The winter season has its own characteristics, including for road users. Winter tires are a mandatory requirement for all vehicles; failure to comply will result in penalties and create a dangerous situation on the road. The tread depth of winter tires is an indicator that every driver should monitor, especially if the tires are not new. The team of the publication "AutoFemida" will tell you how to determine the tread height of winter tires, and what requirements the traffic police imposes on them.

Tread depth of winter and summer tires

With a tread depth of 4 mm, the tire's grip on the road surface is reduced, especially on wet roads. Your tires may lose contact with the road, preventing you from braking or turning. Therefore, we advise you not to wait until the tread pattern wears down to the minimum permitted depth of 1.6 mm. Summer tires need to be retreaded with a tread depth of 2 to 2.5 mm, winter tires - 4 mm. Tread depth is measured at the deepest point of the grooves, elevations and fastenings have no significance in measuring tread depth.

Tire damage

In Russia, the quality of roads does not always meet international standards. Inadequate quality of services also occurs.

This is why rubber damage occurs:

- A puncture is a small defect characterized by a violation of the integrity of the tire. Once its cause is eliminated, it is almost invisible.

- A cut is a noticeable defect that suggests a leak in the seal. Usually appears due to a collision with a curb stone, glass fragments, etc.

- “Hernia”, swelling of rubber. It can occur due to the detachment of rubber from the cord when air “swells” the resulting cavity. This happens due to the breaking of the frame threads.

- Changing wheel geometry. This usually occurs without air leakage. This is a consequence of damage to the cord/bead ring or due to a manufacturing defect or errors during tire fitting.

- Worn tread pattern.

Initial and permissible minimum tread depth for winter tires

- European. The main application is tread adhesion to wet asphalt and sleet. Therefore, they are cut by drainage channels and have a slightly directional wedge pattern. Thereby removing it for better drying of the contact patch between the tread and asphalt. They perform well on ice at low temperatures from -15˚C. Ideal for cities where roads are sprinkled with reagents to ensure slush removal. The tread depth of new winter tires is 5-6 mm on asphalt.

- Scandinavian. Serves to bite into frozen surfaces, providing better grip. This is ensured by a large number of rectangles and diamonds placed at a large distance. The presence of small stripes (lamellas) is very important. Thus, the machine pushes through the solid surface of the ice or crust. But this type of tire provides poor braking on wet asphalt.

Winter tire tread depth

Wear should be even across the entire circumference of the tread, without sharp dents or irregularities.

A tire with uneven wear is not suitable for use. Over the entire circumference of the tread, wear should be uniform, without sharp dents or irregularities. A tire with uneven wear is not suitable for use.

In the field of car enthusiasts, there is an opinion that limiters are used in order to change and buy new tires more often... ... This is a misconception. The limiter warns that driving on these tires is dangerous.

Numerous tests of tires with tread less than 1.6mm show long braking distances on wet roads. The hydroplaning effect is activated, endangering the lives of the driver and passenger.

Winter tire tread depth indicator The optimal tread depth for winter tires is greater than for summer tires. Compacted snow is more difficult to remove from the wheel contact patch, so the grooves must be deeper.

For winter tires, the depth is 4 mm, but we note that this is the RECOMMENDED value.

Type of "rubber" for technical inspection

This parameter is important in terms of compliance with the maintenance season.

Summer

Tires for this time of year improve traction during hot periods.

Other features of summer tires:

- copes well with wet surfaces due to the tread that drains water from under the wheels;

- show excellent results on dry roads (also thanks to the tire coating pattern);

- a special composition due to which the tires do not heat up to extreme temperatures.

But in cold weather, such tires not only lose their advantages, but also become a threat to a safe trip. From 2022, it is prohibited to drive on summer tires in the winter months. It will not be possible to undergo maintenance during the snowy period on out-of-season tires.

Moreover, the inspector has the right to fine you for violating traffic rules.

Winter

This is a car tire designed for use in cold weather (temperatures +7 °C and below). The advantages of such tires are the properties of the material from which they are made, which allows them not to harden even in severe frosts.

In addition, winter tires can be studded or non-studded. Each species has a lot of “fans”. One thing they have in common is the need to “change shoes” after the snow cover melts. Because it will not be possible to pass a technical inspection on winter tires in the summer, since the law clearly states that the tires correspond to the season.

All-season

Such tires are most beneficial for the car owner because they have a number of advantages over seasonal ones:

- you can ride all year round without having to change your shoes;

- cheaper than seasonal tires;

- do not cause any complaints during maintenance.

