Despite the fact that the VAZ-2121 SUV was developed quite a long time ago, this car is still very popular. In 1994, the model was changed to VAZ-21213. Many people buy these cars because of their high cross-country ability, which can be the envy of some jeeps from famous brands. Others like reliability, unpretentiousness and high maintainability. A simple design and excellent off-road characteristics made this vehicle a vehicle for lovers of travel, hunting, fishing and tourism.

Niva cars 211213 are equipped with a 1.7 liter engine. It is carburetor, and is based on a VAZ-2106 engine. There is also a five-speed manual transmission and a proximity ignition system. The power system is equipped with a Solex 21073 carburetor for the Niva. Many novice car owners are intimidated by carburetors and everything connected with them. But a carburetor is not a death sentence. You just need to understand its basic structure, how to adjust it, and how to repair it.

Float mechanism

The Solex 21073 carburetor, installed on the Niva, has a float chamber of two sections. They are located on both sides of the main cameras of the device. The system consists of two ebonite floats, which are mounted on a lever.

The latter swings on an axis pressed into the bosses of the device cover. There is a tongue on the bracket. The element presses the needle valve needle through a special ball. The float mechanism serves to adjust the level of fuel required for normal operation of the carburetor. The needle valve is a non-separable type. It is not being repaired. The valve body is mounted on a thread in the carburetor cap. The ball protects the needle from shock when the machine moves. If the chamber is empty (for example, if the driver is using LPG), then the floats will knock.

"Solex" and "Ozone"

The VAZ 2121 Niva model can be equipped with an “Ozone” carburetor with the serial designation 2107-110-7010-10 or 2107-110-7010-20. They differ from each other in that the first option has an old-style breaker and does not have a vacuum corrector. The second carburetor does not have a microswitch from the economizer, which affects the environmental friendliness of emissions and has some impact on fuel consumption.

This is the car part

The Niva 21213 is equipped with Solex type carburetors (model 21073-110-7010). They are considered quite “capricious”, which is primarily due to the negligence of the owners themselves. The incorrect operation of the device is primarily affected by low-quality fuel with a large amount of impurities, since in this model the fuel is taken through holes in the bottom of the float chambers (in other models these elements are raised above the bottom).

In addition, problems arise for those “nivovods” who do not promptly change the fuel or air filter, and also do not pay attention to proper cleaning of the carburetor from oil soot emissions through the ventilation system.

Adjustment of the VAZ carburetor is usually carried out in the float mechanism or in the starting and idle systems. These are very important operations that are best left to the experts.

The float mechanism on the Niva 2121 is adjusted in terms of the position of the floats relative to each other and relative to the walls of the float chamber. In addition, the mechanisms in the open and closed positions of the needle valve may need to be adjusted. In order not to disturb good adjustment, the car owner needs to carefully handle the carburetor cover when removing it, monitor the level of wear of the shut-off cone from the needle (its seat and tongue), as well as the axis of the mounting bracket.

Main dosing systems

The first and second chambers are equipped with diffusers. There is one large and one small element. Spray devices are also made together with small diffusers. The latter are connected through channels to the emulsion wells, and they communicate through one channel with the float chamber. To ensure that gasoline flows in certain portions, the main fuel jets are located below in the emulsion wells. These same wells have special tubes. Each of them is equipped with an air jet at the top. Air is supplied to them from the neck of the device.

Operating principle of the main dosing chamber

Under the influence of vacuum that occurs in the engine cylinders, air is drawn through the filter. Next, oxygen is supplied to the first chamber. It passes through diffusers. Due to the fact that the air flow speed has increased, an even greater vacuum is created in the nozzle area.

Under its action, the fuel rises from the emulsion well from the atomizer. At the same time, air passes through the air nozzle into the emulsion tube and is then mixed with fuel. As a result, an emulsion is formed, which is sucked at high speed into the carburetor channels, where it connects with the air flow. The installed Solex 21073 carburetor on the Niva operates on this principle. Its design may vary depending on the modification. But the principle of operation of the systems is approximately the same for all devices.

Niva index designations

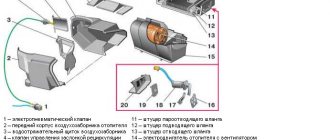

The wiring diagram may vary slightly depending on the design features of the vehicle.

