Home » Domestic auto industry

Reading time: 9 minutes. Updated 08/04/2019

What is the best lubricant for CV joints and why is it needed? Front-wheel drive cars have a number of advantages over rear-wheel drive cars. The production of front-wheel drive cars is simpler; they are resistant to skidding on wet and snowy road surfaces. But in addition to the advantages, these cars also have disadvantages, these include the use of a constant velocity joint in the car drive, which ensures confident movement.

The CV joint is a part that contributes to rapid wear of the transmission. To extend life, it is necessary to use a specialized lubricant for the outer and inner CV joints, which increases the wear resistance of the CV joint and transmission components. Today there are a huge number of different lubricants and car owners have to rack their brains over the question of which lubricant option will best lubricate CV joints and their joints before choosing the right one.

Why do you need lubrication anyway?

Any competent motorist understands why lubrication is needed. With its help, premature wear of metal elements that are subject to friction is prevented. In addition, such a substance allows you to reduce the load on components and allow them to rotate freely.

Grease for CV joints also performs a number of other important functions. Thanks to it, you can greatly reduce fuel consumption, as well as reduce transmission losses of the machine. In addition, such a substance helps prevent the occurrence of corrosion (namely, rust is mainly the cause of failure of CV joints).

If you are thinking about what you can replace the lubricant with, then you should choose substances that are gentle on organic matter and synthetic polymers. Indeed, for additional protection of this unit from external influences, anthers made of plastic or rubber are used. It is important that the lubricant does not dissolve such materials.

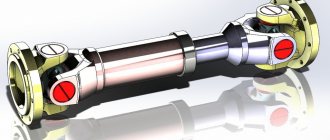

Tripoid CV joint design

Structurally, the tripoid joint is made in a housing in which a three-beam fork is located. It is pressed onto the output shaft. To ensure good rotation, rollers that have a hemispherical shape are attached to each beam of the fork. They rotate using (needle bearings).

In order for this mechanism to serve for a long time and reliably, it is necessary to provide constant care and timely lubrication. Unfortunately, experts note its insufficiently advanced lubrication mechanism. Since it is a boot where the lubricant is stored. Because the boot itself, made of rubber or plastic, is a rather vulnerable part to mechanical stress that occurs while driving on a bad road. Such an impact leads to its damage, leakage of lubricant and, as a result, failure of the entire CV joint mechanism.

The use of needle bearings ensures high wear resistance of the tripoid joint. In addition, torque losses during friction of the elements of the unit itself are significantly reduced, and sets certain requirements for the properties of the lubricants used.

They must have a given consistency and contain appropriate additives that allow them to work in a given temperature range. In addition, it is necessary to take into account the specifics of the operation of both CV joints, both external and internal.

Main characteristics of the lubricant

Based on the tasks of lubrication for tripods and other types of CV joints, the characteristics that such a substance should have include:

- wide temperature range. Thanks to this, the unit will operate normally in any temperature conditions. It is also worth remembering that inside the node the temperature reaches 100 degrees Celsius or more;

- high level of adhesion (assumes good adhesion to the surface). To put it simply, the lubricant should be sticky and stick to the surface of the assembly;

- high anti-scuff properties. As a result, the substance will be able to ensure normal sliding of the element over a long period;

- mechanical and physico-chemical stability of the composition. It is important that the lubricant maintains its effectiveness, regardless of the external environment.

Below is a video about choosing a lubricant for a CV joint:

Use of lubricants at low temperatures

Many car owners living in the northern regions of our country are interested in the question of choosing CV joint lubricants that would not freeze in severe frosts (for example, -50°C...-40°C). The decision must be made based on the information provided by the manufacturer. This is very important, not only for lubrication of CV joints, but also for other oils and fluids used in cars in the north.

According to reviews from car owners living in the far north or close to them, domestic lubricants “CV joint-4” and RAVENOL Mehrzweckfett mit MoS-2 . However, we will touch on the choice of lubricants a little later.

