The design of any modern car, the VAZ 2114 is no exception, is such that the successful production of a car depends on a number of positions. Previously, this was enough for the mechanical pump to supply fuel to the carburetor, and for the spark plugs to produce a spark. Today there are a lot of problems that prevent the engine from starting. An electronic injector requires the participation of several sensors, and the matter is not limited to them. In this article we will tell you why not and how to deal with it.

In general, all causes of malfunction can be divided into two large categories:

- Fuel system problems. This group includes any breakdowns as a result of which fuel is not supplied to the engine at all, is supplied incorrectly, or mixture quality errors occur.

- Electrical problems. Ignition of the fuel mixture is ensured by sending an electrical signal to the spark plugs. If problems arise here (and there are a huge number of electrical elements), the car will not start.

The most terrible malfunctions can be included in a separate category - for example, a “knocking” VAZ 2114 engine, a broken timing belt and, as a result, bending of the valves. In these situations, expensive repairs cannot be avoided.

Fuel system problems

Among the elements of the fuel system, the following factors influence engine starting:

- presence of gasoline in the tank;

- the integrity of the fuel lines under the “belly” of the car;

- cleanliness of the filters: coarse cleaning (located in the tank) and fine cleaning (located under the car, to the right of the spare wheel compartment).

Also included in this category are electrical components that are directly related to the fuel supply. This is an electric fuel pump and a fuel pump relay.

Before checking other methods, you must be completely sure that the VAZ 2114 with an injector is filled. “Yes, there are still five liters there” according to the indicator on the tidy or “I filled it up yesterday, I couldn’t spend that much” are not suitable. The gauge may be lying, and there may be leaks in the tank or fuel lines. Carefully check the car for fuel leaks; just in case, fill in 5-7 liters of gasoline from a canister.

The mesh in the tank rarely gets clogged, leave this option for last, but it’s worth trying to change the fine filter if electrical problems are ruled out.

The operation of the fuel pump is checked by ear (after turning the key, its operation should be heard; if not, the pump has “died”, or the pump relay, or a wiring break). According to the manual, you need to connect a pressure gauge to the fuel system. If the pressure does not stay within 2-2.5 atm, the VAZ 2114 will not catch due to insufficient fuel pressure.

Low voltage circuit

Using a 12V lamp, you can check the low voltage circuit. The lamp must be connected with the first contact to the low voltage terminal, and the second to the car body. Next, you need to close the distributor contacts and start the ignition. If the circuit is OK, the lamp will light when the contacts open and go out when the contacts close.

If the lamp does not light up when the contacts are opened, this means that the problem is in the low voltage wiring or in the ignition coil, or rather, in its winding.

There is a special offer on our website. You can get a free consultation with our corporate lawyer by simply submitting your question in the form below.

Electrical faults

Most of the problems lie here, so we’ll look at each option in detail here:

Nothing happens when I turn the key

On a VAZ 2114, this usually indicates a violation in the ignition switch - starter line, but one of the reasons for the breakdown “for blondes” is a dead battery, do not forget about it (checked with a voltmeter: it should be at least 11.8 V - and with a hydrometer, if the battery is serviceable : at least 1.22 in each jar).

Let's move on. The cause of such a malfunction may be a breakdown of the ignition switch cylinder, and the injector has nothing to do with it. If, when turning the key, new sensations arise (something catches, turning has become easier or, conversely, more difficult), that’s the problem.

Under the panel, approximately above the clutch, there are two relays: ignition switch and starter release. The reason may be a malfunction of one of them. They are checked according to the manual by a good electrician or replaced with a known working one.

Starter. Often the cause may be a jammed “retractor”. If you are standing in a field, you should try hitting it with something heavy like a large key (without fanaticism) - it may help. If the car is parked in a garage, you should remove the starter and try to start it directly from the battery.

To do this, press the housing to the zero terminal of the battery, install the wire with the alligator clip on the positive terminal of the battery and bring it to the positive of the retractor. If the starter tries to jump out of your hands, everything is fine (be careful, it is not recommended to carry out this procedure without basic knowledge of safety precautions and an assistant!).

If there is no reaction, the problem is in the retractor. If the relay buzzes, but the starter does not turn, the problem is in the brushes. If the starter makes a terrible sound, but does not turn, the problem is in the bendix.

If the starter turns, replace the battery and check the power supply to the chips that are connected to the starter (with an assistant, one turns the key, the other measures it with a multimeter).

