During operation, a gasoline internal combustion engine produces sounds characteristic of a diesel engine. The causes of this phenomenon and the dangers associated with it. How to determine the malfunction. Tips and tricks.

A normally working mechanism is said to work like a clock. The gasoline engine of a passenger car that has just left the passenger compartment really justifies this comparison. However, the time comes when the driver notices a changed nature of the engine.

The accompanying sound becomes rougher, extraneous noises and knocks appear, the engine runs unevenly, with vibrations. Since this sounds aurally reminiscent of the operation of a diesel engine, they often call it a “diesel engine”. Moreover, this may not necessarily happen on an old car. The article discusses the factors that contribute to this behavior of the engine.

Refueling with low-quality fuel

Many systems and devices of the power unit can contribute to the fact that a gasoline engine operates like a diesel engine. However, there is one external reason that contributes to the appearance of unusual sounds. This is low-quality fuel.

The main property of gasoline, which characterizes its resistance to detonation (explosive pre-ignition), is the octane number. If the engine is designed for AI-95 gasoline, and at the gas station you were filled with low-octane fuel, troubles are inevitable.

- Under certain loads, fuel detonation occurs, accompanied by detonation knocks reminiscent of the ringing of piston pins and, remotely, the sound of a running diesel engine.

- To increase the octane number, octane-increasing additives are added to low-grade gasoline, which are deposited in the nozzles of the working injectors on an injection engine. The supply of fuel to different cylinders becomes uneven, which leads to harsh engine operation. In advanced cases, the injectors become completely clogged, as a result of which the engine begins to “trouble.”

- The additives contained in “bodied” gasoline cover the electrodes of the spark plugs with a layer of red soot, and due to misfires, the engine again “troubles.”

Tip: try to refuel at chain gas stations located in large populated areas or along busy highways. If you run out of fuel, fill up the minimum amount of gasoline at the first gas station you come across in order to get to the nearest verified gas station.

Wear of ShPG parts

The connecting rod and piston group is subject to significant loads during engine operation. As long as the gaps between the rubbing surfaces do not exceed the permissible limits, a gasoline engine is much quieter than its diesel counterpart.

However, as the gaps increase as a result of natural wear and tear, metallic knocks of various types begin to superimpose on the pleasant rustling background. The gasoline engine operates almost like a diesel engine. Sources of knocking in the connecting rod and piston group:

- Main bearings, wear of which is accompanied by low-frequency knocks emanating from the crankshaft beds. The sound changes according to load and crankshaft speed. A possible cause of wear is engine oil starvation. The appearance of such sounds requires urgent contact with a car service in order to minimize possible consequences.

- Connecting rod plain bearings. These parts produce distinct, loud metallic knocks, the source of which is the middle of the cylinder block. Knocks are heard especially clearly when the load increases. To determine their source, the spark plugs are turned off one by one. Driving with such symptoms is fraught with engine destruction.

- The piston pins produce high-pitched ringing sounds, somewhat reminiscent of detonation knocks. This sound is less dangerous than knocking of crankshaft bearings, although in any case it must be eliminated. Before visiting a repair service, you can drive for a while, avoiding increased load and high engine speeds. You should also monitor the operation of the lubrication system, and most importantly, monitor the oil level.

- Worn pistons. They make dull knocks, somewhat reminiscent of the rumble of a diesel engine, which can be heard after a cold start. As the engine heats up, their audibility decreases. You can drive in quiet mode, but you shouldn’t put off major engine repairs too much.

Attention: when a knocking noise in the engine appears suddenly, you must stop driving and call a tow truck to get to the nearest auto repair service.

Specifications

Before we begin to directly consider the issue of a malfunction associated with the tripping and blinking “CHECK” on the dashboard of a Gazelle Business car, it is worth considering the technical characteristics of the UMZ 4216 power unit:

| Name | Characteristic |

| Type | Row |

| Fuel | Petrol |

| Injection system | Injector |

| Volume | 2.9 liters (2890 cm3) |

| Power | 123 horsepower |

| Number of cylinders | 4 |

| Cylinder diameter | 100 mm |

| Consumption | 11 liters per 100 km |

| Cooling system | Liquid, forced |

| Econorm | Euro-3 |

Ignition system malfunctions

As mentioned above, low-quality gasoline has a detrimental effect on the operation of spark plugs. However, even when using good fuel, do not forget about replacing them regularly. Previously, spark plugs were most often changed when the engine began to clearly lose its dynamic qualities or have difficulty starting.

