Grow up everyone. And so, in this entry I would like to tell you how I got confused with the Solex 21083 carburetor. A lot has already been written about the Solex, a video has been shot and a very large number of solutions to certain problems. But perhaps I’ll repeat myself in my post. In this post I will try to tell you how I customized it for myself and my car. The recording is not a guide to action, since I am far from a carburetor specialist and two and a half years ago I only knew its approximate location under the hood. The goal was to optimize the work, namely, to make the idle times stable, to make stable work in transient modes, to achieve smooth dynamics over time, to improve performance in power modes. And so a little about the Solex 21083 device from Murzilka:

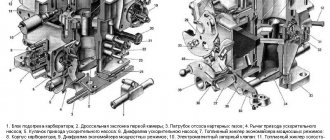

1. Carburetor heating unit 2. Throttle valve of the first chamber 3. Pipe for suction of crankcase gases 4. Accelerator pump drive lever 5. Accelerator pump drive cam 6. Accelerator pump diaphragm 7. Power mode economizer fuel nozzle 8. Pump housing 9. Economizer diaphragm power modes 10. Shut-off solenoid valve 11. Idle fuel jet 12. Carburetor cover 13. Main air jet of the first chamber 14. Air damper 15. Accelerator pump nozzles with fuel supply valve 16. Starter diaphragm 17. Starter adjustment screw 18. Adjusting screw for the amount of idle mixture 19. Locking lever of the second chamber 20. Pipe for supplying vacuum to the vacuum regulator of the ignition distributor 21. Adjusting screw for the quality of the idle mixture 22. Throttle valve control sector 23. Throttle valve drive lever 24. Adjusting screw for opening the throttle damper of the first chamber 25. Air damper control lever 26. Starter rod 27. Electrical wire of the limit switch of the forced idle economizer 28. Air damper lever 29. Main air jet of the second chamber 30. Emulsion tube 31. Sprayer of the main dosing system of the second chamber 32. Fuel supply pipe 33. Fuel drain pipe into the tank 34. Fuel filter 35. Needle valve 36. Second chamber throttle valve 37. Second chamber throttle lever 38. Second chamber main fuel jet 39. Second chamber throttle drive lever 40. Float

I would like to say that Solex was specially designed for cars with a transverse engine, specifically for the Samar family, and was also designed to operate the internal combustion engine on a lean mixture!

Cleaning.

All carburetors are cleaned only with a special liquid and then blown with compressed air. No brushes, rags or other crap. The holes in carburetors are sometimes very small in size, and a piece of thread that accidentally gets into the system can simply negate all cleaning efforts, and in rare cases, kill the carburetor.

So. I completely removed the carb from the intake manifold. I had difficulty getting the spacer out. Two rubber-metal ones and a heat-protective spacer. Everything is replaceable. The intake manifold was covered with a rag with processed edges (without threads or trash on the sides). Due to low mileage and high humidity, an emulsion got under the throttle from the breather, which led to a drop in idle speed at power modes. Actually, this was the reason for completely cleaning the carb and reconfiguring it. A push so to speak.

There are many different modifications of Solex carburetors, while the 21083 series is the basic version with a minimal diffuser cross-section. This model is usually installed on 1.5-liter engines of VAZ cars. We previously wrote about the “Ozone” setting on models 2106 and 2107.

The enormous popularity of this series is due to the possibility of grooving diffusers. Thus, almost any modification to the carburetor can be made. Experts do not recommend installing Solex on engines with a volume of more than 1.5 liters, as in this case the engine will be “choked” at high speeds. If you intend to configure this carburetor for the UZAM power unit, it is necessary to replace the jets due to the fact that a richer fuel mixture must be provided.

Possible problems when setting up XX

When the quantity screw is tightened, the engine does not react at all . This problem can occur when a large amount of fuel enters the idle diffuser. There may be several reasons for this:

- an XX jet of a larger size than necessary is installed;

- the plug or solenoid valve is not tightened properly, so gasoline is sucked in, bypassing the XX jet;

- The jet or its seat is deformed.

To identify the specific cause of the above problem, it is necessary to disconnect the wire from the valve while the engine is running, and the motor should immediately turn off. If this happens, most likely the wrong size XX jet is installed. When the engine does not stall when the power supply to the valve is turned off, it means that fuel is supplied bypassing the exhaust system, including the nozzle itself.