Also pay attention to the ground wire that goes to the battery. If there are breaks in the wiring at the point of contact with the body or at the terminal, it must be replaced. It is also worth disconnecting the wire from the body and thoroughly cleaning it with a metal brush. The reason for the failure to start may be simple oxidation.

The starter turns, but the car does not start

This is the most common situation in the case of the VAZ 2114. The procedure for solving it must begin with answering the question of whether there is a spark. To do this, take an assistant, unscrew one spark plug, put an armor wire on it and very carefully (avoid touching live parts, hold the insulated part of the wire) apply the spark plug to the cylinder head cover. While the assistant turns the engine, watch the behavior of the spark plug. If there is no spark, you need to look for it.

If there's no spark

The ignition module is one of the key problems of the VAZ 2114 on the injector. It breaks often and sometimes a new one comes with a defect. You can read more about checking the ignition module in other material on our website. Please note that the problem may also lie in the chip that is connected to the module. The presence of power on it must also be checked.

DPCV is another reason why there may be no spark. Since this sensor monitors the firing phases of the cylinders, it is one of the key elements of the ignition system. Note that the probability of its failure is lower than that of the ignition module. It is checked by an electrician using an oscilloscope; garage methods do not provide an accurate assessment of the condition of the sensor (only replacement with a guaranteed working one).

ECU. “January” is a relatively reliable injector, but the “brains” can also malfunction from time to time. Often the problem with them is identified by a violation of the injection phases: for example, a spark is supplied only to cylinders 2 and 4, or only to cylinders 1 and 3. Sometimes the issue can be resolved by simply cleaning the contacts on the ECU chip; it is also subject to oxidation, which causes signal loss.

If there's a spark

Not often, but this problem does happen. By all indications, the car should start (gasoline splashes into the ramp, the starter turns, there is a spark), but the engine does not catch. There are also pitfalls here.

Injectors. In most cases, the problem is in them; it is worth taking the car for diagnostics and cleaning it with ultrasound. If trouble strikes you on the road, pay attention to the candles. If the injector supplies the mixture, they must be filled with gasoline; if the spark plugs are dry, the probability of an injector malfunction is high. However, keep in mind that injectors rarely fail suddenly and all at once. As a rule, the engine should start running before the car stops starting.

Poor quality gasoline. It is assumed that a serviceable engine should start almost on water, unless it runs poorly. In reality this is nonsense. There are enough examples of “dead” engines after refueling (both at “Uncle Ashot” and at completely official gas stations of well-known brands). Keep this in mind. If the car stops gripping immediately or a short time after refueling, you should not discount this option. The solution is to drain the gasoline and add another.

Lack of required pressure in the ramp. Here we return to problems with the fuel system. Perhaps the problem is the pump or problems with the TPS (unlikely). If you have January 7.2, the cause may be a malfunction of the mass air flow sensor. Unlike January 5.1, here this sensor is polled at startup and, if there is an error, the ECU may prevent the engine from starting.

Finally, we note that the reasons for non-starting in the presence of gasoline and spark may include the following:

- the phases are incorrectly set when replacing the timing belt, as well as its breakage or rotation - it’s worth checking;

- due to overheating, the cylinder head “started”;

- uneven compression in the cylinders, “stacking” of the rings.

Unplanted VAZ 2114 is a common situation, and there are many reasons that cause it. Therefore, it is worth approaching this issue fully armed.

Coil

In the case of the coil, it can be characterized as a fairly reliable and durable element of the ignition system. It rarely fails and causes trouble for the car owner. But sometimes problems appear and need to be fixed.

Most often, problems with the coil are caused by damage to the winding itself. If this happens, a breakdown occurs in the insulation, which can cause a short circuit that is dangerous for injection engines.

Another reason for damage to the coil is considered to be overload caused by malfunctioning spark plugs or damage to the high-voltage wiring (high-voltage wires).

Before you start checking the spark on the coil, be sure to make sure that the room where the diagnostic work is being carried out is dry. You can do the test yourself, and no special devices or professional equipment are required.

Diagnostics is carried out according to a standard scheme, which involves performing several sequential procedures:

Thoroughly clean the distributor cover from accumulated dirt. Only after this can it be opened and removed; After turning the engine crankshaft, it is necessary to close the distributor contacts; The ignition is turned on; The high-voltage wire coming from the distributor is brought to the ground of the car

It is important to ensure a distance of 5 mm; To increase the accuracy of the test, it is periodically necessary to manually open the distributor contacts.

