As a rule, if the automatic transmission is in good condition and operates in optimal modes, this type of gearbox provides a significant increase in comfort and facilitates the process of driving a vehicle.

Moreover, even on new cars with an automatic transmission, the owner may encounter the fact that the automatic transmission, under certain conditions, begins to shift gears with jerks and jerks. Also, the transmission oil in the machine may darken too quickly, etc.

Quite often the cause of such failures is overheating of the automatic transmission. Next, we will look at how to understand that the automatic transmission is overheating, the reasons why the automatic transmission overheats, and also what needs to be done in this case.

Off-season rules (don't forget)

- Do not skid or tow.

These modes overload and overheat the units even in cool weather, and simply kill them in hot weather.

Particularly dangerous for an automatic transmission or CVT is slipping in mud and towing a heavy trailer in the heat.

Particularly dangerous for an automatic transmission or CVT is slipping in mud and towing a heavy trailer in the heat.

- Monitor the level of working fluid in the box.

In the heat, leaks through the slightest leaks intensify. Overload from the heat combined with an incorrect fluid level will quickly lead to the death of the unit.

Regularly check the level in the box using a dipstick. Important: measurements must be taken at the temperature specified in the instructions for the car.

If there is no dipstick, inspect the box body and the place where you park the car more often.

If your car has a dipstick to control the fluid level, consider yourself lucky.

If your car has a dipstick to control the fluid level, consider yourself lucky.

Automatic transmission overheating: consequences and signs

So, let us immediately note that a significant increase in the temperature of the transmission oil in an automatic transmission usually manifests itself in the form of certain malfunctions in the operation of the automatic transmission.

Ignoring such symptoms can lead to a reduction in the life of the unit itself or breakdowns. In other words, in this case, the automatic transmission often fails, after which an expensive overhaul or replacement of the transmission with a contract one is required.

- Let's move on. The reasons for overheating of the automatic transmission may be different. First of all, the unit itself contains a large number of loaded elements that interact with each other. As a result, a large amount of heat is generated, which is removed using ATF.

Another feature of many hydromechanical automatic transmissions is the high heating of the gearbox oil in the torque converter. This device is actually an automatic transmission clutch, while the torque from the internal combustion engine is transmitted through the transmission fluid.

It becomes clear that problems in the automatic transmission or gas turbine engine, deviation from the norm in the oil level in the automatic transmission, a decrease in ATF pressure, as well as loss of properties of the transmission fluid itself lead to an increase in the temperature of the automatic transmission. In some cases, the oil in the automatic transmission heats up to 120 degrees or more.

Such heating is critical, the oil loses its properties, the unit malfunctions, and gearbox wear increases significantly. The consequences of automatic transmission overheating manifest themselves in the form of breakdown of solenoids, friction discs, as well as a number of other gearbox elements.

In practice, after a couple of tens of minutes, operating the automatic transmission in maximum heating mode will be enough for the unit to fail. For this reason, it is important to promptly identify symptoms of automatic transmission overheating. In cases where the automatic transmission overheats, signs of excessive heating can be determined independently. If the automatic transmission is severely overheated, the transmission ECU can switch the unit to the automatic transmission emergency mode.

The check or A/T light on the dashboard indicates problems with the automatic transmission. Various automatic transmission sensors record an increase in temperature, a decrease in ATF pressure, etc. In such a situation, it is not uncommon for the torque converter to literally turn blue from strong heat, the automatic transmission wiring melts, and the clutches burn and crumble.

In this case, when the automatic transmission goes into emergency mode, it is optimal to immediately stop using the car and take it to the service center under your own power, so as not to further worsen the situation. Moreover, if you plan to tow without hanging the drive wheels, then you need to separately take into account all the rules and nuances of such towing a car with an automatic transmission.

- Please note that the machine will not always “fall” into an accident if it overheats. Often the box works, the check is not lit, but the temperature is approaching a critical level. In such a situation, after the automatic transmission reaches operating temperature, the driver usually feels obvious jerks, jolts during shifts, the automatic transmission slips, delays gear shifting, etc. At the same time, the box works fine when cold.

