One of the main elements of the Volkswagen Polo gasoline engine control system is the ignition coil. If a part fails, ignition does not occur in the cylinders.

The coil converts electrical impulses with an amplitude of 12 volts into high-voltage impulses (15 thousand volts). Such a high voltage ensures breakdown of the working area of the spark plug.

Malfunction in the ignition system of the Polo Sedan

The Polo Sedan is equipped with a high-energy microprocessor ignition system (MPI). A voltage of approximately 40,000 V is supplied to the spark plugs, and although at low current it is not life-threatening, a possible electric shock when checking the ignition system can lead to serious consequences. Therefore, if you handle the tip of the spark plug while the ignition is on, use a thick rubber glove or, as a last resort, pliers with insulated handles.

Before checking the ignition system, place the gear shift lever in neutral and leave the parking brake on.

Squeeze the clips and remove the decorative cover of the cylinder head.

Check the fit of the ignition coil on the spark plug

Check the serviceability of the low voltage ignition coil circuit

If the ignition coil low voltage circuit is normal, check for spark at the spark plugs. Remove the ignition coil and reconnect the wiring harness block to it.

Insert a spare spark plug into the tip of the coil and connect its body to the vehicle ground in any convenient way. Have an assistant turn the engine crankshaft with the starter. Check the other ignition coils in the same way.

Reliable contact of the spark plug body with ground is mandatory, since if a larger additional spark gap appears than the gap between the spark plug electrodes, damage to the engine control system unit or the high-voltage circuit of the ignition coil is possible.

Carry out this check for no more than five seconds so as not to damage the exhaust gas converter as a result of gasoline that has not burned in the engine cylinders entering it.

If there is no spark at any of the ignition coils, check for blown coil fuses in the mounting block located in the instrument panel fuse mounting block. If the fuses are blown, replace them and start the engine.

Do not install fuses with a higher current rating, as this may cause damage to the electrical equipment and even cause a fire.

If there is no spark. replace the ignition coil with a new one. If there is a spark, but the engine does not start, replace the spark plugs with new ones. You can also first try to install not new, but proven ones, from a “working” machine.

If after this the engine does not start, check the serviceability of the engine management system.

When is it necessary to change spark plugs on a Polo Sedan?

According to the maintenance instructions for this car, spark plugs are replaced after every 60,000 km.

Installing spark plugs with platinum or iridium coating can extend this service life. Also, at the time of replacement, it is imperative to check the serviceability of the components of the ignition system, such as: ignition coils, spark plug tips and coil fuses.

Checking the spark plugs requires a visual inspection for the presence of soot (the color of soot can tell almost everything), oil stains and, of course, clearance.

READ How to remove Granta mirror cover

The gap on the Polo Car spark plugs should be within 1.0-1.1 mm.

Volkswagen Polo ignition coil

One of the main elements of the Volkswagen Polo gasoline engine control system is the ignition coil. If a part fails, ignition does not occur in the cylinders.

The coil converts electrical impulses with an amplitude of 12 volts into high-voltage impulses (15 thousand volts). Such a high voltage ensures breakdown of the working area of the spark plug.

Replacing spark plugs Polo Sedan

Let's start replacing the spark plugs; according to the regulations, this function must be carried out every 60 thousand kilometers. First, remove the plastic decorative protection.

We take a screwdriver, pick out the coils one by one and lift them so that they come out of the spark plug wells.

You can’t just get the last spark plug; you need to disconnect the power connector.

We take the sixteenth spark plug head and put it on the key.

We take out the old spark plug from the key, insert the new one and tighten it.

Having finished with the candles, we put everything back together, namely, we install the coils in their places.

We put the motor cover in place. That's it, the spark plugs have been changed.

The Polo Sedan has a 1.6 liter internal combustion engine with a power of 105 hp. For the proper functioning of all systems, you need to monitor the technical condition of your own car. In preparation for periodic maintenance, replacement of spark plugs in a Volkswagen Polo Car is recommended.

Disconnect the block from the ignition coil.

Symptoms of a problem

In most cases, ignition coil failure occurs suddenly. Most often this leads to the impossibility of continuing movement.

Owners of sedans recommend carrying a spare part with them - if it breaks, you can quickly replace it and continue driving. The main signs of a possible malfunction of the ignition coil can be considered the following:

- The engine "troits". In this case, a spark passes in one or more cylinders;

- At night, “breakdown tracks” appear on the case;

- Chips and cracks appear in the dielectric zone;

- The structure heats up excessively;

- Traces of burning are visible on the tips of high-voltage wires;

- The reel shows traces of oil and dirt.

