23.09.2019

| (Votes: 2, Rating: 5) |

Issues discussed in the material:

- How does engine braking work?

- What are the pros and cons of such braking?

- How to brake with a manual engine

- Is engine braking possible on automatic and variator?

Reducing the speed of the car by pressing the brake pedal cannot always be considered the optimal solution. Experienced drivers use engine braking in some situations. However, to use this method, you must have certain skills. Incorrect actions can lead to accelerated wear of the motor and various breakdowns. In this article we will tell you in what situations it is worth using engine braking on cars with different designs.

How to brake correctly with manual brakes

To properly brake with a manual transmission before a traffic light, it is necessary to take into account both the characteristics of the vehicle, weather conditions, and the condition of the road surface. Let's assume you have to stop at a traffic light on a road with a smooth, dry asphalt surface.

We perform the following sequence of actions :

- The left foot presses the clutch.

- The left foot remains on the clutch pedal, the right foot presses the brake pedal.

These actions must be performed smoothly in order to prevent an abrupt stop, standing ten meters before the traffic light and not “catch a kiss” from the car behind. When the car comes to a complete stop, you must, while holding the clutch and brake depressed, engage first gear, which will allow you to immediately start moving when the permission signal lights up.

When should you use this braking method?

A correct assessment of the situation will allow the driver to determine whether it is possible to slow down in a particular case or not. Under certain conditions, performing engine braking is not only irrelevant, but also dangerous. Disputes often flare up among motorists over whether it is possible to brake with a manual engine, whether this is harmful to the unit and gearbox, and whether the use of the method is actually justified. There is an opinion that braking by reducing speed harms the engine, contributing to wear of the piston rings, and also negatively affects the gearbox synchronizers and other elements, and increases the level of oil consumption.

In reality, proper use of braking skills will not harm anyone's car. In addition, competent execution of the technique will allow you to avoid stress. It is also not advisable to use engine braking regularly; you need to look at the situation and not practice the method unless necessary. The use of the method is relevant under certain circumstances:

- In case of partial or complete failure of the brake system;

- On wet and slippery road surfaces for better traction;

- On long descents;

- On mountainous terrain, serpentines.

When the road is slippery, you need to work with the clutch very carefully, because if it is suddenly released, this may result in the drive wheels locking. It is recommended to hold the clutch pedal for a second at the moment of pickup. An important point is the braking distance - it, as well as the rapidity of the drop in speed, is important to take into account when performing the technique.

Braking in extreme weather conditions

Being able to slow down and stop on dry road surfaces with a manual or automatic transmission is not the most important thing. It is much more difficult for a novice driver to prevent skidding or skidding. The most important thing is to learn how to brake your car correctly in cold weather on slippery road surfaces.

How do you need to brake with a manual transmission and at the same time prevent skidding and skidding in icy conditions? First of all, you need to drive the car more calmly than in the summer on good and not wet asphalt.

On a wet or icy road or in snow, due to poor adhesion of the car wheel surface to the road surface, the braking distance increases several times.

Even if you have foreseen the worsening weather conditions and “changed” your car into winter “shoes”, be more careful, drive your car more smoothly, and start braking in advance. Remember: driving in the summer and in the cold season are two completely different styles of driving your car.

Use engine braking to properly stop a manual transmission on icy road surfaces. This method can be used not only in icy conditions. But first, let's understand what engine braking is and why it should only be used in limited driving situations.

Protection of the engine and turbine from overheating after shutdown

On specialized auto forums, many people are interested in why the fan is running when the engine is off. Also, new owners of turbo engines often raise the topic: “I can’t turn off the engine with the key.” To make it clear, most modern cars have standard protection. For example, if you immediately stop a hot engine, then:

- after stopping the internal combustion engine, the risk of local overheating of the CPG and other engine elements increases;

- if the air temperature outside is negative, then the hot engine will be affected by a sharp temperature change;

Both overheating and rapid uneven cooling can lead to damage to various parts of the unit (pistons, rings, cylinder head, etc.). For this reason, the engine cooling fan may run for some time after the engine is stopped, powered by the battery. This solution allows you to cool the engine, minimizing possible consequences.

As for turbocharged units, many cars have a so-called turbo timer. In simple words, this device allows you to automatically turn off the engine with a turbine after a specified period of time.

Otherwise, the engine will not stop immediately after the key is removed from the ignition. This solution is “insurance” in case the driver forgets to let the diesel engine or gasoline unit idle after driving. Also, installing a turbo timer allows the driver to immediately get out of the car and put it in security mode, without waiting for a certain time to cool the turbine. The main disadvantage can be considered the need to put the car on the “handbrake” on a car with a manual transmission, which can lead to freezing of the rear brake pads in winter after a long stay.