If the coil is in good condition, during this test you will see a bright, fairly powerful white-blue spark.

When a spark appears, but it is quite weak and unstable, and does not form every time the contacts are closed, such a coil is no longer suitable for further use and must be replaced. In the vast majority of cases, it is impossible to repair the coil.

When installing a new element, do not forget about the importance of observing polarity. If you ignore this point, the coil will break again

If you contact a service center, they can check the coil on a special professional stand. Its advantage is that such diagnostics allows you to test the coil to determine its performance in different modes. But still, almost every motorist can independently figure out how to correctly check the spark on his injection type engine by diagnosing the installed ignition coil.

No spark VAZ (injector, 8 valves)

The other day, out of the blue, the car (Kalina 1.6, 8 valves) began to shake terribly. Diagnostics showed misfires in cylinders 1 and 4. After a little checking (see how to check correctly here), I came to the conclusion that there was no spark . And only in cylinders 1-4.

Next, in order to find out the reason for the loss of spark, I will go in order.

The first thing to check is the spark plugs. The spark plug looked normal, so I didn’t have much hope that replacing it would fix the situation. And so it happened - the new spark plug still refused to produce a spark.

This is interesting: The starter turns poorly when the battery is charged

The second is checking high-voltage wires. They are checked with a conventional multimeter in resistance measurement mode. The resistance should be within 15 kOhm. The wires also turned out to be fine.

Third, and probably most important, is the ignition coil. She, like no one else, is responsible for the spark. Its operability is also checked with a multimeter in continuity and resistance measurement mode. First you need to check the resistance between pins 1-4 and 2-3. It should be about 4 kOhm. If the tester shows infinity, then the coil is broken and must be completely replaced. Next, check the resistance between pins 1a and 1b. There shouldn't be a break here. And the last thing is to check the central contact for breakdown to the housing. The tester should show infinity.

My reel passed the test perfectly. It seems that all the main parts are working properly, so why is there no spark? After digging a little on the Internet, I realized that I still need to check the circuit from the ECU to the coil itself.

A 3-pin chip is placed on the ignition coil, therefore you need to check these 3 wires. The central contact is +12V, which is constantly supplied when the ignition is on. The extreme contacts - 1a and 1b - provide a control signal (negative) at the moment when a spark is needed. How can all this be checked? Very simple - using a regular light bulb.

We connect the lamp to the central terminal and contact 1a and ask a partner to crank the engine a little (first remove the fuel pump fuse and relieve the pressure in the rail). When cranking the starter, the lamp should flash. The same procedure must be done with pin 1b - the lamp should also blink.

When I turned on the ignition, the lamp started to light up, just constantly on (pin 1b and central). This means that the control wire has a short to ground somewhere or that the transistor (VT1) in the ECU is broken. To find out, we need to find the ECU, disconnect the wiring harness from it, find the wires we need (1b) and test them for integrity.

Having found the contact diagram, I found out that contact 1b goes to pin 5 of the ECU, 1a goes to pin 2, 3 goes to ground of the ignition circuit. I rang them for integrity - they were all intact. I called ground and everything is fine too. Therefore, you need to check the transistor in the controller itself.

My car has a January 7.2 controller. Inside there are 2 transistors that pass control signals to pins 1a and 1b of the ignition coil. So one of these transistors was broken, i.e. was constantly in the open position.

How to check the transistor for serviceability? It has 3 pins - 2 of which are soldered. It is necessary to ring each outer terminal with the central one. In both cases, the tester should not beep. The contacts must not be closed.

Now all that’s left to do is to unsolder the broken transistor (its marking is gb10nb37lz), solder a new one in its place and rejoice at the spark that appears.

Reason #5 – Burnout of transistors in the ECU

The lack of a spark can also be explained by broken transistors in the VAZ electronic control unit. To detect faulty elements, you will need to dismantle the controller and also remove the protective cover.

To check the functionality of the transistors, you will need to use a multimeter. The device is put into dialing mode, then both contacts of the transistor, as well as ground, are checked. When a short circuit is detected, the multimeter will emit a corresponding squeak, and the broken transistor must be replaced with a similar serviceable element.

There is no spark in the VAZ 2114 car

Probably, many car enthusiasts have encountered a problem when there is no spark on the high voltage wires, so if the vehicle engine does not start, but the driver hears the functioning of the fuel pump in the tank, then you need to pay attention to the ignition system. One of the most common problems with a car's ignition system is that there is simply no spark at high voltage wiring. That is why the main topic of today’s article will be the following questions:

Why are there no sparks on high voltage wiring? What to do if there are no sparks on the high-voltage wiring of the VAZ 2114?