But still, these tires are less safe than winter or summer tires:

- braking distance exceeds that of specialized tires;

- susceptible to aquaplaning on wet surfaces;

- reduced cross-country ability on snowy roads.

Studded

Since 2022, there has been debate about the use of spikes. According to a number of experts, ridges on tires reduce the life of the road surface. Others believe that studded tires are mandatory on icy winter roads and save drivers from a large number of accidents.

In any case, according to clause 5.5 of the eighth appendix to TR CU 018/2011 “On the safety of wheeled vehicles,” the use of studded tires is possible in winter and unacceptable in summer.

Maintenance on spikes is allowed in December, January, February, but not in June, July, August. In other periods, the climate situation at that time is assessed.

Studless

The tread pattern is designed to have the shortest braking distance on icy roads and maximum cross-country ability on snow. On ice, the best results are still shown by spikes. But studless tires have an advantage on snowy roads. Despite the absence of studs, it will not be possible to pass maintenance in the off-season on tires with winter markings.

What is the minimum permissible tread depth

With a tread depth of 4 mm, the tire's grip on the road surface is reduced, especially on wet roads. Your tires may lose contact with the road, preventing you from braking or turning. Therefore, we advise you not to wait until the tread pattern wears down to the minimum permitted depth of 1.6 mm. Summer tires need to be retreaded with a tread depth of 2 to 2.5 mm, winter tires - 4 mm. Tread depth is measured at the deepest point of the grooves, elevations and fastenings have no significance in measuring tread depth.

The pattern of each stripe is designed taking into account its place on the tread. Therefore, a tire with an asymmetric tread has an “outside” side and an “inside” side. And since such a “composite” pattern usually has at least one track with a directional pattern, such tires are divided into left and right, and are placed only on one of the two sides of the car.

The nature of the pattern divides the tread patterns into “European” and “Scandinavian”. A diagonally directed network of grooves, lamellas and lugs along the contour of the tread (shoulder) are the distinctive features of a pattern that is beneficial when driving in mild winter conditions, on roads cleared of snow, heated by intense road traffic. movements. The mixture of water, snow, and sand covering the asphalt is quickly removed from the contact patch of the “European” tread, and the shoulder elements come into play when deep snow passes.

Vehicle cross-country ability

A vehicle's cross-country ability is its ability to move on bad roads and in off-road conditions, as well as to overcome various obstacles encountered along the way. Passability is determined:

- the ability to overcome rolling resistance using traction forces on the wheels;

- overall dimensions of the vehicle;

- the vehicle's ability to overcome obstacles encountered on the road.

The main factor characterizing cross-country ability is the ratio between the greatest traction force used on the drive wheels and the force of resistance to movement. In most cases, the vehicle's cross-country ability is limited by insufficient traction between the wheels and the road and, therefore, the inability to use maximum traction force. To assess the vehicle's ability to pass on the ground, the coefficient of adhesion weight is used, determined by dividing the weight on the drive wheels by the total weight of the vehicle. Cars with all wheels are driving have the greatest cross-country ability. In the case of using trailers that increase the total weight, but do not change the adhesion weight, the cross-country ability is sharply reduced.

The amount of adhesion between the driving wheels and the road is significantly influenced by the specific pressure of the tires on the road and the tread pattern. Specific pressure is determined by the pressure of the weight of the wheel on the footprint of the tire. On loose soils, the vehicle's maneuverability will be better if the specific pressure is lower. On hard and slippery roads, traction improves with higher specific pressure. A tire with a large tread pattern on soft soils will have a larger footprint and a lower specific pressure, while on hard soils the tire will have a smaller footprint and the specific pressure increases.

Vehicle cross-country parameters

The vehicle's cross-country ability in terms of overall dimensions is determined by:

- longitudinal radius of passability;

- transverse radius of passage;

- the smallest distance between the lowest points of the car and the road;

- front and rear cross-country ability (approach and departure angles);

- horizontal turning radius;

- overall dimensions of the car;

- height of the car's center of gravity.

Permissible minimum tread depth for winter tires

For example, in Europe, tires with a tread depth of less than 3 mm are not allowed for use. But how can you determine whether it’s worth buying new “shoes” for your car or not? How to determine the tread height of new summer tires? To determine this parameter, there is a special device that allows you to effortlessly measure the required indicators.

But if you are an ordinary person, most likely you do not have such a device. But solving this problem is very simple: you just need to take an ordinary coin.

Insert it into the groove and mark with a black marker where the rubber ends. Then measure the depth of the coin using a ruler. You can also use a regular ruler to measure. If you are not a supporter of “handicraft” methods, you can also determine the degree of tire wear using a special indicator, which is made in the form of a separate protrusion on the tire.

