The water pump, or simply pump, is not the most complex component of a car and fails extremely rarely. Its main task is to increase the efficiency of the engine cooling system. Water cooling is an order of magnitude better than air cooling, but its operation requires the installation of additional equipment. And such equipment includes a pump that pumps coolant through the system. Let's look at the most popular types and which pump is best installed on a car, depending on the model.

What does a pump do on a car?

The cooling pump is mounted closer to the front of the cylinder block, and the torque is transmitted by the generator belt. The element solves the function of constant supply of coolant (coolant), which significantly increases the effect of heat removal from the engine.

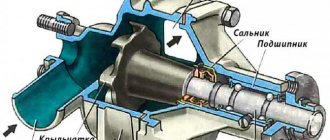

The part consists of a housing, a shaft with an impeller, a sealed seal and bearings. As a rule, the housing and impeller are made of aluminum or magnesium alloy. As for the impeller, it is made of plastic.

If we keep in mind the design diagram, then the VAZ classic pump consists of two halves: one does not contain any moving elements and is permanently attached to the cylinder block, the other includes moving parts, such as an impeller and bearings.

Bearings ensure the rotation of the shaft. The housing has special channels for supplying and discharging liquid. The impeller rotates, a centrifugal force arises, which throws the coolant towards the outer walls of the housing. Thus, pressure is created, forcing the liquid into a specially designed tube located in the cylinder block (cylinder block). Making a large circle (circulation), the liquid again enters the pump through the lower pipe.

Pump design in the engine cooling system

Due to this precise sequence and fluid circulation effect, the hottest engine elements are cooled.

As mentioned above, the detail on the classic has some features. Due to the fact that the pump consists of two parts, when replacing, many people confuse the front cover with a full-fledged pump. In fact, the name water pump refers to the entire assembly, which also includes pipes.

A sealed gasket is installed between the cover and the pump body to protect against leaks. During the replacement process, it should also be updated.

What to look for when purchasing

The pump in a car is a very important element; its malfunction can lead to the engine boiling. To avoid this, you should take a responsible approach to choosing the unit. Below is a brief summary of the main selection criteria:

Impeller material

Refers to actuators, pumps antifreeze through the cooling system. An important point is the material from which it is made.

- Impeller made of plastic. Let us remind you that most modern cars are equipped with pumps with a plastic impeller. This design is lightweight, with low inertia, and the thin blades do their job perfectly. Their disadvantage is the fragility of the material, and they can also deform under the influence of high temperatures.

- Iron impeller. They have a huge resource and are very durable, but they have great inertia. In addition, if you use low-quality antifreeze or ordinary water in the cooling system, it can rust.

- Cast iron impeller. Such pumps are inexpensive; their production does not require the use of special technologies. Corrosion resistant. But due to the heterogeneity of the surface, the efficiency of the entire system decreases. In addition, thick blades increase the weight of the unit, which leads to even greater inertia of the pump.

- Aluminum impeller. An excellent option – the blades are thin and uniform. The unit has low weight and low inertia. The downside is their cost.

- Made from sheet steel. Such pumps have the thinnest blades, high-quality material is resistant to corrosion. But they have a flat shape, which reduces efficiency.

Impeller parameters

A very important parameter is the height of the impeller blades. Low ones have low productivity, high ones may not be suitable for design.

Another criterion is the reach of the impeller; the proximity of the blade to the response part of the pump increases the efficiency of coolant pumping. When choosing, you should pay attention to the quality of its pressing onto the shaft. If there is an imbalance, play will quickly appear, which will shorten the service life and also lead to a strong hum.

It is better to immediately refuse to purchase the cheapest pumps, since it will not be possible to control all these points on them.

Oil seals

The tightness of the pump depends on the seals. To increase the sealing properties, coolant with added lubricant is used. Most modern pumps have ceramic seals; they consist of two elements similar to a flat spool.

Bearing

The most common designs are double-row closed ball bearings or roller bearings. Must be lubricated with high temperature grease.

Pulley

The diameter of the pulley determines how fast the pump shaft will rotate. Manufacturers select optimal sizes for specific models.

In total, three types of pulleys are used on pumps:

- toothed - it is driven by a timing belt;

- belt - rotates with a regular belt;

- electromagnetic - a clutch that regulates the speed of rotation of the pump using a magnet.