Naturally, in addition to these questions, we will consider several more and here are a few of them:

- What is the ignition system of the VAZ 2114 car injector?

- Diagnostics of the electronic part of the VAZ 2114 system;

- The main breakdowns encountered by the ignition system of a VAZ 2114 car;

- The main signs of failure of the ignition module of the VAZ 2114 injector;

- Diagnostics of the ignition module VAZ 2114 injector;

- Algorithm for removing and installing the ignition module VAZ 2114 injector;

- How to check whether sparks occur or not?

- What to do if there is no spark on a VAZ 2114 car?

About the purpose of the coil

To ignite the combustible mixture of gasoline and air compressed in the working area of the cylinder, a high voltage is required on the spark plug. Its value exceeds 30 thousand volts. The on-board voltage of the car in most cases is 12 Volts. The ignition coil is designed to obtain the required value.

Photo of ignition coil VAZ 2101-2107

This component of the car must be given due attention; if other systems fail, the car can independently reach the parking lot or service center. In the case where there is no spark, this is impossible to do.

You will have to look for a tow truck or call a tow truck.

Basic information about the ignition system of a VAZ 2114 car

An injector is a method of guiding a car's engine system. In addition, it is a method of supplying the fuel mixture.

On cars with an injection engine, the fuel mixture is supplied using a computer through special nozzles. Most likely, every car owner has ever encountered a problem when there is no spark on the high voltage wires, but the driver can hear how the fuel pump functions, then pay attention to the ignition system of your vehicle. One of the most common problems with a car's ignition system is that there is simply no spark at high voltage wiring.

During operation of the machine, some malfunctions of electrical components may occur and this may affect the functioning of:

- Instruments, and this does not make it possible to control the ignition system and other components;

- power unit, thereby making it impossible to develop standard power;

- Light fixtures and convenience mechanisms, which include lighting, heating and power windows.

The main breakdowns encountered by the ignition system of a VAZ 2114 car:

- Reduced vehicle power;

- Failure during the development of vehicle engine power;

- Idle speed instability;

- Violation of the normal functioning of the cylinder.

You need to start looking for the cause of malfunctions in the ignition system with the formation of sparks on high voltage wiring.

Sparking process

If you hear the fuel pump operating, but there are no sparks on the high-voltage wiring, then check the functioning of the ignition system. The system is checked for the presence of sparks on high voltage wiring, and for this a special device called a spark gap is used. The use of this device is considered more comfortable, because most injector-type engines use static ignition distribution with simultaneous transmission of high voltage to two spark plugs.

To carry out such a test, you need to connect the spark gap and crank the engine using the starter. If sparks appear only on one of the wires, then the reason is a breakdown at the wire ground or at the coil terminal. Sometimes the reason may be a broken wiring or winding that relates to the car's ignition system module.

If there are no sparks on several wires at the same time in any sequence, then the cause of the malfunction lies in the coil, module or vehicle controller.

Please note that damage may occur due to the fact that the high voltage wiring line is broken. In this case, it is necessary to check the high voltage wiring for integrity, and this can be done by taking measurements of the resistance level of the wiring itself. The standard resistance value on the wiring should be no more than 200 kilo-ohms. It is also worth paying your attention to the fact that there should not be a large difference between the resistance levels of the wiring.

Ignition module on a VAZ 2114 car

If the discharge of sparks from high-voltage wiring has always been stable, this indicates that the cause of malfunctions in the injection engine lies in the spark plugs.

If there are no sparks, then the cause of the malfunction may lie in the primary circuit that runs from the generator to the ignition coil. Most often, the cause is a malfunction of the ignition module, and the easiest way to determine whether this is the cause or not is to establish a properly functioning device. That is, if sparks appeared after replacement, then the problem was in the ignition module, and the instructions for use do not provide for its repair.

Algorithm for removing and installing the VAZ 2114 injector ignition module:

- Disconnect the negative terminal on the battery or using the ground disconnect button;

- Remove the tip from all candles;

- We bend the clamp, disconnecting the low voltage wiring block of the module;

- Disconnect the high voltage wiring from the module connectors;

- We unscrew the 2 bolts securing the crankcase to the engine using a 13mm wrench;

- We loosen the 3rd bolt together with the head using a 17 wrench;

- Remove the module together with the bracket;

- Unscrew the bolts securing the module to the bracket. They are located under the hexagon;

- Installation occurs in reverse order.

