The appearance of a characteristic metallic ringing in the front part of the power plant of a VAZ-2107 vehicle indicates problems with the gas distribution mechanism drive.

The cause of this ringing is the weakening of the drive chain as a result of its strong stretching or weak tension by the tensioner.

And if severe stretching of the chain can only be eliminated by replacing it, then tensioning it is a procedure that is included in the list of maintenance work and must be carried out in a timely manner.

But there are also cases when the tension was recently carried out, the chain has not yet exhausted its service life, and ringing has already begun to appear.

This is often due to the chain tension mechanism.

Replacing the chain tensioner VAZ 2107

The appearance of a characteristic metallic ringing in the front part of the power plant of a VAZ-2107 vehicle indicates problems with the gas distribution mechanism drive.

The cause of this ringing is the weakening of the drive chain as a result of its strong stretching or weak tension by the tensioner.

And if severe stretching of the chain can only be eliminated by replacing it, then tensioning it is a procedure that is included in the list of maintenance work and must be carried out in a timely manner.

But there are also cases when the tension was recently carried out, the chain has not yet exhausted its service life, and ringing has already begun to appear.

This is often due to the chain tension mechanism.

Features of the tension mechanism and its possible malfunctions

Tensioner is a drive element that provides a certain tension to the timing chain.

The “native” device of this car is a plunger type. That is, in the design of this element there is a spring-loaded plunger, which, due to the pressure of the spring, provides the necessary tension.

This element works in this way - the spring pushes the plunger out of the body, it rests on the shoe and pushes it until the plunger stops the resistance of the chain, while the slack is removed from it by a powerful tensioner spring, the chain is tensioned.

But its design is such that after taking out the slack in the chain, the plunger is fixed with a cracker.

However, over time, the chain stretches more and more and its additional tension is required, for which it is necessary to remove the lock nut fixation of the plunger with a cap nut so that the spring makes a selection again.

One of the main disadvantages of such a tensioner is the possibility of debris getting between the plunger and the body, which can cause it to jam.

Sometimes jamming can be eliminated by lightly tapping the body, but not always. Damage to the housing always leads to the need to replace it.

It is not always convenient to periodically sample chain slack, so instead of a standard tensioner, you can install an automatic one, which performs the sampling itself.

At the same time, the design of such a tension mechanism is very simple and the possibility of jamming is practically excluded.

Automatic tensioner, design, operating principle

The automatic mechanism uses a ratchet mechanism, which itself takes out the slack of the chain as it stretches.

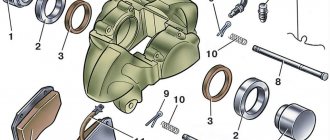

This element consists of a housing in which a spring-loaded ratchet pawl is installed.

Inside the housing there is a spring and a tensioner rod with a toothed sector.

The sector teeth are small, have a pitch of 1 mm, and are inclined in a certain direction.

This is how an automatic tensioner works.

As the chain sag, the spring pushes the rod and it, acting on the shoe, makes a selection.

But the pawl of the ratchet mechanism, which places one of its ends between the teeth of the sector, prevents the rod from returning back.

As the chain stretches, the rod moves out, and the pawl, jumping over the teeth, prevents it from returning back. Thus, the tensioner constantly maintains chain tension.

If it is discovered that the standard tensioner has ceased to perform its functions due to damage or jamming, which could not be eliminated by tapping the body, then it must be replaced.

This operation can be divided into partial, when only the damaged element is replaced, and complete, in which the shoe is also replaced.

Timing chain tensioner VAZ 2107

The VAZ 2107 was equipped with engines with a timing belt and chain drive. Although a chain is more reliable than a belt, the design of the drive unit is nevertheless imperfect and requires periodic tensioning, for which a special mechanism is used - a tensioner.

Purpose of the device

The chain tensioner in the power unit performs an important function by monitoring the chain tension in the timing drive. It follows from this that the coincidence of valve timing and stable operation of the engine directly depend on the reliability of this product. When the chain weakens, the damper breaks down. In addition, it can jump over the teeth, causing the valves to hit the pistons, which will lead to engine damage.

Types of tensioners

The timing chain tensioning mechanism comes in several varieties: automatic, hydraulic and mechanical.

Mechanical

In a mechanical type tensioner, the required amount of tension is provided by a plunger spring. Under its influence, the rod comes out of the body and pushes the shoe. The force is transmitted until the chain offers resistance, i.e. it is sufficiently tensioned. In this case, sagging is eliminated. The tensioner is fixed by tightening the cap nut located on the outside. When it is necessary to adjust the tension, the plunger lock nut is unscrewed, as a result of which the spring presses the rod, eliminating sagging of the chain.

