Hi all! How unpleasant it is when, even with careful care, all sorts of chips, scratches and damage appear on the hood. It's a shame for those who put a lot of effort into protecting the body. Therefore, today’s material will be devoted to such a topic as protecting hoods from chips.

The main cause of damage to the hood is in front of you when you drive your car. This is gravel, sand, and wind-blown debris flying away from cars moving in front of you. In some cases, a large chip appears immediately, in others, the debris acts as an abrasive, gradually erasing and damaging the factory paintwork.

Today I will talk about how and with what you can protect the hood. In fact, all this applies to protecting the body from chips and scratches. I also advise you to read this material further.

Why do you need to protect your car hood?

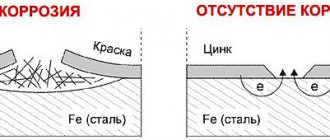

The technical condition of the car is the first and practically the main thing that its owner pays attention to and maintains during operation. Few people take sufficient care of the exterior of the car, including its body, although it is one of the most vulnerable elements. Over the entire period of operation, the surface of the car is subject to various destructive influences, which lead to the formation of chips, scratches, cracks and other defects. They can cause much more serious consequences - corrosion, which over time will destroy the metal of the body. The most vulnerable places are the bumper and the hood: it is they who collide while driving with stones, sand and other objects that fly out from under the wheels of the vehicle in front and cause damage.

Based on this, we can safely say that the car body requires reliable and high-quality protection that could protect it from scratches, chips and other damage, preventing their transformation into serious defects that threaten to destroy the integrity of the metal.

Film for car (reservation)

polyurethane film for hood

This wrapping process is called car lamination. The film itself has elastic properties, it is thin and practically invisible, since it is 99% transparent, due to this it remains invisible on the car body. Using such a film, you can provide the following protection to the most vulnerable parts of the car:

- Wheel arches and arch edges;

- Protection of the hood and front parts of the car;

- Bumper protection;

- Protection for headlights and side mirrors.

- Place near door handles and keys;

- Thresholds and lower part of the door.

anti-chip protective film for hood

When anti-gravel film is applied to fog lights or main headlights, the light dispersion remains the same. That is, it does not interfere with the transmission of light in any way. This film lays flat and completely conforms to the contours of the car parts. When removing the film, there are no adhesive residues on the covered part.

Anti-gravel film armor

Automotive services offer several types of anti-gravel films:

- Vinyl;

- Polyurethane;

Methods of protection

Additional body protection is installed only after all damage and defects on its surface have been eliminated. Minor scratches are buffed out, while chips and other defects that could lead to corrosion are removed and sanded. The treated areas are eventually painted in the color of the car body.

Deflectors

Mechanical protection of the hood in most cases means a deflector - a structure that changes the aerodynamics of the car, which redirects air flows that pass higher and prevent stones from colliding with the metal surface. The deflectors are made from high-quality plastic and are fastened with rivets - this installation method does not require drilling additional holes in the body. The color palette of such designs is huge - they can always be matched to the color of the car, so the product will not stand out and spoil the design of the vehicle.

Mechanical protection of the car hood - deflectors that protect the body from damage

Anti-gravel film

Polyurethane anti-gravel film is another way to protect the body from damage. It is cut out exactly along the contours of the part that needs to be protected and carefully glued onto it, leaving no marks. The film is as easy to remove as it is to apply, and it can protect the car from chips and scratches. Thanks to such a film, the impact energy from an incoming stone or debris is distributed over a larger surface and is quickly absorbed without causing harm.

Applying an anti-gravel film to the car body is another option for mechanical protection.

Body surface polishing

This method cannot be called complete protection - it is rather an option for eliminating small and minor scratches. Polish not only protects the paintwork, but also makes the body look brighter and fresher. The only disadvantage of polishing is that the applied product is quickly washed off - it is enough to take the car to the car wash several times.

Polishing a car body is a way to remove minor scratches and abrasions.