The State Traffic Inspectorate indicated the tread depth for all vehicles

Truck Gazelles will be able to roll tires until the tread depth is less than 1.6 millimeters. "Gazelle" minibuses will have to change tires when the tread depth is less than two millimeters.

The corresponding bill was prepared by the Department of Road Safety of the Ministry of Internal Affairs of Russia. It was developed by order of the President, which indicated the need to establish uniform requirements in government regulations regarding the use of car tires when operating vehicles.

It can be assumed that the whole problem was in the Gazelles. The fact is that the rules of the road, in particular the provisions for authorization for the operation of vehicles, stipulate that the tires of passenger cars have a residual tread depth of less than 1.6 mm, trucks - 1 mm, buses - 2 mm, motorcycles and mopeds - 0.8 mm.

Truck Gazelles will be able to roll tires until the tread depth is less than 1.6 millimeters

"Gazelle", as well as the Korean Porter, are category "B" cars. Their maximum weight does not exceed 3.5 tons. That is, the tread depth should be 1.6 mm. However, in all other respects, these are trucks. They are designed for transporting goods. That is, they can roll tires down to one millimeter?

According to the requirements of the technical regulations on the safety of wheeled vehicles of Russia, according to the requirements of the same regulations of the Customs Union, they remain trucks. Category N1 - vehicles intended for the transportation of goods, having a maximum weight of no more than 3.5 tons.

In general, everything is very complicated with the classification of vehicles. What, for example, include pickup trucks? They also belong to category N1 in both international and Russian qualifications, despite the fact that many of them can be driven with an open category “B” license. Here cars are already divided according to their functionality. By the way, many pickup trucks are prohibited from entering the city center without the appropriate pass: the carrying capacity is more than a ton. Many of them can be driven with a category “C” license; their maximum weight is more than 3.5 tons.

Now, in accordance with the instructions of the President, the Ministry of Internal Affairs has decided to indicate the tread depths for each vehicle. For vehicles of category L - these are all mopeds, motorbikes, motorcycles, as well as motorcycles, scooters and even tricycles and quadricycles - the residual tread depth is set to at least 0.8 mm.

For vehicles of categories N2, N3, O3, O4 - these are trucks and trailers, the maximum weight of which is over 3.5 tons - 1.0 mm. For vehicles of categories M1, N1, O1, O2 - these are passenger cars, as well as trucks, the maximum weight of which does not exceed 3.5 tons, as well as trailers for them, which also do not exceed this weight - 1.6 mm.

Winter tires are marked with a symbol in the form of a mountain peak with three peaks and a snowflake inside it, as well as the symbols “M+S”, “M&S” and “MS”. If the tire has wear indicators, then there is no need to measure the tread depth with a caliper.

For vehicles of categories M2, M3 - these are buses, that is, everything with more than eight passenger seats - 2.0 mm. For the first time, the Basic Regulations for the admission of vehicles to operation spell out the requirements for winter tires and explain which tires are considered such.

The remaining tread depth of winter tires intended for use on icy or snowy road surfaces during operation on said surface is no more than four mm. Please note that we are talking specifically about their use in snowy or icy areas.

Winter tires are marked with a symbol in the form of a mountain peak with three peaks and a snowflake inside it, as well as the symbols “M+S”, “M&S” and “MS”. If the tire has wear indicators, then there is no need to measure the tread depth with a caliper.

What penalties will be provided for this is still unknown. It is clear that tires that do not meet these requirements will not pass inspection.

It is not yet clear whether penalties will be introduced on the roads. As the traffic police told us, we first need to introduce requirements, and then think about fines.

FAQ

Let's look at frequently asked questions from car owners.

What is the best tire tread pattern?

The nature of the tire pattern is of great importance. Thus, non-directional tires are most widespread due to their versatility. They are used by a large number of car owners because they are of excellent quality, and can also be installed on any side of the car, since they do not have a specific direction of rotation. Tires with a non-directional tread pattern provide the car with good directional stability and are inexpensive.

There are also tires with an asymmetric tread pattern. The outer part of the tread provides excellent traction with various types of soil and asphalt, as well as off-road performance. As a rule, this type of tire is preferred by those drivers who drive a lot on country roads in temperate climates.

Tires with a directional pattern provide good directional stability, prevent the effect of aquaplaning, and are also ideal for driving on asphalt roads (winter tires perform excellently on icy conditions, providing the necessary safety while driving). The tread pattern indicates the direction of rotation of the wheels and therefore cannot be installed in the wrong place

Please note that if all wheels have a directional tread pattern, the spare tire should be of the same type in order to avoid deterioration in handling in difficult weather conditions

If the driver of a sports car needs to pay attention to low-profile hard tires. There are a large number of different variations of such wheels, which are designed for driving at speeds of 300 km/h on various types of sports tracks

Is it possible to install tires with different treads or different sizes?