Lithium

They arose almost immediately after the CV joints themselves. As a result, such a substance is in good demand.

The composition is based on a lithium solution and organic acid. The result is a yellowish, viscous substance that thickens as temperatures drop, making it much more difficult to spread in winter. Using compositions of this type, it is possible to reduce the load on drive elements by a couple of tens of times.

At the same time, we are pleased with the high preservative properties of the substance. It prevents dust, dirt, moisture and other elements from penetrating metal elements. At the same time, such compositions are very aggressive, so they can dissolve anthers. Read the manual for your car. It indicates whether the use of lithium substances for lubricating joints is permissible.

Recently, lubricants of this type have become somewhat less popular, giving way to more innovative options. At the same time, they can still be found on the market. The most popular options now are XADO, Very Lube and RENOLIT.

Manufacturers ShRB-4

In the Soviet years, the production of lubricants was carried out exclusively by the Berdyansk Experimental Oil and Oil Plant, which, after the collapse of the USSR, became the Azmol Public Joint Stock Company, located outside the Russian Federation. Now this enterprise is called AZMOL British Petrochemicals (AZMOL British Petrochemicals).

In the Soviet Union, ointment for CV joints was not in particularly great demand for two reasons. Firstly, the number of cars owned by citizens was much smaller than at present.

Secondly, thanks to the durability of the lubricant, one can of ointment was enough for each car owner for a long time, so there was no need to buy it often.

Today, ShRB-4 lubricant is produced in Ukraine by the above-mentioned Berdyansk enterprise under the Agrinol brand, packaged in 400-gram jars.

In Russia, the production of ShRB-4 is carried out, located in the village of Starosyrovo in the Novomoskovsky administrative district of Moscow. This company packages the product in cans of twice the volume - 0.8 kg each.

Molybdenum

A more progressive option, which is made from the same lithium soap, only now the additive is molybdenum disulfide. Lubricating properties are the same as the previous version. At the same time, molybdenum compounds have one important advantage - they have high anti-corrosion properties.

This was achieved by using metal salts in the composition, which replaced some acids. In addition, the substance is completely safe for rubber and plastic elements, so it will not lead to premature wear of the boot.

One of the disadvantages of such a substance is its low resistance to moisture. As a result, if even a little water gets under the boot, due to certain chemical reactions the composition turns into an abrasive. This only promotes friction, which leads to a number of CV joint failures. To prevent such a situation, it is necessary to regularly check the node.

There is also an opinion that the use of molybdenum lubricants leads to the restoration of damaged transmission components. This statement is incorrect, so if you hear a crunching noise in the CV joint, it is better to contact the service center technicians.

Among the most popular options available in our country are CV joints-4 and LM47 lubricants.

Kinds

Lithium:

This type of lubricant is very common in our country. Lithium compounds have excellent anti-friction properties and also significantly reduce the load on the hinge components. Lithium greases are highly water resistant and dust resistant. The need for replacement depends on its quality; on average, it is recommended to do this every 50-60,000 km.

Litol CV joint-4 from Gazprom Neft, judging by the reviews, is one of the leaders in the segment. It is replaced approximately every 100,000 km.

Molybdenum:

Abroad, most manufacturers have switched to molybdenum disulfide as the basis for CV joint-4 lubricant. This type has better anti-corrosion properties, as well as higher extreme pressure properties. Its only drawback is hydrophobia. If moisture gets into the lubricant, it instantly loses its effectiveness. Replacing such lubricant is required on average every 100,000 km.

The most popular among auto mechanics is the CV joint-4 from Liqui Moly.

Lubricant for internal CV joints

Previous types of lubricant were relevant for external hinges and internal hinges with ball bearings, but are not suitable for internal ones due to their higher temperature (160). Most internal joints use needle bearings. Their lubrication should be carried out with a polyurea-based composition, which does not contain the slightest solid particles. Car owners highly praise the Castrol LMX CV joint, which is designed specifically for needle bearings.

