The adsorber began to be installed on the Lada Granta for the first time since its release in 2011.

Adsorber

The equipment is designed to absorb and redirect the flow of gasoline vapor back into the fuel tank. This prevents fuel from entering the intake manifold.

During operation, the product wears out and often fails. Increased fuel consumption is the first sign of a malfunctioning adsorber.

Let's consider the algorithm for replacing the canister purge valve on the Lada Grant on our own.

Where is the canister purge valve located on different modifications of the Lada Granta?

Regardless of the modification of the power unit (8 and 16 valve), the sensor is installed in the upper left part of the engine compartment. Closer to the drive belt.

In the 16-valve engine version, the top of the engine is covered with a decorative plastic cover. Before starting work, carefully remove the decorative element and begin the repair.

Sequence of actions when replacing the adsorber purge valve with your own hands

- We place the car within the perimeter of the repair area, install wheel chocks, and activate the parking brake.

- We open the hood, the engine cools down to a safe temperature so as not to damage the skin.

- An adsorber valve is installed in the upper left part of the engine compartment. Carefully pry up the block with wires with a screwdriver and remove the contacts.

Link on topic:

Replacing the timing belt Lada Granta 8/16 valves. Why does the belt break?

Removing contacts

- Unscrew the screw and remove the sensor from its original place

- We troubleshoot the unit, check the integrity of the circuit, the absence of deformation or damage.

- We install a new valve and assemble the structure in the reverse order.

Replacement of the Lada Granta adsorber sensor is completed.

Replacing the adsorber sensorError P0441

Owners of Lada Kalina often note that during the operation of the car, error P0441 appears, indicating that the gasoline vapor purge system is not operating correctly (the air flow differs from the norm). The cause of this malfunction may be:

- inoperative adsorber valve;

- clogging of the air line from the control unit to the air filter;

- air leakage through connecting pipes.

What should not be immediately considered is the line from the gas tank to the adsorber; here, a breakdown does not in any way affect the readings of the computer or diagnostic scanner. Still, most often Evap-Solenoid fails; this is a characteristic “disease” on Kalina.

If the EVAP valve stops functioning normally, it is not at all necessary that the engine will lose power, the fuel pump will fail, and so on. Mainly due to problems with the control gear, exhaust toxicity increases, and the Check Engine on the dashboard periodically lights up. There are car owners who do not pay attention to the diagnostic warning light, continuing to operate the car, but do not experience any great inconvenience. And most often in such a case, gasoline consumption does not exceed the norm, the engine starts normally, and no serious problems occur in the fuel system.

Valve malfunctions, solutions

| Signs | Diagnosis/fix |

| Systematic smell of fuel in the car interior | The circulation of gases is disrupted, there is a leak. Due to the proximity to the air filter, gases enter the car interior. |

| Valve knock | To check the serviceability of the valve, it is enough to sharply accelerate; if the knocking does not disappear, the purge valve is faulty. Replace with a new one. |

| Increased fuel consumption | A faulty gas ventilation valve cannot fully control the flow. Install a new valve. |

| The flow of exhaust gases in the exhaust system has increased | The solenoid valve for purge the adsorber does not work properly. |

| Engine operation is accompanied by hissing | The first sign of excessive gas accumulation. Maintenance of the unit, replacement of worn elements. |

| Uncharacteristic sounds coming from the gas tank | At the same time, the valve can operate normally without giving any “signs”. Maintenance of the unit, dismantling the vapor trap. |

| Error - P0441 | Diagnostics of the on-board computer, deletion, elimination of data in the firmware. |

The canister valve is knocking, clicking or clicking

We make sure that the noise comes specifically from the adsorber valve, and not from the timing belt, rollers and other elements. To do this, simply press the gas pedal sharply. If the chattering noise does not change, then the source of the noise is the adsorber valve. It is not uncommon for the clatter of the adsorber valve to appear only in cold weather at sub-zero temperatures.

What can you do about it?:

1. Contact an authorized dealer with the problem. If the adsorber valve is truly faulty, it will be replaced under warranty. If they consider that such valve operation is the norm, then there is no point in writing in support of AvtoVAZ.

2. Advice from car enthusiasts (you lose your warranty!). There is an adjusting screw on the side of the valve, which is filled with glue. Remove the glue and turn the screw clockwise 90 degrees. After this, the adsorber valve no longer clicks in the cold.

