In technical and structural terms, a car is a rather complex means of transportation. The components and mechanical parts and systems included in it must work harmoniously and properly. If one unit is damaged and any part malfunctions, a significant deviation in the functionality of the vehicle or its breakdown may occur. Among most important car structures, the ignition system is considered one of the most significant. It significantly affects the possibility of uninterrupted operation of the car. Today we know about three types of ignition systems that can be installed on a car: contact, non-contact and microprocessor. The latter is considered the newest achievement in the automotive industry. This useful material will take a closer look at contactless and contact systems and describe their differences.

Contact ignition coil

In a contact ignition system, the coil consists of several important elements: a core, primary and secondary windings, a cardboard tube, a breaker and an additional resistor. A feature of the primary winding compared to the secondary is a smaller number of turns of copper wire (up to 400). In the secondary winding of the coil, their number can reach 25 thousand, but their diameter is several times smaller. All copper wires in the ignition coil are well insulated. The coil core reduces the formation of eddy currents; it consists of strips of transformer steel, which are also well insulated from each other. The lower part of the core is installed in a special porcelain insulator. Now there is no need to list the principle of operation of the coil in detail; it is enough to just mention that in a contact system such an element (voltage converter) is of key importance.

Replacing old with new

Many people, faced with problems caused by the contact ignition system, prefer to improve it or replace it altogether, but lovers of classic cars and car restorers prefer to keep the original. And this procedure is quite expensive - although the replacement work is quite simple and consists mainly of replacing parts and assembly, the kit itself is expensive.

The non-contact type is better than the contact type in that it is devoid of contacts, which often burn during prolonged use.

Unlike contact, contactless has a switch - this device replaces contacts, but performs the same functions. This is, in fact, the only difference between these ignition systems.

Contactless ignition coil

In a contactless ignition system, the coil performs exactly the same functions. And the difference manifests itself only in the direct structure of the element that converts voltage. It is also worth noting that the electronic switch interrupts the power supply circuit of the primary coil. As for the ignition system itself, the non-contact one is much better in many respects: the ability to start and operate the engine at low temperatures, there is no disturbance in the uniformity of spark distribution in the cylinders, and there is no vibration. All these advantages are provided by the coil itself in a contactless ignition system.

Coil comparison

When it comes to the differences between a coil of a contact ignition system and a contactless one, everyone immediately pays attention to the markings. Indeed, from it you can immediately find out for which system the coil is used. However, we are interested in the external and technical differences of the coils, so we will present the differences in these parameters:

- The coil in the contact ignition system has a larger number of turns in the primary winding. This change directly affects the resistance and the amount of current passing. In addition, limiting the current on the contacts is related to safety (so that the contacts do not burn).

- The coil breaker contacts in a contactless ignition system do not become dirty or burn. This reliability allows for one important advantage: setting the ignition timing does not take much time.

- The coil in a contactless ignition system is more powerful and reliable. This advantage is directly related to the fact that the most contactless ignition system is a more reliable option. Therefore, in such a system, the coil provides greater engine power.

The lid is no different. The geometry is the same. The lids have different properties. There was a test in ZR for a long time. The best were the gray plastic lids. Maximum breakdown voltage. No one makes black and brown thermoset anymore.

Runners differ in resistance rating. For KSZ 2 kOhm, for BSZ 5 kOhm.

Do you know what a delta pulse is? Open the theory of filtration, it is well written about its properties.

So, if we remove all resistance from the spark path, we get practically a delta pulse (large amplitude and short duration). Radiation spectrum from 0 to infinity with linear power distribution. You will catch even in the FM band. If the amplifier catches interference, don’t go to a fortune teller. Nonlinearities will detect the interference and listen to it clearly in the audio range.

Electronic ignition device VAZ 2106

The contactless system (abbreviated as BSZ) of the Zhiguli includes six devices and parts:

- the main distributor of ignition pulses is a distributor;

- a coil that produces high voltage for a spark;

- switch;

- connecting cable with connectors;

- high voltage cables with reinforced insulation;

- spark plug.

BSZ inherited only high-voltage cables and spark plugs from the contact circuit. Despite the external resemblance to the old parts, the coil and distributor are structurally different. New elements of the system are the control switch and wiring harness.

The coil operating as part of a contactless circuit differs in the number of turns of the primary and secondary windings. Simply put, it is more powerful than the old version, since it is designed to create pulses of 22-24 thousand volts. The predecessor supplied a maximum of 18 kV to the spark plug electrodes.

Trying to save money on installing an electronic ignition, one of my friends replaced the distributor, but connected the switch to the old “six” coil. The experiment ended in failure - the windings burned out. As a result, I still had to buy a new type of coil.

The cable with connectors is used for reliable connection of the terminals of the ignition distributor and the switch. The structure of these two elements should be considered separately.

