Electronic carburetor control in its standard version has several components, among which the most important role is played by the solenoid valve. This element of the fuel distribution mechanism is responsible for stabilizing and fine-tuning the idle speed of the engine, which ultimately allows the owner of the carburetor unit to save tens of thousands of rubles on fuel annually. We will talk in more detail about what this miracle unit is, how it works and what kind of breakdowns it is susceptible to in the material presented below.

Operating principle

To determine the cause of the problem and take action to troubleshoot the EPHH, you need to know about the principle of its operation.

- The economizer is equipped with output and input circuits.

- The input circuits are a limit switch and a wire that connects to the switch.

- The throttle (throttle) limit switch tells the economizer whether the gas pedal is depressed or not at that particular moment.

- If the pedal is not depressed, the limit switch closes to ground.

- As soon as the gas pedal is pressed by the driver, the contact is switched off.

- The wire that connects the switch and the economizer reports the number of pulses to the ignition coil. In fact, due to this, the economizer is able to find out about the actual current speed of the power unit.

- The EPHH has only one output circuit - the XX solenoid valve of the carburetor system (XX - idle speed). The economizer can turn this valve on and off.

- Fuel economy is ensured by closing the XX fuel jet at high engine speeds.

- If the gas pedal is not depressed, the throttle limit switch closes to ground, the speed is less than 2.1 thousand per minute, then the economizer opens the XX solenoid valve.

- When the gas pedal is depressed, the limit switch opens, leaving the valve open anyway. The valve closes only when the engine speed exceeds 2.1 thousand per minute.

- The valve is in the closed position until the speed drops below 1.9 thousand per minute.

If the car is coasting with the gear engaged and the accelerator pedal released, the EPHH will not turn on, even if the revolutions drop below 1900 per minute. The economizer monitors the closed position of the damper. If the engine speed at idle is too high, it is perceived as coasting.

Actually, this is all you need to know about the operation of such an element as EPHH.

Practice and research show that the use of an economizer allows you to save about 5 percent of engine consumption.

Symptoms of a problem

There are several main signs indicating failure of the EPHH:

- The engine regularly stalls at idle;

- Detonation occurs in the engine when the ignition is turned off;

- The engine stalls when coasting braking is performed.

You can check whether the EPHH and its control unit are working correctly with your own hands. To check the valve, you should monitor its activation in various operating modes. Correct operation is determined by ear or using a voltmeter.

Valve check

There are three main steps to checking the functionality of the solenoid valve.

Verification method

Your actions

Basic operating mode of EPHH

Engine braking mode

Fuel cut-off when ignition is turned off

In addition to the solenoid valve itself, you should also definitely check the EPHH control unit.

Plus and minus

Checking the control unit

To check the control unit of the solenoid valve of the carburetor VAZ 2109 you will need a wire. The length of the wire should be such that it is sufficient to connect the valve to the positive terminal of the battery. Plus, you will need a standard voltage control light.

Your steps when checking the control unit will look like this.

- Disconnect the power wire from the valve without interfering with the operation of the carburetor itself. After this, connect the valve via the prepared wire to the positive terminal of the battery.

- The supply wire of the solenoid valve, which you disconnected in the previous step, must be connected to the positive terminal of the control lamp. The minus connects to the mass.

- Turn on the engine and let it idle for a while. The crankshaft should rotate at a speed within 850-900 rpm. The control lamp should light up.

- Begin to gradually increase the speed, reaching 2100 units per minute. If the control unit is working properly, when this level is reached, the light will go out. Reducing the speed again to 1900 units per minute, the lamp should light up.

Useful diagram

If a malfunction was discovered during the check of the valve and its control unit, it will be necessary to replace the corresponding failed components of the carburetor power system of the VAZ 2109.

