When a car has been in use for a long time, the car owner begins to notice a gradual increase in engine problems. Extraneous noise appears, power decreases, and engine starting becomes difficult even when using high-octane fuel.

Domestic cars with an engine capacity of 1300-1500 cm3 are most susceptible to these problems. But often on Russian roads, especially when using low-quality gasoline, even an expensive imported car begins to let its owner down.

Fortunately, in many cases it is quite possible to restore (or maintain for a long time) the original characteristics of a car even for an inexperienced car enthusiast without contacting service centers. The easiest way to do this is to use various automotive additives.

Their range is quite wide, and they can solve various problems with the car. The most common reason for a drop in power is a decrease in engine compression.

Which brand of engine additive is better to choose?

Automotive supply stores offer many different engine products. Many additives are produced with additives and have their own specifics: some are better to choose for new cars, others for used cars. Expert opinions can help you decide which additive to pour into the engine. After conducting a series of tests, they recommend the following brands:

- Suprotek is a research and production corporation engaged in the development and production of automotive chemicals. In 2002, Suprotek appeared on the Russian car market, then on the global market. Products are supplied to countries in Europe, Asia, Australia, South America, and North America.

- Kerry is a Russian company engaged in the production of automotive chemicals and car care products. Kerry started its activities in 1999. Production is carried out at the Elf Filling JSC plant, owned by the Russian Technical Aerosols concern.

- Resurs is a manufacturer of lubricants and additives for automobile engines. Resurs products produce auto chemicals for cars, trucks, and special vehicles. The “KAMAZ-Master” team chooses Resurs funds to cover the routes of the “Silk Way” rally.

- HI-Gear is an American brand of auto chemicals and auto cosmetics, operating since 1995. The products are famous for their high efficiency. HI-Gear production is located in the United States of America and is known for its environmentally friendly technical processes.

- Bullsone is a Korean company producing machine chemicals and cosmetics. Bullsone oils, additives, washes, and shampoos are in demand in Russia, Ukraine, Kazakhstan, and Belarus. In 2011, the brand received American and European awards.

- Winns is a world-famous additive manufacturer with a 75-year history. Winns management calls its products one of the best investments in a car. The brand's line is represented by products for new and old engines.

- Liqui Moly is a company founded in West Germany more than 60 years ago, producing motor oils, auto chemicals, and vehicle care products. In our own production, strict control is carried out at all stages. Liqui Moly guarantees the quality of all its products.

- Bardahl is a concern that produces lubricants and car cosmetics. Bardahl production facilities are located in 3 countries - Italy, Belgium, France. The products have international certificates of conformity and awards from famous automakers around the world.

The best fuel filters

Answers to frequently asked questions

What additives can be poured into the engine?

The most suitable for worn-out internal combustion engines are tribotechnical compounds and friction geomodifiers. These additives are better than others at increasing the surface of damaged parts and are excellent as formulations for gasoline and diesel SUV engines (as they reliably protect the piston group during heavy vehicle use).

What additive should I choose if it smokes?

The “stop-flow” additive allows you to reduce oil waste after 600 km. It partially restores the elasticity of all plastic and rubber gaskets and seals. As a result, blue smoke from the exhaust is eliminated.

Do regenerative additives actually work?

Yes, additives really work. It’s just important to select the composition based on the symptoms that appear in your engine. With a mileage of more than 50 thousand km, almost all additives are recommended to be used in 3 stages: in the old oil before changing, after a scheduled change and after one full cycle of 10 thousand km (second oil change).

Engine additive rating

Choosing the best additive for your engine requires a responsible approach. Among the large assortment you can find products designed for different types of engines and their different conditions. By comparing the properties of the drugs declared by the manufacturer, as well as reviews of engine additives, you can identify the TOP best.

Applicants were considered according to the following criteria:

- Purpose by engine type, service life;

- Type of engine fuel used;

- Compound;

- Manufacturer's warranty;

- Consumption;

- Price.

From several dozen additives, the best drugs were selected based on a combination of indicators, as a result of which they were grouped by purpose and properties. The rating discusses in detail the advantages and disadvantages of each product.

Best Air Compressors

Diagnostics using special devices

The symptoms described above can only indicate insufficient compression in the engine. In order to carry out restoration, you will need to accurately determine the cause of the malfunction, and for this you need special equipment:

- compression gauge;

- a set of special keys;

- a little machine oil;

- syringe.