The latter does not need to be sealed with oil seals; it never leaks. The pulley is rigidly fixed to the axle with bolts or a corkscrew connection.

Pump body

Passenger cars are often made of aluminum. It is easy to process, so you can make any, even the most complex, shape from it. Thanks to aluminum casting, precise dimensions can be achieved.

For trucks, cast iron ones are more common. They have more strength and are designed for fewer revolutions. Have longer service life.

Signs of a faulty water pump on a classic

The pump on a VAZ is a very important detail. It largely depends on it whether the car will heat up or not. Needless to say, element failure is an unpleasant thing, but it also has its advantage. Thus, a failing part always gives a sign to an experienced driver, who must be able to recognize the main signs of an impending breakdown.

First of all, let's look at the signs of deteriorating pump bearings. Albeit insignificant, but excessive play of the drive pulley is already a reason to think about it. Also, rustling, howling, roaring and other characteristic sounds of worn-out bearings should alert the driver.

Experienced motorists make an interesting comment on the sounds. The engine, they say, does not creak, but knocks or makes noise. On the contrary, everything that squeaks or creaks are characteristic signs of a generator, rollers or pump. A howl indicates that the timing belt or alternator belt is overtightened.

If you don’t pay attention to these signs, then after several tens of kilometers the car’s run, coolant may begin to leak, although this is not an axiom, because there are so many examples when there was no leakage when the pump completely collapsed. It is better to focus on noise: the grinding noise of bearings will only intensify over time, and it will be impossible not to notice it.

As for leakage, it depends more on the quality of the seal. It is located in the pump and is designed to ensure tightness. Liquid can come out of the drain hole if it is provided on the pump (depending on the pump model - there are ones with or without holes). Over time, the leak will only get worse if replacement measures are not taken.

You can check the bearing visually:

However, if there is no whistle and the play is very insignificant, then the pump will continue to run for some time. You can remove the alternator belt and check the pulley like this. This will allow you to better feel the free play.

Thus, as long as there is no specific grinding noise, and there is no critical release of antifreeze to the outside, you can drive. From the first sign of rustling or faint whistling to complete failure, it is possible to travel another 1000–6000 kilometers. Here, depending on your luck, there are no magic tips.

On the other hand, and this must be taken into account, the pump can fail much earlier, before reaching the grinding stage. Everything can happen quickly and unnoticed by the car owner, and you should not wait until the noise level increases to replace the pump.

It is important to understand that there is such a breakdown of the water pump that there will be no loss of antifreeze or noise at all. And the engine will boil. For example, this happens when a plastic impeller moves away from the shaft. In fact, the shaft is spinning as before, but the impeller is inactive and just dangles. At the same time, the stove will stop heating.

There is another option for the motor to overheat. The pump is in good condition, new. However, in hot weather or in difficult off-road driving conditions, in traffic jams at traffic lights, the fan often turns on and the engine begins to heat up. This happens due to a mismatch in the design features of the pump: for example, if an impeller of a smaller size than necessary is installed inside (on older models of the pump, the impeller is equipped with small blades that may not be able to cope with the cooling of a more powerful engine).

If the owner has a choice when purchasing a new pump, then it is better to give preference to models with a larger impeller.

Pump impellers: small (left) and large

A large gap between the impeller and the pump body can also cause insufficient antifreeze flow through the cooling system. The gap should be no more than 1.5 mm. This deficiency is especially pronounced at idle speed, in traffic jams.

Turbo pump?! I haven’t heard of it)))) Waiting for your comments! Comparative test of water pumps for classics!

I ordered the pump to the store (On sale) Luzar-LWP 01014 TURBO, mine is still working, but I’m thinking of replacing it with a turbo in the summer, maybe someone has installed such a pump, write in the comments, the manufacturer says: What are the advantages of LUZAR water pumps?

1) Double row ball roller bearing.

LUZAR pumps are equipped with the best and most suitable bearing from all possible and available options. The installed bearing has a smaller contact surface area and can therefore operate at high speeds. This guarantees maximum and long-term use. It happens that on some pumps, due to the small height of the housing, ball roller bearings cannot be used, therefore, in such cases, special double-row angular contact ball bearings are used.

2) Metal-ceramic sealing element.