First, let's look at the index notation:

- VAZ 21213. This index designates a vehicle equipped with a carburetor. The volume of the power unit is 1.7 liters.

- 21214. In VAZ 21214 cars, the scheme involves the use of a similar engine with the same volume. The only difference is that the car is equipped with a fuel injection system.

- There is another model with the index 21213. In VAZ 21213 cars, the electrical circuit includes the same elements, only depending on the year of manufacture, the car can be equipped with a 1.8 liter engine.

- Version 21073. The SUV is equipped with either an injection engine with nozzles or a Solex carburetor engine. One of the features of these cars is a contactless ignition circuit.

- 21215. These SUVs were originally produced for export, so these cars are difficult to find on our roads. It is worth noting that they were equipped with Citroen diesel engines.

At the beginning of the article there is a diagram of the VAZ electrical equipment using the example of the Niva 2121 model. If you are the owner of version 2131 or any other, then there will be a difference in the circuit diagram, but not fundamentally. If we are talking about carburetor engines, then in this case the circuit, as well as the ignition, will not be protected (the author of the video is Nail Poroshin).

Idle system

The device is equipped with an idle system. It is designed to allow the engine to operate at low speeds. At this moment, the vacuum in the diffusers is very small. Fuel cannot enter the main metering system. At idle speed of the engine, fuel is supplied under the throttle valve of the first chamber of the carburetor. There the vacuum is strong enough to form a stable combustible mixture.

Air is supplied through the main jet and the emulsion well of the first chamber. The fuel will then flow to the idle fuel jet. After this, it is mixed with air supplied from the XX air jet. Oxygen is supplied to this element through a special channel. This operating scheme allows the engine to ensure a smooth transition from load to idle and prevents fuel from leaking out of the float chamber.

Troubleshooting

Car components do not last forever, and sometimes the installed Solex 21073 carburetor on the Niva fails. Repairing it must begin with diagnostics. It may be possible to get by with a simple adjustment. So, during operation, solid particles can enter the carburetor, which ultimately causes clogging of the jets. Low-quality gasoline leads to the formation of deposits on the walls of the channels in the device. This significantly reduces their cross section. Failure of carburetor systems can be diagnosed by the following symptoms:

- Increased fuel consumption.

- Difficulties in starting the engine. Reduced power and dynamic performance.

- Unstable operation at idle.

In this case, it is necessary to clean the installed Solex 21073 carburetor on the Niva. The adjustments that will be made after this will allow the device to work as it should again.

Selecting a new part

Which carburetor to install on Niva 21213? Almost unanimously, experts choose the DAAZ 21083 model for the VAZ Niva 21213 with a 1.7 liter engine. This carb best meets the requirements of the internal combustion engine and significantly reduces fuel consumption. The disadvantages include a decrease in engine response due to the smaller diameter of the throttle valve, and a smaller float stroke. Installation and adjustment are quite possible without outside help. The cost is average (about 6,300 rubles), but the build quality and durability completely pay for it. Additionally you will need to consider:

- you will need a set of larger diameter fuel jets;

- you will have to buy a new throttle control system;

- you will need to bore the seat for a new carb.

You should choose a carburetor for Niva 21213 very carefully. Even factory-packaged components may be defective. So, for example, all screws must be secured with factory-made plugs, all moving elements must move without jamming. Such products are supplied from the factory already adjusted. Some elements (jet jets, repair kit) can be used from the old unit.

How to restore carburetor operation?

For repairs, most often you have to remove the device from the engine. First, remove the air filter. Then the fuel lines, air pipes, wires and cables are removed. then unscrew the fastening nuts.

It is best to disassemble the carburetor on a table or other convenient surface. The parts should be laid out in some order. This will help you not lose them. The process of adjusting the needle valve is performed using a special template. To wash the device, you must use special liquids. Replacement jets can be purchased at any auto stores. Often, disassembling and flushing the carburetor helps solve a lot of problems.