You need to understand that problems cannot be avoided in the future, since constant overheating, even if not critical, significantly reduces the life of clutches and solenoids, and can cause deformation of the valve body, etc. Under conditions of increased heating, the transmission oil itself also quickly loses its properties and becomes heavily contaminated. This means that the owner must constantly check the level and quality of the oil in the automatic transmission.

It is also important to note any changes in the operation of the unit and immediately carry out diagnostics, promptly change the automatic transmission oil and filter in the automatic transmission, and use high-quality fluids recommended by the transmission manufacturer itself.

How to understand that the machine is overheated?

- It is not always possible to determine whether an automatic transmission is overheating without removing the box and examining it in detail, but certain signs still exist.

- Errors. If there are problems with the box, including overheating, errors may appear on the panel.

- Smell of burnt oil in the box. If you remove the dipstick, the “burnt” oil will have an unpleasant odor.

- Kicks, pushes, jerks. If the switching is accompanied by any of the above, it can be assumed that the box is overheated.

- Gear shift violation. Gears can shift with delays or advance.

- Incorrect gear shift. There may be a violation of the gear shift sequence, for example, after 2nd comes 4th.

Normal automatic transmission temperature

The machine heats up from the transmission oil (it is special, called ATF fluid ). This fluid is a transmission link - in simple words, it transmits torque from the engine to the wheels. All this happens in a torque converter, when one turbine (turbine wheel), conventionally tied to the engine, transfers the oil pressure to another turbine, which is tied to the transmission.

As you understand, it is the oil that heats up, and not the automatic transmission itself, and this heat heats up everything else.

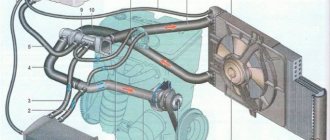

In order to level out excess heating of the liquid in the machine, it is passed through a cooling radiator, which is precisely why destructive heating does not occur.

It is worth noting that the normal temperature of the oil inside an automatic transmission is between 65 and 95 degrees Celsius. If the temperature exceeds 100, and even more so 110 degrees, then you already need to think and watch. Otherwise, breakdowns are nearby

Now let's think about what could be the reasons why the machine overheats.

What happens to ATF when it overheats?

- Overheating, even short-term, promises trouble for the owner. Once the temperature of the liquid exceeds the permissible threshold of 130-150°C, its properties are lost. The fluid can no longer provide the required efficiency, wear of parts increases, and deposits may appear on surfaces and in channels. All this, one way or another, will worsen the performance of the box and very soon the “automatic machine” may completely fail.

- Friction discs. Damage to clutches is a fairly common occurrence on automatic machines. Friction discs are made of metal or alloys. A lot depends on their quality and reliability, for example, how they will behave in extreme situations - they will burn out or withstand the load.

- Solenoids. Since solenoids in automatic transmissions are usually made of plastic, naturally high temperatures for them are like death. If the oil boils, but the gearbox “gets”, then the solenoids may melt, resulting in the clutches closing or opening. In addition, the wiring of the box may also suffer from high temperatures.

How to avoid overheating of oil in automatic transmission

Enlarge the cooling circuit. Installing an additional automatic transmission radiator will help avoid an increase in operating temperature and extend the life of the automatic transmission. In cars where the automatic transmission radiator is built into the main cooler, an additional section is cut into the general circuit and mounted on the outside of the radiator.

The choice of heat exchanger size must be justified. Too large will be costly to maintain, while a small one will not help regulate the operating temperature.

Radiator manufacturers recommend following the following calculations:

- for passenger cars with engine capacity up to 2.0 l - 4-row design;

- for vehicles with a trailer and an engine up to 3.0 l - 6-row;

- for more powerful cars - 8-row.

Initially, the cooling circuit is designed for a specific thermal power, and installing an additional radiator upsets the balance of heat transfer, i.e. In winter, it will take longer to warm up the automatic transmission. To solve this problem, thermostats are installed on the way to the additional heat exchanger. The system will be able to connect the cooler automatically when the threshold of dangerous operating temperature of the automatic transmission oil is reached.