In order to strengthen the very movable “body-shaft” connection, a double mechanical seal is used, where the movable and stationary rings are made of ceramic. Thanks to the special properties of the material used, friction between the rings is minimized and there is almost no air gap. Therefore, all guarantees are given for the highest possible tightness and long service life.

3) Installation of the oil seal and additional sealing of connections.

Based on long-term and numerous experiments conducted by the LUZAR Company (more than five thousand studies), it was found that almost twenty percent of bearing failures occur because coolant enters through the oil seal, where the oil seal-shaft and oil seal-housing interfaces are located. .

This trouble occurs due to very small pores, examined under a microscope, in the casting of the water pump housing and the “loosening” of the sealing element during operation. A solution was found - the use of adhesive sealing for the sealing element of LUZAR pumps, due to which the service life was extended for a significant time.

4) One hundred percent ultrasonic inspection of the housing.

Microscopic defects in the smelting of the pump casing can cause the pump to become unusable and lose its required performance. Therefore, we carry out special checks and monitor the quality of casting of pump housings, guaranteeing excellent connection of parts.

5) One hundred percent control of the impeller “overhang”.

As many people know, the closer the impeller is to the counterpart of the water pump, the higher the performance of the pump. Absolutely all LUZAR water pumps have a mandatory gap of 0.9 to 1.3 mm, which is controlled during manufacture.

Note: There are frequent cases when deposits occur on the body of the pump response. Due to such deposits, it may not be possible to install the pump. If this happens, then you need to: carefully clean off unwanted deposits or use a special additional gasket before installing the pump.

6) Installation hardware.

The water pump is installed in a very hostile environment that causes corrosion. In this case, the pump fasteners become covered with salt deposits and become unusable. Therefore, in order to avoid such unpleasant situations, all LUZAR water pumps come complete with special additional installation fasteners, which must be used when replacing the pump.

7) The warranty is given for two years or until you drive 125 thousand kilometers.

Source

Replacing the pump on a VAZ 2101–2107 (injector and carburetor)

So, the pump is faulty and a decision has been made to replace it. By the way, this procedure can be directly related to the renewal of the coolant.

Location

The pump sits on the BC. It is bolted to the block body (indicated by arrows in the photo).

Location of the pump on the block of a VAZ car (nuts are indicated by arrows)

Subtleties of choice

Choosing a pump is a responsible matter. If you don’t give it proper attention, you can end up with a bad deal - spend money on a “left-handed” or refurbished, but used product.

You especially need to check the seal. It is advisable that it be a new model, not an old one. New samples come with springs, old ones - without them.

The body of a real VAZ pump should have the TZA logo, which means it was manufactured by casting. If there is no sign, it is a handicraft work.

Purchasing an original VAZ pump is a guarantee of reliability and durability. Only as a last resort, if there is no suitable option, can you listen to the recommendations of a seller or professional who advises you to select the most optimal pump.

Tools and materials for replacement

You will need the following tools:

A pry bar is needed to hold the pump pulley from turning.

The set of wrenches must contain all the main sizes

The container for draining the coolant must be wide

In addition to tools, you will also need materials:

Replacement algorithm

Access to various elements of the cylinder block is now open.

The rest of the assembly process is carried out in reverse order.

Video: how to remove and install the pump

Pump repair

In some cases, the water pump can be repaired. It is recommended in situations where either wear of the bearings or the oil seal located inside the device occurs.

Repairing the pump will save you about 600–700 rubles, which in principle is not so little. The maintainability of the pump is determined by the condition of the impeller and shaft. If they are relatively new, then they can be restored.

A complete replacement of the pump on VAZ cars is only for the better. The new unit is inexpensive, and after replacement the car’s engine will begin to function fully.

Source

Pump VAZ 2107

On cars with a liquid cooling system, including the VAZ 2107, one of the main elements responsible for maintaining the operating temperature of the engine is the pump. Thanks to this unit, the circulation of coolant is ensured. If problems arise or if the water pump fails, the normal operation of the power unit is disrupted, which can lead to serious consequences and expensive repairs.

Purpose

The operation of the pump is aimed at continuous circulation of coolant (coolant) through the engine cooling jacket. The antifreeze is heated under the influence of the rubbing elements of the power unit, and the necessary pressure in the system is created by a water pump. The liquid is directly cooled in the main radiator, after which the coolant again enters the cooling jacket. If circulation is interrupted for at least 5 minutes, the motor will overheat. That is why it is so important to monitor the proper operation of the node in question.