Such tensioners have one significant drawback: the device becomes clogged with small particles, which leads to jamming of the plunger. To eliminate this malfunction, tap the tensioner during adjustment. However, you should not make special efforts to avoid damaging the body of the product.

How to understand that you need to pay attention to the timing assembly

Timing chain problems manifest themselves in a variety of ways.

In some cases, the power unit begins to triple, and in others, at idle you can hear floating speed. In advanced cases, a carburetor or injection VAZ-2107 can simply stall, and some modifications completely fail when the chain jumps. Other symptoms may include:

- an increase in temperature in the cylinder-piston group (leads to accelerated wear of its parts);

- a metallic ringing sound coming from the front engine cover;

- knocking noise from under the valve covers;

- Belt tension does not eliminate extraneous noise.

We recommend that you do not delay repairs if you hear the first signs of incorrect engine operation.

Auto mechanics recommend regularly checking the timing belt tension to detect problems at an early stage. You also need to pay attention to the condition of the shoe; if it is worn out, then you should not delay repairs.

Signs of stretching

The symptoms of this problem are specific. And it will be very difficult to confuse them with something else.

In some cases, the damper breaks. In this case, only replacing it will help. How to tension a chain on a VAZ-2107 (injector)? Photos of the process are in our article.

By the way, on a VAZ-2107 with a carburetor power system, unlike injection engines, to turn the crankshaft it is enough to turn the ratchet. But let’s not get ahead of ourselves and consider several ways to tighten the motor chain on a VAZ-2107.

How to tension a chain on a VAZ-2107 without removing the valve covers?

First we need to place the car on a flat surface and secure it with anti-roll bars. Next, fix the gearshift lever in the neutral position. Then remove the drive cover. Once access to the chain is free, the tensioner should be slightly loosened. It is located next to the water pump. Next, using a 36-degree socket, rotate the crankshaft 360 degrees. After this, tighten the tensioner to the maximum. We start the engine and check the tension level. The clatter must disappear.

Suitability test

After removing the part, you need to check the element for clogging. Oil can carry small particles and other contaminants that can negatively affect the performance of the device in question. Their excessive accumulation causes unstable operation of the plunger rod and its jamming.

You can clean the tensioner yourself without much effort. Place the part in a tank of gasoline for several hours, rinse and dry it thoroughly. When inspecting the case, you need to pay attention to the presence of dents, cracks and scratches. The plunger mechanism is checked in the same way. If no visible damage is detected, check the functionality of the device.

The device is taken in one hand, and with the other we try to move the plunger rod in the frame. It should move freely without getting stuck. If movement is difficult, the washing process must be repeated. If this does not help, the part must be replaced. The element is installed in the reverse order of removal.

Before starting work, it is better to place the car on a flat surface and put it on the handbrake. The gearbox knob is placed in neutral position.

You will need a number of tools, namely:

If the listed keys are available, you can proceed directly to tensioning the chain.

For a carburetor (performed if it is necessary to determine the integrity of the damper): remove the air filter housing from the carburetor and disconnect the “gas” draft from the roller;

Disconnect the traction lever;

Disconnect the bracket hose;

For injection (performed if necessary): remove the throttle cable and breather hose.

Using a 10 mm tubular wrench, remove the cover from the cylinder block;

Tightening the chain while removing the valve covers

If the chain is still noisy, perform the following operation. Using keys, we remove not only the drive, but also the valve cover from the cylinder head side. In this case, the chain tension can be checked manually as the camshaft sprocket is released.

So, loosen the tensioner a little and turn the crankshaft two turns. After this, fully tighten the timing chain tensioner. Next, we check the element manually. There should be no sagging. The chain must be elastic. If so, replace the valve cover and drive cover.

Adjustment Details

Sometimes the process of adjusting the tension level may be required several times. Therefore, let us consider in detail how this procedure is performed. After the cover has been removed, it is necessary to relieve the pressure in the tensioner. To do this, unscrew the corresponding lock nut.

How to tension a chain on a VAZ-2107? Use a large wrench to turn the crankshaft. It should stop at the point of greatest resistance. Just turn it a couple of turns. Using a wrench, fix the shaft in this position and tighten the cap nut. How to further tighten the chain on the VAZ-2107 with your own hands?

We connect the tensioner and check how secure it is. If the chain is elastic, install all the elements in place and start the engine. When checking the operation of the timing drive, there should be no extraneous noise, which will increase with increasing crankshaft speed.