Fault diagnosis

Many people who are not particularly savvy in the auto repair industry often ask the question: “How to actually check whether the solenoid valve and its control unit are working or not?” There are no particular difficulties in this, but there are a number of basic nuances. In order for every reader of our resource to understand exactly how to identify problems with EPC, our resource has prepared a step-by-step diagnostic algorithm. In general it is as follows:

- First you need to find the place where the economizer is located specifically on your make of car. It often looks like this;

- Then start the engine, drive the car, turn it off and analyze its operation at idle. If the XX fails at all stages of engine acceleration, first of all it is worth checking the solenoid valve;

- Next, when the engine has cooled down, you need to start it again and disconnect the EPHH from the carburetor by carefully removing the corresponding terminal with tweezers. After which it is worth observing the operation of the engine. If everything is normal and the economizer rod (needle) has moved out, then it is unlikely to be faulty. In this case, most likely there is a problem with the main idle jet or other carburetor components. If the rod does not extend and the car quickly stalls after turning off the economizer, then the latter is faulty;

- Now you need to remove the EPHH from the car and connect it to an alternative power source (for example, directly to the battery). After 10-120 seconds, the rod of the operating economizer should extend and make a characteristic click. If this happens, but when connected to the car’s network, the EPHV needle does not extend, then either its control unit or the valve wiring is faulty. If the rod remains in place in both cases, then the economizer needs to be changed, or even attempted to be repaired.

Do not forget that the final malfunction of the solenoid valve can only be determined if all other carburetor components are guaranteed to be in good working order. Under other circumstances, specific conclusions should not be drawn.

This concludes, perhaps, the most important information on the EPC of modern carburetors. We hope the material presented above was useful to you. Good luck on the roads and in repairs!

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them

Video - Installation of the EPHH system

An increase in fuel consumption can be due to many factors, including improper operation of the EMR. If the valve spring is weakened or broken, the economizer valve will be constantly open, re-enriching the air-fuel mixture. When the gas pedal is fully pressed, this increases engine power, but in other modes, on the contrary, it leads to a drop in power. Because of this, the driver is forced to press harder on the gas, which further increases fuel consumption. If the EMR diaphragm has lost its seal or the cap is not tightened properly, gasoline will enter the intake manifold below the throttle valve and also leak out. The latter is especially dangerous because it can cause fuel to ignite.

Operation and repair

The VAZ 2109 carburetor, like all other parts, tends to break. Typically, a breakdown involves the failure of any spare part. In such cases, repair usually helps.

The first thing that can break is the accelerator pump. Its purpose is to enrich the fuel mixture, regardless of the air supply, when the throttle valves are opened. If, when you sharply press the gas pedal, the car jerks, it means that there is either not enough fuel, and significant gaps occur in the supply, or, on the contrary, there is too much of it, and it overflows the spark plugs. So, to avoid this problem, an accelerator pump is used. It regulates the exact amount of fuel required for normal engine operation, even when the gas is pressed hard.

The accelerator pump more often becomes clogged with sediment than breaks down, and then repairs are not needed, but simply cleaning is enough. But, if this is not the case, but there is still a breakdown, then the pump needs to be repaired urgently, otherwise operation of the engine of the VAZ 2109 car will be impossible, and you are guaranteed to have pedal failures.

The first symptoms that the pump is faulty is that when you press the pedal, the speed does not increase steadily, but floats. This is due to a shortage, or vice versa, an excess of fuel. The spark plugs do not have time to burn out all the gasoline, and they are simply flooded, so the car jerks while driving. Also, the pedal may fail when pressed.

Repair for such a breakdown is as follows:

We take out the sprayer; Shake it. If there is a characteristic knocking sound of the ball inside, then the sprayer is working, if not, then this will be the reason why the pedal failed; The pump has a rather heavy structure with parts. A large number of holes and channels increases the chance that the pump will clog, and pedal failure will be inevitable. If the holes are clogged, then repairs are not needed. You just need to buy carburetor cleaning fluid and use it to blow out the channels.

Scheme of operation of EPHH

If the VAZ 2109 jerks when idling, and there are dips when you sharply press the gas pedal, then the EPHH control unit has a malfunction. Its repair primarily depends on which control unit is installed. They can be 4 or 6 pin. Repair of EPHH must be carried out by a specialist. If you do not have the appropriate knowledge, simply replace the part with a new one.

The reason that the VAZ 2109 jerks when driving, or even stalls, and when you press the gas pedal, failures occur, may be not only the carburetor or the EPHH control unit, but also the spark plugs. When used for a long time, carbon deposits appear at the contact site. Because of it, the spark plugs do not completely burn out the fuel in the cylinder.