Among domestic analogues we can highlight the super-4ml CV joint.

Barium

Recently, such CV joint lubricant has been in increasing demand on the market. The progressive composition allows you to extend the service life of the hinge, as well as protect it from a number of negative influences. The main advantage here is that the substance is not at all afraid of moisture.

Thus, if the boot ruptures, there is no need to change the substance. In addition, the lubricant has excellent corrosion resistance and is also suitable for use even in fairly aggressive conditions. The composition is chemically neutral, so the anthers will not be damaged, regardless of the material of the seals.

The main disadvantage of such a substance is its relatively high price, which is caused by the complexity of the production process. We produce only ShRB-4 lubricant; everything else has to be purchased in other countries.

At the same time, the latter option is even more expensive. Another drawback of this composition is its inability to withstand low temperatures.

Properly lubricate the tripod joint

Despite the fact that the design of the tripoid hinge is based on the use of needle bearings, lubricating them with 158 grease, which is usually used for needle bearings, is strictly prohibited. The fact is that a lithium thickener is used for its manufacture, and it can work at a temperature no higher than 120 ○ C, and the temperature of the internal grenade reaches 160 ○ C. Since the lubricant for the internal grenade is quite liquid, it is better to pour it inside the boot installed on drive, and then assemble the tripoid. You need to fill in from 100 to 130 g of lubricant. More precisely, to the question, “how much?” the manufacturer will answer.

What lubricants should not be used

There are also a number of compounds whose use is not recommended. Among other things, it is worth highlighting the following types of compositions:

- graphite. Such substances are suitable as a lubricant for bearings and a number of other elements in electric motors. The use of graphite lubricant on CV joints is inappropriate, as this will lead to failure of the unit after 20-25 thousand kilometers. In addition, low-quality substances are often added to such compositions, which only further accelerate the wear of moving parts;

- hydrocarbon (including technical petroleum jelly). Yes, such compositions prevent the penetration of moisture and also inhibit the development of corrosion. At the same time, when the temperature reaches 45 degrees Celsius, the substance will begin to break down. Since the temperature in the CV joint is an order of magnitude higher, the use of hydrocarbon compounds will lead to deformation of the unit over time;

- consistency compositions made from calcium or sodium. They are suitable for bearings and a number of other moving joints, but in the case of CV joints they show complete incapacity and also contribute to the development of corrosion. After only 15-30 thousand kilometers, metal elements can completely fail;

- zinc. Such compositions, like iron-based substances, are completely contraindicated as transmission lubricants, since they lead to a deterioration in its functional characteristics, as well as complete failure.

RAVENOL Mehrzweckfett mit MoS-2

This product is produced in factories located in Germany. The basis of the composition is molybdenum disulfide. Operation of the substance is indicated at a temperature range of -30-+120 degrees.

The composition is resistant to moisture, including salt water. The cost is 2-3 times higher than in the case of domestic analogues, but here you pay for quality.

Products are manufactured in Ukraine. The option has good quality and a fairly affordable price. First of all, the models are used to protect external CV joints.

The composition does not contain molybdenum disulfide, but there are revitalizants - substances that significantly slow down the wear and deformation of not only the hinge itself, but also a number of other components and mechanisms. The lubricant can withstand temperatures from -30 to +140-150 degrees

What is a tripod?

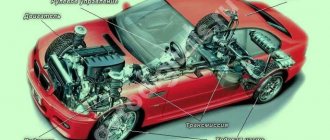

The CV joint consists of two autonomous units:

- the internal assembly is attached directly to the drive axle;

- the second is integrated into the drive wheel hub.

They are used to equalize angular velocity with large balls moved along special grooves. Depending on the car model, a specific lubricant is used for the internal CV joint and external analogue. The disadvantage of the mechanical design is that it does not provide for axial movements of the suspension. Needle joints have these properties.