Any of the above signs may indicate an imminent failure of the part. Purchasing a new coil for a Volkswagen polo is not difficult - most specialized stores offer original and analog spare parts to choose from.

Price of ignition coil for Volkswagen Polo

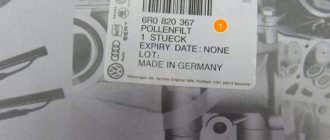

Since the Volkswagen Polo is a fairly common car in our country, you can buy spare parts for the car almost anywhere. In the table below you can compare the cost of original ignition coils and popular analogues.

When choosing a spare part, you need to take into account the vehicle modification, year of manufacture and other technical characteristics.

How to check the ignition coil on a Volkswagen Polo

You can check the serviceability of the ignition coil yourself. To do this, you will need a special device - a multimeter, designed to measure voltage in electrical circuits. The procedure is carried out in several stages.

- Disconnect the connector and high-voltage wire from the ignition coil.

- Check the resistance between the terminals of the primary winding (the indicator should be at least 0.5-1.5 Ohms).

- Measure the resistance between the terminals of the secondary winding (the device should show about 2.5-4 kOhm).

- If the device readings do not correspond to the standard, the coil must be replaced.

- Disconnect the three-pin wiring connector from the ignition coil.

- Connect the multimeter using wires to the corresponding contacts.

- Turn on the ignition. The multimeter reading should be 11 V.

- If there is no voltage, turn off the ignition.

- Check the wire between the contact of the three-pin connector and ground for an open circuit. The standard resistance is 1.5 ohms.

If problems are detected in the operation of the ignition coil, the optimal solution would be to timely replace the part. The coil can also be repaired. To do this, the part is disassembled and checked for chips, cracks and scratches. Damage is cleaned or eliminated using a special composition.

Most often, a faulty coil is simply replaced. It is advisable to select spare parts with identical technical characteristics. When connecting a new coil, you need to carefully monitor the correct connection of the wires.

If anything is connected incorrectly, the contacts will overheat and cause a short circuit.

If, when checking the ignition coil, the multimeter readings are normal and a spark is present, the part is in good condition. In this case, the cause of the malfunction will have to be sought in other components of the ignition system. As practice shows, in most cases the cause of the malfunction is a breakdown of the ignition switch.

Step-by-step instruction

Before you start changing the spark plugs on the Volkswagen Polo sedan 1.6, you should first get to them. To do this, you will need to unfasten two fasteners on the plastic cover of the cylinder block and move it to the side so that it does not interfere with you in the future.

Next, to get to the spark plug, you will need to remove the coil with contacts. And this is quite easy to do, using a special hook, or, at least, using an ordinary nail bent at an angle of 90 degrees.

Lower the hook into the hole with the coil, guide it into a special hole (on the sides of each coil on the Polo Sedan there are special plastic ears with which the device can be removed from the groove), and pull the hook towards you.

But, you should keep in mind that a block with wires is attached to the top of the coil, which will need to be disconnected by pressing the latch. Therefore, it is not recommended to stretch the coil very quickly, so as not to damage the integrity of the wires.

So we have opened access to one of the 4 candles. Now all that remains is to throw the key prepared in advance on it and unscrew it from the socket (previously, when considering how to change the spark plugs on a Volkswagen Polo 1.6 car, we mentioned that the key must be marked 16. And this is a very important nuance. After all, if you choose a different size of the key head , the spark plug will not stay tightly in it during dismantling, which will cause severe difficulties in removing it from the engine).

The above function should be repeated for the 3 remaining candles. Well, after you have all four consumables in your hands, you can start replacing them with new elements. There are usually no problems with this either. After all, if you understand how to remove the spark plugs, then the installation diagram is also known to you, because it repeats the above-mentioned function, only in reverse order. And for a better perception of the picture, we advise you to watch the short video annotation attached below.

Using a tall spark plug head “16” with an extension, unscrew the spark plug.

Purpose, principle of operation of the ignition coil

The device is the most conservative part in a gasoline internal combustion engine. Its prototype was invented in Germany by the engineer Ruhmkorff in the mid-nineteenth century. It replaced magnetos in automobile engines in the early 20th century.

The main purpose of the device is to convert low-voltage electrical pulses with an amplitude of about 12 Volts (vehicle on-board voltage) into high-voltage pulses with an amplitude of more than 15,000 Volts. High voltage is necessary to break down the working area of the spark plug.