Pump design

On the VAZ 2107, as on many other passenger cars, the pump has almost the same design. The unit consists of a housing with a central shaft located inside, on which the impeller is fixed. The shaft is secured against axial displacement by means of a bearing, and the tightness of the structure is ensured by an oil seal that prevents coolant leakage. There is a hole in the pump cover through which the shaft comes out, where the pulley hub and then the pulley itself are attached to it. A belt is put on the latter, which on the “seven” rotates the generator and pump from the crankshaft. On modern cars, the pump rotates via a timing belt.

Where is

On classic Zhiguli models, the pump is located on the front of the power unit and is attached not to the block, but through a separate housing. By opening the hood, you can easily notice both the pump pulley and the assembly itself.

Which pump is better

For the VAZ 2107, water pumps with catalog numbers 21073–1307010, 2107–1307011–75 and 2123–1307011–75 are suitable. The last two options have an enlarged impeller and a slightly reinforced structure. Initially, these pumps were produced for Niva. The slightly higher cost of such pumps is fully justified by the better performance.

On “Sevens” equipped with both injection and carburetor engines, the same water pumps are installed, and their repairs are carried out in the same way.

The product in question is produced today by many companies, but the most popular are:

At the car market you can find pumps with impellers made of different materials: plastic, cast iron, steel. Products with plastic impellers, which are equipped with embossed and elongated blades, receive positive reviews. Elements made of cast iron are characterized by lower performance, and as for steel ones, they are susceptible to corrosion and are quite often fake.

The pump can be purchased either complete with a housing or separately. If the housing is not damaged, then it is enough to replace the pumping part. If the design has serious flaws or is completely broken, then you cannot do without replacing the housing.

Video: which pump to install on the “classic”

Which pump is better to choose?

Below is a rating of the most popular water pumps among car owners in the domestic automobile industry. The list includes the best-selling pumps across the country and is compiled based on recommendations from experts and auto repair mechanics. Each brand will have a short description outlining its advantages and disadvantages so that everyone can determine what is best for them.

FENOX

The list begins with a very well-known company in certain circles. Under the name of this brand, a large number of various spare parts for VAZ cars, both classic models and more modern ones, are manufactured. When choosing a water pump for a new Niva or a classic, most people in the know will point to the Phenox.

The company has large production capacities in many CIS countries and is focused on producing parts specifically for the domestic auto industry. Therefore, pumps, and other equipment of the brand, meet the requirements of manufacturers and the required quality.

Since last year, pumps from this company have not been widely used due to their low cost and short service life. However, if you put in some effort, you can find a pump, and with moderate driving in LADAs it will last quite a long time.

Advantages:

- very low price;

- proven well-known brand;

- good power.

One of the disadvantages is the large number of fakes on them. In addition, sometimes marriage occurs.

View best prices

METELLI

Next on the list is a company with production facilities primarily located in Poland. Manufactures and distributes automobile pumps both as replacement units and parts mounted during vehicle assembly. Due to the high quality of their products, they are often purchased by auto industry giants like Ferrari, Fiat and Peugeot, and put their logos on them.

All units undergo strict quality control and are tested for reliability, meeting the international standard ISO 9002, which is a guarantee of durable and reliable operation. In addition, there are almost completely no counterfeits of METELLI on the market, since all devices are ordered through an official dealer or trusted suppliers. The company's pumps are perfect for Kalina or a similar model, tested and reliable. Recommended for installation on VAZ Kalina, Priora, Granta, Vesta with a 16-valve engine and on VAZ 2110, 2114 with an 8-valve engine.

Reviews from car enthusiasts who have become Metelli clients are mostly positive.

Advantages:

- minimum defects in production;

- good performance;

- average cost;

- high quality;

- long service life;

- rubber gaskets are included.

The main drawback is the lack of price lists for some brands of cars.

View best prices

DOLZ

The majority of car owners agree that the best pumps for the VAZ 2107 are manufactured by DOLZ. In addition, the company’s assortment includes a huge variety of pumps for any car, both domestic and foreign.

