1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

Malfunctions of vehicle electrical equipment are very common and occupy one of the leading places in the list of breakdowns. They can be roughly divided into faults of power sources (batteries, generators) and faults of consumers (optics, ignition, climate, etc.). The main sources of power for a vehicle are batteries and generators . The malfunction of each of them leads to a general malfunction of the car and its operation in abnormal modes, or even to immobilization of the car.

In the electrical equipment of a car, the battery and generator work in an inextricable tandem. If one fails, after a while the other will also fail. For example, a damaged battery leads to an increase in the charging current of the generator. And this entails a malfunction of the rectifier (diode bridge). In turn, if the voltage regulator supplied from the generator malfunctions, the charging current may increase, which will inevitably lead to systematic recharging of the battery, “boil-off” of the electrolyte and rapid destruction.

Common battery problems:

- short circuit of battery electrodes/plates;

- mechanical or chemical damage to the battery plates;

- violation of the tightness of battery cans - cracks in the battery case as a result of impacts or improper installation;

- chemical oxidation of the battery terminals. The main causes of these malfunctions are:

- gross violations of operating rules;

- expiration of the product's service life;

- various manufacturing defects.

It is very useful for a motorist to know the main causes of generator malfunctions , how to eliminate them, as well as preventive measures to prevent breakdowns.

All generators are divided into alternating and direct current generators. Modern passenger vehicles are equipped with alternating current generators with a built-in diode bridge (rectifier). The latter is necessary to convert current into direct current, on which the vehicle's electrical consumers operate. The rectifier, as a rule, is located in the cover or housing of the generator and is integral with the latter.

All electrical appliances of the car are designed for a strictly defined operating voltage range. As a rule, operating voltages are in the range of 13.8–14.7 V. Due to the fact that the generator is “tied” with a belt to the engine crankshaft, it will work differently . It is for smoothing and regulating the output current that the relay-voltage regulator is designed, playing the role of a stabilizer and preventing both surges and dips in the operating voltage. Modern generators are equipped with built-in integrated voltage regulators, colloquially referred to as “chocolate” or “tablet”.

It is already clear that any generator is a rather complex unit, extremely important for any car.

How many volts should the generator produce?

The key parameter is voltage. The operating voltage of the Lada Priora generator is 14 Volts: this voltage should be produced by the generator on the Priora without and with air conditioning. A deviation from the nominal value to a lesser extent will lead to unstable operation or failure of the electrics, deterioration of performance, and to a greater extent it can cause burnout of circuits and blocks. If abnormalities occur (low current or too high), the device needs to be diagnosed and replaced, if necessary.

The second parameter is the current strength. On Priors there are generators with 115 amperes, 90, 80, etc. This depends on the year of manufacture of the car, body type and configuration. Models with air conditioning have higher power.

Photo source: https://primahim.ru/p361170614-generator-2170-115a.html

The generator is an electromechanical device, and the causes of its failures lie in both electrical and mechanical components. Common faults:

- damaged or worn pulley;

- wear of slip rings or brushes;

- a failed relay (regulator) of the voltage of the Priora generator;

- destruction of bearings;

- short circuit on the stator winding;

- physical damage to wires;

- diode bridge problems.

It should be borne in mind that voltage problems do not always indicate a breakdown of the generator itself. The reason may lie in the battery, wiring and other components.

Types of generator faults

Due to the fact that any generator is an electromechanical device, there will be two types of faults - mechanical and electrical.

The first includes the destruction of fasteners, housing, malfunction of bearings, pressure springs, belt drive and other failures not related to the electrical part.

Electrical faults include winding breaks, diode bridge faults, brush burnout/wear, turn-to-turn short circuits, breakdowns, rotor beating, and relay-regulator faults.

Often, symptoms that indicate characteristics of a faulty generator can also appear as a result of completely different problems. As an example, poor contact in the fuse socket of the generator field winding circuit will indicate a generator malfunction. The same suspicion may arise due to burnt contacts in the ignition switch housing. Also, the constant lighting of the generator malfunction indicator lamp can be caused by a breakdown of the relay; the blinking of this switching lamp may indicate a generator malfunction.