According to the type of design and ignition circuit, the coils are classified:

- single;

- double (triple, four-block);

- individual.

Ignition coil device

Single devices are used in systems with an ignition distributor. Twins are used in four-cylinder internal combustion engines without a distributor. One part forms a high-voltage pulse to the 1st and 4th cylinders, the second serves the 2nd and 3rd. Triple and quad coils are sometimes used in six-cylinder and eight-cylinder engines, respectively. Individual coils are widely used in modern cars. They are installed on each spark plug individually. A custom spark plug coil has a number of advantages over conventional ones:

- failure of one of the devices does not lead to a complete stop of the engine;

- it is easier to organize an electronic control scheme;

- the absence of a mechanical ignition distributor makes the system more reliable;

- distribution of pulse load reduces currents and increases service life;

- it is easier to identify a faulty device, which is easily done by computer diagnostics;

- Most individual coils have a pulse amplifier installed; it is controlled by low signal currents, which reduces electrical interference and increases the reliability of electrical equipment.

Description of ignition and problems

In our world, there are currently three main types of ignition systems in use:

Classic system with a spark distributor (distributor). This system is obsolete and has not been installed on new cars for a long time. But it still occurs often on older cars.

READ Tome Software and Ford continue B2V development

Double ignition system (DIS) - this system does not have a spark carrier and due to this it has become widespread. It is popularly known as the idle spark system. The thing is that two spark plugs are connected to one coil and, accordingly, spark breakdown occurs simultaneously in two cylinders at once - in one on the compression stroke, and in the second on the exhaust stroke (idle spark). This particular system is installed on the Chevrolet Lacetti.

Coil On Plug (COP) - literal translation - “ coil on a spark plug”. The name speaks for itself. That is, each candle has its own coil . This is the most modern ignition system at the moment.

Ignition systems are constantly being modernized and improved, but one thing remains unchanged - the use of the principle of inductance to convert low voltage to high voltage. In other words, all these systems are united by the use of ignition coils. They may differ in type, power, voltage, and so on, but the principle of operation is unchanged. This means that the verification methods are almost the same.

Symptoms of malfunction

More often than not, the bobbin does not suddenly fail. This is usually preceded by a number of warning symptoms.

The main symptoms of a faulty ignition coil:

- misfires in one or more cylinders, they can be determined using a scanner by the presence of the “triple” effect of the engine;

- the appearance of “breakdown tracks” on the housing can be determined visually when starting the engine in the dark;

- the occurrence of cracks and chips in the dielectric zone;

- overheating of the structure;

- burning of rubber tips of high-voltage wires;

- oiling, contamination.

If the above symptoms appear, you should consider purchasing a replacement device. You can't stand by and watch an ignition coil die. In the event of a sudden coil failure, further independent movement will be impossible (unless you have individual coils installed).

Ignition coils

In what cases is it necessary to replace spark plugs?

High voltage is applied to the SZ, with the help of which a spark appears between the electrodes, igniting the combustible mixture. The quality of spark plugs affects the efficiency of the internal combustion engine and fuel economy. Therefore, you need to monitor their condition.

Signs of wear

Replacing the SZ on any car is done for two reasons:

- according to the technical maintenance regulations;

- when worn out or malfunctioning, which causes improper operation of the motor.

According to the regulations on Volkswagen Polo , replacement of the SZ must be done after 30 thousand kilometers.

But it is necessary to change the spark plugs if the following symptoms occur:

- the car jerks while driving;

- the starter does not work immediately; it takes several idle revolutions to start the engine;

- increased fuel consumption;

- Motor power drops.

In addition, it is recommended to have a technical inspection of the car every 15 thousand km. During the inspection, the condition of the SZ should be inspected. Spark plugs require replacement if a visual inspection reveals cracks in the body or peeling of the insulator. It’s better to change the entire set of SZ (video creator – Autolikbez).

There are a huge number of companies and types of candles. Traditional ones are more popular because they are affordable. Platinum and iridium have a longer service life, and their cost is higher. Below are traditional candles from 3 companies.

Causes of ignition coil failure

Let's look at the reasons why the ignition coil fails.

Natural wear and tear

Like all electrical and electronic units, the reel has a certain trouble-free operation life. The average service life of ignition coils is approximately seven to ten years of operation or 150,000 - 200,000 thousand mileage. The device is operated in extreme conditions with large differences in temperature, humidity, and the possibility of ingress of moisture, dirt, and foreign liquids. In this case, large currents flow through the primary winding, and a high-voltage pulse is formed in the secondary winding.