If you decide to buy a canister purge valve, then look for it by article number:

- 82 00 248 821 (for Lada Vesta or XRAY).

- 11180-1164200-00, 11180-1164200-01 (for Lada Granta/Kalina)

- 21103-1164200-01, 21103-1164200-02 or 21103-1164200-03 (for Lada Priora and Niva 4x4)

- 8200692605 (for Lada Largus)

Have you encountered problems with the adsorber valve?

It clicks for me too, I don’t think I noticed it before or didn’t pay attention

I discovered it only with a mileage of 5700 km, I hadn’t noticed it before, but it seems like it should be)) gasoline 95 Well, as soon as I paid attention, many people began to notice, for some reason I assume that it’s a matter of low temperatures, in the summer I definitely have Everything was quiet, I listened carefully in the car, maybe the gasoline vapor pressure in the tank is lower in the cold, or the condensation has frozen. IMHO

Well, as soon as I paid attention, as many began to notice, for some reason I assume that the problem is in low temperatures, in the summer everything was definitely quiet for me, I listen carefully in the car, maybe the gasoline vapor pressure in the tank is lower in the cold, or condensation where frozen. IMHO

You will laugh, but I just noticed a few days before your post, I listened to the engine, it seemed that the gene began to howl and noticed clicks, although earlier at the beginning of the start of sales I read about it, but did not pay attention

Forum members, I have a stupid question. on the cap I saw an adsorber, such a huge thing next to the battery, but on the grant I don’t see anything, where is it?

ps additional supply vapor from the tank changes the ratio of the gas-air mixture, but the brains don’t take this into account, especially when evaporation is most active in the heat.

DK will immediately catch this.

and damn, I’m definitely dumb about the exhaust.

Intervals for prevention and replacement. Consequences of ignoring a fault

Failure to respond to a malfunction in a timely manner contributes to premature wear of the fuel pump. Gasoline vapors accumulate in the intake manifold, the engine loses power, and fuel consumption rapidly increases. This ultimately leads to a complete engine stop.

The instruction manual does not contain an exact replacement interval. A prerequisite is preventative maintenance at every scheduled maintenance. The technicians install a new valve as soon as the standard one fails.

In practice, the average service life is 75 – 85 thousand km.

How to repair the adsorber and valve

It’s worth noting right away that in most cases both the adsorber and the valve cannot be repaired; accordingly, they need to be replaced with similar new units. However, as for the adsorber, in some cases, over time, the foam in its body rots, which is why the carbon contained in it clogs the pipelines and the solenoid valve of the EVAP system. Rotting of foam rubber occurs for banal reasons - from old age, constant temperature changes, exposure to moisture. You can try to replace the foam separator of the adsorber. However, this cannot be done with all units; some of them are non-separable.

If the adsorber body is rusted or rotten (usually also due to old age, temperature changes, constant exposure to moisture), then you can try to restore it, but it is better not to tempt fate and replace it with a new one.

Similar reasoning is valid for the solenoid valve of the gasoline vapor recovery system. Most of these units are non-separable. That is, the electromagnetic coil is sealed into its body, and if it fails (insulation breakdown or winding break), it will not be possible to replace it with a new one. Same with the return spring. If it has weakened over time, you can try to replace it with a new one, but this is not always possible. But despite this, it is still better to perform a detailed diagnosis of the adsorber and its valve in order to avoid expensive purchases and repairs.

Some car owners do not want to pay attention to the repair and restoration of the gasoline vapor recovery system, and simply “turn off” it. However, this approach is not rational. Firstly, this really affects the environment, and this is especially noticeable in large cities, which are not known for their clean environment anyway. Secondly, if the EVAP system does not work correctly or does not function at all, then under pressure gasoline vapors will periodically escape from under the gas tank cap. And this will happen as often as the temperature in the gas tank increases. This situation is dangerous for several reasons.

Firstly, the tightness of the tank cap is broken, the seal of which is broken over time, and the car owner will probably have to periodically buy a new cap. Secondly, gasoline vapors not only have an unpleasant odor, but are also harmful to the human body. And this is dangerous provided that the car is parked in an enclosed area with poor ventilation. And thirdly, fuel vapors are simply explosive, and if they come out of the gas tank while there is a source of open fire next to the car, a fire hazard will arise with very dire consequences. Therefore, there is no need to “turn off” the fuel vapor recovery system; instead, it is better to keep it in working order and monitor the adsorber and its valve.