To eliminate the malfunction, first remove the plug or solenoid valve and check the condition of the nozzle and seat for any deformations. If the seat is damaged, you will have to replace the carburetor cover. If no damage or deformation is detected, put the jet on the solenoid valve and lubricate the o-ring with oil. Then we tighten the nozzle with a wrench, holding it with one finger without much effort.

Second chamber of the carburetor: purpose and principle of operation

Carburetors have been used in automobile construction for many decades. Often, single-chamber fuel distribution units were introduced into the design of carburetor units, which made it possible to provide the vehicle engine with stable and uninterrupted power. Over time, this operating principle definitely became outdated, and automotive engineers began to think about how to save carburetors in the modern field of mechanical engineering. One of the successful solutions was the introduction of two-chamber carburetors.

In general, the structure of such units does not have any special differences from single-chamber ones: the same float chamber, diffusers, fuel channels, jets, and so on. However, instead of one fuel mixing chamber, two or more are used, depending on the “chamber” indicator of the part. This approach to work, of course, marked a significant complication in the structure of carburetors and their settings, but components of this type will clearly have more advantages.

If we consider the operating principle of these fuel distribution parts, it is based on the formation of a fuel mixture in two chambers in the carburetor, which allows:

- connect one of the cameras for operation at high speeds (in this case, the second throttle valve will open more strongly or additional jets will be connected to operation);

- distribute fuel transfer between the cylinders more evenly and stably (as a standard, the first chamber always works, and the second is connected in specific situations);

- create the most optimized working mixture for work in different modes.

As a result, the presence of a second chamber helps to organize more economical operation of the motor with its fairly solid power. In addition, the modern organization of such units often has an economizer on the so-called forced idle, which also increases gasoline savings while the engine is running.

Today, the most popular samples of the parts in question are the Ozone carburetor, similar units from DAAZ, Solex and the “K” series of domestic spare parts. You can find out exactly what kind of fuel distribution mechanism is on your vehicle by studying it in detail from all sides; at a minimum, there should be some markings.

How to choose jets?

The selection of jets for Solex 21083 is made taking into account the engine size. Experts recommend starting the selection with a fuel nozzle for the first chamber. Having selected the desired sample, we select the corresponding air analogue for it. And then in the same order we select the jets for the second chamber. First you need to look for a factory carburetor designed for the size of your engine, remove the jets from it and take them as a reference point. Further selection of jets is made according to this principle. If you need to lean the mixture a little, choose a larger jet by one pitch. If you want to enrich it, use a smaller jet.

Carburetor overflows

“Overflow” on carburetors 2108, 21081, 21083 Solex and 2105, 2107 Ozone in VAZ cars 2108, 2109, 21099, 2105, 2107, etc. is a fairly common phenomenon.

“Overflow” is a strong over-enrichment of the fuel mixture entering the cylinders of a car engine, due to one or another malfunction of the carburetor and/or fuel system of the car. Sometimes even with the naked eye you can see how fuel leaks from the diffuser nozzles at idle, while a persistent smell of gasoline reigns under the hood.

Signs that the carburetor is overflowing

If the carburetor “overflows,” then quite often it is simply impossible to start the car engine (especially a warm engine); there are unstable or increased idle speeds, which often cannot be adjusted. When the engine is running, black smoke comes out of the muffler - a consequence of excess fuel burning out in it. “Disruptions” are possible when you press the gas pedal - as the rich fuel mixture floods the spark plugs. And the candles themselves are covered in black soot or even wet. The exhaust pipe of the car muffler smells of gasoline.

Reasons for carburetor overflow

First of all, when there is “overflow” on carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone of VAZ 2108, 2109, 21099, 2105, 2107 carburetors, you should pay attention to the operation of the float chamber:

— The needle valve is faulty (not sealed)

In some cases, it may simply “hang” in the open position (sometimes this can be treated by lightly tapping the carburetor cover with a hammer). You should also pay attention to how tightly the needle valve body is wrapped and the presence of an O-ring under it. The needle valve is checked by applying a vacuum to it.

Valve Inspection Articles:

“Carburetor needle valve 2108, 21081, 21083 Solex”,

"Carburetor needle valve 2105, 2107 Ozone."

Checking the needle valve with vacuum on carburetors 2105, 2107 Ozone, 2108, 21081, 21083 Solex

— “Broken” (not sealed) float

It drowns in gasoline and pulls the shut-off valve needle with it. It turns out that the needle valve is constantly open and gasoline is pumped freely into the float chamber. You should remove the float, shake it over your ear and determine by the sound whether gasoline is splashing in it or not. A “broken” float can be soldered, but it is better to replace it with a new one.