Electrical breakdown

Let's figure out why the ignition coil breaks. Firstly, over time, as a result of high temperature changes, the dielectric insulation cracks, and salty moisture, which is a conductor, can enter microcracks. For voltages of more than 15,000 volts generated in the secondary winding, even pure undistilled water acts as a conductor. Secondly, during operation, the physical properties of the dielectric and rubber insulation of the tips of high-voltage wires, especially those of dubious production, change. High-voltage breakdown can be caused by the installation of non-standard high-voltage wires in which there is no distributed current-limiting resistance. A breakdown can occur as a result of severe contamination or waterlogging. Even in the event of a single breakdown, irreversible changes occur in the structure; further operation is not recommended.

Some vehicles have ignition coils installed directly at or near the top of the engine. If there is no air access to their structure for natural ventilation (this is possible when installing additional equipment), the device may overheat and fail.

Mechanical load.

The coil mount must be standard. Some car enthusiasts neglect these requirements by “hanging” it on homemade structures.

Wear of spark plugs, high-voltage conductors

Despite the fact that the circuit has a limiting resistance, wear of spark plugs and high-voltage conductors can cause electrical breakdown in them. Then the load current increases and the bobbin may overheat.

Generator voltage regulator relay malfunction

Sometimes it leads to an increase in the voltage of the vehicle’s on-board network and failure of the electronic amplifier (switch).

Malfunction of the contact group of the lock, electronic switch

If, during parking, +12 Volts are constantly supplied to the coil in the event of an abnormal closure of the lock contact group, the device may overheat and fail. The same situation is possible if the switch is faulty.

To prevent premature failure, all possible causes of malfunction of the ignition coil in the car should be eliminated as much as possible.

Checking the voltage on the coil windings

Possible reasons why the Volkswagen Polo sedan does not start

The main advantage of a new car is that it is new. There is no need to change “consumables” before the first maintenance, the body is perfectly “clean” without a single scratch, the chassis fits tightly at all levels, the engine runs like a clock.

How to check and repair the ignition coil of a Polo sedan, Jet

But the moment comes when everything goes wrong. Cars also age, and their old age is a snowball: small “problems” over time turn into full-fledged problems that require real resuscitation of the “iron horse”.

Each car has its own medical history. Some suffer from rapid wear of the chassis, others experience difficulties with electronics, and still others complain of problems with the engine and transmission.

The worst thing is when malfunctions occur in the power plant components. The engine is the most valuable “organ” of a car. Accordingly, the cost of repairing it is one of the highest.

Engine performance directly depends on the ignition system. Thanks to it, the power plant can be started. Failure of starting system elements is a real nightmare for any motorist, especially for a beginner.

Imagine: getting into your car early in the morning to go to work, turning the key in the ignition, trying to start the engine, but it won’t start! You repeat the procedure again and again, but all in vain. Just burn the candles with gasoline. You have to walk to the stop and go to work by public transport. The whole day is ruined.

Many car enthusiasts face this situation. There can be many reasons for its occurrence. The first thought that should creep into a motorist’s head is whether the starter works? And also how quickly it “spins”.

Symptoms of a problem

The main signs of ignition coil failure are lack of ignition. If it is a single device with a distributor, then in all cylinders; if it is a double or single device, then in those served by it. The absence of a spark is not necessarily a 100% sign of a faulty coil. Perhaps the limiting resistor has burned out, the spark plug is faulty, the high-voltage wire has broken, or there is a malfunction in the ignition system. A comprehensive fault diagnosis is required.

Visual signs that the ignition coil is not working:

- the presence of “breakdown tracks”, oxides on the coil;

- change in dielectric color;

- burning of contacts and connectors;

- traces of overheating on the body;

- increased pollution.

»How to maintain spark plugs

Spark plugs are a very important part of a gasoline engine and must be kept in good condition to ensure the best performance. The spark plug electrodes must be clean and sharp to produce the powerful spark needed for ignition.

A warped or dirty spark plug can cause erratic ignition, which can lead to misfiring or poor performance. It can also waste fuel and lead to deposits on the cylinder head.

The great thing is that spark plugs are easy to repair, maintain and replace as needed. We'll walk you through the steps to checking and maintaining your spark plugs. With this information you can decide whether you want to change your spark plugs.

Removal

- Raise and support the front of the vehicle.

- Delete:

- Top motor cover.

- Golf / Estate / Plus / Passat / Touran: Windshield washer reservoir filler neck.

- Disconnect the connector from the diesel particulate filter (DPF) pressure sensor.