Take care of your car

Changing the ATF every 40-60,000 km will help avoid the dangers caused by rising operating temperatures. The maintenance schedule depends on the car brand. Thus, 6-speed automatic transmissions produced by ZF are installed on BMW and Range Rover. BMW calls its gearbox maintenance-free, and Range Rover recommends lubrication every 60,000 km.

Many manufacturers produce their product modified for a specific series of cars, but allow the use of analogues that meet the specifications:

| Manufacturer | Names of recommended ATF oils |

| BMW | Bottles ZF under its own brand |

| Volkswagen, Audi, Skoda | VAG G 052 025, G 055 005 Esso Type LT 71141 |

| Toyota, Lexus | Toyota Type T,WS |

| Hyundai,Kia | Hyundai SP-III, SP-IV, SP-IV-RR |

| Nissan, Infinity, Datsun | Nissan Matic |

| Ford | Mercon 5 |

| Volvo | Volvo T-IV Mobil JWS 3309 |

| Chevrolet | Dexron 6 from GM, Mobil, ZIC Mercon 5 |

According to statistics, regular replacement of transmission fluid solves 8 out of 10 problems with gear shifting and increasing the operating temperature of the automatic transmission.

Consequences of operating a car with overheating CVT

A slight increase in temperature has a detrimental effect on the properties of the oil. It is designed for a certain operating mode and in the worst case it loses its characteristics. At a service station, specialists usually take ATF for a sample, draining approximately 50 ml of liquid. This amount of material is enough to make a diagnosis: a dark color and a burnt smell will indicate overheating of the CVT. If you turn a blind eye to overheating and continue to calmly drive your car, you need to be prepared for a major overhaul soon. First of all, solenoids and friction discs fail. Quite often, overheating causes a violation of the geometry of the hydraulic plate. Such breakdowns are repaired at great financial cost; drivers usually look for contract units.

Temperature range CVT

The gearbox temperature is one of the special characteristics of the unit. Car manufacturers even provide a self-diagnosis system consisting of temperature sensors that record temperature changes. If it rises, the control unit puts the CVT into emergency mode and the car simply stops. The driver will be able to observe the activated indicator “!” on the instrument panel. The variator is installed together with a heat exchanger - a special device in which heat is exchanged between two media that have different temperature indicators.

In addition to the heat exchanger, an additional radiator is installed in the engine compartment in front of the air conditioning condenser. These devices are necessary to maintain optimal temperature conditions, heat removal and cooling of the unit. But the problem is that both the heat exchanger and the radiator become clogged over time. Some devices have such poor designs that they damage the gearbox even before 60-80 thousand km have been covered. One of the main conditions for a constantly stable CVT temperature is a clean heat exchanger and cooling radiator.

Signs of variator overheating

Even a slight increase in temperature can have unpleasant consequences in the future. Electronics do not always respond to high temperatures, so the driver is left to navigate the behavior of the car. The following symptoms appear:

- car jerking;

- the box kicks;

- difficult gear shifting;

- The variator “thinks” for a long time.

As a rule, these symptoms appear when the unit is “hot”, and after cooling the unit they completely disappear and the CVT continues to operate as usual. Ideally, when overheating occurs, the indicator on the instrument panel lights up and the gearbox goes into emergency mode. You should not continue driving even if after idle time the transmission has returned to functioning properly. The best solution would be to call a tow truck and go to a service center, since further use of the car may cause serious damage to the CVT. In an overheated variator, the oil smells burnt and takes on a dark color; it loses its original properties and contributes to increased wear of the unit’s hardware.

Why the machine gun knocks out in the dashboard: reasons

Reasons why the machine knocks out

If you still have traffic jams, then without hesitation you should install automatic machines. A correctly calculated rated current of the machine will preserve your electrical wiring and significantly reduce the likelihood of a fire.