If sparks still do not begin to form, then it is very likely that the reason lies in the controller or the wiring connecting the module and the ignition coil. In this case, you need to check for the presence of sparks on all cylinders one by one, and if there is no spark on one coil, then replace it with the one next to it. If after replacing one coil with another a spark appears, then the reason is a broken coil, otherwise the controller or wiring is broken.

Signs of broken or dirty injectors

Diagnosing the operation of a car engine is a rather complex process, as it requires accuracy. It often happens that with the same symptoms, the causes of the malfunction can be completely different.

For example, increased fuel consumption and poor engine starting can be caused by both dirty, broken injectors and bad spark plugs. Therefore, it is better to once again make sure that the diagnosis is correct.

The most common symptoms of faulty fuel injectors are the following:

- a sharp increase in fuel consumption;

- loss of dynamics, drop in engine speed;

- problems with ignition, engine starting;

- fuel leaks accompanied by a strong smell of gasoline;

- Frequent engine vibrations when changing gears, slowing down, jerking while driving.

Fuel consumption jump

A significant increase in gasoline consumption during vehicle operation often indicates a clogged fuel injector. The quality of the air-fuel mixture formation process can be greatly affected even with minor contamination, since the injector nozzle has a very small diameter.

As a result, a larger volume of gasoline burns inside the exhaust manifold. Because of this, the dynamic characteristics of the car are reduced, the load on the ignition coil, high-voltage wires, and spark plugs increases.

RPM drop

In cases where too much fuel is sprayed inside the cylinder, the engine speed is “flooded” with gasoline. Because of this, the dynamics of the car during acceleration are significantly reduced. In addition, with a constant load while the machine is moving, the engine speed will vary significantly. Normally, they should remain at a stable level.

Fuel leak

If the fuel injector housing is damaged, gasoline begins to leak out of it. As a result, the fuel simply does not reach the injector. Leakage often occurs through a defective device seal, which often cracks over time. When checking the injector, traces of leaks can be found on the nearest fuel rail.

Along with fuel leaks, a persistent smell of gasoline often appears. On the other hand, this situation occurs when a stuck injector is left open or damaged

Under such circumstances, it is important to find the real cause of the odor.

Problems with ignition and starting

If the injector nozzle is clogged, a sufficient amount of fuel does not flow into the cylinder, so the power unit will misfire while the car is moving. This will clearly manifest itself as a certain pause when pressing the accelerator pedal. If the proportions of the air-fuel mixture are violated, the power unit is susceptible to overheating.

Frequent vibrations

Injector malfunctions lead to interruptions in the ignition process of the air-fuel mixture inside the cylinders. Therefore, while driving, the engine will vibrate and tremble. This occurs due to interruptions in the operation of one or more cylinders.

In some cases, this problem occurs due to clogged fuel lines or faulty ECU sensors.

VAZ 2114: no spark injector

A very good opportunity has arisen to show in practice how to look for a fault on VAZ fuel-injected cars. Here we have a clear, understated nine. Now I’ll show you something else interesting. Problem: won't start. Primary diagnostics showed that there is no spark, and now we will look for the reason. In order to determine the reason, we need to look at the signals on the connector...*. Now let's turn on the ignition and take a look.

This is interesting: Checking the starter from the battery

We must have a ground indicator on the connector....* On the connector we have plus 12 V and ground, and also two control signals. We can now see the control signals, or should, in any case, see them when the starter rotates. We should hear a squeak. But there are no squeaks, because the control signals also do not arrive, so there is no spark. You can also check the signals on the injectors, but there are none either, so you can’t do without diagnostics and a computer (computer).

As I said earlier, when you turn on the ignition, look at the “Check” light. The light is on, which means the brains are turned on. We also listen to the fuel pump - the fuel pump turns on. And when the starter rotates, the fuel pump turns on again, this indicates that the crankshaft position sensor, if faulty, is at least receiving some impulses. The injectors do not open. Just in case, I turned off the immobilizer, it is located here, I just pulled out the connector. Accordingly, the diagnostics, of course, will not work now, but you never know... And, since it is not clear what is the reason for the lack of a spark and injectors*, suspicion fell on a glitchy immobilizer. And now we are flashing the block. I downloaded the firmware, removed the immobilizer from the firmware and uploaded it back.

