Every car owner someday begins to learn the basics of how to design and repair his vehicle. If you have never had to adjust the ignition timing, then it’s time to learn all about it, and the problem can be met head on.

- 2 Changing the OZ on a gasoline engine

- 3 Is adjustment of the OZ necessary - check on the go

- 4 Installing the correct OZ on the injector and diesel engine

- 5 How to set the OZ in a car with LPG or entrust this task to a CVT

Internal combustion engine and ignition timing

Before focusing on ignition angles, you should understand the operating principle of the entire system. It's no secret that ignition timing plays a huge role in the operation of internal combustion engines. It occurs before the piston reaches its highest point during the compression stroke. The consequence of such a mini-explosion is the expansion of gases, as a result of which the piston continues its movement and the working stroke occurs.

Despite the fact that all these processes occur very quickly, they still take some time. And since the crankshaft also rotates at enormous speed, therefore, the piston has time to travel some distance from the moment the mixture ignites until the gases expand. So, if ignition occurs strictly while the piston is at TDC, then combustion will occur at the beginning of the power stroke and will also end a little later. This will all reduce the gas pressure.

Car crankshaft

But when the ignition of the combustible mixture occurs, on the contrary, very early, the gas pressure will reach its maximum even before the piston is in its uppermost position. This means that there will be some opposition to his movement. This has the most negative impact on the operation and condition of the engine. Therefore, adjusting the ignition timing is very important.

Before we touch on adjusting the ignition timing (IPA), let's figure out what it is and what its effect on the condition of the car is. The optimal situation is when the combustible mixture ignites and burns completely before the piston reaches the TDC position. It is customary to determine this moment by the position of the crankshaft, and the designations are carried out in degrees. In other words, we are talking about the angle between the crankshaft and top dead center. If the shift occurs towards TDC, then such an angle is called late, in the opposite direction, respectively, early.

Ignition timing

It should be noted that the value of the SOP depends on the crankshaft speed. The higher it is, the earlier the ignition timing must be set. If this characteristic is selected incorrectly, then the engine power is reduced, overheating occurs and the unit will fail prematurely, which will entail large material costs. Fuel consumption will also increase and the amount of harmful substances in the exhaust gases will increase. So you will harm not only your car and financial situation, but also the environment.

How to set the OZ in a car with LPG or entrust this task to a CVT

Lately, gas equipment (GBO) has gained many fans. And all thanks to efficiency, because such fuel is much cheaper than gasoline or diesel fuel. It should be noted that gas consumption is somewhat higher, and the combustion of the fuel-air mixture lasts longer and occurs at the exhaust stage. You can adjust these parameters; you just need to adjust the ignition timing, and we’ll look at how this is done if the car is equipped with LPG.

It is not difficult to set the OZ, and the fuel will burn even before the exhaust valve opens, which means that the car parts will not be subject to negative thermal effects, and the engine efficiency will increase. The characteristics themselves for gasoline engines and LPG are somewhat different. True, there is an opinion that in modern cars equipped with an on-board computer, such adjustments are carried out automatically. However, this is not quite true. Indeed, in injection systems, the OZ is set in accordance with detonation, but for LPG this phenomenon is unusual.

Adjusting the OZ using the on-board computer of a car with LPG

Owners of cars with gas equipment have an assistant - a variator. This part can change the SOP on the fly without your participation. But this is not the basic equipment of the car, and you should buy a CVT. Actually, gas equipment is also installed at the initiative of the owner, and not the plant. Today, there are different ignition timing variators for gas equipment on sale. This device connects to the sensor responsible for the crankshaft position (CPCP) and corrects its readings to the desired value. Moreover, depending on the variator model, the displacement is carried out either by a fixed amount or depends on engine speed. This device is activated when the HBO is turned on.

Let's look at one of the connection diagrams for the variator for adjusting the gas pump. To begin, select the most convenient place where this element will be located. The far left corner of the engine compartment, not far from the gearbox, is perfect for mounting the variator. Now remove the cover from the device and make a direct connection in accordance with the attached instructions.

Connecting the variator for adjusting the UOZ to the gas equipment

One pin is responsible for supplying voltage to the sensor to which we will attach the variator. We attach the second one to the leg of the gas valve in the gas equipment. But the ground should be connected to the screen of the DPKV cable. Then we strip the sensor wires and connect the corresponding variator leads to each of them. Now all that’s left to do is set up the device and enjoy operating the vehicle. Experts claim that the presence of a variator in the LPG system saves fuel by almost 25%. Most likely, the figure is inflated by marketers, but there really is a benefit.

