not stuck in the closed position, then the motor would have overheated and knocked.” Misha Kim, driver, Andreevsk.

Features of testing on VAZ series cars

VAZ cars continue to be a truly “people's” vehicle. Let's look at how to check the thermostat on a car of this brand.

To begin with, we note that on all models of the Volzhsky Automobile Plant (VAZ 2107, 2114, 2109, 2110, 2114 and others), the principle of checking the thermostat is identical. The only thing that can change is the opening and closing temperature. But this information can be found in the instructions for your car.

As in previous cases, verification is carried out using two methods.

Coolant temperature sensor (DTOZH)

Coolant temperature sensor (DTOZH) VAZ-2104, VAZ-2105, VAZ-2107

To perform work on checking the VAZ coolant temperature sensor you will need: a multimeter, a thermometer (with a measurement limit of at least 100 ° C), a small heat-resistant container with a volume of about 0 .5 liters for water and about 0.2 liters of water heated to boiling point.

Sequence of work to check the coolant temperature sensor VAZ-2104, VAZ-2105, VAZ-2107

1. Release the clamp of the wiring harness block and disconnect it from the coolant temperature sensor.

2. Connect the negative voltage probe of the VAZ engine.

3. Having turned on the ignition of the VAZ car, use a voltmeter to measure the voltage at terminal “A” of the coolant temperature sensor wiring harness block. The voltage at the coolant temperature block terminal must be at least 12 V. If voltage is not supplied to the block, this indicates a malfunction in the power circuit or the computer.

4. Turn off the ignition on the VAZ-2104, VAZ-2105, VAZ-2107.

5. Using a 19 mm wrench, unscrew the coolant temperature sensor and remove it together with the sealing washer from the engine cooling system pipe housing.

6. Connect an ohmmeter to the terminals of the coolant temperature sensor.

7. Fill the container with hot water and immerse the working part of the coolant temperature sensor into it. We record the readings of the device at a temperature of about 90 “C. As the water cools, we measure the resistance of the coolant sensor at temperatures of 80, 60, 40, 30 and 20 °C.

The resistance of a working coolant sensor should approximately correspond to the data shown in the table:

| Coolant temperature, °C | Coolant temperature sensor resistance, Ohm |

| 90 | 250 |

| 80 | 340 |

| 60 | 670 |

| 40 | 1500 |

| 30 | 2250 |

| 20 | 3500 |

If there are large discrepancies in the data, replace the coolant temperature sensor.

Installation of a coolant temperature sensor on a VAZ-2104, VAZ-2105, VAZ-2107 car

1. Installing the coolant temperature sensor on a VAZ car is performed in the reverse order.

2. Start the VAZ engine and make sure there is no coolant leakage from under the sensor. If necessary, additionally tighten the sensor. If it was not possible to eliminate the leak in this way, reinstall the coolant temperature sensor by applying a heat-resistant sealant to its threaded part.

Source

How to check a thermostat when purchasing

When purchasing a new thermostat, blow into the fitting. This will ensure that the fitting is closed as tightly as possible when cooled.

Although this does not guarantee 100% quality, it will at least partially protect you from defects. Unfortunately, there are many defective thermostats on the market now.

Knowing how to check a thermostat, you can always identify a malfunction and avoid damage to the power unit.

Please remember that ignoring failures of this device can lead to engine overheating and failure. The result is even greater costs.

What signs of malfunction occur?

This device can get stuck in both the open and closed states, as well as in one of the middle states. Therefore, cooling malfunction can be of two types,

- The engine will overheat and the antifreeze will boil if the valve is closed and the liquid does not enter the radiator. Then, at least for some time, turning on the stove at full heat and maximum airflow can help. Naturally, this option is the most dangerous.

- The engine will take much longer to warm up if the valve is “stuck” open. This is still better than the first option, but the thermostat still needs to be replaced.

Spare parts for replacing the thermostat in Kalina

So, what you will need for work:

— a new thermostat itself, preferably previously tested for operation with boiling water, so as not to have to do all the work again if it becomes defective;

— 1 liter of coolant of the same brand that is poured into the system; see here

— an empty, clean container of at least 5 liters;

- silicone sealant; for example, like this

- a set of plumbing tools - screwdrivers, pliers, socket wrench - internal hexagon "5".

- desire, minimal plumbing skills and a couple of hours of free time.

It is highly advisable to wash the engine first. You don’t have to work in a garage, you don’t need a hole and you don’t have to crawl under the car. So, let's begin.

Principle of operation

The operation of the thermostat is based on opening the valve and increasing the radius of the circulation system. When starting a cold engine, the valve is closed, coolant circulates only inside the engine itself. When the temperature reaches 80–90 degrees, the valve opens, allowing the radiator to also be used for cooling. Circulation increases. The thermostat is designed to reduce engine warm-up time.

Cleaning

Often the cause of thermostat failure is scale, which clogs the cavities of valves and springs. The result of this is a “freeze” of the valve, which leads to the fact that the power unit cannot reach the optimal temperature regime without heating up enough or, conversely, overheating. It is best to replace such a “stuck” thermostat.

Resuscitation of the device is available to almost every car enthusiast. Any product for kettles or water heating equipment is suitable for cleaning. The technology itself boils down to boiling a thermostat in such a solution for 20 minutes.

After this procedure, you should flush the entire cooling system using special products.

Heater device VAZ 2105

The layout of the heating system of the VAZ classic is by and large standard, but there are still a number of features. The car interior is heated according to a well-known scheme - with outside air, which is heated in a heater radiator connected to the cooling system. In the “five”, outside air is taken in through grilles located on the hood near the windshield. This air duct is isolated from the engine compartment in order to prevent smoky air from entering the cabin from the engine compartment. When it hits the reflector, the outside air is separated from the water (which is important in rainy weather), changes direction and moves towards the stove radiator. The amount of air supplied for heating can be adjusted using a lever that controls the position of the air distribution cover.

The heater radiator is included in the cooling system circuit after the power unit, so the antifreeze entering the radiator is very hot. The outside cold air entering the walls of the heater radiator tubes heats up, cooling the antifreeze, and enters the fan already hot. The fan speed can be controlled via a three-position switch located in the cabin. The fan directs hot air to the air duct nozzles to heat the windshield, side windows, driver/passenger footwells and the upper part of the cabin.

A special feature of the VAZ-2105 heating system is the presence of exhaust ventilation. Air from the cabin is removed through decorative grilles installed on the rear side panels. To prevent outside air from penetrating into the cabin through the decorative grilles during strong crosswinds, a valve is built into the corresponding air duct that allows air flow in only one direction.

According to the manufacturer, in severe frost (exceeding minus 25ºС), the heater is able to warm the air in the cabin to 25ºС, and in the foot area - up to 30 degrees. In reality, such indicators are only achieved on a new car - over time, the radiator and air ducts become clogged, and heating efficiency drops sharply. Therefore, when the first signs of such deterioration appear, it is necessary to find out the cause of the phenomenon and take measures to eliminate the problems.