Features of engine braking

This type of braking can be used in a number of situations:

- It is necessary to stop or brake on a steep or long descent,

- The brake pedal has failed.

What does engine braking mean? In fact, this method should be called braking not by the engine, but by using the gear lever. Although, if we evaluate it in terms of the influence it has on the mechanisms of the machine, in this case the engine is mentioned here quite rightly.

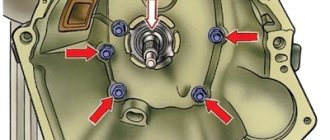

To start engine braking, you need to release the accelerator pedal, then you need to alternately switch from higher speed gears to lower ones.

Please note : these actions must be performed one by one.

If you go from 5th gear directly to 1st, you will immediately lose control of your vehicle. In this case, the car will skid, and the engine may break. It will be a great success if on your way in this case there is a flat, clean field, and not an oncoming collision with rushing cars, or another equally dangerous obstacle.

Thanks for subscribing!

Pros and cons of the method

The advantages of engine braking are so great that they must be used, especially on long descents:

- if the same amount of energy as the engine is capable of receiving is released into the service brakes, then they will inevitably overheat and fail, but this will not harm the engine in any way;

- if the main braking system fails, deceleration with the help of the engine will remain the only way to save the car, passengers and everything that gets in the way of the faulty car;

- in mountainous conditions there are no other ways to safely descend; brakes capable of withstanding mountain conditions are not installed on civilian vehicles;

- when braking by the engine, the wheels continue to rotate, that is, they do not lock, and the car retains the ability to respond to the steering wheel, with the exception of extremely slippery surfaces when the tires will lose contact even with slight deceleration;

- with rear or all-wheel drive, the car is stabilized by the deceleration vector;

- The life of discs and pads is saved.

There are some downsides:

- the deceleration intensity is low, the difference between energy and power should be understood, the engine can absorb significant energy, but not in a short period of time, here the braking system is much more powerful;

- deceleration is difficult to control, the driver must have knowledge and skills, and automatic types of transmissions must include appropriate shifting algorithms;

- not all cars are trained to turn on brake lights during this type of braking;

- With front-wheel drive, sharp braking can destabilize the car and send it into a skid.

We can talk about the advantages and disadvantages only in terms of information; in fact, the mode is vital, without it the scope of use of the car is greatly limited.

Automatic engine braking

To use engine braking on an automatic transmission, you should pay attention to the advice of experienced drivers. There is nothing particularly complicated here. Before driving along a downhill road, you need to switch to the D3 downshift mode; for steeper descents, guided by your feelings, you can switch to the D2 (L) mode. To apply additional braking, use the Hold button.

Anti-lock braking system

Another discovery of the modern automotive industry is the anti-lock braking system ABS. When you press the brake pedal sharply, the car's wheels will not skid, but will remain under the control of the car computer.

Under normal road conditions, a vehicle equipped with ABS has a significantly reduced braking distance. Extreme situations, when the wheels of the car skid or slip, are minimized. A car equipped with an ABS system does not skid.

If your car has such a system, questions about proper braking with ABS are unnecessary, just start braking. At some points on a slippery road surface or in other difficult road conditions, the brake pedal begins to tremble and put pressure back on the driver's foot. There is no need to worry, the ABS system is working, continue to brake confidently.

A number of car models are now equipped with a button to turn off the ABS system. Sometimes seasoned car owners use this function. But even for them, we do not recommend turning off the system! If your car does not have such a button, but you still need to disable the ABS, then this can be easily done by removing the fuse responsible for its operation.

There is an opinion that the use of the ABS system leads to an increase in braking distance. This opinion will be correct only under the following conditions:

- The road surface is uneven and loose . For example, gravel or sandy surface, deep snow. Under such conditions, a car not equipped with ABS will most likely “burrow” and stop moving if the wheels are blocked. It is in such conditions that experienced motorists use the function of disabling the anti-lock braking system.

- “Bald” tires . Driving on such tires becomes much more dangerous in a car equipped with ABS.

ABS has a number of irrefutable advantages that make braking easier in difficult conditions:

- There is no need to make a series of quick and intermittent presses on the brake pedal - the ABS is activated with 1 long press

- The car remains under full control of the driver.

- Even sharp maneuvering at higher speeds is now possible, since the ABS braking system is more sensitive and confident.

determine the reasons for a sudden engine stop both when starting the engine and while the car is moving. The causes of malfunctions that cause the engine to stop and methods for eliminating them are given below.

When starting the engine:

- insufficient fuel supply to the float chamber;

- The carburetor air damper is not installed correctly;

- increased fuel level in the float chamber;

- The air purifier is dirty with road dust.