Replacement of components of the fuel vapor recovery system on a Lada Granta (VAZ 2190) car

At the beginning of the article, we looked at the process of replacing the adsorber purge valve. However, this is only an integral part of the entire system, which includes:

- adsorber;

- vapor separator;

- gravity valve.

Related link:

Features of replacing the cooling radiator on a Lada Grant with your own hands

Each of the above elements is dismantled from its regular place for the purpose of prevention and replacement.

Note to the driver! Before starting work, disconnect the terminals from the battery to avoid a short circuit in the circuit.

How to check the adsorber valve

If after checking it turns out that the adsorber is in more or less working condition, then it makes sense to check its purge solenoid valve. It’s worth mentioning right away that for some machines, due to their design, some actions will differ, some of them will be present or absent, but in general the verification logic will always remain the same. So, to check the adsorber valve, you must perform the following steps:

- Visually check the integrity of the rubber hoses included in the fuel vapor recovery system, in particular those directly approaching the valve. They must be intact and ensure the tightness of the system.

- Disconnect the negative terminal from the battery. This is done to prevent false alarms of the system diagnostics and to enter information about the corresponding errors into the electronic control unit.

- Remove the absorber (usually it is located on the right side of the engine, in the area where the air system elements are installed, in particular the air filter).

- Turn off the electrical power to the valve itself. This is done by removing the electrical connector (the so-called “chip”) from it.

- Disconnect the inlet and outlet air hoses from the valve.

- Using a pump or medical bulb, you must try to blow air into the system through the valve (into the holes for the hoses). It is important to ensure the tightness of the air supply. To do this, you can use clamps or a thick rubber tube.

- If everything is in order with the valve, it will be closed and air will not be blown through. Otherwise, its mechanical part will fail. You can try to restore it, but this is not always possible.

- It is necessary to supply electric current from the power supply or battery using wires to the valve contacts. At the moment the circuit closes, you should hear a characteristic click, which signals that the valve has actuated and opened. If this does not happen, then perhaps instead of a mechanical failure there is an electrical failure, in particular, its electromagnetic coil has burned out.

- With the valve connected to an electric current source, you must try to blow air into it in the manner described above. If it is working properly, and therefore open, then this should work without problems. If it is not possible to pump through air, then the valve has failed.

- Next, you need to reset the power from the valve, and there will be a click again, indicating that the valve has closed. If this happens, it means the valve is working.

You can also check the adsorber valve using a multifunctional multimeter, switched to ohmmeter mode - a device for measuring the insulation resistance value of the electromagnetic winding of the valve. The probes of the device must be placed at the coil terminals (the places where the wires coming from the electronic control unit are connected to it; there are various design solutions), and the insulation resistance between them must be checked. For a normal, serviceable valve, this value should be within approximately 10...30 Ohms or differ slightly from this range. If the resistance value is small, it means that there is a breakdown of the electromagnetic coil (short interturn circuit). If the resistance value is very large (calculated in kilo- and even mega-ohms), then the electromagnetic coil breaks. In both cases, the coil, and therefore the valve, will be unsuitable for use. If it is sealed into the housing, then the only way out of the situation will be to completely replace the valve with a new one.

Thus, in order to know how to check whether the adsorber valve is working properly, you need to dismantle it and check it in a garage. The main thing is to know where its electrical contacts are located, and also to perform a mechanical inspection of the device.

Dismantling the adsorber Lada Granta VAZ 2190

Due to the design features of the Lada Grant, access to the adsorber is difficult. First we perform the following steps:

- We remove the fuel tank from the bottom of the car, unscrew the six bolts around the perimeter, and disconnect the block with wires from the fuel pump.

- Disconnect the canister vent pipe and press the lock.

Disconnect the pipe

- We remove the adsorber, remove it from the retainer, replace it with a new one, and assemble the parts in the reverse order.