Carburetor floats 2108 Solex, 2105, 2107 Ozone

— The float touches the walls of the float chamber

Its position relative to the walls of the carburetor float chamber is disturbed. Remove the carburetor “cover” and look at the position of the float relative to the imprint on the cardboard gasket. Everything must be in parallel. Along the way, we check the ease of its movement, the levers and racks for deformation and distortion.

Aligning floats on carburetors 2105, 2107 Ozone, 2108, 21081, 21083 Solex

— Fuel level in the carburetor float chamber is too high

Remove the top part (“cover”) of the carburetor and check the fuel level in the float chamber. On carburetors 2105, 2107 Ozone level is in the middle of the inclined plane of the front wall of the float chamber. On 2108, 21081, 21083 Solex 29±2 mm to the bottom of the float chamber.

Fuel level in the float chambers of carburetors 2108. 21081, 21083 Solex, 2105, 2107 Ozone, after removing the cover - shown by the red line

If there are any deviations, we adjust the fuel level:

“Adjusting the fuel level in the float chamber of the carburetor 2108, 21081, 21083 Solex”,

“Adjusting the fuel level in the float chamber of the carburetor 2105, 2107 Ozone.”

In addition to problems with the float chamber, other elements of the vehicle's power system may also be the cause of fuel overflow.

— Fuel pump is faulty

There is its increased performance (the gasoline pump “pumps”), due to which excess fuel is pumped into the float chamber. This is especially true for VAZ 2105, 2107 cars, where there is no return line and nowhere to dump excess fuel. Check the serviceability of the fuel pump: its valves, return spring diaphragm.

Main elements of the fuel pump for VAZ (DAAZ) cars

Article on the topic: “Fuel pump malfunctions in VAZ cars.”

— The fuel drain line to the carburetor (“return”) is faulty

Only for carburetor 2108, 21081, 21083 Solex. The “return” may be clogged, deformed, or the check valve built into it may be faulty. With this malfunction, it becomes difficult to dump excess fuel back into the gas tank and it goes into the float chamber and then into the engine cylinders. It is necessary to visually inspect the return line for damage and blow it and the check valve in the direction from the carburetor to the gas tank.

“Return” and check valve of carburetor 2108, 21081, 21083 Solex

Article on the topic: “Cleaning the fuel lines of VAZ 2108, 2109, 21099 cars.”

— The rubber o-ring on the fuel channel of the idle system is damaged or missing

(for Solex carburetor)

In this case, fuel leaks out from under the cardboard gasket. The carburetor may be leaking fuel. Remove the top of the carburetor, check the presence and integrity of the rubber O-ring.

Rubber sealing ring on the connecting tube of the fuel channel of the carburetor 2108, 21081, 21083 Solex

— The economizer of the carburetor power modes is faulty

(only for carburetor 2108, 21081, 21083 Solex)

If the diaphragm in the economizer body is damaged, the fuel, which is not restrained by anything, flows through its channels under the influence of vacuum into the second chamber of the carburetor. The same situation occurs when the economizer valve ball sinks.

Economizer device for power modes of carburetor 2108, 21081, 21083 Solex

Check the economizer of the power modes of the carburetor: “Checking and repairing the economizer of the power modes of the carburetor 2108, 21081, 21083 Solex.”

— The air jet of the main metering system of the first chamber of the carburetor is clogged

The fuel mixture is re-enriched due to the reduction of air entering the carburetor. A larger diameter jet may have been installed. Remove the carburetor cover, unscrew the air jet of the first chamber, clean and blow it out.

Air jets GDS carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone (on Solex they are combined with emulsion tubes)

See “Signs of clogged air jets of the Solex carburetor.”

— The position of the carburetor throttle valves is broken

For example, due to an incorrectly adjusted drive, the damper of the first chamber may be slightly open. The same is true with the second chamber; the increased gap between the chamber wall and the throttle valve increases the vacuum and causes gasoline to flow out of the diffuser nozzle even at idle.

The throttle valves of carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone are completely closed (carburetors removed from the engine)

Adjust the position of the dampers:

“Adjusting the throttle valve drive of the first chamber of the carburetor 2108, 21081, 21083 Solex”,

“Adjusting the throttle valve drive of the second chamber of the carburetor 2108, 21081, 21083 Solex”,

“Adjusting the throttle valve drive of the first chamber of carburetor 2105, 2107 Ozone”,

“Pneumatic drive of the carburetor throttle valve 2105, 2107 Ozone.”