They were called tripods, from the English word tripod. Hinges of this type compensate for the lack of ball analogues. The angular velocity is equalized due to the movement of the rollers along special channels during turns or axial instability.

Since the inquisitive thoughts of engineers do not stagnate, CV joints have been created with hinges of a ball mechanism that allows for axial movements. As an example, it is worth citing the domestic car of the Volzhsky Automobile Plant, modification 2108-2110. They were produced with a needle version and a ball version.

How to change the lubricant

When the question of how to replace the lubricant has been decided, you should think about how to carry out this process. It is worth noting that the procedure is distinguished by its simplicity, so that even the most inexperienced drivers can easily cope with all this.

It is only important to follow the following points:

- disassemble the body. Quite often, two locking rings are used to secure it together. To remove them, you will have to use a flathead screwdriver;

- dismantle the boot and seals. It is very important to check the integrity of these elements. In case of visible damage, it is necessary to purchase a new element;

- we take out the internal parts, after which we completely disassemble them;

- We wash all elements with gasoline or solvent. This will help remove old grease.

It is also important to clean the internal walls of the case from the substance:

- put a little lubricant in a glass;

- place the tripod on the axis in its place;

- We report more substances. It is important to do this evenly to fill the case as much as possible;

- We assemble the unit.

How often to change the lubricant

As a rule, replacement is required after 50-60 thousand kilometers, but here you need to read the instructions - for some manufacturers the lubricant service life can reach as much as 100 thousand km.

In addition, if the vehicle has not been used for 9 months, or has been rarely used for 18 months, then it is also recommended to replace the substance. At the same time, in some cases the composition must be replaced prematurely, so it is worth checking the condition of the lubricant sometimes.

We strongly recommend that you regularly change the CV joint lubricant, following the instructions and rules established by the vehicle manufacturer. Remember that the cost of such a procedure will be an order of magnitude lower than repairing or replacing the hinge itself. As for the choice of substance, the modern market offers a fairly large assortment of lubricants. There is no need to save money and buy the cheapest substances. It is better to trust trusted manufacturers. Moreover, the difference in price will be relatively small.

Next is a video about the best lubricant for CV joints:

Each vehicle component has its own operating and maintenance features. Before purchasing anything, you should read the instructions and find out the recommended lubricant.

Lubricant selection

If the manufacturer does not indicate which lubricant to use for CV joints, then you can use a universal product. You should choose carefully, since the device is operated under serious loads.

For your information! All lubricants are made from petroleum. Beware of fakes.

In auto stores you can purchase a special mixture, which differs:

This is required to keep the substance on the surface of moving parts even at high temperatures. The oil features:

- stability of characteristics under changing conditions;

- anti-corrosion properties;

- the ability to retain its original characteristics for a long time.

When to change the lubricant

The viscous substance in CV joints is replaced in the following cases:

- with a unit mileage of over 100 thousand km;

- when replacing the assembly boot;

- when replacing the CV joint itself.

The amount of lubricant required when replacing is indicated:

- in the car’s operating manual – not always;

- always on the packaging.

Disassembling the unit and lubricating it

Disassembly of the internal CV joint (TRIPOD)

Attention! Remember the locations of the parts of the assembly. Make marks. Everything should go back to its place, especially the balls.

Parsing algorithm for replacement:

- Unscrew the hub nut.

- Discard the balls.

- Loosen the inner CV joint boot.

- Bend the posts.

- Get the part.

- Remove the retaining ring.

Lubrication

Attention! Prepare materials in advance to remove old grease. Solvent must not be used.

The removed parts must be cleaned to a shine. It is advisable to use paper to remove old grease, and a towel for final cleaning and polishing.

Indiscriminate replacement

You can replace the lubricant in the CV joint without removing its components. To do this you need:

- Remove the CV joint itself from the car.

