Any car owner knows that there is a zero-resistance filter to replace the standard engine air filter, which provides an increase in engine power. However, there are many controversial issues due to which the vehicle owner does not dare to carry out such tuning.

Zero resistance filter

Zero resistance filter: what is it?

Air contains many mechanical particles and chemical compounds. First of all, dust that gets into the engine cylinders can damage it. To prevent possible breakdowns, the air must be purified. This requires an air filter that performs mechanical cleaning.

Engine power depends on the amount of air contained in the working mixture. The more air is filtered, the less air enters the engine, and the more power is reduced. Standard paper filters have much greater air resistance because they are made of very dense material. As the filter gets dirty, the pores become clogged, and it generally stops letting anything through, greatly increasing the air resistance.

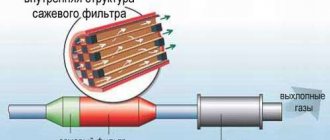

Its filter component has several layers of cotton fabric impregnated with a special mixture and installed between an aluminum screen. It allows almost unimpeded air flow into the engine. Dirt particles settle on the filter fibers without reducing its throughput. The zero-resistance filter is called that because it practically does not prevent the penetration of air into the intake. Moreover, this property of the “nulevik” does not affect the quality of cleaning. It is for this reason that it is installed on sports cars.

An important component that can extend the service life of the engine

This is a theory. Practice says that the engines of modern cars have such a component, a part, as an air filter. Through which the air passes to form a combustible mixture in the engine. The air passing through the filter is cleaned of dust and abrasive particles. However, like any medal, this one also has a downside. And it lies in the fact that an ordinary, standard paper filter becomes an obstacle to the air flow. This leads to a drop in engine power. Not so much that it is very noticeable, but to a certain extent such a decline is present.

Relevant, first of all, for sports and forced engines.

For standard engines, such a drop is not only not scary. It may even be imperceptible. However, if, say, a car enthusiast spent money on tuning the engine of his car, preferring a sporty style and driving style, then in this case, as they say, every “horse” counts. And then the resistance of the standard air filter becomes a serious obstacle.

How does it work?

For full operation of the internal combustion engine in any vehicle, a sufficient amount of air is required. For this purpose, the engine takes air masses from the atmosphere. However, the air around us is not famous for its cleanliness, for this reason foreign objects (dirt, dust, fluff...) can get into the internal combustion engine, which can cause great harm. To avoid the above process, an air filter is used, which protects the engine from particles of dust, sand and other objects. Factory filters provide an impenetrable barrier to these types of substances, but at the same time they greatly impede the penetration of air at the inlet. In addition, the standard filter gradually becomes clogged, resulting in less engine power.

The zero filter has pros and cons that are very different from the standard one. Firstly, it does not interfere with air intake, thereby the internal combustion engine “breathes deeply” and works without interruption. This is most noticeable at high speeds, because this is where the most air is required. A standard filter cannot cope with such a task at high speeds due to its characteristics.

However, the main task for an air filter is not throughput, but to create a barrier to protect the internal combustion engine from foreign objects. As a rule, zeros are made of synthetics or cotton, and the layer is made as small as possible.

This ensures minimal resistance to air masses at the entrance to the intake manifold.

How to install zerovik?

You can install a zero-resistance filter on any vehicle with an internal combustion engine; now universal products are produced that allow you to install a zero-resistance filter on any type of engine.

Installation can be performed without the help of specialists; the procedure is very simple and does not take much time. The algorithm of actions is quite simple: remove the standard filter and install a new one. When installing a universal product, you will need to dismantle the standard air filter housing, but this will not be a big problem either.

Zero Resistance Filter Parts

It is very important to maintain the tightness of the pipes, this will prevent foreign objects from getting into the engine. In addition, it is worth focusing on the location of the filter. When installing a sports one with a flexible pipe, you should secure it away from heat sources (the hotter the air, the more discharged it is). This will allow the maximum amount of oxygen to enter the combustion chamber.