Exceeding the rated current of the machine

If the permissible current of the switch is exceeded, the thermal release, heating up, will disconnect the contacts of the machine from the power supply. The shutdown time depends on the current value. For old electrical wiring, a 16 A automatic machine is installed.

For a new one, with copper wires and a cross-section of 2.5 mm², install a 25 A switch. To circumvent the cause of the overload, when the machine in the panel knocks out, you need to turn on all electrical appliances and lighting so as not to exceed the rated current of the machine.

If you need to turn on different electrical appliances with a total power higher than the permissible load of the circuit breaker, then you need to use a priority relay. After turning off the machine, you need to wait some time for the bimetallic plate of the thermal release to cool down, otherwise the machine will not turn on.

If the cause is short circuit

This type of malfunction, in which the machine knocks out when turned on, is also not uncommon. Short circuits can occur in old electrical wiring and damp walls, in electrical appliances and lighting. If this malfunction occurs in electrical appliances, then you can find it by plugging the household appliances into the outlet one by one.

A short circuit in household appliances is determined by the smell of burnt insulation, plastic, its melting and the appearance of soot. A short circuit can also occur in sockets when the contacts are loosened or in light bulb sockets or junction boxes.

In this case, you must first find the room with this malfunction. They find such a room by turning off all the rooms in the switch boxes one by one and calling them with a multimeter. In the found room, all the wires in the junction box are disconnected and all circuits are connected separately. Found wires with short circuit. replaced completely or partially, depending on the degree of insulation failure.

Circuit breaker malfunction

This type of malfunction is possible due to poor quality of manufacture of the switch or poor contact of the wires. Poor wire contact can cause sparking and carbon deposits.

Do not leave carbon deposits on the contacts; it can cause heating of the contacts and melting of the device body. If you are replacing a machine, try to choose a more reliable company. When the machine turns off, you need to look for the cause immediately without delay, in order to avoid more severe consequences.

Reasons for turning off the differential machine

It is a little more difficult to find the reason for turning off the automatic circuit breaker, since in addition to the circuit breaker, it also includes an RCD. All the reasons discussed above why the machine knocks out apply to the automatic machine. In addition, reasons are added that relate only to RCDs. Basically, these reasons relate to the appearance of leakage current.

Differential automatic

- A differential circuit breaker leakage current can occur if a phase wire with damaged insulation touches the body of the electrical panel connected to the neutral wire or ground. The main options when a current leak occurs in the load circuit of the automatic machine are;

- — violation of the phase wire insulation and current leakage to the device body; - through old electrical wiring with damaged insulation on damp walls; — pickup from strong lightning strikes; — malfunction of the “Test” button or failure of the differential device itself;

- — violation of the rules for installing a difavtomat.

Prevention of overheating: how to extend the life of an automatic transmission?

The main reasons for transmission overheating, in addition to an aggressive driving style, are considered to be:

Failure to comply with maintenance regulations, operating an automatic transmission with clogged filters and contaminated oil;

Insufficient efficiency of the cooling radiator or damage to the cooling line;

Automatic transmission slipping, operating the vehicle in an overloaded state.

Remember! Preventing the consequences of overheating or eliminating malfunctions in a timely manner is always better than ignoring the problem. Compliance with maintenance regulations and carrying out scheduled repairs will protect the automatic transmission from overheating and save you from many headaches.

Source

How to eliminate automatic transmission overheating?

Repairing a transmission in case of problems with overheating involves diagnosing the automatic transmission cooling system, which makes it possible to determine the cause of the temperature increase. An experienced technician will be able to quickly localize the problem and repair the gearbox in the shortest possible time. In most cases, to eliminate overheating of the automatic transmission, it is necessary to clean the valve body and external heat exchanger. This work presents a certain complexity, since it is necessary to dismantle the hydraulic unit and remove all the pipes that lead from the box to the heat exchanger. Cleaning can be carried out using modern technological means, which allows us to ensure the maximum quality of the repairs carried out. All this allows you to eliminate the problem of overheating.

Cleaning the valve body when overheated