What is included in the motorist's kit: mandatory equipment

Ceramic coating can be considered a true innovation. Effective, impressive, but expensive. The hood protection level is the highest. After application, a ceramic shell effect is formed. The material is durable and wear-resistant.

There are also liquid films applied under high pressure. It is extremely easy to process the hood and edges. But you shouldn’t count on a long service life.

These are the methods of protection for the hood that I was able to cover. Do you know alternative means and methods?

Subscribe, leave comments, ask questions and tell your friends about our project!

Pros and cons of surface protection

Precise selection of car hood protection will allow you to fully realize all its strengths and protect the body from damage.

Strengths and weaknesses of deflectors

The undeniable advantage of the deflector is the method of its fastening - on latches that do not require making holes in the hood. High-quality and reliable models are installed using stickers and metal fasteners. When choosing a deflector, special attention is paid to its surface - it must be perfectly smooth, without chips or nicks, otherwise the car body will be hopelessly damaged. The ease and simplicity of both installation and removal of the deflector are another of its advantages, allowing the car owner to remove or return the part at any time.

A correctly installed deflector protects the car from damage to the body.

When choosing a deflector, it is necessary to apply it to the hood of the car - there should be a small gap between the surfaces, due to which the air flow necessary to protect the body is created. Most drivers, dissatisfied with the use of deflectors due to the appearance of scratches and chips on the hood after such parts, selected them incorrectly, which led to such sad consequences.

And yet, deflectors have their drawbacks - for example, deterioration in aerodynamics while driving. This is not far from the truth - such designs really have a detrimental effect on aerodynamic drag. However, in the conditions of domestic roads this does not play a special role - it is almost impossible to accelerate a car to high speed, but catching a couple of stones is quite possible.

Video: how the deflector works

Pros and cons of protective film

Automotive protective films are made of vinyl or polyurethane and are glued to the body using a special adhesive. They do not leave any obvious marks on the surface of the hood; moreover, they are practically invisible even in bright light. The most popular are polyurethane anti-gravel and vinyl protective films.

Vinyl film

This protective material is manufactured using casting technology. Vinyl is often used to cover the side surfaces of a car body, thereby protecting them from gravel, crushed stone and other objects that can damage the paintwork and metal.

Wrapping a car with vinyl film protects the body from minor damage

Advantages of vinyl film:

- The flexibility of the material allows you to cover almost all elements of the car body;

- Protection of paintwork from exposure to ultraviolet rays;

- Low cost compared to polyurethane film.

The disadvantages of vinyl film are its small thickness and strength, hardening under the influence of low temperatures. In addition, the material tears very easily, which can also be attributed to its disadvantages. At the same time, vinyl film is considered a universal protective material used for covering almost all elements of the car body.

Anti-gravel polyurethane film

This protective material is most often pasted over the front part of the hood, mirrors and bumper of the car. Compared to vinyl film, anti-gravel polyurethane film has several more advantages:

- High level of strength;

- Great thickness and density;

- Increased wear resistance;

- Long service life.

Wrapping a car with anti-gravel polyurethane film

At the same time, due to its increased thickness and density, polyurethane film cannot be used to protect elements with bends - it is not able to bend properly. To completely cover the surface of the body, cuts have to be made on the material. Anti-gravel film is not able to protect the paintwork from fading, since it transmits ultraviolet rays. The downside of polyurethane is that over time it begins to turn yellow.

Preparatory work

There are a number of requirements for how to properly cover a hood with carbon film. Booking is preceded by a preparatory period:

- The car undergoes a professional wash.

- The coating is thoroughly degreased.

- Damage is puttied, painted, dried.

A lighted, clean room is used to cover the hood and bumper with film. Work is carried out at a temperature of at least 17 degrees Celsius.

The master works in smooth overalls.

Methods for protecting the hood from chips

Polishes

Protective polishes for the car body, protecting it from damage and giving it an aesthetic appearance.

Protective polishes not only protect the car body from damage, precipitation and exposure to chemicals and ultraviolet rays, but also give the paintwork shine.