The main signs of a faulty generator:

- When the engine is running, the battery discharge warning lamp flashes (or stays on continuously).

- Discharging or overcharging (boiling) of the battery.

- Dim car headlights, a rattling or quiet beep when the engine is running.

- Significant change in headlight brightness with increasing speed. This may be acceptable when increasing the speed (re-throttle) from idle, but the headlights, having lit up brightly, should not increase their brightness any further, remaining at the same intensity.

- Extraneous sounds (howling, squeaking) coming from the generator.

It is necessary to regularly monitor the tension and general condition of the drive belt. In case of cracks and delaminations, immediate replacement is necessary.

Priora generator does not charge

Several times I found myself in an unpleasant situation when the prior generator did not charge, and at the most inopportune moment, due to the battery being discharged, I could not start the car.

At the same time, the control light did not light up while driving, but the fact that it did not light up and when I turned on the ignition, I did not pay attention to it. The generator was not charging. When you turn on the ignition, a lot of warning lights come on and it’s very difficult to see that any are off, and you almost never pay attention to them.

Generator repair kits

To eliminate these generator malfunctions, you will need to carry out repairs. When you start searching for a generator repair kit on the Internet, you should prepare for disappointment - the kits offered usually contain washers, bolts and nuts. And sometimes the generator can only be restored to functionality by replacing brushes, a diode bridge, a regulator... Therefore, the brave person who decides to repair it makes an individual repair kit from those parts that fit his generator. It looks something like this, as shown in the table below, using the example of a pair of generators for a VAZ 2110 and a Ford Focus 2.

| Generator KZATE 9402.3701-03 | ||

| Detail | Catalog number | Price, rub.) |

| Brushes | 1127014022 | 105 |

| Voltage regulator | 844.3702 | 580 |

| Diode bridge | BVO4-105-01 | 500 |

| Bearings | 6303 and 6203 | 345 |

| Generator Bosch 0 986 041 850 | ||

| Detail | Catalog number | Price, rub.) |

| Brushes | 140371 | 30 |

| Brush holder | 235607 | 245 |

| Voltage regulator | IN6601 | 1020 |

| Diode bridge | INR431 | 1400 |

| Bearings | 140084 and 140093 | 140/200 rubles |

What generators were installed on the VAZ 2110

A total of two types of generators were installed on the VAZ 2110 car. The first type was installed on a carburetor car. This unit has the number 9402–3701. The second type was installed on the VAZ 2110 injector. This species is numbered 3202–3771. These generators are not very different from each other, so their faults are similar.

Let's look at the main types of breakdowns:

- If the car has a large amount of equipment installed that requires a lot of electricity, then the generator simply will not be able to cope with the heavy load. Because of this, the battery will not receive the required amount of charge, which will lead to rapid wear and tear of the battery.

- Incorrect battery selection. If you choose a battery that is more powerful than what the generator is capable of charging, the battery will be constantly undercharged. This will cause the battery to wear out quickly.

Troubleshooting

On modern cars, using the “old-fashioned” diagnostic method by removing it from the battery terminal can lead to serious damage to many of the car’s electronic systems. Significant voltage drops in the vehicle's on-board network can damage almost all on-board electronics. That is why modern generators are always checked only by measuring the voltage in the network or diagnosing the removed unit itself on a special stand. First, the voltage at the battery terminals is measured, the engine is started, and readings are taken while the engine is running. Before starting, the voltage should be about 12 V, after starting - from 13.8 to 14.7 V. A deviation towards the higher side indicates that you are “overcharging”, which implies a malfunction of the relay regulator, towards a lower level - that no current is flowing. The absence of recharging current indicates a malfunction of the generator or circuits.

Other causes of low voltage

A small potential difference in the system is not always associated with a breakdown of the generator or a bad battery. If the diagnosis of these elements does not reveal any problems, then you should pay attention to the following:

- condition of the battery terminals - connection density and oxidation;

- electrical wiring problems - oxidation, violation of its integrity;

- output contacts to electrical appliances;

- correctly selected energy consumers.