The first thing you will need to do to obtain reliable data is to set the gaps correctly. Otherwise, all the information you have collected to restore compression inside the engine will be useless.

A compression meter allows you to obtain the most accurate data. Although you can carry out all measurements manually. However, in this case, the accuracy of the collected data will be in doubt.

In order to determine what exactly causes compression problems in the engine, you need to carry out the following manipulations:

- leave only one candle in the nest. Unscrew all the rest;

- the crankshaft must be cranked to the end of the compression stroke;

- The spark plugs must be unscrewed one at a time, while gradually rotating the crankshaft.

As a result of these simple manipulations, you will be able to understand what exactly causes compression problems in the engine and carry out restoration.

Attention! It is best to carry out all measurements when the engine is slightly warmed up.

Before taking readings from the device, start the car. As soon as the temperature in the engine reaches 85 degrees, turn it off. After this, you will need to unscrew the spark plugs and open the throttle.

To get accurate data, one person should be at the engine and the other should be driving. The assistant's task will be to turn on the starter while simultaneously pressing the gas pedal to the floor.

Important! The compression gauge must be inserted into the spark plug hole.

The crankshaft can only be turned when the starter is turned on. You will have about two seconds to obtain information that will help restore compression in the engine. To determine the problem area, several measurements will be needed.

When measuring engine compression, you must take into account that each car model will have its own ideal value. Typically, this data should be provided by the manufacturer in official documentation or on its website.

It is worth recognizing that car wear and tear is a natural fact that cannot be avoided. Therefore, after your vehicle has driven a sufficient number of kilometers, check the engine for compression. In addition, it is always easier to repair a small fault than a large one.

The best additives for engine cleaning

Engine cleaning products not only rid the engine of waste products, but also partially restore it. The effectiveness of using these drugs is visible before diagnostics and minor engine repairs.

Bullsone "Cleaner 3 in 1"

Additive for cleaning the fuel system of a gasoline engine Bullsone “Cleaner 3 in 1” eliminates harmful deposits on the internal combustion chamber and cleans the intake valves. The drug has a positive effect on the operation of the engine, makes it as efficient as possible, and improves the quality characteristics of the engine oil. Bullsone is absolutely safe to use with gasoline engines, has European and American quality marks, and international certificates of conformity.

Advantages

- Positively affects the properties of the oil;

- Does not add exhaust emissions;

- Non-toxic when used correctly;

- Low price.

Flaws

- An inconvenient container with a substance.

For efficiency, it is recommended to use Bullsone “Cleaner 3 in 1” every 5,000 kilometers of the car.

Wynns Injector Cleaner Petrol

Multifunctional fuel additive Wynns Injector Cleaner Petrol is intended for use in cars with gasoline engines. The drug helps maintain the injection system in efficient condition. The product rids the fuel pump, injector, valves, combustion chamber, and air intake manifold of deposits formed as a result of engine operation. After cleaning, it keeps the car running in good condition, protects against rust and corrosion. Additional lubrication of cleaned parts makes the engine operate more efficiently.

Advantages

- High-quality cleaning;

- Additional protection of parts;

- Convenient bottle;

- International certificates of conformity.

Flaws

- More expensive than some analogues.

For every 4,000 kilometers, the manufacturer recommends using 325 milliliters of the substance. This will help the system stay in working order longer.

The best anti-freeze products

Liqui Moly Speed Benzin Zusatz 3903

The Liqui engine additive is a universal complex for the care of gasoline engines. The components that make up the drug, when interacting with gasoline, form a protective layer of polar molecules. This process protects the motor from corrosion. Liqui Moly Speed Benzin Zusatz 3903 provides additional lubrication of engine parts and improves the operation of the piston system of the unit. A distinctive feature of this product is that it is recommended to add it every time you refuel the car.

Advantages

- Cleans the motor;

- Prevents excessive friction;

- Optimizes work power;

- Convenient to use.

Flaws

- High price.

Liqui is often used by car owners as a gasoline preservative when storing a car in the winter. Not all motorists use cars all year round.

What is compression and how is it measured?