The service life of polishes may vary depending on their composition. For Teflon compounds, the service life is three months, while resin-based polishes protect the body for a year. This difference in timing is explained by the different reaction of the paint and varnish material with the composition of the protective substance.

Nanopolishing is considered the most durable and reliable: it keeps the paintwork intact for two to three years, while being resistant to chemical and physical influences.

Liquid glass

A protective composition applied to the surface of the car body and forming a durable glass film. This coating gives the car a mirror-like shine, protecting it from damage, repelling dirt, moisture and protecting it from environmental influences.

An unusual protective agent for the body - liquid glass made by Japanese Willson

Japan is considered the main manufacturer of liquid glass - they produce Willson composition, the service life of which is up to three years. In the climatic conditions of our country, the shelf life of glass is reduced to one year.

Liquid case

A protective substance applied to the car body and forming a dense film

. A protective substance applied to the surface of the body using a spray or brush and forming a film that protects the car from the effects of small particles and corrosion. The composition is applied to the surface of the body in three layers. This protection is resistant to atmospheric influences, is not afraid of sudden temperature changes and can be easily removed - just roll the material.

However, such a protective composition has its drawbacks: a short service life - no more than 10 days, an unattractive appearance and the harmful effects of moisture, which forces the film to peel off.

Protective case

The simplest and most cost-effective way to protect the body from damage.

The simplest and most common way to protect the body. However, using a leather case has its disadvantages:

- The cover must be selected for the specific make and model of the car;

- There should be no moisture, dirt or debris between the car body and the cover, otherwise such proximity can lead to corrosion and rust.

Tent for Gazelle with advertising: how to get it for free for your car

These include the following solutions:

- ceramic coating;

- liquid rubber;

- liquid film.

Liquid rubber is called an innovative method, but you can use it yourself. It is created on the basis of a polymer-bitumen emulsion. Must be applied by spraying. After application, the surface becomes elastic, strong and durable. The easiest way to apply the product is with a spray can. Usually 2-3 layers are enough. A very common type of anti-gravel for cars.

Damage and chips

As the vehicle is used, various damage to the protective paint coating may appear on its body:

- Minor scratches on the top layer of the coating that do not affect the base layer. They can be eliminated by polishing the body with polish, pencil or wax.

Minor damage to the body, which can be removed by polishing - Medium depth scratches on the top layer. They are removed by painting the damaged area.

Damage eliminated by painting the area - Scratches down to the ground layer. With a pencil you can remove only those of them that are not very wide. The remaining damage is either painted in two layers or eliminated locally with restoration of the body geometry.

Defects that can be eliminated by painting in several layers - Scratches reaching to the metal of the body. They are eliminated by priming the damaged area and then painting it in three layers. The primer is applied very thinly so that the area does not stand out.

Can be removed by priming and painting damaged areas - Scratches on the surface of the bumper. Such defects are painted over with a repair balloon.

Painted over using a repair paint can - Scratches that cause rust and corrosion. The damaged area is cleaned of paint and primer using special means, after which it is re-primed and painted.

The most complex defects eliminated using special anti-corrosion compounds - Chips. If the defect affects the metal, then it is painted over, if only a primer, then it is polished.

Chips of paint on a car hood that can be removed by painting or polishing - Bubbles of paint. They are removed by painting the area in several layers and polishing it.

Bubbles in body paint that can be removed by polishing or repainting

Equipment for gluing procedure

To apply film to the hood you will need the following set of tools:

- spray guns - they are needed for additional funds required for the pasting process;

- hair dryers for working with film - when the film is heated, it will lie better on the surface, without the formation of bubbles;

- magnets and Velcro - necessary to hold the film on the selected area before covering it;

- paint rollers - will simplify the application of film to the surface and leveling of large pieces;

- degreaser - will simplify cleaning the hood surface before pasting;

- cutting tapes and knives - for easily dividing the film into certain areas.

Wax or various types of polishes are usually spread by hand to ensure even application.

How can they be removed?