Each contact must be tightly adjacent and intact, that is, there must be no formations (for example, sulfation) that will disrupt the flow of current. Incorrect connection of contacts leads to accelerated battery discharge even when the car is not running.

To improve the connection of the elements of the car's electrical system, it is necessary to clean all contacts and restore the integrity of the wires by replacing them or connecting them and wrapping them with insulating tape.

In conclusion, I would like to repeat that stable operation of the car requires constant monitoring of all elements, and the generator should attract special attention. The battery is charged from it and provides electricity to the entire car system. Pay attention to all elements: generator brushes, slip rings, voltage regulator, equipment winding.

The most correct measurements should be carried out when the battery is fully charged and in various modes. Remember that the manufacturer links the characteristics of the generator to the number of engine revolutions - they help produce a certain current.

Detailed video on how to check the generator:

Do you have experience diagnosing an alternator and solving problems in a vehicle's electrical system? Please share your experience and opinion with our readers in the comments. If you have questions about the topics covered, we will be happy to answer them.

Good afternoon Priora 2010 lux. The car is under warranty.

Problem: the voltage in the network when driving with consumers turned off is 13.4 V (measured according to the “State”). At idle, when parked with off. consumers, the voltage according to the “State” is 13.4V according to the multimeter, at the battery terminals, the same 13.4V, i.e. The “State” can be trusted.

Question. What should be the voltage at the battery terminals pr XX according to the standards (and what can you refer to, in which documents these standards are prescribed)?

Is the voltage measured only at idle with the consumers turned off, or are there still control measurements?

Can the guarantee providers send me away because they have installed an add-on that is not theirs? equipment if I change the voltage with the music turned off, etc. and so on.?

Causes of breakdowns

Common causes of generator malfunctions are simple wear and corrosion. Almost all mechanical failures, be it worn brushes or collapsed bearings, are a consequence of long-term use. Modern generators are equipped with sealed (non-maintenance) bearings, which simply must be replaced after a certain period or mileage of the vehicle. The same applies to the electrical part - often the entire components must be replaced.

Also reasons may be:

- low quality components;

- violation of operating rules or operation outside normal operating conditions;

- external factors (salt, liquids, high temperature, road chemicals, dirt).

How to check the generator voltage on a Priora

To measure, you will need a voltmeter, which determines the voltage level at the machine battery terminals.

- Start the car.

- Warm up to operating temperature.

- Turn on all energy consumers (heating, heated seats and windows, high beams, radio).

- Raise the gas pedal to 2500 rpm.

- Check the voltage of the Priora generator with a multimeter. You can check with a regular voltmeter, doing this between the “ground” and the B+ terminals of the generator, and at the terminals.

The device should show 13.8-14.4 V with slight deviations. If their value is too significant, one can judge the failure of the LV, worn brushes and other problems. A similar conclusion is drawn if the current begins to “jump”.

Photo source: https://www.drive2.com/l/7902681/

Next, turn off all electrical appliances and measure again. The normal value in such conditions is up to 14.5 Volts. If it is greater, a conclusion is drawn about a probable malfunction of the regulator. If the voltage of the Priora generator fluctuates, the unit needs additional checking.

Self-test of the generator

The easiest way is to check the fuse. If it is in good condition, the generator and its location are inspected. The free rotation of the rotor, the integrity of the belt, wires, and housing are checked. If nothing arouses suspicion, the brushes and slip rings are checked. During operation, the brushes inevitably wear out, they can become jammed, skewed, and the grooves of the slip rings become clogged with graphite dust. A clear sign of this is excessive sparking.

There are frequent cases of complete wear or failure of both bearings and stator failure.

The most common mechanical problem with a generator is bearing wear. A sign of this malfunction is a howling or whistling sound when the unit is operating. Of course, the bearings must be replaced immediately, after first inspecting the seats. Loose drive belt tension can also cause poor generator performance. One of the signs may be a high-pitched whistle from under the hood when the car accelerates or accelerates.