Changing the OZ on a gasoline engine

You need to start work by preparing the tool. We will need a wrench and a test light. You can't do without a special wrench that can be used to turn the crankshaft. After all, in fact, its position determines the value of the OZ. You can also purchase a special ignition timing corrector, which can set this characteristic automatically.

Place the car in neutral and apply the parking brake. Then you need to remove the cover from the breaker. This way you can easily get to the crankshaft, which is turned with a special wrench until the distributor runner is in the sector of the first cylinder of the distributor. Also, be sure to follow the positions of the marks on the ebb of the front cover and the pulley; they must match.

Removing the cover from the breaker

Now, to correctly set the ignition timing, you need to connect the control lamp. One of its terminals is connected to the ignition coil, and the second to the engine ground. Slightly loosen the distributor fastening and turn the key in the ignition. We clamp the slider against the stroke and turn the distributor in the opposite direction of movement of its roller until the control lamp goes out. To be safe, turn the distributor a little more and very carefully return it in the opposite direction. It is necessary to record the moment of ignition of the lighting device. In this position, you need to align and secure the body of the breaker-distributor with bolts. All that remains is to return the lid to its place.

To automate the ignition timing adjustment as much as possible, a vacuum regulator is introduced. Such a device automatically changes the SOP depending on the load. If the engine is idling, then the vacuum regulator turns the chopper disc towards late ignition. As soon as the load increases, a vacuum occurs. Then the vacuum regulator rotates the breaker disk in the opposite direction. So it seems to turn off, because it cannot create a leading angle. At this moment the centrifugal regulator comes into play. Now only he sets the advance angle.

Vacuum regulator UOZ

The fact of vacuum allows you to record the sensitive diaphragm with which the vacuum regulator is equipped. On the one hand, it is affected by our atmosphere, and on the other, by pressure from the carburetor. So it turns out that when the throttle valve is closed, rarefied air from the system does not reach this diaphragm and the vacuum regulator fulfills its mission. As soon as the rarefied atmosphere hits it, it bends and the device stops working, returning everything to its place.

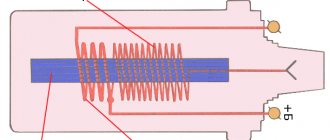

The device of the ignition system of the VAZ 2106

The ignition system (IS) of a gasoline engine is designed to create and timely supply pulse voltage to the spark plugs.

Composition of the ignition system

The VAZ 2106 engine is equipped with a battery-contact ignition system.

VAZ 2106 cars are equipped with a battery-contact ignition system

The ignition system includes:

- accumulator battery;

- switch (ignition switch with a group of contacts);

- double-winding transforming coil;

- distributor (distributor with contact-type breaker and capacitor);

- high voltage wires;

- candles.

The ignition includes low and high voltage circuits. Low voltage circuits include:

- battery;

- switch;

- primary winding of the coil (low voltage);

- breaker with spark arresting capacitor.

The high voltage circuit includes:

- secondary winding of the coil (high voltage);

- distributor;

- spark plug;

- high voltage wires.

Purpose of the main elements of the ignition system

Each SZ element is a separate unit and performs strictly defined functions.

Accumulator battery

The battery is designed not only to ensure the operation of the starter, but also to power the low voltage circuit when starting the power unit. During engine operation, voltage is supplied to the circuit not from the battery, but from the generator.

The battery is designed to start the starter and supply power to the low voltage circuitSwitch

The switch is designed to close (open) contacts of a low-voltage circuit. When you turn the ignition key in the lock, power is supplied (cut off) to the engine.

The ignition switch closes (opens) the low voltage circuit by turning the key

Ignition coil

The coil (bobbin) is a step-up two-winding transformer. It increases the voltage of the on-board network to several tens of thousands of volts.

With the help of an ignition coil, the voltage of the on-board network is increased to several tens of thousands of volts

Distributor (distributor)

The distributor is used to distribute the pulse voltage coming from the high-voltage winding of the coil to the rotor of the device along the contacts of the top cover. This distribution is carried out by means of a slider having external contact and located on the rotor.

The distributor is designed to distribute voltage across the engine cylinders

Breaker

The breaker is part of the distributor and is designed to create electrical impulses in a low-voltage circuit. Its design is based on two contacts - stationary and movable. The latter is driven by a cam located on the distributor shaft.

The breaker design is based on moving and stationary contacts

chopper capacitor

The capacitor prevents the formation of a spark (arc) at the breaker contacts if they are in the open position. One of its outputs is connected to the moving contact, the other to the stationary one.

The capacitor prevents sparking between the open contacts of the breaker

High voltage wires

Using high-voltage wires, voltage is supplied from the terminals of the distributor cover to the spark plugs. All wires have the same design. Each of them consists of a conductive core, insulation and special caps that protect the contact connection.