Removing the adsorber

Addresses of companies providing installation/replacement services (Moscow, St. Petersburg, Kyiv region)

| № | Name | Address |

| 1. | "Diesel Master" | Russia, St. Petersburg, Moskovskoe highway, 13A, Zvezdnaya metro station |

| 2. | "Author+" | Russia, St. Petersburg, Mineralnaya str., 13O, Vyborgskaya metro station |

| 3. | "Service Team" | Car service, automatic transmission repair, tire side cut repair, car air conditioner repair, Strogino metro station, Marshala Proshlyakova street, 12k1s1 |

| 4. | "Berlin Motors" | Car services, repair of electronic vehicle control systems, repair of electrical equipment, repair of fuel equipment for diesel engines, metro station Gagarina Square, Vavilova, 13a, 1st floor |

| 5. | "Kulibins" | Kyiv, st. Borova 2/38 |

| 6. | "Renault-Life" | Kyiv, st. Novokonstantinovskaya, 1 G |

Related link:

Tips from experts on replacing Lada Granta glass with your own hands

List of online stores providing goods (Moscow, St. Petersburg, Kyiv region)

| № | Name | Address |

| 1. | "Dion Auto" | https://dionauto.com.ua/ |

| 2. | "PROM.ua" | https://kiev.prom.ua/ |

| 3. | "Skladexpress" | https://skladexpress.ru/ |

| 4. | "Remkuzov" | https://www.remkuzov.ru/ |

| 5. | "Avito" | https://www.avito.ru |

| 6. | "Drom" | https://baza.drom.ru/ |

Review of prices from different manufacturers

| Manufacturer article number | Price, rub.) | Resource (Thousand km) |

| VAZ 2190-1164200 | From 400 | 75 – 95 |

| 2190-1164200-01 | —/— | —/— |

| UTES, ULYANOVSK 11181164200 | —/— | |

| Canister purge valve with tube for 16-valve. LADA Kalina / Granta 11184-1164042 | From 600 | —/— |

| 11184-1165678 | —/— | —/— |

| 11184-1166541 | —/— | —/— |

*prices are current as of November 2, 2018.

Reviews

| № | Positive |

| 1. | Vladilen: I have no problems with the gas exhaust system, the mechanism works properly. I regularly carry out technical inspections and fill up with high-octane fuel. |

| 2. | Vitaly: at 30,000 km the purge valve began to knock. I took the car to the service center, they replaced it with a new one, since then there have been no comments on the work, the mechanisms are working properly. |

| 3. | Kirill: I’ve been actively driving Grant for the second year, it works like a watch, there are no complaints. I believe that compliance with maintenance schedules, high-quality oil, high-octane fuel is the key to long-term operation |

| 4. | Ivan: I’ve been actively using the car for a year and a half, there are no complaints about the quality of workmanship or assembly. Breakdowns happen, but they are minor. I fix it myself, I don’t go to a workshop. |

| 5. | Vladlen: two years have passed since I bought the car, I haven’t made any investments. My recommendations to motorists: buy domestic. |

| 6. | Dmitry: in a year and a half of using the car, I went to the service station twice unscheduled, no breakdown was found, but there was a whistle in the exhaust system. |

| 7. | Georgy: I’m happy with the purchase of the car, the car works like a watch, there are no complaints. I strictly comply with the manufacturer’s requirements, visit official services, and fill up with high-quality fuel. |

| Negative | |

| 1. | Ignat: the first valve flew 30,000 km, the second after 20,000 km. The workmanship is low, the model is crude, there are many shortcomings and shortcomings. I expected better from the Lada Grant. |

| 2. | Dmitry: I drove it for a year and a half without problems, after which the car began to fall apart, I visit service stations more often, carry out repairs and preventive maintenance. |

| 3. | Victor: I do not recommend the domestic brand due to the poor quality of the machine and many defects. |

Related link:

Idle speed sensor on Lada Grante: where is it located and how to replace it

Where is the adsorber located on the grant?

The structure of a modern car has many different parts, the existence of which the average car enthusiast is not even aware of. The adsorber, the adsorber valve, malfunctions of which can significantly impair the operation of the machine, is an example of this.

Purpose

This spare part was not always part of the car. We owe its appearance to modern requirements for the environmental performance of cars, and to be more precise, the Lada Granta acquired an adsorber thanks to Euro-3.

(Euro-3 is an environmental standard that was introduced in 1999, but Russian manufacturers were able to meet its requirements only in 2008.)

The adsorber, for which Granta became one of the first “shelters” in the domestic automotive market, is a spare part directly connected to the catalyst. It allows you to accumulate gasoline vapors to prevent them from entering the exhaust manifold.

Such actions allow you to preserve the catalyst and prevent its premature wear, since the combination of a cold catalyst with gasoline vapor is unacceptable. As soon as the engine warms up to the required temperature, the adsorber purge sensor is activated. The adsorber valve drives the vapors back into the gas tank.