To check the rotor field winding for short-circuited turns or breaks, you need to connect a multimeter, switched to resistance measurement mode, to both contact rings of the generator. Normal resistance is from 1.8 to 5 ohms. The readings below indicate the presence of a short circuit in the turns; above – direct winding break.

To check the stator windings for ground fault, they need to be disconnected from the rectifier unit. If the resistance readings given by the multimeter are infinitely large, there is no doubt that there is no contact between the stator windings and the housing (“ground”).

To check the diodes in the rectifier block, use a multimeter (after completely disconnecting it from the stator windings). The test mode is “diode test”. The positive probe is connected to the plus or minus of the rectifier, and the negative probe is connected to the phase terminal. After this, the probes are swapped. If the values of the multimeter readings differ greatly from the previous ones, the diode is working; if they do not differ, it is faulty. Another sign indicating the imminent “death” of the generator diode bridge is oxidation of the contacts, and the reason for this is overheating of the radiator.

OTHER REASONS FOR NO CHARGING

If the battery is not charged or is insufficiently charged, in addition to a faulty voltage regulator, there may be other reasons related to the generator:

- The belt is poorly tensioned;

- Poor contact or break in the wires supplying power;

- Faulty rotor or stator winding;

- Poor contact of the brushes with the rotor commutator, the brushes are simply worn out.

New and worn alternator brushes

should the charging rate be 13.7-14.8 correct?

Good evening. 14.8 is a lot. It will be fine for winter and short trips, but over long distances the battery will boil out. The norm is 14.2. And the fact that it drops to 13.3, you need to measure what it gives directly at the generator. If it differs from what is on the battery, then the problem is still in the contacts. And if it doesn’t differ, then the problem is in the generator. And additional a diode is not a solution, it will raise too much.

should the charging rate be 13.7-14.8 correct?

Good evening. 14.8 is a lot. It will be fine for winter and short trips, but over long distances the battery will boil out. The norm is 14.2. And the fact that it drops to 13.3, you need to measure what it gives directly at the generator. If it differs from what is on the battery, then the problem is still in the contacts. And if it doesn’t differ, then the problem is in the generator. And additional a diode is not a solution, it will raise too much.

The generator itself shows 14.1 to 14.2 when measured with a multimeter. The battery shows more, 14.5.

How can this be? In any case, the generator produces more than what reaches the battery. Maybe you're not measuring correctly? You measure between the generator terminal and the battery positive, then between the generator housing and the battery negative. Then turn on a load such as headlights and heated rear window and check again. What indications will there be? Ideally it should be zero.

Repair and troubleshooting

All mechanical problems are eliminated by replacing faulty components and parts (brushes, belt, bearings, etc.) with new or serviceable ones. Older generator models often require grinding of slip rings. Drive belts are replaced due to wear, maximum stretching or expiration of service life. Damaged rotor or stator windings are currently being replaced with new assembled ones. Although rewinding is common among auto repair services, it is becoming less and less common - it is expensive and impractical.

But all electrical problems with the generator need to be solved by checking both other elements of the circuit (in particular the battery), and directly its parts and output voltage. One of the common problems that car owners have to deal with is overcharging , or, conversely, low voltage of the generator . Checking and replacing the voltage regulator or diode bridge will help eliminate the first malfunction, but low voltage output will be a little more difficult to deal with. There may be several reasons why the generator produces low voltage:

- increased load on the on-board network by consumers;

- breakdown of one of the diodes on the diode bridge;

- failure of the voltage regulator;

- slipping of the poly V-belt (due to low tension)

- poor contact of the ground wire on the generator;

- short circuit;

- drained battery.

Many car owners are faced with a situation where, after starting the engine, the on-board computer or one of the devices begins to show that the battery is being recharged.

The consequences of this situation are very different and depend on how much the voltage in the on-board network exceeds the nominal one.