The company has been operating for over 80 years and has long established itself as a reliable and trusted supplier of automotive components. The manufacturer concentrated on the manufacture and distribution of pumping equipment for passenger cars and trucks, which provided them with the ability to make only high-quality units.

A narrow focus in production made it possible to provide 95% of European cars with pumps. At the same time, create only high-quality products. The company was able to achieve such success thanks to patented technologies. Impellers made of special alloys are resistant to abrasion and cavitation wear, which eliminates the negative consequences of using low-quality antifreeze or water in the cooling system.

Advantages:

- large range of models;

- high availability;

- anti-counterfeit systems;

- long mileage.

There is only one drawback that should be highlighted, namely the high cost.

View best prices

SKF

He is a representative of a Swiss company specializing in the production of auto components. It has a large number of production sites and facilities throughout Europe and the CIS. When buying products from this brand, you should not focus on the country where the product was produced; strict quality control ensures the reliability of all products, regardless of the place where they were produced.

The brand's products are very popular among domestic car owners due to their high quality and relatively low cost. An excellent option for VAZ 2114 or similar cars. According to users, the pump can not be changed up to a mileage of 130,000 km, which is 20 - 30% more than similar ones.

However, due to their great popularity and widespread availability in markets, pumps are often counterfeited. Therefore, when choosing a pump, you need to be careful and careful. Company representatives point out that the original products have the mark of the assembly shop on the body and markings on the packaging. If at least one of these elements is missing, you should refrain from purchasing. Recommended for installation on VAZ Kalina, Priora, Granta, Vesta with a 16 valve engine.

Advantages:

- meets the high requirements of the manufacturer;

- high quality units;

- relatively low cost;

- widely distributed on store shelves.

Among the disadvantages, as mentioned above, is a large number of fakes. However, by following the manufacturers' recommendations when choosing, you can avoid purchasing counterfeits.

View best prices

HEPU

An excellent choice for Niva, Kalina and similar domestic cars on the advice of specialists and service station mechanics. The company has its own research laboratory, which studies the properties of metal and the impact of corrosion processes on them, and also promptly introduces changes in the metal manufacturing process for parts and assemblies.

Tests carried out on the strength and durability of the pumps indicate that the pump has a service life of up to 90,000 km, with average load intensity. However, on store shelves there are units with manufacturing defects - poor-quality mechanism, insufficient amount of lubricant in the bearings, large play between the shaft and the impeller, etc. Although this is extremely rare. The HEPU product is of high quality and has proven to perform reliably. Recommended for installation on VAZ Kalina, Priora, Granta, Vesta with a 16 valve engine.

Advantages:

- large assortment of goods;

- high prevalence on the market;

- reliable operation;

- low cost.

The only drawback of water pumps from the HEPU brand is the presence of manufacturing defects in the product.

View best prices

VALEO

The company produces and supplies components for many well-known car brands and their assembly lines. It is worth noting that pumps from the brand are supplied to the buyer along with guide rollers, a timing belt and all the necessary gaskets. All this ensures reliable operation of the unit for 150 - 180 thousand kilometers.

Original products are not cheap, but the price is well compensated by their durability and stability. Fits perfectly on most Ladas and fits Vesta perfectly.

The high cost of goods and the opportunity to profit from honest buyers has led to the emergence of a large number of surrogate products. When purchasing you need to be extremely careful. Produced in many countries, including Russia.

Advantages:

- very long service life;

- tolerate even very heavy loads well;

- huge selection of models;

- good equipment.

There are two disadvantages: the first is the high price, and the second is a large number of fakes. But if the cost is compensated by reliability and durability, then fakes are disappointing.

View best prices

LUZAR

The pump under the Luzar brand is an excellent choice for domestic cars. Installed on VAZ-2110, 2111, 2112, Lada-Kalina (before 2008), Lada-Priora of all years of manufacture.

All elements are made of durable materials, the impeller is metal. The kit includes the pump itself, technical documentation, gaskets and components for installation.

The pump has been tested under extreme loads, so its quality and reliability are confirmed. The products have good heat transfer. The mileage indicated by the manufacturer is 125,000 km. 2 year warranty. Recommended for installation on VAZ Kalina, Priora, Granta, Vesta with a 16-valve engine and on VAZ 2110, 2114 with an 8-valve engine.

Advantages:

- high reliability of all elements;

- manufacturer's warranty;

- stable operation under heavy loads;

- no fakes.