Today, most manufacturers recommend in service books to replace spark plugs annually or after 15 - 20 thousand kilometers. In this case, they are not the cause of deterioration in engine performance. However, you can buy defective products, and then signs of their poor performance will appear, including misfires.

Therefore, you should not buy cheap candles from an unknown manufacturer - the savings may backfire. Missing sparks can also be caused by the ignition distributor and the high-voltage part of this system: wires and coils.

Malfunctions and solutions

Fuel system

Signs of a fuel system malfunction:

- The engine will not start;

- prolonged engine start;

- the engine starts and stalls;

- lack of traction and dynamic characteristics;

- increased fuel consumption;

- frequent popping noises caused by a lean mixture;

- failures during acceleration.

One of the most common fuel system malfunctions is the ineffective operation of the fuel pump or its complete failure. It is possible to evaluate the operation of the fuel pump by connecting a pressure gauge to the injector rail. When the fuel pump is turned on, the pressure gauge needle should quickly, within 1.0 - 1.5 seconds, settle to the position of 3.8 atm, and when turned off, the pressure is allowed to drop to 3.0 atm.

If the pressure from the zero position increases slowly to 3.8 atm, this indicates that the filters installed in the tank on the fuel pump module and on the car frame are dirty.

A rapid drop in pressure to zero after turning off the fuel pump can be caused by a number of reasons:

- malfunction of the fuel pressure regulator installed under the fuel pump module cover%

- malfunction of the check valve on the fuel pump motor;

- the appearance of a crack in the corrugated fuel supply pipe to the main line or its leaky fit into the engine inlet fitting.

Fuel pump module

Failure of the fuel pump often occurs due to a lack of supply voltage, which is supplied from the turn-on relay. The relay is located in the engine compartment, on the rear wall of the engine compartment (literally under the windshield). Since the fuel pump relay is installed in the same block with two other relays for turning on the cooling fan and the main one, the car owner often has a question about their exact identification.

This can be done in different ways:

Method-1. Performed with an assistant without a warning lamp. The method works by sensing the activation of the relay electromagnet. The tester places his fingertips on all three relays, and the assistant turns on the ignition. At this time, two relays will operate simultaneously - the main one and the fuel pump, and the inspector will feel the click of the operation of the electromagnets. After 5-8 seconds, the fuel pump relay will turn off with a click of the relay, which will also be reflected on the inspector’s finger.

Method -2. Performed with an assistant and using a test lamp. Having hooked one of the test lamp probes to ground, the other is connected from the reverse side of the block to terminal “87” of the supply voltage. The assistant turns on the ignition and the inspector determines by the indicator lamp that one of the three relays is turned on. After 5-8 seconds have passed, at the relay where the control lamp turns off, this is the fuel pump relay. On the main relay, the control lamp will remain on continuously until the ignition is turned off, and on the fan relay, the lamp will not turn on.

The method is convenient in that the fuel pump relay is simultaneously detected and the presence of supply voltage is diagnosed by a control lamp.

Method-3. Performed without an assistant. The method is designed to identify the fuel pump relay based on the color scheme of the wires. On all Gazelle cars (ZMZ, UMZ engines) the outgoing wire from the fuel pump relay connector (pin “87”) is white.

Fuel pump relay (left)

If, during the check, the integrity of the wiring is established and there is voltage and ground at the fuel pump connector, then it is recommended to remove the fuel pump module from the tank and carefully inspect all existing contacts for burning. Sometimes a defect is detected instantly by the state of the melted motor.

Based on the results of checking the fuel pump, its normal operation is established, but the engine does not start or runs unbalanced after starting.

In this case, it is necessary to check the integrity of the electrical wiring harness connecting the injectors to the main cable and the control unit, check for the presence of positive voltage at all injector connectors, as well as incoming switching pulses when cranking the starter.

Missing pulses at the injector connectors with a simultaneous absence of a spark at the spark plugs indicates a malfunction of the synchronization sensor, the signal of which can be determined by diagnostic equipment.

The engine heats up and starts to stall: why does this happen?

Almost every car enthusiast sooner or later encounters such a fairly common malfunction of the internal combustion engine, when the engine stalls. As a rule, in certain situations the engine stalls when hot or only when cold, and tripping can also occur constantly (regardless of the temperature of the power unit, operating mode, load level, etc.).

In short, engine tripping means that one or more cylinders are not firing, and there can be several reasons for such a malfunction. In this article we will talk about why the engine stalls after warming up, how the malfunction can be diagnosed, and what signs help to accurately identify the problem.