Slightly increased parameters will only negatively affect the battery (boiling of the electrolyte followed by its evaporation), but if the voltage coming from the generator greatly exceeds the norm, then electrical consumers may fail.

In any case, overcharging is a phenomenon that must be eliminated, otherwise it will not have the best effect on the service life of the battery and electrical appliances.

Why does the battery light on the Priora dashboard light up?

To prevent any speculation on this topic, let us immediately note that the lighting of the battery lamp while the car is moving does not threaten immediate catastrophic consequences, unlike the oil pressure lamp.

Moreover, when such a warning signal appears, it is recommended to continue driving to a place where you can carry out diagnostics and repairs. Otherwise, if you turn off the engine, you risk that the battery will not have enough charge to start the engine again.

Long-term consequences are another matter: failure to charge the battery, in addition to creating problems with starting the power unit, will lead to rapid degradation of the battery, which is by no means cheap.

So you still have to start looking for the causes of the malfunction. And it’s not at all obvious that it will be quick and easy; in some cases you will need a multimeter and experience working with electrical equipment.

But let's move on to considering the specific reasons for the battery lamp lighting up on the Priora dashboard.

Generator relay-regulator burnt out

A voltage regulator is a device that controls the charging of a battery. The fact is that the current parameters produced by the generator are not constant and depend on the engine crankshaft rotation speed. Meanwhile, current consumers require stable voltage characteristics, including the battery, and it is the relay-regulator that ensures that it is charged within the permissible ranges of the generator output voltage. Overcharging and undercharging are dangerous to approximately the same extent, so when the battery light comes on, you should make sure that the voltage regulator is working properly.

Alternator belt problems

The transmission of torque from the engine to the generator on the vast majority of cars is carried out through a belt drive, and it is this that is the narrowest link in the operation of the generator. Over time, the belt stretches and weakens, causing the belt to slip and reduce the rotation speed of the generator shaft. As a result, the battery does not receive enough charge and eventually discharges so much that the warning light comes on.

Blown fuse or poor contact

If the equipment is in good working order, the fuse should not blow, but in some cases (for example, lighting a battery from a donor power source), currents of a higher rating are supplied to the generator, and then the diode bridge, which is precisely designed to protect against such troubles, burns out.

But shorting the wiring can cause the fuse to blow. Since he is responsible for the entire instrument cluster, such a malfunction is difficult not to notice.

Charging of the Priora battery may also fail due to oxidation of contacts on any part of the circuit. In this case, the light will blink until the contact deteriorates so much that the current to the battery stops flowing altogether.

Battery charging circuit

For a general understanding of the reasons for overcharging, first consider the battery charging circuit diagram. And although it is structurally different on different cars, the general principle of construction is the same.

This circuit includes:

- Generator;

- Rectifier block (diode bridge);

- Relay regulator;

- Fuse box;

- Egnition lock;

- Charge indicator lamp;

- Battery

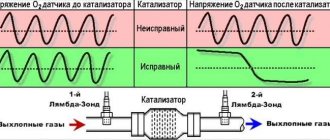

The recharging system works using the example of the VAZ 2106 and other cars from the VAZ classic series as follows: after starting the power plant, by means of a belt drive, the crankshaft begins to rotate the generator rotor, as a result of which this unit begins to generate electricity.

But since automobile generators use alternating current, the generated energy goes to the rectifier unit, where alternating current is converted into direct current.

After the rectifier unit, the electricity goes to the relay-regulator, whose task is to maintain the voltage in a given range.

After the regulator, the electrical energy passes through the circuit through the fuse box, the ignition switch and the charge indicator lamp, then returns to the output of the generator, and from there it is supplied to the battery.

The detailed diagram is shown below.

What to do if the battery on the Lada Priora is not charging

The warning lights coming on when the ignition is turned on is such a common phenomenon that many motorists, if you ask them what specific indicators we are talking about, simply cannot answer. Another thing is the appearance of a red warning signal when the engine is running - be it a Check Engine light, an oil pressure lamp or a lack of battery charging.

