When designing the small car VAZ Oka 1111 and 11113, many components and mechanisms were “borrowed” from other VAZ models, which made it possible to reduce the cost of car production and speed up the start of production. But the designers had to significantly rework some components in order to adapt them to the features of the Oka engine. One of these components is the ignition system.

When creating the ignition system, the designers used modern developments of those years. The VAZ Oka received a non-contact ignition system. At the same time, the features of the power plant made it possible to somewhat simplify the system and reduce the number of components, which had a positive impact on the reliability of this component of the power plant.

Design

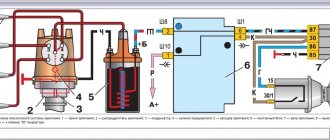

The ignition system of the VAZ Oka consists of only seven main elements:

- Auxiliary relay;

- Egnition lock;

- Circuit breakers;

- Switch;

- Spark moment sensor;

- Coil;

- Candles;

All elements are connected to each other by wiring.

Using the ignition switch, the driver controls the power supply to the system from a source - the battery, while the voltage passes through the auxiliary relay and fuses. The lock has three positions - “0”, in which all electrical consumers are turned off, “1” - voltage is supplied to the ignition system and a number of other devices, and “2” - current is supplied to the starter. This switching sequence ensures that the ignition system is activated at the moment the engine starts.

Spark torque sensor

The spark timing sensor is one of the main ignition components, since it sets pulses that are subsequently converted into a spark discharge between the spark plug contacts. This sensor is driven by the camshaft, which allows you to accurately set the timing of the spark in the cylinders.

The main working elements of the unit are the Hall sensor and a special screen with slots mounted on the drive shaft interacting with the camshaft. The interaction of these elements leads to the emergence of control impulses.

The sensor not only sets pulses, it also “adjusts” to the operating conditions of the motor, adjusting the advance angle depending on the operating conditions of the motor (speed, load).

The adjustment is carried out by two regulators - vacuum and centrifugal, included in the design of the spark generation moment sensor.

Related link:

Adjusting Oka valves

Until 1989, Oka used a sensor of type 55.3706, and after that it was replaced by model 5520.3706.

Switch

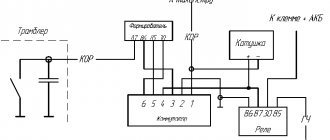

The switch acts as a circuit breaker for the primary winding of the coil, using control pulses coming from the spark sensor. Circuit interruption in the switch is performed by the output transistor. The switch is completely electronic, without any moving elements, so the ignition system is contactless.

Several types of switches were installed on the VAZ-1111 and 11113 - 36.3734, 3620.3734, as well as HIM-52. The switch is installed in the engine compartment near the engine panel. It is secured with two bolts, so replacing the switch is quite simple.

Coil

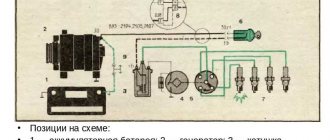

Oka received a two-terminal ignition coil, which made it possible to remove the distributor from the design.

It is noteworthy that the high voltage in this coil is supplied simultaneously to both spark plugs. Moreover, due to the offset strokes in the engine cylinders, only one spark discharge is working, the spark on the second spark plug is the so-called “idle”.

The standard coil on the Oka is type 29.3705, but it has an analogue that is suitable for use on a small car - 3012.3705.

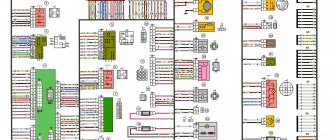

Wires, spark plugs

All wiring consists of low and high voltage wires. The first ones are used to connect all the components up to the coil. These are ordinary wires of small cross-section, which is quite sufficient, since the voltage in the circuit up to the coil is low.

High voltage wires are used to connect the coil terminals to the spark plugs. For ease of connection, lugs are installed at the ends of these wires.

Recommended for use on Oka are spark plugs of type A17DVR - with an extended thread and an interference suppression resistor, as well as their analogues.

Video “Instructions for replacing the ignition coil”

Learn more about how to replace the ignition coil in Oka with your own hands from the video below (author - Butovsky Gulyak channel).

Good day!

Some time ago I noticed that my Oka periodically shoots at the silencer. At the same time, I have never heard detonation on it, except very briefly when starting off very sharply. I noticed that the distributor was turned 1 division counterclockwise relative to its average position (i.e., 8 degrees along the crankshaft, as they say in the book). I turned the distributor approximately 1/4 notch clockwise (that is, I set it to 2 degrees earlier). It became noticeably easier to move away (it became almost as easy as driving a UAZ truck - the car stopped either stalling or jerking sharply), and it seemed like the traction at the bottom increased. and the engine stopped firing from the muffler.

Maybe try to tighten it up some more?

I heard that on engines 2108/09 (and therefore on Oka, probably) detonation is not as audible as on other engines (Volga, UAZ, Lada, etc.). And in the instructions they write (unlike the UAZ) to adjust not by detonation, but by strobe (which I don’t have, of course).

How to set the ignition correctly on Oka?

Thanks for any answers!

Setting the ignition “by ear” We set the sensor firmly to “+”, not paying attention to any risks and so on. We find a flat section of the road, accelerate on it to 60-65 km/h (if the jerker is 1111 - up to 55-60 km/h), stick the fourth gas pedal firmly to the floor. Engine detonation will be clearly audible with a characteristic metallic tinkling sound (they still ignorantly say that “fingers are knocking”). We stop, turn the sensor a little to minus, and repeat the ride. The goal is to ensure that when the pedal is pressed to the floor, the detonation knock is practically one or two “dings” and immediately stops. I drove with this setup for several years and didn’t know any grief.