Popular on the site

Currently on the forum:

This page is searched for the following queries: Lost spark on VAZ-2114, VAZ-2114 forum, discussion of VAZ-2114.

Currently commenting:

Jet black or grey-black

I would like to know the model of injectors, the type of internal combustion engine, the power supply system of the internal combustion engine..

Dimensions and tidy do not light up. CHY, all relays and presets are in order! New button! Backlight on p

On my smartphone it freezes every once in a while, then crashes, it says the pages could not be loaded

Thanks, I think so too

Often, when opening a page, it says that there is no such page, although a few minutes ago someone

Hello! I can’t find the lower rubber bands for the injectors, I found the upper ones, they fit from ten

Do not bother. Xenon in a headlight not intended for it is definitely already a collective farm. And St.

Mine doesn't understand. Is this the end of the update or what?

Wroom.ru

Media registration certificate No. FS 77-76203 16+

If the car engine does not start, but you can hear the fuel pump in the tank running, then you should pay attention to the vehicle’s ignition system. The most common problem is the fact that there is no spark on the high-voltage wires, this especially applies to the VAZ 2114 injector.

How not to check for a spark?

"Old-fashioned methods" of checking for the presence of a spark are not reliable and can lead to more serious damage to the ignition system. You can verify this by reading the material presented below. If you plan to check for a spark by placing the wire at a short distance from the vehicle's ground, keep in mind that in this case the ignition module or its controller may burn out. This usually occurs due to the fact that a large self-induction current appears and at the same time a large spark gap is formed. Moreover, when performing such work, a person can receive a very unpleasant electric shock in the event of a breakdown through the insulating coating. If the spark test passes through the contact of the spark plug with the car body, with a high-voltage wire put on it, then due to the fact that there will be poor contact between it and the ground of the car, a large self-induction current can again form and again there is a high probability of failure of the controller and module ignition Therefore, experts recommend the use of a special spark gap, since it is not only safer, but also much more convenient, since VAZ 2114 injection engines use static ignition distribution while simultaneously supplying high-voltage voltage to two spark plugs.

How to save 20% fuel?

This thing really saves 10-30% on gasoline. You simply install this device on the fuel supply hose and...

My homemade adapter is used. Let's connect to the brains...* The loader used is this one - CombiLoader, this version is like this. I downloaded the firmware for myself, I’ll read why this firmware is cool. Maybe people saw it that way according to the version, I don’t know. Usually, when I repair a car, I use standard water and there are no more problems. And then all sorts of Sports, Economy and others - you won’t understand later that it* works so poorly. I'll show you the results.

I deceived you, unfortunately, I won’t show you how the problem was solved. And the problem was quite interesting. It seems that, based on the first signs, the crankshaft sensor was alive, one might say “conditionally alive”, because when the crankshaft rotated, the fuel pump turned on again and I, as it were, temporarily got rid of this problem. But, as it turned out later, the car had recently been repaired, the head was removed, and inexperienced mechanics laid a wire leading to the crankshaft position sensor near the exhaust manifold.

The wire melted and one of the wires shorted to the braid. For those who don’t know, there is a shielded cable in which two wires are laid. Surprisingly, the brain recognized the pulse in this position and turned on the actuator, that is, the fuel pump relay was turned on, but, accordingly, the engine control unit* was unable to calculate the position of the top dead center, or calculate the position of the pulses. I noticed it purely by chance (I was already freezing, I had no time for filming), just moving the wire near the crankshaft position sensor.

I took it off, checked the sensor - the sensor seemed to start* correctly. Pulling the wire, rotating the starter, the engine began to seize. At this point it became clear that the problem was with the wiring, and after looking carefully at the wire, I saw that it was burnt out. I cut out the damaged area, connected it - and the car started up perfectly and drove away*. It was already dark, I wanted to go home, so there was no time for filming. Nevertheless, I am reporting on the results and a little bit (about) my technique, which I talked about a little earlier in the video, about how to find a spark - the sensor can turn on the pump and at the same time not give a spark - a very interesting case came across. I think you'll take note.

Why does the starter not respond to turning the ignition key?

After turning on the ignition, power from the battery is supplied to the on-board electrical systems and the computer (if equipped). If there is an immobilizer (standard or an installed security system), this occurs only after the tag is recognized. When the key is turned to the start position or the start button is pressed, the contacts of the solenoid relay are closed, resulting in power being supplied directly to the starter. At the same time, the starter overrunning clutch (Bendix) engages with the flywheel crown, setting it in motion and ensuring the engine starts. Often, switching is carried out through an additional starter control relay, which removes the load from the lock.