Some of them are so critical that they prevent the vehicle from moving further. Today we will look at the possible consequences of a light bulb with a picture of a car battery lighting up on the Priora dashboard.

Features of the circuit

The above is a general diagram of the circuit, without details, but it is enough to understand how everything works. Now about the features of battery recharging.

The generator cannot independently regulate the parameters of the generated electricity, so the output voltage from it varies, and in a significant range, it depends on the crankshaft speed and the load in the on-board circuit. That is, the battery is essentially constantly being recharged while the generator is generating electricity.

How to equalize the generator voltage on a Priora

Stable voltage is the key to uninterrupted operation of automotive electrics. The regulator assembly is responsible for its alignment. This is an inexpensive and reliable part, but sometimes it breaks down and the current begins to drop low, jump or disappear.

Not every VAZ owner thinks about how many volts the generator should supply to the Priora battery. But this question is important - the charging speed of the battery, its service life and the general condition of the car’s electrics depend on the normal operation of the part.

Reasons for overcharging

A malfunction of the relay regulator is the most common cause of battery overcharging.

Due to a breakdown, this unit ceases to perform its functions and “passes” all the voltage generated by the generator into the on-board circuit, and it can reach 25 V. Naturally, not a single electrical appliance in a car is designed for such a voltage, so the elements of the on-board network begin to burn out .

Regulator failure can be partial or complete. In the first case, this element still performs its functions, but “passes” a voltage slightly higher than needed (for example, 15 V).

In this case, the overcharge of the battery can only be detected by readings from measuring instruments or the on-board computer. Electricity consumers practically do not “suffer” from such voltage, but even such an overcharge negatively affects the condition of the battery - with a constant process, the battery “boils out” and fails.

If the relay-regulator is completely malfunctioning, high readings (over 16 V) begin to damage consumers - light bulbs and fuses burn out first, then other devices. A significant excess of voltage can cause a fire in the electrical wiring.

Despite the fact that a partial breakdown of a relay does not pose a significant threat to the vehicle’s on-board network (with the exception of the battery), it should not be ignored, since at any moment it can develop into a complete failure of the element.

Since the relay-regulator is the only element that prevents the battery from overcharging, many car enthusiasts, when they detect increased voltage in the on-board network, immediately replace this unit.

But installing a new regulator does not always help; often the problem remains. Naturally, suspicion in this case falls on the generator. This unit can actually overcharge in the event of a breakdown of the diode bridge or a break in the windings, or a breakdown of the armature to the housing.

READ ON THE TOPIC: Car generator voltage, normal at idle and under load.

But if replacing the regulator relay does not help, you should not immediately change or send the generator for repair.

IMPORTANT: Often the reason for overcharging the battery lies in poor contact of the wiring of the battery charging system circuit (described above).

The reason is very simple: at the point where the contacts are oxidized, resistance arises, which the relay-regulator “perceives” as a load in the on-board network. For example, this can happen in the fuse box.

To compensate for it and prevent a drop in voltage, the regulator begins to “pass” large values, resulting in an increased voltage being supplied to the battery.

Therefore, in searching for the cause of battery overcharging, you should first check the relay-regulator, then the charging system circuit (all connections, as well as the fuse), and only after that remove and diagnose the generator.

Probable Causes

There can be quite a number of reasons why the battery on a VAZ 2114 is not charging.

The most likely ones look like this:

- the on-board network (and with it the generator - are overloaded);

- the generator does not match the used battery and vice versa;

- contacts have become loose or oxidized;

- the brushes are worn out;

- the drive belt is loose;

- there was a break in the generator windings;

- the rotor has closed;

- a stator short-circuit has occurred;

- bearings have failed;

- the control relay has failed.

As you can see, there are quite a few reasons why the VAZ 2114 generator does not charge, and the search should begin with the most probable and simple ones, moving on to more complex ones.

Diagnostics of the relay regulator

Checking the relay regulator when recharging the battery is not a complicated procedure and you can do it yourself using a multimeter.