There is only one drawback - the high cost of the products.

View best prices

AT

Manufacturer – China. Under this brand, not only pumps are manufactured and distributed, but also many other spare parts for VAZ and most popular foreign cars. Available in most stores in Russia.

They are characterized by low cost, with fairly good quality. It is not recommended to subject it to heavy loads. Designed for careful and moderate driving. There are many positive reviews from car owners, but there are also negative ones.

Advantages:

- low cost;

- good quality.

Among the disadvantages, it is worth noting the short service life, and also the fear of overload. Sometimes you get defective products.

View best prices

TZA

Water pumps from the manufacturer fit perfectly on the VAZ-2107 and other classic Lada models. They have a low cost and are often found on the shelves of many stores.

The kit includes gaskets and a data sheet. It has protection against counterfeiting in the form of a specific sticker on the box, and each product has its own number.

The impeller is made of plastic and has 7 blades. A relatively short service life of the products was noted; over time, play appears. Not recommended for installation on 16 valve engines VAZ Kalina, Priora, Granta, Vesta.

Advantages:

- low price;

- can always be found in stores;

- manufacturer's warranty.

The one downside is that it is a small resource, but this is compensated by the low cost.

View best prices

Signs of a pump malfunction

Sooner or later, problems arise with the pump and the unit fails. This may be due to both the high mileage of the car and the installation of a low-quality product. Therefore, it is worth considering what malfunctions may occur with the pump and what to do in this or that case.

Oil seal leak

It is quite easy to detect coolant leakage through the oil seal: a puddle usually appears under the car. If the sealing element is damaged, for example, as a result of wear, antifreeze will get to the pump bearing, as a result of which the lubricant will be washed out of the device, and the part itself will soon collapse. To prevent this from happening, it is necessary to periodically inspect the car and eliminate possible problems.

Appearance of noise

If extraneous noise is heard from the pump area while the engine is running, this indicates an imminent breakdown of the unit. The most likely cause of noise is failure of the bearings or weak fastening of the impeller. In any case, the part needs to be dismantled, subsequently damaged, repaired or replaced.

Tools

For repair you will need:

- Keys at 10, 13, 17;

- metal brush;

- sealant;

- container for draining coolant.

As for which pump to choose, there are 3 proven brands:

At the same time, TZA is preferable, but they are rarely found on sale. They also advise choosing pumps with a metal impeller, explaining that plastic ones can fall apart or dissolve in low-quality antifreeze, but I have never seen this.

Pump repair

If it has been determined that the pump needs repair or replacement, you first need to prepare the necessary tools for work:

Removal

After preparing everything you need, you can start disassembling:

If the pump is replaced without a housing, then there is no need to remove the nozzles and tube (points 5 and 6).

Disassembly

Repair work will require disassembling the water pump. The procedure is carried out in the following order:

Video: how to disassemble a pump on a “classic”

Bearing replacement

To replace the bearing, you will need to disassemble the pump and knock the shaft out of the housing. On the “classic”, the bearing and shaft are one part. Therefore, if one of the parts fails, the entire product is replaced. In order not to make a mistake when buying a pump shaft for a VAZ 2107, you need to take the old part with you, since the axles can differ in both diameter and length, which the seller does not always know about.

The shaft is changed in the following order:

Replacing the oil seal

Due to constant contact with antifreeze, the oil seal sometimes fails, which leads to a leak. To replace the part, it is necessary to dismantle the impeller and knock out the shaft and bearing. To do this, you can use an old axle, which is inserted with the opposite end into the pump hole.

Then the shaft is driven in by striking with a hammer until the oil seal comes out of the housing. The new sealing element is inserted and pressed into place using a suitable adapter.

Replacing the impeller

If the impeller is damaged, for example, the blades are broken, then the part can be replaced. Damage usually occurs upon contact with the housing due to severe wear of the shaft or bearing. Regardless of the material of the impeller, the part is attached to the axle by pressing. To replace the plastic impeller you will need:

When reinstalling, the part is pressed onto the shaft using a hammer and a suitable attachment, avoiding damage to the blades. You need to make sure that the lower part of the impeller rests against the ring on the oil seal, after which it needs to be seated 2-3 mm inward. This will ensure a tight fit of the rotating part to the ring.