- Insert the tip of the tube and press the oil into the assembly.

- Press the tube tightly and wait until the color of the substance changes to fresh.

- Wipe the part, removing excess substance.

- Put the part in place.

Attention! This method has one drawback - a thin layer of old substance remains on the walls of the parts inside.

There is no need to rush to use the lubricated unit when driving. It is worth turning the assembly in place while the car is suspended on jacks. This is necessary to evenly distribute the lubricant over the parts.

Attention! On a car with an automatic transmission, with the wheels hanging, the pressure in the system will quickly drop.

The replacement process is not that complicated and if you have a minimum set of tools and skills, you can easily do it yourself. This will save money and allow you to get a better feel for the car. And remember, high-quality replacement of lubricant in CV joints cannot be done without removing it. If it is not possible to remove the assembly, then it is better to go to a car service center and see specialists.

- How to change the front silent blocks on a Mercedes 211 4matic

- How to change silent blocks on a Daewoo Nexia

- How to change silent blocks on Mazda cars 3-6

- How to change silent blocks on a Chevrolet Aveo: video

Components of the unit

The unit has been known to mankind for a long time and is indispensable in cars. The design is simple and, with proper maintenance, will serve without fail and for a long time.

Components of the CV joint:

- body – in the form of a bowl;

- clip with oil - located inside;

- separator – annular hole;

- six balls - like in a bearing.

For trouble-free operation of the device, its timely maintenance is required. Since the unit contains rubbing parts, they need to be lubricated for the following purposes:

- reducing friction;

- reduce wear;

- reducing the load on rubbing parts;

- protecting metal from corrosion.

Molybdenum grease and its application

Molybdenum grease is one of the most common lubricants for industrial units and machine systems. And this is not surprising. Molybdenum disulfide (MoS2) exhibits excellent extreme pressure and anti-wear properties, helps prevent premature aging of the metal and protect friction units during severe mechanical loads. The compound of molybdenum and sulfur is mined in the form of ore, then purified and takes the form of black fibrous crystals that, when rubbed, leave a gray-green mark. Lubricants with molybdenum disulfide are characterized by high adhesion to metal surfaces. This means that a protective microfilm is formed on the surface of the friction unit part, which levels the working surface, preventing the formation of scuffing and reducing the temperature in the friction area.

Distinctive properties of lubricants with the addition of molybdenum disulfide:

- High specific strength;

- Chemical stability;

- Temperature resistance;

- Low coefficient of friction;

- Good alloying properties;

- Anti-seize qualities.

NPP MAPSOL LLC has molybdenum lubricants in its product line, which are perfect for use in machine tool building and the automotive industry for lubrication of ball and roller bearings, worm gears and hard-to-reach components.

Greases with molybdenum disulfide under the MAPSOL trademark are the optimal choice for servicing units and mechanisms operating under heavy loads and high temperatures.

Why does a CV joint need lubrication?

It's no secret that manufacturers decided to lubricate some car parts with special technical fluids for a reason. There were reasons for this - tasks/problems that this liquid could minimize or solve. In a constant velocity joint such bases are:

- preventing the appearance and spread of corrosion - in metal elements it leads to the appearance of cavities, called cavities in CV joints, which significantly reduce the efficiency of the transmission and create a clearly audible knock when turning the steering wheel;

- reducing the coefficient of friction, ensuring free rotation of elements and, as a result, minimizing the load on the front axle transmission;

- reduction of energy losses during power transmission (less energy losses - less fuel costs);

- safety in relation to synthetic and organic polymers, because plastic or rubber boots are always used to protect the hinge joint from dust and dirt, so the lubricant used in this joint should not corrode them.

Not every lubricant is capable of solving all these problems at the same time, so let’s immediately eliminate all unnecessary things and leave only those options that meet this requirement.

Types of lubricants for CV joints.

Lithium (Renolit, Xado, Litol-24, Very Lube).