The test comes down to measuring the voltage at the battery terminals under different operating modes of the power plant. That is, we simply connect the multimeter probes to the terminals and measure the voltage first at XX, then at medium speeds, and then at high speeds.

At idle, the normal voltage is 13.2-14.0 V, at medium speeds - 13.6-14.2 V, at high speeds - up to 14.5 V.

If the values exceed the specified values, you should check and clean the contacts of the charging system circuit and repeat the procedure again.

If cleaning does not help, we check the relay separately (removed from the car), but for this you will need a power source with regulated voltage (you can use a battery charger), as well as a regular 12 V lamp.

The essence of the test is this: we connect the negative wire from the charger to the housing, and connect the positive wire to the regulator terminal. The lamp is connected to graphite brushes (polarity is not important).

When checking, we first set the voltage at the source to 12.7 V, at which the lamp should light up. We gradually increase the value to 14.5 V. When the specified value is reached, a working regulator should operate and the lamp will go out.

If it continues to light when exceeding 14.5 V, then the unit is faulty and requires replacement.

Signs of a faulty voltage regulator

The engine and auto electrics must receive constant current. The stabilizer maintains the uniformity of the network voltage coming from the generator, preventing it from falling or rising too much. Initially, this unit was made electromagnetic, but the relay (regulator) of the new model received a completely electronic semiconductor design. Often it is this part that causes voltage surges and sags.

The generator produces low voltage

In the case of a low level, the cause may be a breakdown or excessive wear of the graphite brushes of the regulator. Sometimes the generator on the Priora produces low voltage due to short circuits and open circuits. All this leads to a small current or its disappearance. In such cases, the node needs to be diagnosed and, possibly, the device needs to be replaced.

- dim headlights;

- turning off on-board equipment, radio;

- Battery drains quickly, its charging is poor.

Power surges

- fuse burnout;

- shaking of the voltmeter needle on the panel, if present;

- flashing headlights and interior lighting;

- “jerking” of the engine, including at idle.

The brush assembly can unnecessarily increase the power level in the network: many Lad Prior owners complain about this.

- poor contact;

- generator malfunction.

The general recommendation in this case is to check the regulator by measuring the voltage with a voltmeter at the battery terminals.

The generator does not produce current

If this situation occurs, the battery error indicator on the panel lights up.

Among other reasons why the unit stops producing the proper current:

- critical wear of armature brushes or slip rings;

- general malfunction of the LV (voltage regulator);

- more unpleasant failures of bearings, stator, rotor, etc.

There are situations when there is actually voltage, but it is not displayed on the dashboard. This usually indicates a burnt-out light bulb in the panel.

Getting to the repair site

Finally, about what to do if an overcharge is detected while on the road and you need to get to the place of repair.

If the voltage does not exceed 15 V, then you can safely continue driving, but try not to give high speed to the engine and reduce the number of switched on electrical consumers as much as possible (keep only the necessary ones).

If the overcharge is strong (more than 15 V), you can first loosen the tension of the generator drive belt, which will reduce its performance (although the belt will quickly wear out).

If loosening the belt does not give any results, you can turn off the generator (disconnect the wires from it). In this case, the on-board network will be powered only from the battery.

If the battery is well charged with a minimum number of consumers on its charge, you can drive 70-90 km, but after that the battery will need to be well charged.

Symptoms of loss of battery charging on a Priora

The very first thing that many people pay attention to is that the battery charging light on the dashboard came on. If you have a multimeter at hand, you can measure the output charging current by connecting the contacts to the “+” and “-” terminals, respectively. If even without a load the device readings are less than 13 Volts, this indicates that there are certain problems with charging.

Of course, it is possible (although it is highly not recommended) to remove the “-” terminal from the battery while the engine is running, thereby checking the functionality of the generator. If the engine stalls, this will indicate that there is actually no charging, and accordingly, the generator is faulty.

Also, the charging lamp may glow at half-glow, which also indicates insufficient charging current. If one of the symptoms listed above occurs, it is necessary to diagnose the generator and its parts. If necessary, replace them with new ones. If you have anything to add to this article, you can comment below.