Contactless distributor

The following parts are located inside the distributor housing:

- a shaft with a platform and a runner at the end;

- support plate rotating on a bearing;

- Hall magnetic sensor;

- A metal screen with gaps is fixed on the shaft, rotating inside the sensor gap.

A vacuum ignition timing unit is installed externally on the side wall, connected to the support platform by means of a rod. A cover is attached to the top with latches, where the cables from the spark plugs are connected.

The main difference between this distributor is the absence of a mechanical contact group. The role of the breaker here is played by an electromagnetic Hall sensor, which reacts to the passage through the gap of the metal screen.

When the plate blocks the magnetic field between the two elements, the device is inactive, but as soon as a gap opens in the gap, the sensor generates a direct current. How the distributor works as part of an electronic ignition, read below.

Control switch

The element is a control board protected by a plastic cover and attached to an aluminum cooling radiator. The latter has 2 holes for mounting the part to the car body. On a VAZ 2106, the switch is located inside the engine compartment on the right side member (in the direction of travel of the car), next to the coolant expansion tank.

The main functional parts of the electronic circuit are a powerful transistor and a controller. The first one solves 2 problems: it amplifies the signal coming from the distributor and controls the operation of the primary winding of the coil. The microcircuit performs the following functions:

- gives commands to the transistor to break the coil circuit;

- creates a reference voltage in the electromagnetic sensor circuit;

- counts engine speed;

- protects the circuit from high-voltage pulses (over 24 V);

- adjusts the ignition timing.

The switch is not afraid of changing polarity if the car owner mistakenly confuses the positive wire with ground. The circuit contains a diode that closes the line in such cases. The controller will not burn out, but simply stop functioning - a spark will not appear on the spark plugs.

Signal generation by Hall sensor

The second possibility of contactless spark control can be achieved using a Hall sensor.

The Hall sensor is often used when converting the ignition system from contact to contactless, since it can be installed instead of a breaker on a movable plate.

The non-contact sensor uses the Hall effect (named after its discoverer), which involves the creation of a transverse potential difference in a conductor carrying a direct current under the influence of a magnetic field. The Hall effect is especially effective in special semiconductors. A microcircuit integrated into the Hall sensor further enhances the signal.

- Av A2 - connections, semiconductor layer

- UH - Hall voltage

- B - magnetic field (dense)

- Iv - constant supply current

When the screen with slots (shutter) rotates, the magnetic field periodically acts on the Hall sensor. If the shutter is open between the magnetic guides (the so-called slots), a Hall voltage is induced. If the shutter is closed in the air gap between the magnetic guides, then the magnetic field lines cannot affect the Hall sensor and the voltage is close to zero (Small stray fields cannot be completely suppressed). Thanks to the Hall voltage characteristic, the signal for sparking is again present.

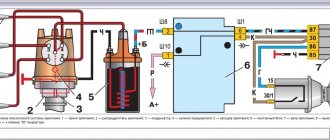

Scheme and principle of operation of BSZ

All elements of the system are connected to each other and to the engine as follows:

- The distributor shaft rotates from the motor drive gear;

- The Hall sensor installed inside the distributor is connected to the switch;

- the coil is connected by a low voltage line to the controller, a high voltage line to the central electrode of the distributor cover;

- high-voltage wires from the spark plugs are connected to the side contacts of the main distributor cap.

The threaded clamp “K” on the coil is connected to the positive contact of the ignition switch relay and terminal “4” of the switch. The second clamp marked “K” is connected to contact “1” of the controller, and the tachometer wire also comes here. Terminals “3”, “5” and “6” of the switch are used to connect a Hall sensor.

Contactless system malfunctions

In terms of reliability, the BSZ is significantly superior to the outdated contact ignition of the “six”; problems arise much less frequently and are easier to diagnose. Signs of system malfunction:

- complete failure - the engine stalls and will no longer start;

- uneven idling, shots in the carburetor when the gas pedal is sharply pressed;

- interruptions and skipped cycles while driving.

The most common symptom is the first one - engine failure, accompanied by a lack of spark. Common causes of the problem:

- The resistor built into the distributor slider has burned out.

A high-voltage coil rarely fails. The symptoms are similar - a complete lack of spark and a “dead” engine.

The search for the “culprit” is carried out using sequential measurements at different points. Turn on the ignition and use a voltmeter to check the voltage at the Hall sensor, transformer contacts and switch terminals. Current must be supplied to the primary winding and the 2 outer contacts of the electromagnetic sensor.

To check the controller, a familiar auto electrician suggests using one of its functions. After turning on the ignition, the switch supplies current to the coil, but if the starter does not rotate, the voltage disappears. At this moment, you need to take measurements using a device or a control light.