Ideally, a set of four new tires should be installed on your car. If one of the wheels requires replacement and cannot be restored, you can try to find tires with the same tread pattern. It is prohibited to install tires from different manufacturers on the same axle. If it is necessary to change summer tires to winter ones that have studs, such tires must be installed on both axles of the car. According to traffic regulations, it is prohibited to install tires on the same axle of a car if they have different sizes, tread patterns, frost resistance and model types.

If the tread depth does not meet the established standards, then operation of the vehicle is prohibited in order to avoid accidents and prevent injuries and deaths of road users. If there are special wear indicators on car tires, the standards for determining the remaining tread depth do not apply to them.

Car tires need to be given priority attention, since the safety and quality of operation of the vehicle depend on it. It is mandatory to comply with the tire pressure requirements of tire manufacturers.

Follow simple rules that will allow you to maintain excellent tire quality and a comfortable ride for a long time under any road conditions.

What to pay attention to

- Tread Wear Indicators: Hard rubber indicators become visible as the tire wears. If they become noticeable, it's time to replace the tire. If you don't know where they are, look for a mark on the side of the tire that says;

- Tread height less than 1.6 mm : according to Russian and European legislation, the tread depth around the entire circumference of the tire should not be less than 1.6 mm for passenger cars.

For winter tires, Goodyear recommends a minimum tread depth of 4 mm. To check the tread depth, a special feeler gauge is used (commercially available and inexpensive). You need to measure the tread depth from different sides of the tire (inner and outer); - Foreign objects: often get stuck between tread pattern elements. Most of them can be easily removed from the tire surface. But if it seems to you that a stuck object (for example, a nail) has pierced the tire, do not remove it yourself, but contact a specialist at a service station. Otherwise, you risk being left with a flat tire;

Hard rubber indicators become visible as the tire wears.

If they become noticeable, it's time to replace the tire. Wear on the outside: If the tire is worn on both sides, it needs to be inflated and checked for air leaks. Losing tire pressure is a common occurrence, but driving on underinflated tires increases fuel consumption and increases the risk of an accident. More noticeable wear on the edges of the front tires indicates that you are not slowing down enough when cornering. It is very important to check your tire pressure regularly;- Center wear: If the tire is worn more in the center than on the sides, it means you are overinflating it. Too high a pressure can cause the tire to burst. Measure the pressure with a special pressure gauge and adjust it to the recommended level;

- Uneven wear on one tire: Patterns of tread wear may indicate problems elsewhere. Uneven scuffs and bald spots may mean the rims need to be balanced or rolled. Sometimes abrasions occur due to wear on the shock absorbers or a malfunction in the suspension;

- Uneven wear on all tires: Tires always wear at different rates. The engine is located in the front part of the car, which takes on most of the load when driving, so the tires on the front axle wear out faster. If you think they are wearing out faster than normal, check the condition of the suspension. If the tires are wearing more noticeably on one side of the car, it's time to check your wheel alignment;

- Jagged "pattern" on tire ribs: A jagged or feather-like pattern on the edges of a tire is caused by uneven friction against the road surface. This indicates that the wheels need to be adjusted.

Increased service life

The guaranteed service life of studded winter tires or classic tires can be extended without compromising the safety of passengers and other road users. Installation is carried out under the conditions of an authorized service station. Its employees rely in their work on the recommendations of the car manufacturer. The operating instructions list the requirements that must be met. Attempts to install it yourself will lead to damage, for example, to the cord layer. The expiration date of winter tires and studs are selected, taking into account the weather conditions in the region. The more often the weather shows a harsh temperament, the higher the requirements for the manufacturer. A qualified service station employee will provide invaluable assistance.

The installation is followed by balancing, which is carried out using computer equipment. Safe use of winter studded tires is only possible with an even load on each wheel. If there is a imbalance, then problems will not keep you waiting. List of other recommendations, compliance with which will extend the service life:

- Constant control of pressure level. The check is carried out at least once every 15-20 days. An increased level of pressure provokes the internal surface, and a lower level threatens the external part.

- Maintaining a sanitary condition - the actual period of use of winter studded tires depends on the prompt removal of traces of oil, dirt, and foreign objects.

- Visual inspection - the problem is eliminated as soon as the first symptoms are recorded. A small cut or chip requires immediate attention.