The most popular lubricant among car owners. It looks like a viscous, thick yellow consistency, which thickens greatly at subzero temperatures (the lubricant becomes so dense that it is practically impossible to spread).

- copes well with friction, reduces the load on the components of the drive mechanism by several tens of times;

- compatible with virtually any type of polymer used to protect constant velocity joints;

- neutralizes dust and dirt accidentally trapped inside the boot;

- practically do not allow moisture to pass through.

- poor corrosion resistance, therefore components treated with lithium lubricants should be checked at least every 50-60 thousand kilometers (with the exception of Litol-24, its manufacturers guarantee 100 thousand kilometers of uninterrupted operation);

- incompatibility with modern high-strength plastics, especially Litola-24, so if they protect the CV joint in your car, before using this or that lubricant, be sure to read the operating instructions, in it you will find recommendations on what is the best lubricant for the CV joint in your specific case.

Lubricants based on molybdenum disulfide (Mobil, Liqui Moly, BP, CV joint-4, ESSO, Texaco).

A modern analogue to lithium compounds. It looks like a thick ointment that is brown, gray or black.

- copes well with friction, no worse than lithium lubricants;

- compatible with any polymers and plastics;

- has high resistance to corrosion, however, to maintain this advantage it must be changed every 100 thousand km. mileage

- the composition is very afraid of moisture and, when encountering it, loses all its beneficial properties, therefore, the effectiveness of lubricants based on molybdenum disulfide is guaranteed only in cases of a whole boot, therefore, when using them, the tightness of the rubber/plastic protection should be checked at least once a month, and also after each off-road driving and strong impacts to the front of the underbody of the car.

Barium lubricants.

They were specially designed for use in constant velocity joints of a vehicle.

Analogs

There is no exact foreign analogue of ShRB-4 for a simple reason. Today, lubricant manufacturers and sellers convince consumers of the benefits of ointments that do not differ in durability. This is due to the fact that, according to the laws of a market economy, this property of a product is unprofitable - business entities are interested in maximum production and sales volumes.

Foreign-made lithium lubricants:

- XADO;

- RENOLIT;

- Very Lube.

List of molybdenum lubricants imported to Russia:

- BP;

- Liqui Moly;

- Mobil;

- Texaco.

A genuine analogue of the products of the pioneer of the domestic chemical industry is called ShRB-4 ointment produced by Expert-Oil, but it is more correct to say that these are the same product, the manufacturer of which has transferred to the status of a foreign company (see below).

Also substitutes for ShRB-4 are Limol and ShRUS-4 from Russian manufacturers.

According to a number of experts, any barium-based technical ointments can serve as a replacement for lubricants.

Tags: amount of lubricant in the CV joint, lubricant in the tripod

Comments 25

Thanks everyone for the answers. There were 60 cubes for each outer one, 80 for each inner one. Just like the 360g tube I bought.

The remains were smeared onto the tube. Well, I’ll scrape them off from the inside...)

80mg? this is almost a quarter of a tube))

The remains were smeared onto the tube. Well, I’ll scrape them off from the inside...)

you wrap the tube in a tube like a carpet and the tube is 98% empty...

if the tube was not included in the kit, then you buy a small one and use the entire tube for one CV joint. It was written below correctly, there is no such thing as too much lubrication.

There is no such thing as excess lubrication, the more of it, the better, usually - if the grenade comes with a tube of lubricant, squeeze some of it into the CV joint, completely covering the balls and the drive hole... and squeeze the rest into the boot about the centrifugal force - he smiled)) here’s a tube, I don’t know how many mg there are in it...

Those. The laws of centrifugal forces do not apply to CV joints? Or is it applicable with the amendment that this is a CV joint?)

Well, if there is little lubrication and centrifugal force, then probably all the lubricant will be distributed in a circle on the boot (like in a centrifuge), and the balls are dry)) The boots do not tear because the lubricant under the influence of centrifugal force tears them, they tear due to bad the quality of the boot itself, , , cracks begin on the folds, etc...