Read in this article

What does “diesel gasoline engine” mean?

A special feature of diesel engine is the increase in engine operating noise.

It is better to leave a car with such a breakdown in the garage; it is unsafe to drive it. Typically, diesel power indicates damage to the power unit, which is best eliminated at the time of its early manifestation. Otherwise, you will soon have to carry out major repairs. Diesel engines make more noise than gasoline engines because their ignition system is designed in a special way. Dieselization of a gasoline engine is the appearance of noise characteristic of diesel engines. Usually noise appears when the engine is running cold or idling. There can be many reasons for this unpleasant phenomenon, but they are all related to the timing belt assembly.

Exhaust system leaking

The exhaust system can reproduce the richest sound gamut. Thanks to constructive measures, developers achieve a noble exhaust sound character.

However, the consequences of winter operation lead to the fact that one day you will hear a rattling sound from the muffler of your car, reminiscent of the exhaust of a direct-flow muffler. From now on, all street racing fans will perceive this sound as an invitation to compete at the traffic lights.

The reason that the engine rumbles like a diesel engine is a leak in one or another element of the exhaust system. All of its components can burn out: the main and additional mufflers, the resonator, the catalytic converter of the exhaust gases, the corrugation, the exhaust pipe (pants) and the exhaust manifold gasket.

Before reaching this state, a small fistula appears through which gases escape (the leaky part “cuts,” as drivers say). Finding the location of the damage is often difficult, so the hole gradually increases until listening to the lion's roar of the exhaust becomes unbearable.

Sometimes there is no external damage, but the tractor sound is present. This happens when you knock out burnt ceramic honeycombs from the catalyst and drive with such an “improvement”.

The revolutions fluctuate and can increase arbitrarily

In the case when all cylinders of the UMP engine operate in a wave-like cycle, i.e. At the same time they increase their energy intensity and also at the same time reduce it; there is a floating of revolutions in a wide range. It should be noted that an increase or decrease in speed (discreteness) is allowed in the range from minus 40 to plus 40. A value above the maximum permissible indicates a malfunction, which is most often caused by the leakage of unaccounted air into the intake manifold. Air leaks may appear on the bottom of the injectors, the sealing rings of which crystallize over time, in other words, “tanner” and, accordingly, the tightness is lost. As a result, unaccounted air penetrates through worn o-rings into the intake tract and the fuel mixture ratio is disrupted. Violation of the air-fuel ratio leads to floating speed and its regular increase with a subsequent drop.

It is difficult to check for air leaks on your own, and the advice of “experienced” people in searching for leaks with water or carburetor cleaner for suspected fistulas is not realistic. Water and spray from carburetor cleaner on a hot engine instantly evaporate and it will not be possible to create a film that temporarily covers the suspected fistula, especially if there are many such fistulas (four injectors, an intake manifold gasket, rubber tubes).

An effective way to check for air leaks is to fill the intake tract with smoke using a diagnostic smoke generator. This device can detect even very small air leaks in the most difficult to reach places.

Smoke generator

Timing faults

Breakdowns or wear of timing parts (gas distribution mechanism) can also be involved in the appearance of extraneous sounds under the hood of a gasoline engine. The most common faults:

- Valves are knocking. This disadvantage is inherent in older gasoline engines, which required periodic valve adjustment, even during the first annual maintenance. Knocking can be caused by unqualified repairs (poor fit of the valve plates to the seats), as well as deformation due to overheating of parts.

- Hydraulic valve compensators are knocking. Modern valve mechanisms equipped with automatic adjustment are more durable, however, even in this case, the hydraulic compensators wear out sooner or later, after which they should be replaced.

- The timing chain drive is loose or worn. In this case, the dangling chain touches the guard cover, which causes a rattling knock.

- The timing belt jumped several teeth, causing the valve timing to be disrupted. The engine runs harshly, untimely combustion of fuel causes a characteristic diesel sound.

- The bearing beds of the camshaft are worn out, which causes noticeable knocking noises, especially when the engine is not warmed up, when the gaps in the bearings have not yet been cleared.

Summarize

The most common reasons why a gasoline engine runs like a diesel are listed above. Other possible causes of a noisy gasoline engine include a failing cooling system, especially when the engine is unable to reach its operating temperature. In this case, the thermal clearances do not achieve optimal performance, resulting in increased noise levels. In addition, the problem may be faulty engine ECU or electrical circuits, timing drive, installation, etc.