Video: how to remove the impeller from the pump shaft

In most cases, owners of VAZ 2107 and other cars do not repair the pump themselves, but simply replace the part.

Installation

Assembly and installation of the unit is carried out in the reverse order. The only thing you should pay attention to is the gaskets - it is recommended to use new ones. In addition, the connections between the pump and the pipes are coated with sealant. When the part is installed, add antifreeze. In order to prevent the formation of air pockets, disconnect the thin hose of the cooling system from the carburetor (on a carburetor engine) and ensure that the antifreeze flows out of the hose and fitting, after which the connection is made. Start and warm up the engine, inspect the pipes for leaks. If everything is in order, the repair can be considered successfully completed.

Replacing or repairing the pump on a VAZ 2107 yourself is within the capabilities of every owner. The only thing is that in some cases special devices will be required. Otherwise, a standard set of tools will suffice. To ensure that the pump operates for a long time, it is recommended to select the part from trusted manufacturers.

Source

When to change your pump

The following signs will indicate the need to replace the water pump:

- During warm periods of the year, engine overheating often occurs, although the antifreeze level is normal.

- There is a leak at the pump connection points or the drain hole.

- While the motor is running, extraneous noise is heard from the pump (knocking, rustling, crackling, etc.).

- In winter, the heater does not heat up even with a well-warmed engine.

Also consider the service life of the part of a specific model. For most cars, this is a mileage of 60–90 thousand km. In rare cases it reaches 120 thousand. It is recommended to replace the pump after its service life has expired.

Purpose and location of the water pump

The water pump (pump) is designed to circulate antifreeze through the engine cooling system in forced mode. This way ensures cooling of the hottest parts of the engine - cylinders, pistons and combustion chambers. Hot antifreeze enters the radiator, where its temperature decreases due to oncoming air flows.

Without a water pump, circulation of coolant through the channels and pipes is impossible. Therefore, when operating a car with a faulty pump, the engine will quickly overheat and fail, and, as a result, expensive repairs will be required.

The water pump is the main element of the engine cooling system

The design of the water pump is quite simple. An impeller is mounted on a shaft built into a housing with a mounting flange on one side, and a hub for the drive pulley on the other. The rotation of the shaft is ensured by a pair of bearings, and the tightness of the housing is ensured by the internal oil seal.

The design of the water pump of classic VAZ models is quite simple

Some manufacturers additionally equip the pump with a grease fitting - a fitting for pumping thick lubricant into the bearing.

In classic VAZ models, the water pump is installed on the front of the engine and is not screwed directly to the cylinder block, but to a separate housing.

The pump shaft and impeller are driven by a ribbed belt running from the crankshaft pulley to the generator. The design and operating principle of this unit are the same for both carburetor engines of classic VAZ models and engines with fuel injection.

The pump is located in the front of the power unit and is rotated by the generator drive belt

Features of the cooling system of classic Lada

The cooling system of the VAZ 2107 is actually no different from other engines built on the basis of the Fiat 124 engine. It is not our plan to describe its operation and design, however, the pump bears the main load and is responsible for the circulation of the coolant. Despite the simplicity of the water pump design, it is subject to a whole bunch of requirements, and failure to comply with at least one of them can cause an antifreeze leak or disruption of its circulation. As a result, the motor will overheat with all the ensuing consequences.

Troubleshooting

The following problems are typical for water pumps of classic VAZ models:

Almost all pump problems are the result of bearing wear. With little wear and play of the shaft, the pump operates normally. As the gaps in the bearing separators increase, the oil seal begins to leak antifreeze, and unnatural noises are heard from the pump installation site when the engine is running - a hum or crackling sound. As a result, the shaft becomes distorted. The further scenario can develop in three ways.

Replacing the water pump

The work of installing a new pump on a classic VAZ model consists of several stages.

It makes sense to purchase a new pump in advance only if you are sure that the old one is faulty or its service life is coming to an end. If there is an auto shop near the work site, you can purchase a pump during disassembly.

Choosing a new pump

Pumps marked 2101, installed on the first series of classic VAZ models, are not currently produced. Suitable pumps (catalog numbers 2107–1307011–75 and 2123–1307011–75) with a larger impeller and reinforced design. Initially they were produced for Niva. These pumps are slightly more expensive than regular pumps. So there should be no problems with the correct choice of a new pump.