Installing a new element

Before installing a new tensioner, if it is a plunger tensioner, it must be “charged”. This concept hides the need to completely insert the plunger into the housing before installation.

To do this, the new element is clamped in a vice, but so that it does not damage the body.

Then use a 13 key to loosen the cap nut, and the plunger will come out of the body under the action of a spring.

Next, the tensioner is removed from the vice. Then, holding it by the mounting ears with your hand, you need to rest the plunger against a hard surface and press on it so that it goes into the body.

While holding it in this position, tighten the cap nut to secure the plunger.

Afterwards, the “charged” tensioning mechanism is installed in place and secured with two nuts.

In order for the tensioner to operate and extract, you need to loosen the cap nut again, after which you will hear a click indicating that the plunger has come out and extracted.

Why is this so important to do?

During operation, the chain is subjected to significant loads. After all, it interacts with two shafts - the crankshaft and the camshaft. Over time, the part stretches out. The chain pitch changes and the engine begins to operate unstably. As a result, the revolutions fluctuate, and the mechanism itself jumps one or more teeth. If the circuit begins to make noise, this is the first sign for diagnosis.

Experts recommend tightening the chain every 15 thousand kilometers. Its resource itself is about 100 thousand. By this time the part must be replaced. The sedative also changes. Before tensioning the chain on the VAZ-2107, check its condition. All the necessary elements can be found in the VAZ-2107 timing belt repair kit.

REPLACEMENT

When it is not possible to tighten the timing chain on a VAZ 2107, it is replaced. Along the way, you will need to change the tensioner shoe and damper. Often a set of all gears (sprockets) must be replaced, but they do not wear out as quickly as other timing parts. Before carrying out work, you will need to buy all the necessary spare parts and prepare the tools. The chain is sold at any auto store that sells VAZ spare parts. The cost of a timing chain is approximately 500-800 rubles, depending on the manufacturer. Suspiciously cheap parts are not worth buying. And you need to remember that the number of links may vary depending on the type of engine (for motor 2106 there should be 116 links). If you need to change a set of sprockets, it will cost about 600 rubles. A shoe and a damper cost approximately 100 rubles each. every.

Tools you will need:

- Set of car keys;

- Screwdrivers;

- Hammer;

- Ratchet wrench VAZ.

So, removing and installing the VAZ 2107 timing chain:

- Remove the valve cover;

- We turn the crankshaft with a ratchet wrench and set the camshaft to the mark on the 4th cylinder;

- Unlock the camshaft sprocket mounting bolt and unscrew it;

- Remove the tensioner by unscrewing two 10mm bolts;

- Unscrew the ratchet nut and remove the crankshaft pulley;

- We unscrew the nuts securing the front engine cover (do not forget that there are still three bolts at the bottom), remove the cover;

- Unscrew the bolts securing the damper and remove it;

- Unscrew the shoe bolt and remove the shoe;

- If you are changing the drive shaft sprocket, you must first loosen the fastening bolt and then unscrew it. In this case, the shaft must be secured against turning;

- Unscrew the chain stop (it is to the right of the crankshaft) and remove the chain.

During assembly, it is important that the crankshaft and camshaft do not rotate during the entire operation (there is a risk of bending the valves). Also, the intermediate shaft must be placed in the same position as it was before disassembly. If the blower shaft nevertheless changes position, you will have to reinstall the distributor in order to set the ignition correctly.

We reassemble in the reverse order and pay attention to the marks - they must match. Before installation, the tensioner should be recharged - loosen the cap nut, recess the plunger and tighten the nut. To tension the chain (when everything is already assembled), we loosen the tensioner nut, the plunger shoots and tensions the chain drive.

Replacing the chain tensioner on a VAZ 2107 does not present any difficulties; it can be removed and installed in literally a matter of minutes.

Replacement

How to replace the timing chain tensioner

Removal: 1) First, remove the two nuts that secure the chain tensioner to the engine.

Unscrewing the chain tensioner fastening nut

2) Then remove the chain tensioner from the car engine.

Note! There is a sealing gasket between the chain tensioner and the engine, remove it carefully, do not damage it! (For information on what a sealing gasket looks like, see the very bottom of the article, in the “For Beginners!” section)

Installation: 1) First, charge the new chain tensioner. (For information on how to charge the chain tensioner, see the article “How to charge the chain tensioner on a VAZ?”)

2) Then reinstall it in the reverse order of removal.