What to do if the car accelerates worse, does not pick up speed, and malfunctions occur during acceleration. Why the engine does not pull, how to find the reason for the decrease in power.

Other reasons

The appearance of “diesel” sounds is influenced by malfunctions in other engine systems. Incorrect cooling operation leads to the fact that the engine temperature does not reach the optimal value for the normal flow of the working process in the cylinders. In this case, the thermal gaps exceed the design ones, which causes additional noise from the contact of interacting parts.

If the oil pressure in the lubrication system is insufficient, the conditions for the formation of an oil wedge in bearings operating in hydrodynamic lubrication mode worsen. The consequence is a rougher interaction of the working journals of the crankshaft and camshaft with their beds.

There are other reasons, sometimes quite rare. For example, after overcoming a deep muddy rut, the space between the oil pan and its metal protection becomes clogged with liquid mud. After the car has been parked overnight, this dirt dries up, and the driver, when starting the engine in the morning, is quite puzzled by the unexpected vibration of the engine unit.

This fever is accompanied by knocking noises reminiscent of the work not even of a diesel engine, but of a construction hammer. It is difficult to discover the cause. It turns out that dried dirt interferes with the damping of torsional vibrations of the engine, and the latter are transmitted to the body of the car, causing vibrations and frequent knocking.

Summarizing the above, we can conclude: there are many reasons why sometimes a gasoline engine works like a diesel engine. Among them there are both harmless and very dangerous, which, if timely measures are not taken, can lead to breakdown of the power unit. Therefore, do not ignore any extraneous noises and sounds that are unusual for the operation of a gasoline engine.

Fuel consumption has increased, power has decreased and it often stalls.

If malfunctions associated with a decrease in engine power, an increase in fuel consumption and unbalanced engine operation simultaneously appear, you should first look for the cause in the correct operation of the gas distribution mechanism, which on the UMP engine is very sensitive to thermal valve clearances. The owner needs to remember at what mileage the technical regulations for adjusting the thermal clearances of the valves were carried out and precisely at the mileage, and not in winter or summer. Adjustment of clearances on the UMP engine is carried out according to the manufacturer’s instructions and is recommended to be carried out every 10 thousand kilometers.

More details about adjustment https://diagnozbibike.ru/regulirovka-klapanov-umz-4216/

Diesel engine

Lada Granta WHITE LEXUS Logbook The check light came on. Emergency engine operation

Pros:

- Low fuel consumption

The obvious reason for the popularity of diesel in commercial vehicles. And among car owners too. And despite the fact that modern gasoline engines can also boast of fairly low fuel consumption, diesel engines still have this innate. At the same time, a diesel engine has greater efficiency and torque due to a higher degree of fuel compression and the nature of its combustion.

Low transport tax

With the same volume, a diesel engine has less power (and higher torque, but we’re not talking about that now). And the transport tax in Russia, as you know, is calculated based on the number of horsepower.

Environmental friendliness

Despite recent scandals with automakers, diesel is still the most environmentally friendly of internal combustion engines. Only hybrids and electric cars are greener.

Durability

Unlike gasoline engines, which have been cursed by downsizing in full force, in our country diesel engines are still focused more on commercial vehicles. And this simply obliges him to live a long time. A very long time.

Engine sound

The diesel rumbling, which has become the talk of the town, caresses the ear of every car enthusiast who loves loud cars.

Minuses:

ECU diagnostics

In order to understand which of the sensors or components affected the unstable operation of the engine, it is worth conducting a comprehensive diagnosis of the on-board computer. This requires an OBD II cable, a tablet and laptop, and software.

It is recommended to turn to professionals for help, who will quickly and efficiently perform diagnostic operations and fix the problem.

Deciphering error codes

If the car owner nevertheless decides to fix the problem on his own, then he will need to decipher the error codes that will appear on the diagnostic computer screen. So, let's look at all the error codes and their interpretation for the UMZ 4216 engine:

| DTC | Description |

| P0105 | Incorrect air pressure sensor signal |

| P0107 | Low signal level from air pressure sensor |

| P0108 | High signal level from the air pressure sensor, |

| P0122 | Low signal level from throttle position sensor (1 track) |

| P0123 | High signal level from the throttle position sensor (1 track) |

| P0112 | Low signal level from air temperature sensor |

| P0113 | High signal level from the air temperature sensor |

| P0115 | Incorrect signal from the coolant temperature sensor |

| P0117 | Low signal level from the coolant temperature sensor |

| P0118 | High signal level from the coolant temperature sensor |

| P0130 | No activity of oxygen sensor No. 1 |

| P0131 | Low signal level from oxygen sensor No. 1 |

| P0132 | High signal level from oxygen sensor No. 1 |

| P0133 | Oxygen Sensor #1 - Slow Response |

| P0135 | Open circuit of oxygen sensor heater No. 1 |

| No. 1 oxygen sensor heater circuit short to ground | |

| Short to power in the oxygen sensor heater circuit No. 1 | |

| P0137 | Low signal level from oxygen sensor No. 2 |

| P0138 | High signal level from oxygen sensor No. 2 |

| P0141 | Open circuit of oxygen sensor heater No. 2 |

| Short to ground circuit of the heater of the oxygen sensor Lg "2 | |

| Short to power in the oxygen sensor heater circuit No. 2 | |

| P0201 | Broken injector of cylinder 1 |

| Ground fault in cylinder 1 injector | |

| Short circuit to power supply of injector 1 cylinder | |

| P0202 | Broken injector of cylinder 2 |

| Injector 2 cylinder short to ground | |

| Short circuit to power supply of injector 2 cylinders | |

| P0203 | Broken injector cylinder 3 |

| Injector 3 cylinder ground short | |

| Short circuit to power supply of injector 3 cylinders | |

| P0204 | Broken injector 4 cylinders |

| Injector 4 cylinder ground short | |

| Short circuit to power injector 4 cylinders | |

| P0217 | Engine temperature is above the maximum permissible |

| P0219 | Engine speed is above the maximum permissible |

| P0221 | Range limit of the difference between 1 and 2 tracks of TPS |

| P0222 | Low signal level from throttle position sensor (2 track) j |

| P0223 | High signal level from the throttle position sensor (2 track) j |

| Open circuit of the fuel relay | |

| P0230 | Fuel relay primary circuit short to ground |

| Fuel relay primary circuit short to power | |

| P0301 | Misfire in cylinder 1 |

| P0302 | Misfire in cylinder 2 |

| P0303 | Misfire in cylinder 3 |

| P0304 | Misfire in cylinder 4 |

| P0327 | Low signal level from knock sensor |

| P0339 | HF Sync Sensor Synchronization Error |

| P0335 | HF synchronization sensor break |

| P0341 | Phase sensor synchronization error |

| P0351 | Broken ignition coil 1 |

| P0352 | Broken ignition coil 2 |

| P0420 | Low efficiency of the exhaust catalyst |

| Open circuit of the canister purge valve | |

| P0443 | Short circuit to ground in the canister purge valve circuit |

| Short circuit to power in the canister purge valve circuit | |

| Cooling fan relay primary circuit open | |

| P0480 | Cooling fan relay primary circuit short to ground |

| Cooling fan relay primary circuit short to power | |

| P0501 | Broken vehicle speed sensor |

| • | Idle air control malfunction | |

| P0505 | Open circuit of the idle speed regulator |

| Idle air control circuit short to power | |

| P0563 | High on-board voltage |

| P0562 | Low on-board voltage |

| P0603 | Control unit EEPROM error |

| P0604 | Control unit external RAM error |

| P0605 | Error in the external ROM of the control unit (ROM1) |

| P0606 | Control unit initialization error |

| Open circuit of the CHECK ENGINE lamp | |

| P0650 | Short circuit to ground in the CHECK ENGINE lamp circuit |

| Short to power in the CHECK ENGINE lamp circuit | |

| P1107 | Low signal level from the barocorrection sensor |

| P1108 | High signal level from the barocorrection sensor |

| P1122 | Low signal level from the accelerator pedal position sensor (1 track) |

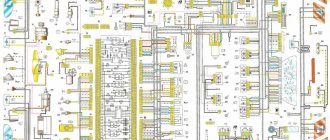

Video: Umz 4216 Works Like a Diesel

The car engine starts and stops immediately after starting: the main causes of this malfunction. Diagnosis of possible causes, tips and tricks.

Signs of cylinder failure (friction and vibration) of a diesel engine. Troubleshooting: compression, diesel injectors, spark plugs, high pressure fuel pumps and much more.

The appearance of knocking noises in different diesel operating modes. Fault diagnosis. The nature of detonation of the crank mechanism, time, fuel equipment.

Causes and results of diesel engine overheating. What to do if the diesel engine warms up: diagnostics and troubleshooting. Important tips.