A Hall sensor malfunction is diagnosed as follows:

- Disconnect the high-voltage cable from the central socket on the distributor cover and secure the contact in the immediate vicinity of the body, at a distance of 5-10 mm.

- Disconnect the connector from the distributor, insert the bare end of the wire into its middle contact.

When the engine operates intermittently, you need to check the integrity of the wiring, contamination of the switch terminals, or high-voltage wires for insulation breakdown. Sometimes the switch signal lags, causing dips and deterioration in overclocking dynamics. It is quite difficult for the average owner of a VAZ 2106 to detect such a problem; it is better to contact a master electrician.

Modern controllers used for contactless ignition of the “six” burn out quite rarely. But if the Hall sensor test gives a negative result, then try to replace the switch using the process of elimination. Fortunately, the price of a new spare part does not exceed 400 rubles.

Video: how to check the health of the switch

FakeHeader

Comments 21

For many years I have had a BSZ switch like in the video, Ukrainian 0529.3734, a Bosch coil, an Oskol distributor. I bought everything separately. I'm very pleased with how it works. No complaints. In reality, you just need to occasionally check the wire contacts on the switch and the Hall sensor. I treat them with hi-gear to protect the high-voltage part of the ignition.

what kind of sonar is this?

From contact ignition it turns into non-contact ignition. You pull out the breaker and in its place in the old contact distributor you put Sonar ik) and voila you have 800 rubles without contact ignition.

The five had the same dilemma, the question was either to pay 3.5 kilo rubles for a contactless distributor or 500 rubles for a sonar. I bought a sonar, installed it in my original distributor in five minutes, and forgot what ignition problems were! The only thing was that I put the old contacts in the trunk and took them with me just in case of fire. I didn’t remove the capacitor, I just threw the wire away... I drove the Sonarik for 3.5 years and it never let me down! My opinion is definitely to take it and put it! And of course it’s up to you...

The Sonarians are definitely not. They work on IR rays (luminous flux). It gets clogged with dirt and you get up, the spark is gone. About increasing the voltage on the staggered coil from such a stray to 400 V (I read it from the instructions for Sonar) - complete heresy, there is about 16,000 V on contact ignition. In general, there are only disadvantages, except for one plus - the price.

Non-contact kit 1. Hall sensor installed in the distributor is essentially eternal and is not afraid of dirt. 2. The voltage on the coil (discharge voltage on the spark plugs) is already about 40,000 V. 3. The ignition pulls out normal sparking at another 8 volts on the switch. 4. Spare parts are available in all stores. 5. I gave everyone five years and everyone was just happy, forgetting about hemorrhoids with contacts and connectors.

And advice - buy a ready-made set, not individually. What if it doesn’t work (I haven’t had this happen, but suddenly. After all, we live in Russia :)) I always handed it in as a set and took another one, but individually, first you have to find what doesn’t work, etc.

Wow! Now I fully understand what's what. Thank you very much for the clarification. Well, I looked in our city and didn’t find the kit. And there is one store where they can change it for me without any problems if something is wrong. Because I’m not afraid to take it in bulk if) I’ll take the ignition completely decided!)

Well good luck. You will not regret. Even savings should appear. Don’t forget - you also need spark plugs for explosive ignition and explosive wires designed for 40 kV.

I want to make the wires zero. The central one is already there. And the difference between them is in the rubber bands on the tips. Spark plugs, if you don’t go deep into the quantity, the gap can be increased and it should be normal) thank you.

The Sonarians are definitely not. They work on IR rays (luminous flux). It gets clogged with dirt and you get up, the spark is gone. About increasing the voltage on the staggered coil from such a stray to 400 V (I read it from the instructions for Sonar) - complete heresy, there is about 16,000 V on contact ignition. In general, there are only disadvantages, except for one plus - the price.

Non-contact kit 1. Hall sensor installed in the distributor is essentially eternal and is not afraid of dirt. 2. The voltage on the coil (discharge voltage on the spark plugs) is already about 40,000 V. 3. The ignition pulls out normal sparking at another 8 volts on the switch. 4. Spare parts are available in all stores. 5. I gave everyone five years and everyone was just happy, forgetting about hemorrhoids with contacts and connectors.

And advice - buy a ready-made set, not individually. What if it doesn’t work (I haven’t had this happen, but suddenly. After all, we live in Russia :)) I always handed it in as a set and took another one, but individually, first you have to find what doesn’t work, etc.

Will it become clogged with dirt? Where will the dirt come from under the distributor cap? I have been using it for more than 3 years and nothing has clogged once. As for the pros, the most important plus is reliability and price. And even if it fails, you can install the old contacts in 15 minutes and move on. But if the hall sensor fails, then you will be on the road... And by the way, with a sonar, the Conder also reclines, and this is the most common hemorrhoids...