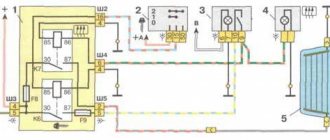

Ignition switching circuit

If a problem arises at any of the above stages, the car will not start: you turn the ignition key and the starter is silent. As a rule, the reasons for this behavior lie in:

- ignition switch contact group;

- alarm and immobilizer;

- control relay;

- wiring from the control relay to the starter;

- starter solenoid relay.

What to do if the engine does not hold speed?

Another problem that often occurs in the VAZ 2114 is that the engine starts, but stalls at speed. The cause is most likely to be found in the battery. Maybe the spark plug is faulty. To check this, you need to remove the spark plug and carefully examine it for damage. Even if there are no visible defects, but there is scale and carbon deposits, the spark plug still needs to be replaced with a new one. This is a part that cannot be repaired, it can only be replaced.

1. Oil pan drain plug. 2. Engine oil pan. 3. Crankshaft. 4. Oil filter. 5. Coolant pump. 6. Exhaust manifold. 7. Piston. 8. Intake pipeline fastening rod. 9. Laying the intake pipe and exhaust manifold. 10. Inlet pipe. 11. Nozzle. 12. Fuel rail. 13. Receiver. 14. Bracket. 15. Cylinder head cover. 16. Camshaft bearing housing. 17. Camshaft. 18. Crankcase ventilation system hose. 19. Valve pusher. 20. Cylinder head. 21. Bolt securing the head to the cylinder block. 22. Valve. 23. Spark plug. 24. Cylinder head gasket. 25. Upper compression ring. 26. Lower compression ring. 27. Oil scraper ring. 28. Piston pin. 29. Fitting for installing the oil dipstick. 30. Connecting rod. 31. Flywheel. 32. Cylinder block. 33. Oil pan gasket. 34. Oil dipstick. 35. Oil intake

It is inexpensive; for the fourteenth model, the price of a set of candles is about 500 rubles. But how do you know if the spark plug is working? A good candle always has a slight brick tint. It must be dry. If the spark plug darkens, it means it has burned out and must be replaced. If it's wet, it means it's flooded. There is no need for replacement, just dry and blow out the part.

Purge occurs when the engine is idling with the spark plugs removed. If the Lada has an injector, then you will have to work longer, also inspecting the fuel system, which is directly related to the operation of the power unit. The injectors are also subject to careful inspection. In winter, there are times when the candle just freezes.

This is not scary, it can be warmed up, cleaned and put back in place, then the engine will start working again. In this matter, such a point as normal fuel supply is also important. If the fuel mixture becomes depleted or, conversely, enriched, this, in turn, causes a serious malfunction, which ultimately affects the operation of the engine.

Pressure also plays an important role. A faulty pressure sensor is involved here too. If its readings are incorrect, it transmits erroneous information to the fuel system, which, in turn, does not supply the required amount of fuel. This creates the problem of a “lean” or “rich” mixture.

https://youtube.com/watch?v=KaBtmIu9P9o

Sources

- https://zapchasti.expert/reshenie-problem/ne-zavoditsya/ne-zavoditsya-vaz-2114.html

- https://remontvazov.com/ne-zavoditsya-vaz-2114

- https://NaDomkrat.ru/ustroistvo-avtomobiley/dvigatel/ne-zavoditsya-vaz-2114

- https://fastmb.ru/autoremont/2257-pochemu-ne-zavoditsya-vaz-2114.html

- https://ladaautos.ru/vaz-2114/pochemu-vaz-2114-ne-zavoditsya-starter-krutit-i-chto-delat.html

- https://expertVAZ.ru/2114/zavoditsya-prichina.html

Frequent malfunctions of the “fourteenth” and ways to solve them

Every owner of Samara 2 has sooner or later encountered such an unpleasant situation when the car starts poorly or does not start at all. This is a common occurrence for domestic cars; moreover, experts say that the norm is when the car starts the second or third time. If you need to start it 5-6 times, then this is already a problem.

So, if the VAZ 2114 does not start, you need to check several systems that may affect the operation of the engine. The most common reason is a dead battery. In this case, the starter does not work at all. To solve the problem, you just need to charge the battery and check all the terminals.