- Remove the diesel particulate filter (DPF) pressure sensor bracket.

- Disable:

- Jetta/ Polo : Fuel supply and return pipes.

- Polo: Fuel preheater valve.

- Delete:

- Golf / Estate / Plus / Passat / Touran: Fuel filter housing. DO NOT disconnect hoses.

- Jetta/Polo: Fuel filter housing.

- Coolant expansion tank. DO NOT disconnect hoses.

- Disconnect the coolant level sensor connector.

- Disconnect the coolant temperature (ECT) sensor connector.

- Jetta / Golf / Estate / Plus / Passat / Touran: Disconnect the coolant pipe support bracket from the engine mounting bracket. DO NOT disconnect hoses.

- Remove the upper timing belt cover [1].

- Engine support.

- Delete:

- Right engine mount.

- Right fender liner.

- Engine protective glass.

- Auxiliary drive belt. Use Tool No. T10060A.

- Crankshaft pulley bolts [2].

- Crankshaft pulley [3].

- Lower timing belt cover [4].

- Rotate the crankshaft clockwise to TDC of the cylinder

- Make sure the arrow on the camshaft sprocket is at approximately the 12 o'clock position [5].

- Otherwise: Rotate the crankshaft one revolution clockwise.

- Lock the crankshaft sprocket [6]. Use tool No. T10050.

- Make sure the alignment marks are aligned [7].

- Make sure the crankshaft sprocket retainer tab is seated in the oil seal housing [8].

- Lock the camshaft [9]. Use tool 359.

- Loosen the camshaft sprocket bolts [10]. Make sure the sprocket can be easily turned by hand.

- Loosen the high pressure fuel pump sprocket bolts [11]. Make sure the sprocket can be easily turned by hand. Use tool no. T10385. NOTE. There are two types of timing belt tensioner pulleys.

- Tensioner roller type A:

- Loosen the tensioner pulley nut [12].

- Turn the tensioner pulley counterclockwise until the locking pin [13] can be inserted. Use Tool No. T10264 [14].

- Insert the clamp into the tensioner pulley [15]. Tool No. T10265.

- Turn the tensioner pulley fully clockwise until it stops [16]. Use Tool No. T10264 [14].

- Hand tighten the tensioner pulley nut [12].

- Tensioner roller type B:

- Loosen the tensioner pulley nut [17].

- Turn the tensioner pulley clockwise to loosen the belt tension. Use Tool No. T10409 [18].

- Hand tighten the tensioner pulley nut [17].

- Remove the timing belt starting from the guide pulley (G2). NOTE: Mark the direction of rotation on the belt with chalk if the belt is to be reused.

Sources:

https://razborov.net/Volkswagen/kak-pomenyat-svechi-na-fol-ksvagen-polo-sedan.html https://dentauto.ru/raznoe/kak-snyat-svechi-zazhiganiya-na-folksvagen-polo -sedan.html

How to identify a faulty ignition coil

The procedure for checking the serviceability of the coil depends on how many ignition coils are in the car. If your car has individual ignition coils, in order to identify the faulty one with a high degree of probability, you can swap the supposedly faulty and known-good coils. If, as a result of this replacement, a spark appears in the cylinder in which there was no spark, and disappears in the other, therefore, the bobbin is truly faulty. In the same way, you can check dual and block coils, but you will have to modify the circuit, which is not always convenient.

How to determine which ignition coil is not working without making changes to the electrical circuit

To do this, you need to stock up on thick dielectric gloves and a dry rubber mat. The use of only ordinary dielectric gloves is unacceptable: they can withstand a breakdown voltage of 6300 Volts; the voltage applied to the candle is approximately three times higher.

If your car has two or more ignition coils, if one of them malfunctions, the car should start, but struggle a lot. By removing the tips of the high-voltage wires of the spark plugs or connectors from individual coils one by one, the stability of the engine is assessed. If the internal combustion engine has not changed its operation as a result of removing the connector, then there is no spark in this cylinder. If the engine starts to shake even more, or stalls altogether, there is a spark, the bobbin is faulty, or it is not receiving impulses or power.

Replacing a failed oil pump

A completely different source of the problem in a Volkswagen Polo car is a malfunction of the oil pump. The device serves to supply oil to the system and lubricate the moving parts of the engine. If the pressure constantly drops as a result of a decrease in the injection rate or leaks in the cylinder body or the pump itself, then the element should be replaced with a new one as soon as possible.