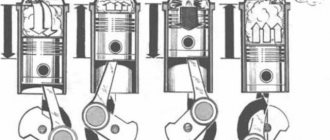

Compression is the amount of maximum pressure created in the cylinder when the piston moves from bottom dead center (BDC) to top dead center (TDC), when the engine is idling with the starter. The concept of “compression” should not be confused with the concept of “compression ratio”, which is a calculated value and denotes the ratio of the volume of the piston space above the cylinder when the piston is at bottom dead center (BDC) (full volume of the cylinder) to the volume of the space above the cylinder when the piston is at the top. dead point (TDC), that is, to the volume of the combustion chamber. Compression testing is one of the simplest and most accessible ways to diagnose an engine. The apparent simplicity of the procedure for measuring compression has gained fame as a kind of “universal” method, capable of not only identifying a malfunction, but also generally assessing the technical condition of the engine as a whole. But this universality is deceptive - the obtained measurement results often require special analysis, and it is not always correct to draw unambiguous conclusions from them, since the pressure in the cylinder at the end of the compression stroke, when the piston is at top dead center (TDC), depends on a number of factors.

How do you check engine compression?

The most common device for these purposes, which will help determine has the compression dropped in the engines - compression gauge. This device is a pressure gauge connected by a hose to a fitting and a check valve. As the engine crankshaft rotates, air is forced into the hose until the pressure in the hose equals the maximum pressure in the cylinder. Its value will be recorded by a pressure gauge. Unlike simple domestic designs, foreign analogues are produced with sets of adapters (adapters) that allow measurements to be taken on cars of any make and model. Compressographs are also easy to use. Their purpose is the same, but the measurement results are recorded on paper or special plastic cards, which makes it possible to archive them for subsequent comparison at different periods of vehicle operation. The disadvantage of the compressor is the difficulty of assessing the dynamics of pressure increase when cranking the crankshaft.Modern motor testers quickly and efficiently measure compression. These devices actually record not the pressure, but the amplitude of the pulsation of the electric current consumed by the starter during cranking - the higher the pressure in the cylinder, the greater the expenditure of starter power to rotate the crankshaft. Thereby, if the engine compression has dropped, it is possible to simultaneously measure the compression in all cylinders in just a few revolutions, without resorting to turning out the spark plugs, which is important for multi-cylinder engines. The disadvantage of a motor tester is that the results obtained are expressed in relative units, for example, as a percentage of the cylinder that works better. Only the most expensive engine testers are capable of measuring the absolute value of compression in each cylinder, but this is only possible on the basis of a large number of statistical data for a specific engine model and their comparison with the actual pressure in the cylinder.

The best additives to reduce oil consumption

Additives that promote oil consumption help to change it less often and preserve its properties longer. The motor also receives additional lubrication, which has a positive effect on the longevity of the machine.

Bardahl "No Smoke"

Bardahl No Smoke anti-smoke additive in engine rebuilding oil has increased effectiveness due to a special high-viscosity formula. At temperatures above average, it creates a barrier to oil entering the combustion chamber. Worn engine parts are additionally coated, extending the life of the engine oil. The substance does not reduce the effect of exhaust gas deactivators and particulate filters. Bardahl No Smoke is suitable for all types of engines.

Advantages

- Effectively neutralizes smoke;

- Promotes an increase in oil pressure;

- Reduces oil consumption;

- Makes the motor less noisy.

Flaws

- High price.

Users note that the drug does not clog the oil filter. Can be used with different types of oils: mineral, synthetic, semi-synthetic.

Wynns Super Charge

The drug for restoring compression and reducing oil consumption effectively copes with its task thanks to a formula that increases oil viscosity. Wynns Super Charge works great in high temperatures, under heavy loads, and reduces engine noise. This is especially true on long trips, when moving through mountainous areas, or when driving with a trailer. Suitable for gasoline and diesel units. It works well when working with old engines.

Advantages

- Reduces oil consumption;

- Extends motor life;

- Does not destroy catalysts;

- Protects against corrosion and rusting.

Flaws

- High price.

The manufacturer recommends using 325 milliliters of the substance per 5 liters of engine oil. Filling must be done at engine operating temperature.

Liqui Moly Visco-Stabli

Liqui Moly Visco-Stabli normalizes the viscosity of motor oil at high temperatures. Additionally, it normalizes oil pressure, which is important for frequent cold starts of the engine. By increasing viscosity properties, oil consumption is reduced. The product is especially effective when used on old, worn-out units. With Liqui the noise level is reduced. Produced in Germany, has international certificates of conformity. Safe to use, does not pollute the environment.