3) Now turn the crankshaft clockwise in order to tension the timing chain. (For information on how to turn the crankshaft, see the article “Installing the piston of the fourth cylinder to the TDC position”, in paragraphs “1-2”)

Note! In the article to which the link is given in paragraph “3”, by clicking on it you will also need to set marks, but if you are replacing only the chain tensioner, then you do not need to set any marks, just turn the crankshaft “1-1.5” turns and that’s it !

4) After you have completed cranking the crankshaft, loosen the cap nut slightly to allow the tensioner to discharge.

Note! When the chain tensioner is discharged, you will hear a click and only then tighten the chain tensioner nut back!

How to change a shoe

You will need: “10”, “13”, “17” wrenches, a special wrench for the crankshaft pulley nut (or a “36” socket), a flat-blade screwdriver, a mounting blade, a hammer, and a bit.

1. Remove the engine splash guard.

How to tension a chain on a VAZ 2107

Before starting work, let the engine cool down. Many people believe that it is necessary to tension the chain when it is hot in order to compensate for its thermal expansion. In fact, an automatic tensioner is installed on the car, which copes with this. In principle, there is no difference at all; you need to let the engine sit so that the oil flows from the head into the crankcase or down the line.

Now let’s look directly at how to tighten the chain on a VAZ 2107:

This completes the tensioning of the chain on the VAZ 2107.

Characteristics of the VAZ 2106 chain drive

The function of the timing chain is based on the connection between the timing shaft and the crankshaft in the engine of the car. They are both equipped with sprockets with special teeth, due to which the chain is fixed. As soon as the engine starts, the above-mentioned shafts begin to rotate synchronously thanks to the presence of this chain. A violation of synchronicity against the background of any kind of circumstances provokes a malfunction in the functioning of the timing belt.

Malfunctions in the functioning of the cylinders are also possible, dips in engine power invariably form, fuel consumption increases significantly, and the vehicle itself does not respond well enough to activation of the gas pedal.

Classic VAZ cars are equipped with timing chains of the same length, the only difference is the number of links. As for model 2106, we are talking about a chain with 116 links with a length of 7.2 mm each. High quality alloy steel is used to make pins, which, thanks to this material, demonstrate increased wear resistance and strength.

Pros of the drive

Timing chain drive has been used for a very long time, but this does not mean that such a system is a relic of the past. Even today, due to its advantages, it is actively used by modern leaders in the automotive industry.

Among the advantages are:

- high resistance to any type of load;

- the ability to operate under conditions of noticeable temperature changes, as well as at extremely low or high temperatures;

- The operating life of the drive can reach 200 thousand km with proper operation.

Disadvantages of the drive

Along with the advantages, it is worth considering the disadvantages:

- the weight is significant, so the auxiliary elements of the mechanism must correspond to it in terms of quality;

- the noise during operation is quite noticeable, higher than that of other types of gears;

- replacing and tensioning a VAZ 2106 chain requires performing related procedures that inexperienced drivers may not be aware of;

- the forced use of compensating elements in the system significantly complicates the drive;

- the design is quite complex, which causes increased production costs; therefore, consumables and parts are relatively expensive.

The mentioned disadvantages cannot be called critical, since because of them there was no global refusal to use this mechanism. The classic VAZ auto industry to this day focuses on precisely this technology.

Consequences of a loose chain on a VAZ 2107

This applies to 2106 and all classics in general. First of all, the chain is manufactured with high precision and durability. This means that at the slightest jump of teeth, the engine will work at random. This is especially true for injection engines, since the crankshaft position sensor will give one reading, but in fact, the shaft will be in a completely different position. Moreover, jumping two or more teeth is fraught with the risk that the valve will punch a hole in the piston, and such a disaster will occur in all cylinders, and if, when the belt breaks, for example, the timing parts move simply by inertia, then in this situation they are still driven into movement from the crankshaft.

When to check chain tension

If you need to tighten the chain, it is not necessary to check the tension. It is enough to use a chain tensioner (this will be discussed below). Checking the tension is necessary if the chain has been replaced or if the chain continues to knock after tensioning. The knock of a loose chain is easy to distinguish from other noises: when the engine speed increases, it disappears.

To check this yourself, you need to open the hood and start the car. Then ask an assistant to press the gas pedal or independently pull the cable that controls the throttle valve with your hand. If the knocking noise at the front of the engine has disappeared, the cause is low chain tension. It needs to be tightened up.

How to check chain tension

The VAZ 2107 timing chain is located in the front part of the engine. It is closed on top by the cylinder head cover, on the bottom by the engine sump, the middle part runs inside the block and can only be reached by removing the chain.