Removing damage from the surface of a car body requires the use of special tools. Today, automobile stores offer a wide range of similar compounds, differing in composition and price. To choose the right product, you need to know what they are all intended for and which one is best suited for a particular car.

Selection and comparison of funds

Abrasive polishes are used to remove small stains and scratches from the body surface. They contain special substances that have cleansing properties - marble powder, clay and other components. It is thanks to them that a polished car acquires a noble appearance and a mirror-like shine.

A type of polish designed to remove minor damage from the body

After polishing, experts advise covering the surface of the body with varnish - it protects the coating, maintains shine and protects against corrosion for a long time.

Another type of damage repair product is wax. They are used most often due to their affordability. Despite the fact that they give the car an attractive appearance, they can only be used to eliminate minor scratches and imperfections in the paintwork, nothing more. Another disadvantage is that they are washed off the first time you wash the car. The most expensive and high-quality wax polishes stay on the surface of the body for a maximum of two to three visits to the car wash.

Wax compounds are one of the types of means for eliminating body defects

The third type of compounds for removing chips and scratches is synthetic compounds. They differ in their composition, and are therefore divided into three categories:

- Cleaners. They contain synthetic components that remove old paint layers and minor scratches. The result of treatment with such compounds is noticeable immediately. Cleaners are divided into two types, one of which is used for metallic paints, and the second for all other types of paints. After treatment with such compounds, the surface of the body is covered with varnish or other protective composition, which will preserve the shine of the body for two to three weeks.

A protective agent that removes traces of minor scratches, dirt and tar from the hood of a car. - Polymer compositions. Remove deep damage from plastic parts. Perhaps the most common type of product due to its advantages and properties: all defects are removed from the plastic and the body is protected at the same time. The second advantage is the durability of the coating: the shine of the body remains for two months even if the car is washed frequently. However, such polishing also has weaknesses: the process is too long and the cost of the product is high.

Designed to remove damage from plastic parts - Silicone polishes. Similar to wax products, the additional advantage is that they are low price and easy to apply to the surface of the body. The downside is the fragility of the coating.

Removing minor scratches

Surface polishing

- Before carrying out work, the car body is thoroughly washed and wiped dry. The location of all defects and problem areas - scratches, dents and chips - is noted.

A mandatory step before polishing the body is washing - Rust and dirt are removed from damaged areas. The polish is applied in a thin layer with a soft, clean sponge in a circular motion. The layer dries completely in 10–20 minutes.

Manually or automatically apply a layer of polish to the body in a circular motion - The surface treated with the composition is polished with suede or soft cloth until shiny. The remaining scratches are removed in the same way.

Rub the polish with a soft cloth until it becomes shiny. - You can remove polish from car body parts using a regular cleaner.

Video: polishing a car hood

Using wax or pencil

Minor and shallow scratches of the paintwork material are eliminated by treating with wax or pencil. Damaged areas are pre-cleaned and degreased - for this you can use gasoline or white spirit.

A pencil that can be used to remove scratches from the surface of the body

Pencil or wax is applied to the damage in several layers and then dried. The disadvantage of such products is their short service life: periodically they need to be renewed in defective areas or a layer of paint must be applied over them.

Primer and surface painting

Deep and serious chips can only be removed by priming and painting the body. Damaged areas are prepared in a similar way - cleaned and degreased.

- A layer of primer is applied over the cleaned chips. The composition used may vary depending on the nature of the damage. The layer of primer applied must be very, very thin; The product is applied with a rubber spatula and dried completely. The treated area is cleaned after the primer layer has dried. Scratches and chips are covered with an anti-corrosion primer if they are affected by rust.

Priming car body damage before painting - Painting is done over the primed area. The perimeter of the damaged area is covered with protective film or masking tape, after which paint is applied. Spray it in several layers to obtain a better and more sustainable result. Painted areas must be completely dry before polishing.

Painting damaged areas of the body using a spray gun - The last stage of processing is local polishing of the body.

The last stage of repairing body damage is polishing it.