For the procedure you will need a Torx T45 wrench, a “5” hexagon and thin pliers:

- We dismantle the oil sump. To do this, remove the engine splash guard and drain the oil from the lubrication system. We remove the flywheel shield and unscrew the twenty fasteners of the crankcase itself. Gently tap the edges of the crankcase with a rubber hammer and disconnect the part.

- Then we dismantle the pump sprocket protection and the tensioner spring in its drive.

- Unscrew the bolt securing the tensioner to the cylinder block and remove the component.

- Then remove the pump sprocket by carefully unscrewing the bolt.

- Finally, we unscrew three more screws holding the pump housing and remove the part.

- We put a new oil pump in place of the old one and assemble everything in the reverse order.

- We fill the reservoir with oil and check if the car starts.

A fresh oil pump for the Polo sedan, just imported from a German factory, costs about 12,000 rubles. A used copy can be purchased at a price several times cheaper. It all depends on the mileage of the car.

How to change spark plugs on a Volkswagen Polo sedan

Spark plugs are an important part of any car. Their quality directly affects engine performance. The service life depends on many parameters, such as high temperatures, fuel quality and various additives.

Often breakdowns of the Volkswagen Polo Sedan are associated with spark plugs. If the engine is running rough, there is a loss of power, the engine is not running smoothly, or fuel consumption is increased, then the first thing you need to do is check their condition. After all, the negative factor of a faulty part is that a non-functioning spark plug can cause the exhaust gas converter to fail, as well as increase the emission rate of gasoline and toxic substances into the atmosphere. Therefore, you need to constantly monitor the technical condition of the candles.

All automakers recommend changing them after an average of 15 thousand km. mileage As a rule, for a Polo sedan it is 30 thousand km when using only gasoline and 10 thousand km. with gas fuel.

For car engines, spark plugs of the VAG10190560F type or their analogues offered by other manufacturers are used.

There are two reasons why it is necessary to replace spark plugs in a Volkswagen Polo:

- Mileage from 30 thousand km. and more (these figures are indicated in the vehicle maintenance regulations).

- Typical malfunctions of the engine (“floating” idle, cold engine troits, etc.).

Technical condition inspections must be carried out at a specialized service center. But if the car was purchased without a warranty and all the necessary tools are available, then you can carry out the replacement and inspection yourself.

First you need to prepare all the tools you will need:

- Spark plug wrench for 16, length 220 mm.

- The screwdriver is flat.

All work must be carried out on a cold engine. The surface of all parts must first be cleaned to prevent debris from entering the combustion chamber.

After all the preparatory work, you need to remove the plastic protective cover from the engine. Its latches are located on both sides on the left and right and open with normal pressure. Under the cover you can see four ignition coils along with low-voltage wires. To get to the spark plugs, you need to remove all these parts.

The coil is usually removed with a special tool, but, as a rule, this device is only available in technical services. Therefore, a simple flat-head screwdriver is used for removal. They start dumping from the first reel. To do this, insert the sharp end of a screwdriver under the part and carefully lift the entire structure upwards.

After all the coils are torn from their places, you need to remove the wires from them. There is a lock on the coil block, when you press it you can remove the terminal with wires.

After this, all ignition coils can be removed. You should check the contact point between the coil and the spark plug. If the connector is oxidized or dirty, it should be cleaned, because this may cause the spark plug to fail, or subsequently lead to failure of the coil.

Then, using a spark plug wrench, unscrew the spark plugs one by one. Here you should also pay attention to their condition. A working part is considered to be one on the surface of which there is no black deposits and various liquids, traces of fuel or oil. If such signs are detected, then a set of measures should be taken to identify the malfunction. This may be a burnt valve, resulting in low compression. Problems may also be in the cooling system or with the oil pump.

Installing new spark plugs is done in the reverse order. From the recommendation, it is worth noting that you need to wrap them by hand, and not with a wrench or other auxiliary devices. If a part does not follow the thread, it can be felt and corrected. To do this, you should unscrew the candle, clean its surface and repeat the procedure. You need to tighten it to a torque of 25 Nm. Over-tightening may damage the internal threads on the cylinder. Which will entail serious repairs.

The ignition coil is inserted until a characteristic click is heard, then the remaining wires are connected to it. All terminals must be placed strictly in the places where they were. If installed incorrectly, the vehicle's ignition may be disrupted.

Possible problems of poor engine starting

If the starter does not activate at all and the traction relay does not operate, then two types of malfunction are likely: in fact, the starter itself has “died” or there is a violation in the electronic circuit. A rare occurrence is a fuse installed on the power circuit. Fortunately, Volkswagen Polo does not own such a device, so we exclude the possibility of a fuse failure.