Common diesel engine malfunctions and diagnostics of units of this type. Checking the diesel fuel system, useful tips.

Hello everyone who is bored!))). I want to describe a recent case of our service with a light commercial vehicle of our corporate client, which happened completely unexpectedly and surprised us all at first)). So here's the thing: a not very old, but very broken machine that is used as an amplifier. Work transport, under different drivers. What actually means the right attitude towards the car. Company. The owner of this car is engaged in servicing electrical networks and street lighting in our hometown of Moscow. And if you notice cars with scattered steps standing near power plants or lighting towers on the streets. Lifts from a person over replacement light bulbs. Then it might just be a questionable car. Accordingly, while the electrician upstairs is slowly doing his job, what is the driver doing? Well, of course he’s sleeping))). And if it's not summer outside, the engine makes a quiet noise at idle, transferring heat to the cabin heater. And therefore, almost every day, making short jerks from the caliper to the support, the motor does not feel serious loads or hours of operation. The “rest” of working time is standing still.

Well, now, actually, to the essence of the matter. After the next “RAM”, the “Gazelle” crawls up to the service station and stands up for repairs in the body shop with some stupid deceiver who did not notice a single car parked in the left lane on the Moscow Ring Road, or information boards warning about the intervention information board. The damage is not so severe that it will have any impact on engine performance, but it does combine bodywork problems and the possibility of simultaneous after-sales service, preventive maintenance and maintenance. After changing the oil, filters, replacing spark plugs and connecting the computer to check errors and engine parameters in memory, the car was assembled and ready for delivery. The engine was noisy, but for the 402 series this is quite acceptable. The driver who came to pick up the car signed the documents, took the keys and went to warm up the engine. To check the sluggishness, Gazan left the salon several times and froze in the position of a hound, which felt the game and stretched its ears))). In fact, there was something to stress about. The sounds of the engine running under the hood clearly indicated that things were not going well. The muffled knock coincided with the speed of the crankshaft, but the engine did not come “bottom”, not top. To check, we opened the plastic top cover (valve), checked the condition and installed valve rods equipped with hydraulic compensators; I checked the operation of each compensator and swing. After turning the spark plugs, carefully inspect the condition of the miniature video camera inserted through the spark plug hole inside the cylinder, the condition of the lower part of the piston for the presence of taps and foreign objects that have fallen inside. No obvious traces of filling or foreign objects were found. Only a large amount of soot was observed on the walls of the combustion chamber and pistons. Based on the nature of the sound and the approximate location of its source, it was determined that everything was happening in the area of the 1st (and possibly 2nd) cylinder. Recalling the design of the 402 family engines, the design of the valve mechanism, which is in the lower position of the camshaft driven by the crankshaft through a textolite transmission, we conclude that the textolite “body” begins the transmission “walking” on a steel hub (that is, on the core ), which on all older versions of the 402 series engines resulted in sounds that were often confused with the sound of the crankshaft. Basically the sound is similar. It was decided to remove the front cover of the engine, which covers the drive gears and the pan (the pan is structurally screwed through pins screwed to the front cover, and in order to remove the front cover, you must either remove the pan (for “right”) or unscrew 4 pins from covers); and also to ensure proper alignment of the crankshaft seal and prevent leakage from under the pan gasket (and a “tongue” remains when removing the cover without the pan), after replacing the cover, simultaneously check the condition of the crankshaft liners.

We removed the pan and removed the front cover. The gear was a visually untraceable “beam” between the PCB and the steel base; When trying to “shake” play forward/backward and additional movements are not detected. And the inserts were perfectly worn. A secret, however)).

There were no obvious signs of a rather unpleasant and quite strong knock. It was decided to remove the engine from the car and completely disassemble it. The engine was removed, new oil was carefully poured into a clean container installed on a special stand. Having completely disassembled the components, we begin a thorough inspection and development of all engine parts. All we have: Inspection and testing of the camshaft drive was negative. This is not the reason for this. The camshaft shows no signs of major wear and the neck and lobes are intact. The camshaft seat in the unit does not have the tin-lead type bushings that are familiar with previous versions of this engine. In this model, the camshaft arrangement is processed by the material of the cylinder block during its manufacture; There are no obvious signs of wear, only a slight misalignment of the holes is noticeable, judging by the traces of friction on the walls of the working surface. On the last and middle “bushing” the contact point is only visible on one side, with the opposite load on the camshaft. Most likely, the geometry of the unit is slightly disturbed, or a non-critical unevenness occurred during the manufacture (groove) of the seat under the camshaft, but this clearly cannot be the cause of detonation. The pusher cups also have no complaints, nor do the pushers.