If the sensor lights up green, it means everything is back to normal. It happens that it is not possible to charge the battery. What to do then? As a rule, in such situations, drivers, if this does not help, then they need to “light up” a random hitchhiker.

If the starter works, but the engine still does not start, then the problem may lie in the temperature of the power unit. It is known from auto mechanics lessons that an internal combustion engine consists of four strokes of the working cycle and two rotations of the crankshaft. At the first stage, the mixture is started, at the second - compression, and at the third - the appearance of a spark.

The last stage is release. If the crankshaft is in working condition and the engine itself has not received serious defects, it does not jam when starting, which means that two problems remain: the condition of the mixture and the spark. That is, spark plugs and carburetor are subject to diagnosis.

By the way, if there is no spark, then you are faced with one of the most common problems for the “fourteenth”, as for all VAZ cars. To try to start a cooled engine, you need to pull out the tray a little and turn the key. Now you can press the gas pedal, just not too hard. As a rule, after such simple manipulations the motor “comes to life”.

Now you can safely drive to your home or garage, where you can once again carefully check the working condition of the vehicle control system. But it happens that this procedure does not help, in which case there is no doubt: something is wrong with the candles. To check the spark, you need to remove one spark plug and run the starter. Spark plugs do not produce a spark for several reasons:

- a gap has formed between the contacts;

- the capacitor has failed;

- the coil is faulty;

- problems with the distributor.

https://youtube.com/watch?v=-kE3OCc7J7w

Among other things, if there is no spark, you should check the condition of the fuel in the carburetor. It's not difficult to do. You just need to tap the carburetor a little with a wrench, but not over its entire surface, but only at the filler hole.

In addition to the needle, the condition of the fuel pump plays a significant role. Also, sometimes you have to clean clogged injectors, which are especially often clogged due to the fact that the car owner fills the car with low-quality fuel or oil. We answered the question of how to start a cold engine.

When hot, as a rule, the engine starts immediately, but there are always exceptions to the rule. If the power unit does not start when hot, this may indicate that the engine cylinders have a rich mixture. The problem is solved by unscrewing all existing spark plugs and cranking the engine. After removing the spark plugs, you can simply leave the car for half an hour to dry.

Main reasons and methods for solving them

Healthy! Maybe you are lucky and resetting the injector errors will help. To do this, you first need to remove the negative terminal from the battery. If after 5-10 minutes the car starts as well, then this is not the problem.

Difficulty starting the engine is influenced by a number of simple reasons, which you can eliminate yourself in the garage, having a standard set of tools with you.

Starter mechanisms (brushes, bendix)

In the process of rebuilding the starter. The arrow indicates worn brushes.

- On used cars, the brushes on the starter wear out. In this case, you need to remove the cover and replace them with new ones;

- A starter that has been in use for a long time can be sorted out, cleaned all the mechanisms, washed with WD-40 and filled with new lithol, since the old one is most likely coked and formed into balls;

Fuel problems

In the process of replacing the fuel pump grid. On the right is the old one, and on the left is the new coarse mesh

Small particles of debris getting into the gas tank. This problem is treated by cleaning the fuel system and replacing the filter.

Incorrect sensor readings

Failure or incorrect signal supply from the sensors to the ECU (their diagnostics are required, and if a malfunction is detected, replacement with new ones):

- Speed sensor.

- Crankshaft position sensor.

- Idle speed sensor.

- Phase sensor.

Wires, filter and spark plugs

Clogged air filter

- High-voltage wires are broken, poor contact on the tips (oxidation). During a visual inspection, it is rarely determined whether the best option is to replace it with new or known good ones. Before replacing, you can clean (blow out) the contacts on the old wires.

- The spark plugs are flooded, mechanically damaged, or the gap is set incorrectly. If necessary, the following is done: new ones are screwed in, the required gap is set, or the old ones are returned to their place.

- The air filter is clogged, causing the air supply to the engine combustion chamber to deteriorate. It is recommended to replace with a new one.

Gasoline pump

The fuel pump does not provide the required pressure, which is why the injectors do not spray fuel, but simply splash it. In order to discard this option, you need to measure the fuel pressure with a pressure gauge (the nominal one should correspond to the norm of 3.2 bar).

If the result is different, the situation requires replacing the fuel pump.

Engine failure

Reduced compression in the cylinders is one of the most terrible situations for a car owner. In this case, flammable gases enter the crankcase, and new vapors do not ignite.

In this situation, replacement of the piston rings is required, and perhaps a major overhaul of the engine.

Sources