Leave a reply Cancel reply

You must be logged in to post a comment.

Source

Why is there no battery charging and where to look for it?

In fact, there are a great many reasons why charging may fail. And most of them are connected with the most important unit in this regard - the generator. Let's look at the main ones that can most often occur.

- Wear of generator brushes on Priora. As mentioned above, when all the parts are still new and without wear, then such malfunctions essentially cannot exist. But when the mark is 90-100 thousand km. has already been overcome, the first calls begin. And the most common reason for the battery not charging is excessive wear of the brushes. This issue can be easily resolved - replace them with new ones. The price of the assembled part is about 350 rubles.

- The second reason can also be compared with brushes, since it is with this part that they come into contact during operation. These are the armature slip rings. It is worth removing the plastic cover of the generator and looking at the contact points of the brushes and rings to understand how much wear these parts have had! It is not always possible to carry out this replacement on your own, but almost any electrician will do it in half an hour.

- Failure of the generator diode bridge. Even if one of the diodes breaks through, there will be poor charging, which will lead to a constant discharge of the battery. In this case, the rectifier unit is replaced.

- Failure of the regulator relay - it is replaced as an assembly with the brush assembly, while the brushes themselves can be replaced separately (again, with the help of a good electrician).

- More serious problems occur with parts such as the stator, rotor, bearings, etc., which are actually much less common than the above cases.

Why is there no battery charging and where to look for it?

In fact, there are a great many reasons why charging may fail. And most of them are connected with the most important unit in this regard - the generator. Let's look at the main ones that can most often occur.

- Wear of generator brushes on Priora. As mentioned above, when all the parts are still new and without wear, then such malfunctions essentially cannot exist. But when the mark is 90-100 thousand km. has already been overcome, the first calls begin. And the most common reason for the battery not charging is excessive wear of the brushes. This issue can be easily resolved - replace them with new ones. The price of the assembled part is about 350 rubles.

- The second reason can also be compared with brushes, since it is with this part that they come into contact during operation. These are the armature slip rings. It is worth removing the plastic cover of the generator and looking at the contact points of the brushes and rings to understand how much wear these parts have had! It is not always possible to carry out this replacement on your own, but almost any electrician will do it in half an hour.

- Failure of the generator diode bridge. Even if one of the diodes breaks through, there will be poor charging, which will lead to a constant discharge of the battery. In this case, the rectifier unit is replaced.

- Failure of the regulator relay - it is replaced as an assembly with the brush assembly, while the brushes themselves can be replaced separately (again, with the help of a good electrician).

- More serious problems occur with parts such as the stator, rotor, bearings, etc., which are actually much less common than the above cases.

Why is there no battery charging and where to look for it?

In fact, there are a great many reasons why charging may fail. And most of them are connected with the most important unit in this regard - the generator. Let's look at the main ones that can most often occur.

- Wear of generator brushes on Priora. As mentioned above, when all the parts are still new and without wear, then such malfunctions essentially cannot exist. But when the mark is 90-100 thousand km. has already been overcome, the first calls begin. And the most common reason for the battery not charging is excessive wear of the brushes. This issue can be easily resolved - replace them with new ones. The price of the assembled part is about 350 rubles.

- The second reason can also be compared with brushes, since it is with this part that they come into contact during operation. These are the armature slip rings. It is worth removing the plastic cover of the generator and looking at the contact points of the brushes and rings to understand how much wear these parts have had! It is not always possible to carry out this replacement on your own, but almost any electrician will do it in half an hour.

- Failure of the generator diode bridge. Even if one of the diodes breaks through, there will be poor charging, which will lead to a constant discharge of the battery. In this case, the rectifier unit is replaced.

- Failure of the regulator relay - it is replaced as an assembly with the brush assembly, while the brushes themselves can be replaced separately (again, with the help of a good electrician).

- More serious problems occur with parts such as the stator, rotor, bearings, etc., which are actually much less common than the above cases.