Advantages

- Removes smoke;

- Saves oil;

- Works well in hot weather;

- Low price.

Flaws

- Inconvenient cylinder.

Liqui Moly specialists recommend using 300 milliliters of the drug per 4-5 liters of motor oil. This is enough even for old cars.

Non-mechanical damage

They are usually observed after poor-quality repairs. Inexperienced craftsmen set the valve timing incorrectly. When viewing, it is noticeable that the valves are closing, but this is not happening at the right time. They remain slightly open during the compression stroke. This is quite enough for air to escape, but the displacement is small. Therefore, the valves do not contact the piston. Another common reason is coking and sticking of the rings. It turns out that the compression valve fits into the grooves. The seal is lost and gas passes through. At the same time, the oil scraper rings continue to work, and the oil does not seal the cracks. When working properly, it is washed off with unburned fuel, but in this case it is simply removed with rings.

Which engine additive is best to buy?

When choosing an engine care product, you need to clearly define the functions that are required from the product, and also evaluate the mileage of the car. Then, in accordance with these parameters, choose an affordable product.

The best representatives of additives include the following:

- HI-Gear is a compression preparation that restores engine parts well and improves piston stroke;

- Liqui Moly Speed Benzin Zusatz 3903 - attracts with its versatility, perfectly cleans, restores, lubricates;

- Bardahl No Smoke - reduces engine oil consumption, reduces smoke, extends engine life.

For efficiency, engine additives must be used in accordance with the manufacturer's recommended proportions. Saving the drug will have a bad effect on the condition of the engine and will not give the desired results.

When to use

Let's compare the additive with tablets. You will not use medications unnecessarily, even if everyone around you praises them and convinces them of their incredible effectiveness and excellent healing effect. The same should be done with auto chemical goods; use additives, adding them to an engine with high mileage, only when the need arises. Experienced drivers consider auto chemicals, which are poured into oil for a diesel or gasoline engine, as a lifeline. If you begin to notice that your engine is not in order, you will only have a few options, from which you will have to choose the most suitable one:

- carry out expensive repairs of the internal combustion engine;

- purchase a new internal combustion engine (we note right away that buying a used engine is not recommended, since you can buy a “pig in a poke”; after installation on your car, it may turn out that it is also in poor condition);

- add the additive to the engine oil.

The most affordable option of the three listed is the introduction of a “miracle cure”. In addition, you can get instant results, whereas repairs are not carried out in one day, nor is installing a new engine. A high-quality additive can revive the engine and allow the car owner to continue using the vehicle for some time, during which the motorist will have time to accumulate the required amount for repair work.

The main causes of low engine oil pressure

Reduced engine oil pressure in the engine can be caused by the following reasons:

- The engine was filled with low-viscosity engine oil that was not suitable for long-term use. A product of this quality in most cases is a fake of poor quality.

- Engine wear, which manifests itself in increased gaps between the bearings and the engine crankpins.

- Wear of the internal surface of the pump and, in connection with this, the inability of such a pump to create the necessary engine oil pressure.

- Significant wear of the cylinder-piston sector, where significant gaps appear between the piston and cylinder. In view of this, oil flows from the walls at a higher speed, which leads to a decrease in oil pressure.

Methods for restoring a parameter

The method of compression restoration is determined by the reason for the decrease in this parameter. Depending on the nature of the problem, the following methods can be used:

- Decoking of piston rings (flushing oils, fast-acting decoking compounds).

- The use of additives to restore compression.

- Engine overhaul.

- Adjusting, grinding in and replacing timing valves.

The service life of the cylinder-piston group depends on the operating mode, the quality of the fuel and engine oil. To reduce the risk of compression loss, your vehicle must be serviced regularly.

To prevent a drop in pressure, you need to use high-quality fuel, change the oil regularly and clean the injector to prevent detonation.

We restore worn areas... using innovative methods and materials

And precisely because the tightness of contact between the rubbing parts of the engine’s cylinder-piston group is lost, one often has to solve the problem of how to increase engine compression on one’s own. In principle, nothing complicated, taking into account the fact that there are numerous additives on sale for restoring friction areas in the area of the cylinder-piston group of the engine.

They really (if the malfunction is correctly diagnosed) can turn out to be very useful, and increase compression by an order of magnitude, increasing the pressure in the engine cylinders.