To check the chain tension, simply remove the cylinder head cover. To do this, you need to unscrew the 8 fastening nuts. After removing the cover, the gasket must be replaced. It is inexpensive, but if this is not done, after installing the cover with the old gasket, it is almost guaranteed that oil will begin to ooze from under it.

When the "valve cover" is removed, the top of the chain is exposed. You can check the tension with your hands, but it is better to use a large screwdriver. It must be inserted between the chain and the cylinder block body and, using it as a lever, try to bend the chain. In this case, the chain should not bend. The tension must be checked on both sides - on the left and right sides of the engine. A chain that is taut like a string and does not bend when pressed with a screwdriver or fingers is a sign of its correct tension. Otherwise, it must be tightened or replaced.

Important: Do not apply too much force by pressing the chain as hard as you can. This can lead to deformation of the chain links. Therefore, it is necessary to press “half-heartedly.”

Timing phases and when to set them according to marks

Valve timing refers to those moments at which the piston in the engine moves up and down over a certain interval. When irregularities in the valve timing occur, the pistons move incorrectly along the interval, resulting in uneven engine operation on the VAZ-2107.

If the driver notices that the car’s power decreases, fuel consumption increases, and engine interruptions occur, then it is necessary to resort to setting the valve timing according to marks. How to set marks on a VAZ 2107 carburetor and injector, we will learn from this material, since the design of the timing mechanism is identical.

How to set timing timing marks

The procedure involves performing the following manipulations:

- The VAZ 2107 needs to be placed on a hard surface, with chocks placed under the wheels and the hand brake pressed all the way. The gear shift lever must be set to neutral mode.

- The cover is removed from the cylinder head by first unscrewing all the fixing nuts to “10”. It is better to replace the gasket with a new one, even if the old one shows no signs of damage.

- Using a key set to “24”, you need to turn the crankshaft on a VAZ 2107 car. This is done in order to be able to align the marks on the moving and stationary parts of the mechanism. To carry out these actions, it is recommended to use good lighting or use a flashlight. The crankshaft rotates until the mark on the pump and generator drive belt pulley coincides with the long mark marked on the block.

- Combining these risks, the mark on the sprocket should eventually coincide with the ebb on the camshaft bed. If the mark ends up at the bottom, then you should rotate the crankshaft 360 degrees.

- If you can’t make sure the labels match, then proceed to the next steps, which are described below.

- The crankshaft is rotated until the marks on the star and the bed ebb align.

- Using the key at “13”, you need to loosen the tensioner. The 2 nuts securing the tensioner are unscrewed, after which this device is removed.

- The bolt that secures the sprocket to the camshaft is unscrewed. To do this you will need to use the key at “17”.

- The sprocket is removed, after which it must be rotated until the marks on the VAZ-2107 timing belt pulley coincide with the long mark on the block. The star fastening bolt does not need to be unscrewed, since after removing the tensioner the camshaft star rotates.

- We put a chain on the sprocket, if it was decided to unscrew it, and install it in place. Finally, the tensioner is installed, for which you should tighten it with 2 nuts to “10”. You can install the tensioner first, but later you will need to use a crowbar or pry bar to get the sprocket into place. Finally, screw the tensioner nut to “13”.

This relative arrangement of the parts allows the piston of the 4th cylinder to be positioned at top dead center TDC.

Features of servicing the timing mechanism

After the timing marks are installed on the VAZ-2107, you need to perform the following actions:

- The timing chain of the VAZ-2107 is being tensioned.

- Adjusting the valves, or more precisely, the thermal gap between the camshaft cams and the rocker arm.

- Setting up the ignition system.

The process of adjusting the valves on the VAZ-2107 is carried out according to the following scheme: initially 6 and 8 valves are adjusted, the report must be carried out from the radiator. After they are adjusted, you need to start adjusting valves 4 and 7, then valves 1 and 3, and finally valves 2 and 5.

How to adjust the valves on a VAZ-2107 car can be found out in more detail in the relevant material on this site. In conclusion, it is worth noting that VAZ-2107 cars are one of the most reliable vehicles, the production of which began back in the 90s.

Annotation on setting up the ignition system of the VAZ 2107 with your own hands

The Zhiguli “classic” VAZ 2107 does not belong to modern cars, manufactured with the latest technology and stuffed with sophisticated electronics. This is its beauty - there is no need to contact car service specialists for any reason; most of the car maintenance work can be done by the owner himself. This also includes the procedure for the ignition option, which anyone can perform, having previously studied the detailed instructions.