While the vehicle is moving:

- loss of spark on the spark plugs;

- sudden cessation of fuel supply to the engine cylinders;

- violation of carburetor adjustment and tightness;

- strong air leaks in the power system;

- use of fuel with a reduced octane number;

- violation of the accuracy of the ignition installation;

- breakage of camshaft gear teeth;

- a sharp decrease in compression in the engine cylinders.

If the engine starts, but suddenly stops, and when it stops, popping noises are heard in the carburetor, it is safe to assume that this malfunction has occurred in the power system. Most likely, the supply of fuel to the engine cylinders has stopped.

It is necessary to check the serviceability of the engine power supply system. Particular attention must be paid to the operation of the fuel pump, as well as to the fuel level in the float chamber.

When, when checking the fuel pump using the manual pump lever or by cranking the crankshaft, a weak stream of fuel comes out of the injection fitting, the reasons may be the activation of the fuel pump drive lever, contamination of its valves, or a decrease in the stroke of the diaphragm rods.

One of the reasons for the engine stopping after starting it may also be an over-enriched fuel mixture. In such cases, you must ensure that the air damper is installed correctly. It should open completely when the choke control lever is pressed all the way and close completely when the lever is released.

To regulate the accuracy of opening the air damper, it is necessary to install it vertically by loosening the screw securing the cable. Set the choke control lever to its original position (press all the way until it stops). After making sure that the damper is installed correctly, secure the cable to the levers with a screw. The position of the damper in the carburetor inlet pipe can be seen by removing the air filter from it.

A sudden stop of the engine after starting it can also occur due to the air filter being heavily clogged with road dust. In this case, it is necessary to clean the air cleaner and change its oil. If the air cleaner filter element is made of nylon stuffing, it is washed in kerosene or gasoline, and if it is made of paper, it is removed from the air cleaner body and shaken or replaced with a new one.

Before installing the filter element, first wipe the inside of the air cleaner housing with a dry, clean cloth and fill it with oil. The contaminated oil is poured out, and the bath is washed with kerosene or gasoline, while simultaneously separating dust deposits from its bottom and walls using wire. This operation is carried out until the kerosene or gasoline that is drained becomes completely clean. Fresh oil is poured into the cleaned oil bath.

Sudden engine stops while driving are more often due to malfunctions in the ignition or power system and less often due to jamming of parts associated with insufficient oil in the engine lubrication system or a sharp decrease in pressure in the lubrication system.

In the latter case, the car engine should be sent for repairs.

A slight explosion in the muffler when the engine stops indicates a malfunction in the ignition system.

An unexpected engine stop can also occur as a result of disconnection or short-to-ground wires of low and high voltage current circuits, breakage of the breaker hammer spring, breakdown of the capacitor, failure of the ignition installation, etc.

The reason for a sudden engine stop may also be a break and disconnection of the wire connecting the battery to the vehicle ground. Therefore, you should carefully inspect the connections and, if necessary, securely fasten the wire.

If the engine suddenly stops with a working ignition system, the reasons for this may be: complete fuel consumption, a broken fuel line, air leaks in the power system, slow filling of the float chamber with fuel, sticking of the carburetor air damper or its automatic valve.

It is also necessary to check the presence of fuel in the tank and the operation of the fuel pump, eliminate fuel leakage or a broken fuel line, air leaks, and make sure that the camshaft gear teeth are not broken. You can verify this using the starting handle. When the engine crankshaft rotates, uneven force is felt on the starting handle, because compression is created only in those cylinders in which the valves remained closed when the teeth broke. If the valves do not move when the crankshaft rotates, this is a sign of broken gear teeth. The engine needs to be repaired.

Very often the engine runs well at medium and full speed, but stalls at idle. This indicates that the idle jet is dirty or the idle system is not adjusted properly. It is possible that air enters the engine cylinders bypassing the carburetor.

If the engine runs stably at low crankshaft speeds, but when the rotation speed increases, popping sounds occur in the carburetor, this means that the main metering system or economizer is faulty, or the coolant temperature is very low.

With severe hypothermia, the engine may stop spontaneously. Reasons: the thermostat valve does not close, the radiator is constantly connected to the cooling shell, the blinds are open for a long time while driving at high speed in winter, there is no cover insulation.

It should be noted that the engine can stop even if there is a lot of overheating and a sharp decrease in compression in the engine. The reasons for decreased compression may be:

- burning of piston rings in the piston grooves, loss of elasticity, high wear or their breakage;

- burning or loose fitting of valves to the seats, breakage of valve springs, violation of the gap between the valve stems and the toes of the rocker arms;

- damage to the cylinder head gasket or weak, uneven tightening of its fastening nuts;

- activation of the cylinder mirrors.