The reason for the lack of power is a dead battery or poorly tightened wires at the terminals. With the wires, everything is very simple: we tighten them, and the power is restored. If the battery is at “zero”, then we cannot do without outside help: we are looking for a good Samaritan who will give us a “light”.

Sluggish starter operation is also not good. This is a sign of a weak battery charge. Therefore, we either charge the battery or replace it with a fresh one.

The vigorous operation of the starter eliminates the preconditions associated with the battery. The depressed motorist faces two other difficulties. The first is located in a plane called the ignition system. The second lies in the fuel supply system.

In most cases, there is one problem. The engine will not start because there is no spark. There is only one question: in what specific part of the system did the problem occur?

The low-voltage part consists of a sensor and a special box stuffed with electronics. The desired spark appears in it. The second component is a transformer, or in common parlance, coil to which the spark plugs are connected. Thanks to distributors, high-voltage wires feed the spark plugs with high voltage current. The final step is the spark plugs, which provide the spark needed to start the engine.

The check must be carried out in a special manner. We start with the high-voltage part: remove the wire from the distributor and fasten its end next to the car body. We make sure that the wire does not touch the surface, otherwise all the electronics on the car will fail. We start the engine and look at the tip of the wire. A charge of electricity should jump between it and the body. If this does not happen, remove the cover from the distributor, clean its contacts, and inspect the “slider” and wires. If there are any flaws, we replace the parts. You also need to dry candles filled with gasoline.

The serviceability of the spark plugs is a new step of verification. We take them out of the coil, connect high-voltage wires to them, collect them into a bundle and start the starter. Small sparks flash on the electrodes of the spark plugs. If there is still no spark, then it means the problem is deeper than expected.

In the next step, we check the coil, or more precisely, the voltage supplied to the element. This can be done using a tester or an engine compartment lamp. If there is no voltage, then the problem with the engine not starting is the coil. The defective part must be replaced. But it may be that the current is not flowing as a result of a disgusting connection of wires or obvious contamination.

The last limit is the low voltage part of the system. The only thing that can be done here is to “poke” the contacts of the distributor connector. Voltage leakage may be due to them. But if there is still no voltage, then it means you should take the car for computer diagnostics of electrical systems. Using special equipment, technicians will identify the cause of the malfunction.

The most unique reason why the engine does not start is a breakdown of the camshaft drive belt. Basically, it is associated with the worn-out serrated surface of the tape. It is better to entrust the repair of the mechanism to experts.

Volkswagen ignition system

One of the main conditions for successful engine starting is a working ignition system. This system provides a spark discharge to the spark plugs at a certain stroke of the gasoline engine.

The standard ignition system consists of:

- ignition coils;

- spark plugs;

- control unit;

- distributor.

Some cars have a contactless transistor ignition system. It consists of the same elements as the traditional system, but the distributor does not have a liquid condenser and a Hall sensor. The functions of these elements are performed by a contactless sensor, the operation of which is based on the Hall effect.

All this applies to gasoline engines. In diesel units, ignition refers to the moment of fuel injection during the compression stroke. Diesel fuel and air enter the cylinders separately from each other. First, air is supplied to the combustion chamber, which becomes very hot. Then, using nozzles, fuel is injected there and instantly ignites.

Setting the ignition of a VW Passat B3 with an ABS engine using the VAG-COM program and a strobe light

The ignition of a VW Passat B3 with an ABS engine is set as follows.

- Warm up the car and turn off the engine.

- Open the timing cover. The mark on the plastic cover should match the groove on the pulley. Otherwise, remove the car from the handbrake, set second gear and push the car (the pulley will rotate) until the marks coincide.

Ignition coil remover

To dismantle the ignition coils, a special tool is used - a puller. Its design allows you to carefully remove the coil without damaging it. You can purchase such a puller at any auto store or order it online.

Video: VW Polo Sedan ignition coil remover

Spark plug diagnostics

Faulty spark plugs can be determined visually by the following signs:

- deposits on the spark plug;

- melted electrodes;

- a layer of soot on the tip of the spark plug;

- traces of oil on the tip of the spark plug.

There are several reasons why spark plugs fail:

- wear and exceeding the service life;

- frequent regular driving over short distances;

- high engine oil level;

- unbalanced air-fuel mixture.

Replacing spark plugs on a VW Polo car

Replacing candles with your own hands is quite simple. Work is performed on a cold engine in the following order:

- Press the two spark plug cap latches.