Pros of a zero resistance filter

So, let's list the main advantages of a zero resistance filter:

- Firstly, this is an increased power factor without reducing the quality of air purification. The filter has a more complex design that guarantees low resistance, but at the same time effective filtration, protecting the piston system from wear and the intake system from clogging.

- Secondly, there is no need to change the filter every 15 thousand km. The cleaning component is easily washed with a special liquid, after which it acquires its original properties.

- Thirdly, the zero-resistance filter produces a characteristic sound typical of racing cars and a few additional “horses”. And at medium and low speeds torque appears.

It is worth noting that in order to obtain a noticeable increase in power characteristics and torque, you should remove the standard air filter housing complete with a filter cartridge and install a cone filter - zero, which is selected in accordance with the mass air flow sensor or on the pipe connected to it. with the diameter of the seat.

Disadvantages of a zero resistance filter

As they say: “It’s not all Maslenitsa for the cat.” Unfortunately, the zero-resistance filter also has a number of disadvantages that can cover all the advantages of this product. We list the main ones:

- The zero resistance filter requires regular maintenance.

- The cost of a high-quality zero filter is several times higher than the price of a conventional filter.

- The driver practically does not feel an increased power of 5-6% when installing a zero-resistance filter, since physically a person cannot perceive a difference in power of less than 5 horsepower.

Advantages and disadvantages

From all this, we can draw the following conclusions about what pros and cons the nulevik has:

- A zero-resistance filter increases the power of an internal combustion engine by 3–7% due to low resistance;

- Easy to install and remove filters;

- Under the hood, the zero-resistance filter does not take up as much space as a standard one;

- The work resource is significantly greater compared to the regular one.

However, we should not forget about the disadvantages.

- A tuned vehicle will need more maintenance. You will need to purchase special impregnations with which you can clean the filter;

- The zero filter is inferior to the standard one in terms of price.

However, if we are talking about “dry” zeros, then there is no need to purchase additional impregnations.

There are also “wet” zeros, their filtering capacity is somewhat higher, but they also require more care. If engines are equipped with film sensors, then it is better to purchase such a zero-resistance filter. However, special aerosols are required to impregnate this type of air filter.

Types of “nuleviks”

Zero filters use cotton fabric as a filter element, which is softer in structure than cellulose and does not provide high resistance to air suction. The screen canvas is folded like an accordion, which increases the filtration area.

To increase the effect, manufacturers use special impregnation of the filter screen. A viscous medium is better at trapping the smallest dust particles. Today manufacturers offer two design options:

- dry;

- with impregnation (“wet”).

The location of the filter is not in the normal place.

Filter material in a dry design reduces motor power by 1-1.5%. The impregnated filter provides almost zero resistance and returns lost 5-7% of power to the engine. The cotton screen is impregnated with a special composition, which must be renewed every 2,000 - 3,000 km.

Installation methods

There are two options for installing the element:

- standard, using the factory box;

- separately.

A separate air filter is produced in the shape of a cone and is installed instead of the standard element. The part is secured with a clamp on the inlet pipe, and the unit is attached to the body through a metal bracket. Most manufacturers recommend purchasing filters that have a separate installation, promising a power increase of up to 7%.

Drivers note that practically, after installing the “nulevik” in a separate place, the car’s power does not increase. This is due to the fact that the filter takes air from the engine compartment, where it has a low density due to heating from the running engine. The hot air that enters the “nulevik” contains 39% less oxygen than the air that enters the filter installed in its original location.

“Nulevik” for installation in a regular place

Standard installation involves replacing the factory filter with cellulose screens with a new one, without changing the insertion location. The standard factory element has the shape of a box; air is taken from below the engine or near the wing, where the temperature is 3 times lower than above the internal combustion engine.

Replacing a standard part with an improved one allows you to increase engine power, but not by 5-7%, as manufacturers claim, but by 2-3% after checking the car on a dynamometer stand.