Those. The laws of centrifugal forces do not apply to CV joints? Or is it applicable with the amendment that this is a CV joint?)

You can also compare the quality and shape of the anthers, for example, Russian BRT; sharp triangular edges contribute to the rapid formation of folds and cracks...

They did the same interesting thing on Sevi. The inner one where there is a very steep bend is a rounded edge. the rest are sharper. I thought that it turned out that way for the forms))

Those. The laws of centrifugal forces do not apply to CV joints? Or is it applicable with the amendment that this is a CV joint?)

or here’s the Japanese one for Corolla and other Kaldins)) round bends and does not feel like plastic to the touch))

Wow. I don’t see the point in having an extra one, it will end up on the boot anyway. And what kind of anthers are there in the very top first photo in the black box?

Weber I took it with a grenade included (last entry in the BZ), but put 27411 (last photo)

Wow. I don’t see the point in having an extra one, it will end up on the boot anyway. And what kind of anthers are there in the very top first photo in the black box?

Lubricant for CV joints is viscous, it does not have the property of spreading like water or oil under the influence of centrifugal force, it is not fluid in general... So, the more lubricant, the longer the mechanism lives, the less friction, etc., etc. There is also Xado lubricant (not advertising) , it contains a remitalizant (or revitalizant, I don’t remember) - the lubricant sticks to the metal, reduces friction (it pokes to help) - this is exactly what was in the CV joint that was changed - there is almost no boot left, but there is plenty of lubricant!

There wasn’t enough money to replace it for hado-lubricant ((

Suprotek lubricant with ceramics is simply awesome. But a good thought comes after)

Suprotek is an easy-to-flow lubricant, you can’t pour it into CV joints, it, like wd40, will find a loophole, leak out and pull the rest of the lubricant with it. And in general, Suprotek is evil ((

I will not conduct a dialogue about Suprotek.

Nope, I’m talking about the Suprotek CV joint and not the engine can. That's why we have a misunderstanding. In general, Liqui Moth also has keratek (the same thing). Shall we have a dialogue about Liquid Moth?))) Or about what our engineers did back in the late 80s?

Suprotek is an easy-to-flow lubricant, you can’t pour it into CV joints, it, like wd40, will find a loophole, leak out and pull the rest of the lubricant with it. And in general, Suprotek is evil ((

I will not conduct a dialogue about Suprotek.

It turns out they came up with it in the 80s, then Forsan appeared, then Suprotec, then Hadot, then Liqui Moly Keratec. But in reality it turns out that Forsan and Suprotek are oh yes, evil. And Liqui Moli - well, these are Germans, the Germans won’t blame you.

Come on! All this was invented and worked out in the USSR! Back then, money was not spared for laboratory research.

And now is the era of salesmen!

And that’s how they think: the label is cooler, the name is foreign and that’s it. They'll buy it! I still have a calculator from the Minsk plant, produced in 1981. 10x5 cm, thickness - 3 mm. LCD screen. Programmable, with engineering functions. The built-in batteries (two “tablets”) lasted for a year. Modern ones, compared to it - complete bullshit!

And after that they will push it on us that our electronics are lagging behind. Not a damn thing! At the level of the best world standards.

Only the sales people don't give a damn about it. The main thing for them is to sell. It's the same with computers. It’s more profitable to buy over the hill and sell here ten times more expensive.

Do you know how much the 80286 cost complete with a monitor in 1998? 43-50 thousand rubles. Like a new nine from the factory at that time! And my office took 22-27 thousand rubles from intermediaries. Intermediaries are naturally even cheaper.

Engine lubricant with molybdenum is not a bad thing. They make it in Lithuania. It's called Mannol. The name was invented there. After using it, not a single office undertakes to sharpen the block. Ceramics on the cylinder walls completely damage the cutting tool.