Video: quick replacement of VW Polo spark plugs

Selection of spark plugs for Volkswagen cars

There are a number of important things to consider when purchasing new spark plugs. Candles differ in design and material from which they are made. Spark plugs can be:

- two-electrode (with one side and one central electrode);

- multi-electrode (with one central and several side electrodes).

For the manufacture of electrodes the following are used:

- yttrium and copper (available, but not very resistant to fading);

- platinum (very reliable, corrosion resistant, but expensive).

When choosing candles, you need to pay attention to the heat rating. Failure to meet the manufacturer's requirements will result in a number of problems. If it is greater than the regulated values, the load on the engine will increase and lead to its forced operation. If the heat rating is low, problems will arise when starting the engine due to an insufficiently powerful spark.

It is advisable to purchase original Volkswagen spark plugs, which:

- have high wear resistance;

- ignite the mixture efficiently;

- function reliably throughout the entire service life.

The highest quality spark plugs are produced by Bosch, Denso, Champion, NGK. Their price varies from 100 to 1000 rubles.

Replacing a failed fuel pump

Replacing the fuel pump on a Polo sedan will also cost a pretty penny. A malfunction in this unit is one of the common reasons why a car will not start.

READ What kind of oil is poured into Polo liftback

An electric fuel pump, through the injection system, pumps a certain amount of fuel to the engine injectors, which is necessary to start the power plant and move the machine. The service life of the device depends on many criteria. Among them, an important role is played by the quality of the fuel received at the gas station, as well as the amount of dirt penetrating the system. The main signs of a clogged pump, in addition to the fact that the engine will not start, are unpleasant sounds in the engine, which begins to stall from time to time.

The operating principle of the fuel pump is simple. The device uses a special float, which lowers as the fuel level in the tank decreases. The potentiometer, which responds to float maneuvers, increases the resistance of the sensor and at the same time lowers the voltage on the arrow indicating the amount of fuel on board. The more the voltage drops, the closer the o on the dashboard becomes.

When dismantling a faulty fuel pump, you should be aware that gasoline vapors contain toxic substances that are harmful to the human body. Therefore, it is recommended to carry out work outdoors.

Sequence of actions for replacing the fuel pump on the Polo sedan:

- We dismantle the battery.

- Remove the cover at the bottom of the trunk.

- To separate the pump from the sensor, you need to unscrew the fasteners located on the sides of the device with a small screwdriver.

- We loosen the pipeline clamps and remove both types: supply and return.

- Close the tube holes.

- Unscrew the union nut 3217 with a special wrench. The device costs quite a bit (about 2000 rubles!), so you can use a wooden peg and a hammer instead: we place the end of the “piece of wood” against the edges of the nut and hit it lightly with the hammer.

- From the neck of the tank we take out the gasket and metal flange.

- Disconnect the fuel pump from the bayonet lock and remove it.

- When reassembling, the following points should be taken into account: before installing a new fuel pump, the O-ring must be moistened in engine oil; The fuel sensor should not be damaged, and it should “look” towards the pipelines.

An original VAG fuel pump for the Polo costs from 11,000 rubles. Its code number is 6rf 919 051 d. The pleasure is expensive, but it’s not like changing the filter!

By the way, the fuel filter should also be replaced. This is where problems with the pump often begin, smoothly flowing into the engine starting system. As a rule, it is recommended to change the fuel filter on a German sedan every 30,000 km. But the figure may vary depending on the degree of blockage of the element.

If an uneven hum appears in the engine, accompanied by a loss of power and an increase in fuel consumption, then there are clear signs of wear on the fuel filter. This thing is inexpensive. The original will cost the sedan owner 1,500 rubles. A similar sample of the popular Filtron brand costs about 1000 rubles. Agree, there is a difference: either buy a whole gas pump for more than 10,000 rubles, or purchase it for 1,000 rubles. a fuel filter that will not only save the resource of the unit, but also increase its service life.

At the end of the “fuel” topic, it is worth noting another culprit of the problem, why the engine does not start. It is the fuel pressure regulator.

The main idea of the device is to maintain the required pressure in the injectors, which changes depending on the operating mode of the power plant.

Checking the pressure is not difficult: we connect a pressure gauge between the fuel hose and the fitting, while simultaneously disconnecting the vacuum wire. When operating properly, the pressure in the system should increase. If this does not happen, then change the vacuum hose and check the value again with a pressure gauge. If there are no changes, then now we know where the dog is buried - we are replacing the regulator.

Thus, the main problem areas that cause failure are the ignition, fuel injection and oil pressure regulation systems.