Sometimes the spark plugs flood even at idle. This is due to the fact that the EPHH control unit is selected incorrectly. The valve opening does not occur synchronously, and the engine speed fluctuates. At the same time, gas pedal failures and late ignition are observed. In order to understand which EPHH is better to install, you need to decide on the choice of carburetor jets. The type of device depends on their diameter.

Replacing spark plugs

In general, before repairing the carburetor, make sure that the speed is fluctuating precisely because of it. Also, gas pedal failures occur for this reason. After all, maybe the candles are to blame for everything. If they are flooded, the car will jerk and stall. But in this case, the cause must be sought in the fuel lines, pump and similar components. But this is better than repairing the carburetor, since this work is quite painstaking.

Didn't find the information you are looking for? on our forum.

Economizer malfunctions

Like any other component, the economizer is subject to wear and breakdown. Signs by which you can determine its malfunction:

- Regardless of engine heating, interruptions occur at idle speed;

- A warm engine does not start well;

- Unreasonably high gasoline consumption;

- A double sign - both consumption has increased and power has decreased. This is especially noticeable when driving in mountainous areas;

- The power mode economizer “sweats” gasoline (typical for a Solex carburetor)

Any of these signs indicates a malfunction of one of the economizers, but only if the other engine systems are in good working order.

Unfortunately, economizers cannot be repaired; to replace them you will have to buy a new one. Some manufacturers produce spare valves, for example, for a Solex carburetor, but DAAZ offers to purchase a whole carburetor. However, given the huge number of engines produced, finding a used carburetor with a working economizer is not difficult.

You shouldn’t immediately run for a new (or serviceable used) spare part. In most cases, a little adjustment helps, or even just cleaning the moving parts of the device. You need to regularly inspect and analyze the operation of economizers, then you will not encounter sudden breakdowns.

Once you understand how the economizer works, you can easily restore the problem unit if there is no damage inside the housing.

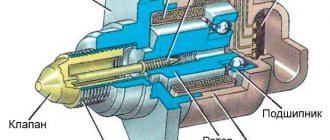

Carburetor economizer device

The unit is designed as a separate module in its own housing. The actuator is located inside and cannot be serviced. On the outside is the electrical part with the connection connector contacts, on the inside (located in the cavity of the carburetor chambers) is the valve head. If the economizer has a mechanical drive, there are no connection wires.

It serves to control the fuel supply. The control module receives data from various sensors (the system works almost like an injector), and, based on the installed factory program, gives commands to the actuators. Accordingly, the mechanical unit operates when the conditions for actuation of the drive are created. The following types of devices are installed on most carburetors:

Forced idle economizer (abbreviation: EPHH)

The device is designed as a technical development of the idle air valve. At the same time, it also has unique functions. The valve can completely shut off the flow of fuel through the idle jet. The control controller receives two signals: a certain number of crankshaft revolutions, and the absence of movement of the accelerator pedal. The system allows you to significantly save fuel when braking the engine. Compression of the cylinders dampens the crankshaft speed, while gasoline does not enter the combustion chambers. Accordingly, there is no negative effect when unburned fuel enters the muffler and burns there. Previously, drivers switched to neutral gear to save money on long descents. This is unsafe and also causes the car to overheat and wear out the brakes. In gear driving mode, car control is more predictable, and there is always the opportunity to slow down with cold pads, which cannot be done when coasting.

When communicating with professional service technicians, you may hear the abbreviation EMV (solenoid valve). This is a slang name for EPPH.

The photo shows how the EPPH is located and how to dismantle it.

Power mode economizer (EMR).

Technically designed like a vacuum regulator. It operates in mechanical mode, which makes it reliable and easy to maintain. The economizer diaphragm ensures a normally open valve (based on the principle of electromagnetic relays). Only instead of a coil and a core, a ball and a spring are used.

The location and components of the EMR can be seen in the illustration:

An open ball valve allows gasoline to pass freely through the nozzle channel. Under moderate loads, a natural vacuum occurs in the carburetor chamber, driving the economizer membrane (diaphragm). This force is greater than the resistance of the ball spring. The additional flow of gasoline stops, resulting in fuel savings. When you press the accelerator harder, the vacuum decreases and the membrane goes into rest mode. The system again opens an additional flow of gasoline, providing additional power pickup due to forced enrichment of the mixture.