— The carburetor solenoid valve is not fully screwed in (fuel jet holder CXX)

Excess fuel flows into the gap formed between the fuel nozzle of the idle system and its seat. Tighten the valve. Its correct position is considered to be such a position when, when removing the wire tip from its terminal, the engine will stall. On carburetors with a plug, you only need to tighten the plug a little.

Solenoid valves for carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone

— The fuel mixture “quality” screw is turned out more than normal

Typically, enrichment of the fuel mixture by turning out the “quality” screw is carried out to compensate for the “sucking” of foreign air into the carburetor and to prevent it from becoming too lean (for example, at idle).

Adjusting screws for the “quantity” and “quality” of the fuel mixture of carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone

It is necessary to identify the place of “suction” of foreign air and re-adjust the idle speed:

“Adjusting the idle speed of an engine with a carburetor 2108, 21081, 21083 Solex”,

“Adjusting the idle speed of the carburetor 2105, 2107 Ozone.”

— Damaged carburetor gaskets

Through the resulting cracks, fuel is sucked into the mixing chambers by vacuum, significantly enriching the fuel mixture. Remove the top of the carburetor and check the integrity of the cardboard gasket. It is also worth checking the gaskets between the body and the throttle body (on Ozone) and the gaskets between the carburetor and the intake manifold.

Carburetor gaskets 2105, 2107 Ozone

— Wear of the rubber o-ring on the nozzle body

When you press the gas pedal, fuel will flow out not only from the nozzle nozzle, but also under the leaky rubber ring. At the same time, the operating efficiency of the UN decreases, as the amount of fuel passing through it decreases. Replace the ring with a new one.

O-ring for sprayer UN 21073

— The balancing channels of the float chamber are clogged

In addition, it is worth paying attention to the carburetor float chamber balancing system. Because if the balancing holes and channels become clogged, the pressure in the heated float chamber increases due to increased vaporization. The steam has nowhere to escape and they press on the needle of the float chamber shut-off valve, which opens slightly, allowing fuel into the float chamber. Accordingly, the fuel level increases, the fuel mixture entering the engine cylinders becomes over-rich, the engine with a rich fuel mixture starts with difficulty or starts and stalls.

“Ventilation system for the float chamber of the Solex carburetor”

“Balancing the Ozone float chamber”

Balancing the float chamber of the carburetor Ozone 2105, 2107

Notes and additions

— If at idle engine speed fuel flows from the diffuser nozzles, then most likely the reason for this “overflow” is described in the first five paragraphs above.

— Details of the overflow into the second chamber of the carburetor: “The Solex 21083 carburetor “flows” into the second chamber.”

Twokarburators VK - More information on the topic in our VKontakte group, on Facebook Twokarburators FS and on Odnoklassniki - Twokarburators OK

More articles on the site on carburetor malfunctions

— High fuel consumption of a carburetor engine of a passenger car (reasons, troubleshooting)

— A cold car engine does not start

— Insufficient power and throttle response of the car engine

— Reasons for low engine idle speed

— The engine “troits”

— Solex 21083 (2108, 21081) starter does not work

Standard reasons why the carburetor overflows

When the carburetor is overfilled, the following deviations can be visually observed:

- difficult starting of the engine, mostly hot;

- Unstable high crankshaft speeds at idle, which cannot be adjusted;

- black combustion products coming out of the exhaust pipe due to the combustion of excess gasoline in it;

- dips in the accelerator pedal when you press it, as the enriched fuel-air mixture floods the spark plugs;

- spark plugs wet from gasoline, covered with black soot (see what spark plugs look like when the engine is not operating properly).

Fuel level in the float chamber

Having noticed one or more characteristic signs of overflow, the car owner must immediately take effective measures to eliminate it. If the carburetor overflows, adjusting and adjusting the metering systems is most effective.

Air-fuel mixture dosage basics

“Overflow” of fuel in the carburetor on VAZ 2107 cars occurs quite often. The basis for such a malfunction, when the carburetor overflows, is a strong over-enrichment of the air-fuel mixture that enters the cylinders of the car engine. The cause may be any malfunction of the metering devices themselves or elements of the fuel system of the vehicle.

| Air/fuel ratio | Description | A comment |

| 7/1 —12/1 | Overrich mixture. Ignition failure. | Rich mixture. Long burning, low temperature. |

It is often observed in practice that at idle speed gasoline directly flows out of the diffuser nozzles. In this situation, the engine compartment space is highly saturated with a stable concentration of gasoline vapors. The carburetor overflows due to many reasons. The most typical of them will be discussed below.