Remove the manifold from the cylinder head, note the huge amount of soot under the intake valve seats, and on the 1st and 4th cylinders the cross section of the intake valve channel is almost half covered with soot.

Lower and remove the valve. Considering that we are holding domestically produced parts (“sovkoproma”) in our hands, a slight unevenness of the valve stems (checked in the machine cartridge) raises thoughts about replacing them. Valve seals, i.e. The valve stem seals are completely “dead” and in a state of numbness. The condition of the pistons and piston rings is flawless, as well as the cylinder walls. The oil pump is ok.

A lot of soot was observed in the intake ports in front of the valves (under the valve seats) and in the combustion chambers themselves. Well, that seems to be the reason. "Banquet". “Unfastened” From the cylinder head, the gasket glued to it drew attention to the fact that, structurally, the piston bottoms in the TDC position protrude slightly above the surface of the mating plane of the cylinder head. Opposite them, on the block head, the layer of soot is so thick that it matches the shape of the edge of the piston crown and has traces of direct physical contact with it. And upon careful inspection of the piston and head of the 1st cylinder, we notice that the soot on the head contains not only traces of contact with the piston, but even an imprint (pattern) of concentric rings left on the metal surface of the piston during its manufacture.

This is probably the reason. While the engine was running quietly, without load and almost constantly idling, sucking oil through dead caps that were deposited as soot on the intake valve and under the seat, as well as in the combustion chamber, nothing terrible happened. But when the driver, taking the car out of repair, energetic “gazanul” several times, a piece of soot from under the valve seat moved away and, falling into the air flow entering the cylinder, sliding into the gap of the open valve, fell into the cylinder. And it's not very good, just below the edge of the piston; and then the piston will be “nailed” to the plane of the block head, where it remains. And the sound, which was not there when the car was in service during production, “suddenly, suddenly” appeared. And the “dull” nature of the sound became clear. When a small hard object (for example, a carburetor nut) falls into the cylinder, the impact area (contact) becomes small in area, and the impact sound is sharp and clearly visible. In our case, the “spot” sound, as well as the overall pronounced increased noise of the engine as a whole, is explained by the fact that the area of physical contact of the parts upon impact through a layer of adjacent soot is large; Also, additional extraneous sounds, not very pronounced, are produced by the 2nd, 3rd and 4th pistons with a gap almost completely filled with soot between the bottom of the piston and the cylinder head.

Piston of the first cylinder.

Piston of the second cylinder.

Piston of the third cylinder.

Piston of the fourth cylinder.

Now everything is falling into place! There are no miracles, there are no definite reasons for simple physical phenomena))), but sometimes even professionals do not always manage to correctly identify them the first time. We clean and reassemble the engine, replace worn and disposable parts, inspect and prepare the vehicle for delivery. The diagnostic and search work was “amazing.” The sounds took a day and a half, knowing the specifics of the client and his cars helped a lot: idling almost 24 a day! The mileage on the speedometer is 90 tkm, one can only imagine how many real hours this engine has been “starting up”. The work of assembling, installing the engine on the car for another two days is up to you to decide whether it will be fast or not, and we can say that the information has indeed been processed, and our case has not hit the Internet, we are in a hurry to correct about I’ll tell everyone about this and “it happens.”

Problems with the cylinder-piston group

If the engine suddenly and distinctly knocks, knocks, pops, friction and crunching are heard, then operating the car is strictly prohibited.

It is necessary to immediately determine the cause of the knocking. In some cases, it will be preferable to abandon the decision to go to a car service under your own power and deliver the vehicle in a tow or tow truck. A low knocking sound at the bottom of the engine crankcase, which intensifies when the engine is under load and when the crankshaft speed increases, may indicate that the main bearings are knocking. When this sound occurs, the engine must be turned off immediately. Main bearings may knock due to critically low oil pressure in the lubrication system. Additionally, the emergency lamp on the instrument panel lights up and does not go out. You can't drive under your own power with that kind of noise.

No less dangerous is the ringing, distinct metallic sound that comes from the middle part of the internal combustion engine (in the area of the cylinder head gasket). This can cause the connecting rod bearings to knock. The sound is heard most clearly under load. You can identify a malfunction in one of the cylinders by disconnecting the spark plugs one by one. A shutdown in a faulty cylinder will cause the rhythmic and ringing sound to disappear. Driving with such damage is prohibited.