The same coal, condensation in the lid, dust - there are 2 ventilation holes in the lid through which there is access from the outside with all factors. . It is easier to block the light emission and the photodetector than the magnetic field. Do you carry contacts and a capacitor with you, as well as a probe or an UZSK device? Why not just carry a Hall sensor in this case? It’s even simpler - you unscrew the bolt and tighten it, and the best part is that there’s no need to adjust the contacts. And by the way, in 15 minutes you can install the condenser + contacts + adjust the contacts, but somehow, since it is impossible to carry out all the procedures efficiently in 15 minutes. Sorry, but as they say, “I’ve been married for several years and I know first-hand what to do and what not to do.”

I don’t force anyone to do as I do, if you have a lot of money, of course you can buy a contactless ignition kit and not reinvent the wheel! But the essence of the question, as I understood it, was how to get away from the contact ignition system at a lower cost, I answered the question. Moreover, he answered not from theory, but from the practice of using this device for more than three years in his car and installing it on a VAZ2106 for his father for more than two years, and not a single problem arose. And as I understand it, you install contactless kits for everyone (that’s understandable, it’s the client’s money, and you can charge more for installation) but you yourself used a sonar? If you have used it and there are cases when it REALLY got clogged with dirt and did not work, please share your experience. And there are a lot of experts who can talk theoretically while sitting on the couch... By the way, in my memory, my friends’ hall sensors died a couple of times for no apparent reason, and 99.9% of people in their cars don’t have a spare sensor, everyone came as they say... I also read (personally, none I haven’t seen a case, I’m just writing facts) that sonars can die suddenly, nothing happens forever, there is a thyristor there as far as I remember, BUT in the event of such a breakdown, I repeat, you can put contacts and get to the place without problems (and contacts are put when presence of direct hands without probes and instruments, and the Conder is in its normal place, just the wire is disconnected). The PRICE of the issue speaks in favor of such a modification, and there is no need to buy additional contacts, you carry the old ones. And you need to buy a hall sensor as a spare, and the high-voltage wires need to be changed, if I’m not mistaken, that’s also money... So if you have facts, write, but theoretically you can crap anything...

Setting the ignition timing

If you forgot to put a mark on the valve cover before disassembling or did not align the marks, the moment of sparking will have to be adjusted again:

- Remove the first cylinder spark plug and remove the main distributor cap.

Attention! When the piston of cylinder 1 reaches the upper position, the notch on the crankshaft pulley should coincide with the first long mark on the timing belt cover. Initially, you need to ensure a lead angle of 5°, so place the pulley mark opposite the second mark.

In a similar way, adjustment is made using a light bulb connected to the ground of the car and the low-voltage winding of the coil. The ignition timing is determined by the flash of the lamp when the Hall sensor is triggered and the switch transistor opens the circuit.

By chance, I found myself at a wholesale car parts market and purchased an inexpensive strobe light. This device greatly simplifies ignition settings by showing the position of the pulley notch when the engine is running. The stroboscope is connected to the distributor and gives flashes simultaneously with the formation of a spark in the cylinders. By pointing the lamp at the pulley, you see the position of the mark and its change as the speed increases.

Video: adjusting the ignition “by ear”

Electronic spark plugs

When installing BSZ on a VAZ 2106 model car, it is advisable to select and install spark plugs that are optimally suitable for electronic ignition. Along with Russian spare parts, the use of imported analogues from well-known brands is allowed:

- original spark plugs recommended by the manufacturer - A17DVR (M);

- NGK - BCPR6ES-9, BPR6ES-9;

- Bosch - FR7DCU, WR7DC;

- Brisk - DR15YC, LR15YC;

- Beru - 14FR-7DU, 14R-7DU.

The letter M in the marking of domestic parts indicates copper plating of the electrodes. There are A17DVR kits on sale without copper coating, which are quite suitable for BSZ.

The gap between the working electrodes of the spark plug is set within 0.8-0.9 mm using a flat feeler gauge. Exceeding or decreasing the recommended clearance leads to a drop in engine power and an increase in gasoline consumption.

Installing a non-contact spark generation system significantly improves the performance characteristics of carburetor Zhiguli cars equipped with rear-wheel drive. Unreliable, constantly burning contacts caused a lot of trouble to the owners of the “sixes”. At the most inopportune moments, the breaker had to be cleaned, getting your hands dirty. The first electronic ignition appeared on front-wheel drive models of the “eighth” family, and then migrated to the VAZ 2101–2107.

And lastly

It should also be noted that the non-contact type has better current characteristics - higher frequency and voltage, which significantly extends the life of the spark plugs. However, this difference also has its drawbacks - you will have to replace standard high-voltage wires with silicone ones, which conduct current better, but are much more expensive.

Some owners of classic cars of the VAZ 2101-07 family are constantly trying to improve, modify, add electronics and convenience. One of these improvements is the installation of contactless electronic ignition.