High-voltage wires transmit voltage from the contacts of the distributor cap to the spark plugs

Spark plug

The VAZ 2106 engine has four cylinders, each of which has one spark plug. The main function of spark plugs is to create a powerful spark that can, at a certain moment, ignite the combustible mixture in the cylinder.

Spark plugs serve to ignite the fuel-air mixture

When you turn the ignition key, current begins to flow through the low-voltage circuit. It passes through the contacts of the breaker and enters the primary winding of the coil, where due to inductance its strength increases to a certain value. When the breaker contacts open, the current instantly drops to zero. As a result, an electromotive force arises in the high-voltage winding, increasing the voltage tens of thousands of times. At the moment such a pulse is given, the distributor rotor, moving in a circle, transmits voltage to one of the contacts of the distributor cover, from which voltage is supplied to the spark plug through a high-voltage wire.

Is it necessary to adjust the OZ - check on the go

There are often situations when the factory settings are lost or simply do not quite suit specific operating conditions. In all cases, you will have to set the OZ yourself. True, you first need to make sure that this operation is necessary, which means we’ll figure out how to check the value of the ignition timing. To do this, we accelerate on a flat area to 40 km/h, then sharply press the gas and listen to our car. If a noise characteristic of detonation appears, which stops after the car reaches a speed of 60 km/h, then everything is in order and the angle is set perfectly.

Exhibiting UOZ

If the detonation does not stop, then the ignition is “early”. But when the moment of ignition of the combustible mixture is slightly delayed, the detonation will end before the car accelerates to 60 km/h. To change the ignition timing, open the hood, slightly loosen the mount of the distributor-distributor and change the position of the distributor. In the first case, the adjustment involves a shift of several millimeters clockwise, and for late ignition - in the opposite direction.

Installing the correct OZ on the injector and diesel engine

With an injection engine everything is also extremely simple. In this case, you should turn on the ignition and look at the instrument panel. If a light comes on on it, indicating a malfunction, then we take a laptop with a special program, connect it to the on-board computer and carry out diagnostics.

At the next stage, the throttle device is subjected to a thorough visual inspection. It is also recommended to check the voltage of the on-board network and the sensor that regulates the throttle position. They must comply with the standards. Thus, the optimal voltage for the sensor is considered to be in the range of 0.45–0.55 V, and for the network – 12 V. The damper opens only 1%. We sharply press the gas pedal. The throttle opening should exceed 90%, and the sensor voltage will drop to 0.45 V. Otherwise, it is necessary to urgently adjust the ignition timing.

Checking the throttle position sensor voltage

Carry out all work using non-conductive rubber gloves, as most elements are live.

Setting the angle begins with the fact that we disconnect the vacuum hose from the engine. Then we connect the positive clamp of the strobe to the positive terminal of the battery. The ignition is adjusted by switching the ground clamp, connecting it to the negative terminal and pulling the wire out of the cylindrical socket on the distributor cover. We insert the strobe sensor into the vacant space, simultaneously connecting it to the wire of the first cylinder of the power unit. Next, we start the engine and direct the beam from the strobe to a special hatch. A mark will appear on the flywheel; its optimal location is between the divisions. If this is not the case, then set the angle by slowly loosening the nuts securing the flywheel distributor.

Strobe

Adjusting the ignition timing on a diesel engine is also not difficult. But this operation should not be underestimated, since a diesel engine can only operate when the fuel is completely burned. This will not happen with an incorrectly set ignition angle. The main difference of this system is the absence of candles. Basically, all actions are the same as for gasoline engines. Only in this case it is necessary to remove the decompression mechanism, the engine meter and the body of the neck through which the oil is poured. Be sure to check the fuel supply level. To do this, move the corresponding lever to the extreme position, install the torque scope and slowly turn the crankshaft.

Detonation combustion

During detonation combustion, a spark ignites the mixture near the spark plug, which simultaneously compresses the remaining mixture. The increase and increase in pressure and temperature cause spontaneous combustion and ignition of the mixture at the opposite end of the chamber. This is a chain reaction of detonation leading to high combustion speeds exceeding 1000 m/s. This causes a characteristic knocking sound, sometimes the sensation of a metal bell. This process exposes pistons, valves, connecting rods and other elements to thermal and mechanical stress. Ultimately, ignoring detonation causes the need for engine repair.

Back in the 80s of the last century, engineers dealt with this harmful phenomenon by installing a piezoelectric knock sensor. Thanks to this, the control computer detects a dangerous phenomenon and selects a normal ignition timing in real time, which eliminates this problem. However, today the phenomenon of detonation combustion is returning in the dangerous form of pre-ignition at low engine speeds. Let's analyze how technological advancement has brought back forgotten threats in the automobile industry.