Another reason why a gasoline engine sounds like a diesel engine could be the high-pitched ringing sound of the piston pins knocking. This knocking sound is slightly similar in tone to detonation, but is clearly audible in all engine operating modes and intensifies under load. It is determined similarly by the method of disconnecting the spark plug. You can get to the service center with such a knocking noise yourself, having first checked the oil level. It is necessary to drive smoothly, avoid increasing speed and minimize the load on the engine.

If the engine has a high mileage, then worn pistons in the cylinders may knock when “cold”. The sound is uniform, reminiscent of muffled knocks, a bit like the sound of a diesel engine. The intensity will decrease as the engine warms up after a cold start. Once it reaches operating temperature, as well as while driving under load, the “diesel” knock disappears. The car can be operated in moderate mode, but you should not delay the repair of the internal combustion engine.

Difficulty starting the UMZ engine when cold

The issue of cold starting is problematic both for specialists and for the car owner. This situation arises due to the fact that the car arrives for diagnostics with a hot engine, and when it is hot it starts just fine. The owner cannot check a cold engine on his own due to the lack of diagnostic equipment.

However, there are a number of important reasons why the UMP engine is difficult to start when cold:

- low compression in cylinders;

- low fuel pressure in the injector rail;

- valve thermal clearances do not meet specifications;

- wear of spark plug electrodes;

- nozzles are not tight;

- faulty coolant temperature sensor;

- leakage and mixing of gas (propane, methane) with gasoline at the time of startup;

- Absolute pressure sensor malfunction;

- malfunction of the mass air flow sensor (if included);

- presence of water in the tank.

It should be noted that experts identify some of the listed defects on a hot engine, but even after they are eliminated, the question remains open until the next time the engine is started on a cold one.

Knocks due to detonation

To identify the problem and answer the question why a gasoline engine began to knock like a diesel engine, you must immediately start by checking the quality of the fuel and the level of the engine oil. A gasoline engine can operate like a diesel engine due to the fact that it is filled with low octane fuel, which is not suitable for this type of engine. Increased noise when the engine is running on low-octane gasoline will partially appear during a cold start, and is also very noticeable during further driving.

The appearance of detonation knocks can be clearly heard at the moment when the engine is under load during acceleration of the car. The knocks are loud, reminiscent of high-frequency impacts of metal on metal. Also, detonation can be caused by a malfunction of the knock sensor, driving in high gear in cars with manual transmission at low crankshaft speeds, dense carbon deposits on the valves and in the combustion chambers. Detonation is also caused by incorrect settings (ignition too late) on cars where the OZ is set independently. The working mixture burns out on the exhaust stroke, causing the engine to work shockingly and roughly.

Detonation under normal conditions is heard when a manual car is going up a hill, but the driver does not downshift, trying to maintain the set speed by pressing the gas pedal to the maximum. The car moves, but does not accelerate further, the engine does not gain momentum. It turns out that the internal combustion engine does not “pull” in high gear under load. In such conditions, the ringing knock of detonation appears most clearly.

Correct driving style, timely maintenance of the unit and driving on suitable fuel will help you get rid of detonation knocks. If the fuel tank is accidentally filled with low octane fuel, then the simplest solution is to immediately dilute the existing gasoline with a more suitable one. The second way is to add a special additive from the group of octane correctors, which allows you to increase the octane number and knock resistance of the fuel.

Malfunction of the injector or nozzles

The injection engine fails in the following cases:

- The injector is faulty, but this is very rare.

- Bad gasoline was poured in or fuel system cleaner was used incorrectly.

- Clogged injectors.

- The electrical power supply circuit for the injectors is open or shorted.

Engine diagnostics and a competent motor mechanic will help eliminate such malfunctions. To independently check the injector and nozzles, you need experience and special equipment.

Possible problems

No car is insured against any kind of breakdown. But among them there are problems that you can eliminate yourself, but there are also quite serious problems that can only be repaired at a service station.

When you hear extraneous engine noise, you begin to imagine all sorts of reasons, trying to eliminate them yourself. Sometimes, you can involve friends who are well versed in the design and repair of a car. Most common problems:

- in case of malfunctions in the thermostat or gas distribution system, it leads to the engine operating like a diesel engine;

- in case of malfunctions in the ignition system;

- problems with the carburetor;

- problems with the electrical or power system;

- When using low-octane fuel, engine operation resembles the operation of a tractor.