Pumps with old-style impellers are no longer produced

VAZ 2101-07 power units equipped with an injector or carburetor use pumps of the same design and size.

The pumps from the following manufacturers are in greatest demand among motorists:

There are pumps on sale with impellers made of plastic, cast iron and steel. Pumps with a plastic impeller equipped with elongated and embossed blades have proven themselves to be excellent. Cast iron parts are less efficient when pumping liquid, while steel parts are susceptible to corrosion and most often turn out to be fakes.

Water pumps are sold both complete with housing and separately. Your choice depends on the integrity of the housing - if it is damaged or corroded inside by an old impeller, then buy the product assembled. When the body is intact, it is enough to purchase only the pumping part.

Video: choosing a water pump

Preparation of tools and workplace

To replace the water pump on a classic VAZ model, you need a flat, well-lit area or a warm garage (in the cold season). Since all work is carried out from the engine compartment, an inspection hole is not required for work.

The following tools will be required:

In addition, you will need high-temperature sealant and 1 liter of coolant for topping up. To drain the coolant, you need to prepare a 10-liter container with a wide neck (a plastic basin or a canister cut off on the side) and a meter-long piece of ordinary hose.

To avoid getting burned, all work should be carried out with the engine cool.

Dismantling the pump

On classic VAZ models, to remove the pump, you do not need to rotate the crankshaft, align marks or disassemble the timing drive, as is done in front-wheel drive cars. It is enough to park the car on a level surface and secure it with the hand brake.

Antifreeze is drained in the following order:

When dismantling the pump, do not drain all the coolant. You just need to lower its level below the pump installation location. But you shouldn’t block the intense stream either, as in this case a lot of antifreeze will be lost.

To allow air to escape from the channels when filling in fresh antifreeze, you should disconnect the thin manifold heating pipe (on the carburetor version of the engine). On an injection engine, such a tube is connected to the throttle body.

For further work, it is necessary to remove the generator drive belt. To do this, use a 17mm wrench to unscrew the tension fixing nut (located on top of the unit’s mounting bracket) and push the generator housing towards the crankshaft with a pry bar. For easier access to the nut, you can disconnect and remove the battery.

To loosen the belt, you need to unscrew the fixing nut and move the generator towards the crankshaft

For further work, it is necessary to remove the generator drive belt. To do this, use a 17mm wrench to unscrew the tension fixing nut (located on top of the unit’s mounting bracket) and move the generator housing towards the crankshaft with a pry bar. For easier access to the nut, you can disconnect and remove the battery.

When the belt becomes loose, remove it from the pulleys and continue disassembly.

Pump installation

Before installing a new pump, you should check how it fits with the old housing. To do this, insert the pump with the gasket into the socket until it stops and twist the end of the shaft. If the impeller touches the walls of the housing, you most likely have come across a fake.

Installing a new pump is carried out in the reverse order.

Before pouring, it is better to strain the old liquid through a fine brass mesh. Pour the antifreeze carefully so as not to stir up the sediment at the bottom of the container.

The system is first filled with fresh antifreeze through the radiator filler neck. Pour in antifreeze slowly, observing the tube removed from the manifold heating block (in an injection engine - the throttle valve). As soon as liquid flows from the tube, immediately put the pipe on the fitting and secure it with a clamp. The remainder of the antifreeze is carefully poured into the expansion tank to the required level (between the Min and Max marks).

The system is filled with antifreeze until it runs out of the manifold heating tube (left) or throttle body (right)

When finished, close the radiator and reservoir caps and start the engine. After warming up to a temperature of 80-90 ° C, inspect the front part of the engine for leaks and be sure to wait for the cooling fan to turn on. This indicates that there are no air pockets left in the hoses, that is, the cooling system is functioning normally.

Video: installing a water pump

Water pump repair

If the body of the old pump remains intact, it can be repaired - change the shaft with bearings and oil seal, which are commercially available. To do this, you will need to press out the impeller with a special puller, and then pull out the shaft. This operation allows you to save up to 60% of the price of a new pump and can be performed independently.

To repair the pump, you will need to replace the shaft with bearings

Replacing the pump in the cooling system of classic VAZ models yourself is not very difficult. A standard set of tools and careful adherence to instructions will allow you to do without outside help.

Source