Adjustment

If the installed Solex 21073 carburetor on the Niva fails, repairs and adjustments help bring the device back to life. The settings allow you to restore optimal modes in which the motor will operate as efficiently as possible. Fuel consumption is at an average level. First of all, start the engine and warm it up a little. Next, you need to remove the fuel hose and the device cover. It is recommended to remove the latter with extreme caution so as not to damage the float. Next, using a measuring tool, measure the distance in each of the carburetor chambers. Measure from the mating surfaces to the edge of the fuel. This size should be approximately 24 mm. If this distance is less or more, then it is adjusted by bending the float. Then you need to start and warm up the engine again. When the level adjustments are successfully completed, you can proceed to adjusting the idle speed.

The engine is turned off. To set up, you will need a flathead screwdriver and a little time. There is a hole on the base of the device in which there is a screw that regulates the quality of the fuel mixture. It is twisted all the way. Then from the extreme position the same screw is unscrewed by about five turns. Then the engine is started. There is no need to use a suction. If you unscrew the “quality” screw, then the carburetor will change the engine speed. Then it is twisted again. It is required to rotate until the operation of the motor is stable and stable. When the engine starts to run smoothly, then the element is unscrewed no more than one turn. As a result, the idle speed will be set at 900. If the engine starts to stall, it is better to slightly increase the idle speed.

Do-it-yourself VAZ 21213 carburetor repair video Telegraph

Download file - Do-it-yourself VAZ 21213 carburetor repair video

The manufacturer claims that Solex is correctly adjusted at the factory, but this statement is not always true. Problems with the engine power system unit arise not only due to its incorrect configuration, but also due to the negligence of the car owner himself. Ignoring recommendations on the frequency of replacing air and fuel filters leads to the fact that the most important mechanism in the engine power system refuses to work correctly. The goal to which all carburetor adjustment processes come down is to ensure stable operation of the power unit over the entire speed range. Adjusting the Solex carburetor comes down to part of the adjustment processes in the float chamber and adjusting the idle system. This is quite painstaking work that requires certain knowledge. The level should be within 25 mm in the chambers, but this may vary since the collector is not horizontal, so you should measure the value in the chambers and average it. If the level exceeds the norm, then use the float tongue to remove some of the gasoline and reassemble the mechanism in the reverse order. Then start the engine again and make observations. Gasoline should not leak from small diffusers, otherwise the appearance of fuel will indicate an overflow. There is no need to press the gas during the adjustment! You can adjust the Solex starting system both on an installed carburetor and on a dismantled one. In the first case, the adjustment comes down to determining the number of crankshaft revolutions, but with the carburetor removed, it is possible to adjust the starting system due to the gaps at the edge of the dampers. On the engine power system device removed from the vehicle, adjust the gap between the damper and the chamber wall - the gap should be 1.1 mm. Adjustment work is carried out using a wrench or screwdriver. More experienced and advanced car owners prefer to adjust the Solex by determining and setting the crankshaft speed. This method is faster, but also requires certain specific knowledge. This technique consists of the following:. Using a gas analyzer, you can also configure the starting system. The device measures the amount of carbon monoxide in gases. This procedure is necessary to ensure that the power unit operates stably and that the exhaust gases contain as few harmful substances as possible. In the garage, using your own efforts, all the work can be done using a tachometer. The motor is first brought to operating temperature, after which the adjustment itself is carried out directly. A similar procedure must be carried out several times until the engine begins to operate stably, and a minimum amount of vacuum in the tube is observed. Correct tuning of Solex will allow the car owner to enjoy high-quality, and most importantly, trouble-free engine operation. Experts recommend adjusting the idle speed twice a year. Thus, it is possible to achieve significant fuel savings and the emission of a minimum amount of harmful substances into the atmosphere, plus, a properly adjusted engine power system mechanism will significantly save personal funds on the services of service stations. Home Purchase and sale agreement Compulsory motor liability insurance calculator European protocol for road accidents Tips All articles. Repair Reviews Operation Tuning Buying and selling Legislation History Production Products. The long-awaited restyling of the Mazda CX Toyota Highlander of the year. Popular manufacturers of towbars in Russia. Laser headlights for cars. Step-by-step adjustment of the Solex carburetor on a VAZ Adjustment of the Solex carburetor comes down to part of the adjustment processes in the float chamber and setting the idle system. The recommended procedure for adjusting the valves of the 3rd generation VAZ Kia Sportage went on sale. Purchasing a used foreign-made car is associated with Copying content is prohibited without inserting an active hyperlink to the source.

V 80m s how many thousand revolutions is this

Comedy quotes