Compression in the engine cylinders is checked using a compression gauge or by hand. To check manually you need:

- unscrew all spark plugs, except for the spark plug of the first cylinder, and use the starting handle to turn the engine crankshaft until the compression stroke ends in the first cylinder;

- Screw the spark plug into the next cylinders one by one and turn the engine shaft again using the starting handle. By comparing the amount of effort expended to overcome the scrolling resistance during the compression stroke in each cylinder, you can find out which cylinder has low compression.

To check compression with a compression meter, you must: warm up the engine to a temperature of 70-85 ° C, unscrew the spark plugs, install the tip of the compression meter tightly into the spark plug hole of the first cylinder, open the throttle and air dampers completely; crank the engine crankshaft with the starter for 2-3 s and note the compression gauge readings.

For a working engine, the pressure at the end of compression should be normal, and the difference in compression gauge readings between the engine cylinders should not exceed 1 kgf/cm2.

In order to quickly and accurately determine the causes of decreased compression, the driver needs to be well aware of all the external signs of this malfunction. Thus, loose closure of the exhaust valve in any cylinder is characterized by shots in the muffler, and a loose fit of the intake valve is characterized by sneezing in the carburetor. A loose fit of the head to the cylinder block can cause gases to leak into the cooling system, into an adjacent cylinder, or out.

Gas leaks can be detected by the appearance of gas bubbles if the edges of the spark plug are lubricated with liquid oil. Gas leakage between the cylinders is determined by removing the cylinder heads, behind the blackened parts of the gasket. Gas leakage can be eliminated by tightening the cylinder head nuts.

To prevent the gasket from sticking to the block and cylinder head, it is recommended to rub it with graphite powder during replacement. Tighten the nuts evenly, starting from the center and gradually towards the edges. To eliminate deformation of the cylinder heads, tightening should be carried out in two steps: first with less force, then finally. The engine must be cold, so the required seal is ensured only by some pre-tension, taking into account the difference in the linear expansion coefficients of the steel bolts and the aluminum cylinder head.

With increased wear on the working surfaces of the cylinders and piston rings, smoke comes out of the muffler and oil filler neck, and oil consumption increases significantly. Increased oil consumption and smoke in the engine can also result from contamination of the gas exhaust pipe of the crankcase ventilation system. Therefore, when these malfunctions occur, it is first necessary to clean the engine crankcase ventilation system, check its condition, and then eliminate other malfunctions.

Worn or faulty piston rings or leaking valves can be detected during such a check. After determining the pressure in the cylinders, pour 23-30 cm3 of engine oil through the spark plug holes and turn the crankshaft with the starter. An increase in compression pressure will indicate a malfunction of the rings or cylinder; if there is no increase, it will indicate leaking valves. Piston rings that are coked are replaced with new ones.

Minor burning of piston rings can be eliminated without disassembling the engine. To do this, you need to prepare a mixture consisting of 50% solvent No. 647 or acetone, 25% kerosene and 25% AC-8 oil, and pour 100 cm3 into each cylinder through the spark plug holes. Then turn the crankshaft a few revolutions, after an hour, add 50 cm3 to each cylinder and leave for 7-8 hours. Next, pour 30 cm3 of a mixture of gasoline and oil into the cylinders and drive the car for 20 - 25 km. Then drain the oil from the engine crankcase and flush the lubrication system with liquid oil.

Violation of the gaps in the valves is eliminated by adjustment, valve leaks by grinding them in, and an engine with a worn cylinder mirror should be sent for repair.

Similar

What to do if the brakes fail

- Warn other drivers! Signal and turn on your hazard lights

- At low speeds, it makes sense to use the handbrake. We press the button and smoothly lift the lever, while paying attention to the clicks, and do not allow sudden braking and blocking of the car wheels.

- Is handbrake braking impossible for some reason? Brake the engine! In critical conditions, it is necessary to turn off the ignition and turn on first gear. In this case, a breakdown of the gearbox or engine is guaranteed, but life is much more important.

- Can't stop? Then look for items that can serve as a deterrent. Damage from a collision with them should be minimal. Thickets of bushes, snowdrifts, and piles of garbage are suitable.

Regardless of what gearbox your car is equipped with or what road surface you are driving on, you first of all need to be firmly confident in your capabilities. That is why, before you get behind the wheel of a high-risk vehicle and drive onto a busy highway, you have to learn how to brake correctly.

What does engine braking mean?

The engine of the car is designed in such a way that it constantly tends to idle. By pressing the gas, the driver forces the engine to speed up, and after the driver releases the gas pedal, the speed is again minimized. For a car moving in gear, this means a reduction in actual driving speed. This is called engine braking. The ability to reduce speed without the participation of the braking system is a very important skill that allows you to eliminate the possibility of wheel locking when braking on a slippery road, as well as in case of malfunctions in the braking system to avoid an accident.