- Balancing – Severe weather conditions have an increased impact. At least once a month he comes to the service station to carry out computer monitoring of the condition of the wheels.

- Storage rules - at the time of purchasing wheels, it is worth checking whether the seller followed the recommendations of the wheel manufacturer or not. Each type of rubber is stored at a certain temperature. If the seller or the owner of the wheels violated the rules, then problems will make themselves felt. Store shoes at a temperature of +24 – + 25 °C. The ventilated area should have a moderate level of humidity.

The car must have a spare tire for quick replacement. Despite the fact that the shelf life of winter studded or studless tires can be long, you need to be prepared for various situations.

On a note! When the tires are replaced, the valve is changed. The driver checks the degree of its tightness.

Check tread wear

Drivers tend to overestimate the condition of their winter tires. To avoid inaccurate assessment of tire condition by eye, Nokian Tires has developed a special wear indicator DSI (Driving Safety Indicator), which allows you to accurately assess the remaining tread depth - it displays the tread groove depth in millimeters and allows you to clearly determine whether the tire meets safety and safety requirements. How large is the remaining tread depth?

Checking with a match

Tire safety can be measured using an ordinary five-centimeter match with a 3-4 mm sulfur head. When placing a match into the tread groove, the head should disappear from view. Check at several points on the tire surface.

If the wax does not disappear completely, the tread is not safe for driving in winter conditions. 4 mm is the minimum tread depth recommended by Nokian Tyres. The law stipulates a tread depth requirement of 4 mm for winter tires and 1.6 mm for summer tires.

Checking with a two euro coin

An even better tool for checking the condition of your tires is a two-euro coin. The width of the silver rim of the coin is less than four millimeters. If it rises even slightly above the tread block when a coin is placed in the groove, it makes sense to consider replacing the tires.

Constantly monitor the condition of studded tires

If the studs are still held in the tire, but at the same time swing from side to side, then the grip of the tire is significantly reduced.

If the studs are still held in the tire, but at the same time swing from side to side, then the grip of the tire is significantly reduced. A bendable spike will not cut into ice and has weak grip on slush and snow. Particularly dangerous are cases where a large number of studs have become loose and the number of studs in the tires varies.

According to the winter tire law, the maximum permissible variation in the number of studs between tires is 25%. This is useful for assessing the safety of your tires, but the results will always be a little inaccurate and unreliable, especially since drivers tend to overestimate the condition of their tires. That's why Nokian Tires has developed a tread wear indicator (DSI) for its new tyres, which accurately displays the remaining tread depth and the distance at which the tires will continue to provide adequate safety.

Results

When operating a vehicle, it is necessary to regularly (at least once a season) check the tire depth, especially if you have been using them for a long time. If you don't replace your tires on time, you risk getting into a traffic accident. The service life of all tires is ten years, but experts recommend replacing them after 6 seasons.

Why is it so important to change tires on time? The fact is that when tires wear 50%, road grip deteriorates by 30%. Resistance to hydroplaning is also reduced. The car becomes noisy and difficult to control. But knowing how to measure tread depth and the standard depth for each brand, you can easily determine for yourself whether your “iron horse” needs to change tires or not.

Source fb.ru

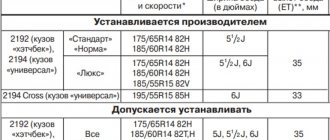

How to understand tire designations?

The tire size is the most important information printed on the tire. The size is indicated by numbers and letters, e.g. 195/65 R15 91H, where:

- 195 – tire width, mm

- 65 – tire height, % of width

- R15 – wheel arch diameter (landing diameter)

- 91 – load index

- H – speed index

- The speed index determines the maximum speed capabilities of the tire. The most important speed indices:

- Q – 160 km/h

- S – 180 km/h

- T – 190 km/h

- H – 210 km/h

- V – 240 km/h

- W – 270 km/h

All tires have markings that can be used to determine whether the tire meets EU, US, or both standards. The letter E, inscribed in a circle with two numbers, indicates that the tire has been tested in accordance with the safety requirements in force in the European Union. The American standard is designated DOT (Department of Transportation).

If tires are certified to both standards, they have both E4 and DOT designations. M+S: mud (Mud) + snow (Snow) – winter and all-purpose tires. AW (Any weather) are universal tires, as are AS (All Seasons). Some businesses use pictograms instead of letters: sun, rain, snowflake. An arrow on the side of the wheel indicates the direction of rotation of the tire.

The year of manufacture on the tire is indicated by four numbers: week and year of manufacture. For example, 1509: the first two digits are the fifteenth week (15), 09 is the year of manufacture (2009).