Is it worth betting

Experienced drivers are clear in their conclusions - a zero-resistance filter will help increase power and reduce acceleration time only for a sports car with an engine power of more than 270 hp, since the real engine performance after installing the zero-resistance filter increases by no more than 2%.

For daily trips, the difference of a few “horses” does not matter; the cost of a dry filter is 10 times higher than the price of a factory filter, while fuel consumption is reduced to only a few tens of grams per hundred kilometers.

The impregnated filter must be systematically cleaned, lubricated and reinstalled. This takes a lot of time, the price of impregnation liquid is from 500 rubles per aerosol can.

Service

To maintain the increase in power, you should wash the filter from time to time. To be more precise, it is advisable to clean the filter components every 500-1000 kilometers.

Nothing complicated: clean, rinse, soak, or filter maintenance

How to maintain a zero-resistance filter so that the effect from using this part is maximum? In fact, everything looks like this. The fabric part of the removed filter must first be “dry” cleaned with a clothes brush, removing large foreign particles and contaminants. Then the filter should be soaked with the same notorious “rinsing”. Then, leaving some time for soaking, rinse in water, without being particularly active, however. You need to wash lightly, under a weak stream.

After this, the zero-resistance filter should be thoroughly dried (usually left overnight, but far from heating devices, the part needs to dry completely on its own). Then you should again saturate the fabric part of the filter with the remnants of the “rinsing” so that no light spots remain (that is, quite thick), and only then put it back in place.

The procedure for cleaning and rinsing the filter may differ slightly depending on the treatment product purchased, and the instructions on the package will be your most faithful assistant. The manufacturer always indicates how to properly rinse and saturate the filter with its product.

In fact, official bench measurements suggest that the zero-resistance filter increases engine power by several horsepower at once (about 3 - 7). However, you can’t just feel this offhand with an ordinary production engine. Therefore, installation and, most importantly, maintenance of this part, namely cleaning and washing, is most likely relevant for forced engines, when even the slightest possibilities for increasing power are valued...

Caring for dry zeros

First of all, they must be cleaned of foreign objects; dirt and dust should not linger on the filter for long, as this weakens the throughput of the product. A soft bristle brush or a regular toothbrush is best for cleaning. After this, you should use a special washing liquid, most often it comes in the form of a spray. Next, you need to wait 15 - 20 minutes, then run the soaked filter under a stream of clean water. It is not recommended to wash the filter with tap water. After the filter has been washed, it must be dried. Hair dryers and other household appliances should not be used. After the filter has dried, you can put it back in place and continue to use it.

Caring for wet zeros

The maintenance process for wet filters is practically no different from dry filters. There is only one difference. After all cleaning of the nulevik, it is additionally impregnated with a special liquid, which provides a barrier to foreign objects.

How to care for such filters?

As already mentioned, one of the main disadvantages of the filter is the need for regular maintenance.

After purchasing and installing the product, it must be washed and treated regularly. In this case, processing according to the “remove-wash-install” principle will no longer work - a special algorithm is required here.

The frequency of washing is every 5-6 thousand kilometers. If the car is operated in dusty areas or off-road, then the filter must be cleaned more often.

If you forget about servicing the device, the machine becomes “gluttonous” and “dumb.”

The algorithm of actions is as follows:

- remove the zero filter from the machine and remove all dust from it using a special brush;

- Wash the unit in a special container with a special cleaning solution, then rinse the filter under water pressure;

- shake off the filter element and inspect it. If there are light spots, the filter needs to be impregnated with a special agent;

- treat the product with a special impregnation (as a rule, it is sold separately from the “nulevik”);

- return the “zero” to its original place.

There are even special kits for caring for “nuleviks”, which include washing and impregnation. A few manipulations as described above, and the product looks like new.

Please note that the total number of washes can be limited and is about 20 pieces. After this, it is worth installing a new filter.