Additional features

Of course, initially, created to create environmentally friendly engine operation, the Lada Granta adsorber, the price of which is insignificant, was underestimated. Manufacturers tried with all sorts of tricks to circumvent this newfangled trend, but the law obliged all car manufacturers who did not comply with this innovation to pay heavy fines.

Although AvtoVAZ has never been known for its large exports, it was forced to take measures to install an adsorber, since it has a small, but still a sales market. Today, the adsorber is installed on the Lada Granta without fail, since world research has revealed the following capabilities of this component:

– reduction in gasoline consumption

A similar result is achieved because the adsorber valve allows gases to be driven back into the gas tank, from where they enter the engine, which, when warm, is capable of processing them. If this device is missing, or the canister valve itself does not work, Granta loses fuel, which significantly increases consumption.

– normalization of exhaust system operation

Thanks to filtration, the likelihood of premature wear of the system and its components disappears.

Valve - as the most important component of the device

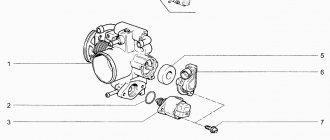

Speaking about how the adsorber valve works, it is necessary to introduce the device itself. It is, roughly speaking, a can of coal, which is equipped with a valve that allows the vapor to condense and direct. The canister purge valve is controlled by the ECU, which sends a signal to open/close it.

Important. The adsorber solenoid valve can create certain troubles for the driver. In the cold season, when starting a cold engine, a certain sound similar to clicking may be heard. This sound is normal, since the valve may not work correctly when cold.

In order not to confuse this sound with possible breakdowns, it is necessary to apply gas control. If there are no changes, you can safely attribute the clicks to the absorber.

Features of valve operation

The Grant canister purge valve itself was inherited from Kalina. Thus, the Kalina adsorber purge valve and the Lada Granta adsorber purge valve are completely identical. This allows us to assert that the signs of adsorber malfunction in both cars are identical.

If we take into account the Kalina adsorber purge solenoid valve, malfunctions and their symptoms can be completely attributed to a malfunction of the adsorber of its younger brother.

How to understand a malfunction of the absorber

Speaking about the adsorber valve, the symptoms of a malfunction will be fairly standardized, which makes it possible to obtain a fairly detailed description. So, signs of a malfunctioning adsorber valve:

– Constant smell of gasoline in the cabin.

This fact is caused by improper circulation of gases, which may have a certain leakage. Due to the proximity of the system to the air filter, odors freely penetrate into the cabin.

Signs of a malfunction of the canister purge valve on the Grant include this sound, familiar to all Grant owners.

(to fix this, you can tighten the nut, or you can purchase a new one; fortunately, the Lada Granta adsorber valve, the price of which is low, is available for purchase)

– Increased fuel consumption.

An inoperative adsorber ventilation valve is not able to control the correct path of gases, which does not allow them to be processed in the form of combustion.

Conclusion

The standard canister bleed valve on the Lada Grant works properly. Cases of breakdowns and premature wear are rare. Mainly related to violation of technical inspection deadlines and vehicle operating conditions.

Often, in order to save money, owners purchase cheap analogs of spare parts. It is obvious that the quality of the components does not correspond to the original spare parts.

When choosing parts, give preference to factory spare parts with original catalog numbers.

What is an adsorber?

An adsorber is a device whose main purpose is adsorption.

They are actively used in oil refining and some industrial sectors. In addition, these days adsorbers have found very wide application in vehicles equipped with internal combustion engines - they prevent gasoline vapors from entering the atmospheric air. These devices are equipped with injection systems; tubes connect them to the gas tank and throttle pipe. Switching operating modes is carried out by means of a valve; it closes when the engine is turned off, stopping contact between the device and atmospheric air. It is then that gasoline vapors enter the adsorber from the fuel tank, after which they are immediately absorbed.

When the engine starts, a special device that controls the injection system begins sending control pulses that initiate communication between the device and atmospheric air. The sorbent begins to be purged, and gasoline vapors enter the combustion chamber, where they are burned. The duration of control pulses and the intensity of sorbent blowing are directly dependent on the amount of air consumed by the motor.

The most important element of the described apparatus is the purge valve. The valves installed on the Lada Granta were inherited from the Lada Kalina, which makes possible malfunctions similar. Below we will look at problems that arise during the operation of the adsorber, as well as their symptoms and methods of elimination.