The parking or handbrake (handbrake) is designed to lock the wheels while the car is parked, and is most often used on uneven sections of the road (downhill slopes).

A properly adjusted handbrake should hold the car in place when tightened by 4-6 teeth, on an area with a slope level of 25%. If the handbrake does not hold, it needs adjustment or repair of the parking brake.

In order to disable the handbrake, you don’t need much, just drive once and forget to take the car off the handbrake. While driving, the pads will quickly wear out and simply will not reach the brake drum when you tighten it.

Adjusting the handbrake VAZ 2107

Restoring the handbrake's functionality should begin by checking the cable tension. To tighten the parking brake cable of a VAZ 2107, you will need:

- pliers;

- a pair of keys for 13;

- metal brush;

- WD-40;

- jack.

The adjustment should be made on an inspection pit or a lift. In the latter case, a jack will not be needed.

The procedure is as follows:

- Raise the rear wheels using a jack or lift so that they can be rotated by hand.

- Tighten the handbrake 2-3 clicks (until the locking position).

- Use a wire brush to clean the threads on the adjusting bolt if they are dirty. If corrosion is severe, use WD-40 to remove the nut from the adjusting bolt.

- Using a pair of 13mm wrenches, loosen the locknut;

- Using a 13mm wrench and pliers, adjust the position of the nut so that the wheels are locked.

Note: if even in the extreme position of the nut the VAZ 2107 handbrake is not tightened sufficiently, it is necessary to replace the cable.

- Make sure that the cable is not overtightened and that when the lever is lowered, the wheels are unlocked.

- Tighten the locknut.

- Lubricate the threads of the adjusting bolt with lithol to prevent corrosion.

As you can see, applying the handbrake of the VAZ 2107 is quite simple.

When adjusting the handbrake, it is worth checking the rear wheel bearings. They should rotate easily and smoothly, without noise. The presence of play indicates the need to tighten the bearings.

Pro Tips

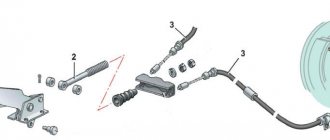

When replacing the parking brake lever, inspect the roller with mounting components: bolt with spring washer (1), roller (2), bushing (3). If there is mechanical damage, the roller must be replaced. Before installation, lubricate the bushings (b) and contacting surfaces of the roller (a) with LSC-15 or Litol-24 grease.

If you need to replace the lever rod spring, unscrew the lever handle button. We take out the spring and, if necessary, change it.

Replacing the handbrake and front parking brake cable on a VAZ 2101-VAZ 2107

Welcome! There are two cables in total in the car, namely the rear and front handbrake cables. The front one, coming from the parking brake and having a short length. It goes to the rear, compared to the front cable it is very long. The rear one goes directly to the two rear wheels. Thanks to the cable system, the car is braked.

Note! You will have to remove the handbrake, which means the following tools will be useful: various kinds of wrenches, a screwdriver and pliers.

Part location

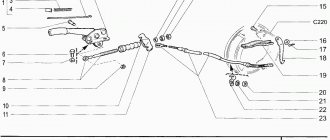

It comes from the handbrake and passes under the bottom of the car, connecting to the rear (main) cable. Below we have attached a photo with a diagram of the handbrake. The front cable is indicated by number 2.

Note! In the diagram above it may seem that cable number two is divided into two parts, but in fact it is not. It is solid, just in the place where it supposedly breaks (in the diagram) there is a roller (indicated by number 8).

When to change the cable and the handbrake itself?

You have to change it when the cable breaks. You will feel this when the handbrake begins to rise very easily and to a very high position, almost to a vertical position. Exactly the same situation will arise if the cable breaks at the back. Therefore, before you go to a car store and buy a new one, inspect the bottom of the car and figure out which cable has become unusable.

Note! The cable tends to stretch over time. It all depends on the quality of the material; a high-quality cable will last longer and stretch to a shorter length. If you see that this cable is sagging and the adjustment does not lead to anything good, then you will have to replace it with a new one!

Now let's talk about when to change the handbrake itself. Firstly, there is a gear sector on the parking brake, thanks to which the handbrake rises up neatly and does not slip between clicks. Secondly, the so-called pawl, which blocks the handbrake after lifting up, its breakdown leads to the handbrake not being held in one position, it will constantly fall. These factors are a reason to replace the part with a new one.

Tension

So, having understood the diagram, you can begin the procedure of tightening the handbrake cables.

Stretch

The tensioning procedure is as follows.

- Place the car on an overpass or pit. If you don’t have a garage and you have the opportunity or desire to carry out the procedure at a service station, use a jack. The rear of the car is raised on a jack. The most extreme option is a curb onto which the car is driven and all you have to do is crawl under it.

- Engage the gearbox in first gear and put the car on the handbrake by pulling the lever up.

- The ideal number of handbrake clicks is from 2 to 5. If there are fewer or more clicks, it is easier to take appropriate measures to tension the cable.

- If there are less than 2 clicks, then the cable will need to be lengthened. If there are more than five clicks, then the cables are shortened.

- Lengthening the cable means relaxing it. To do this, unscrew the locknut. When tightening the cable, the locknut must be tightened in reverse.

- Before you start looking for the required nut on the bottom of the car, release the handbrake lever all the way.

- Take a 13mm wrench under the car and head down.

- Find the handbrake cable equalizer. This is the same element from which the main handbrake cable is divided into two cables.

- In some cases, it is simply not possible to gain access to the equalizer, since the muffler holders made of rubber are in the way. In such a situation, it is better to remove them. This is not difficult to do, but working with the handbrake will be much easier.

- Now there are two nuts in front of you. One is a simple nut and the other is a lock nut. Having two keys in your hands, fix the nut with the first one, and with the second one begin to unscrew or tighten the locking nut. Be careful that the nut does not start to turn.

- Taking into account the condition of the handbrake and the need to loosen or tighten the lever, turn the locknut in the appropriate direction. Remember what is the optimal number of clicks.

- Tighten or unscrew the locknut to obtain the required degree of tension.

Examination

But if you twisted the nuts there, this is not a guarantee that the handbrake now works perfectly. This needs to be clearly verified.

To do this, it is enough to go through a successive stage of verification activities.

Stage

Explanation

Spin the wheels after tensioning is completed

The wheels are lifted one by one on a jack. When the handbrake lever is turned off, they should rotate freely without obstacles. By squeezing the brake, the wheels should lock.

Drive up a slight slope, stop and engage the handbrake

The fact that the wheels do not spin when suspended is good. But you need to make sure that the handbrake holds the car even when exposed to gravity.

If the check shows that the handbrake still does not hold, even if the cable was tensioned exactly according to the instructions, the handbrake is probably simply worn out and the cable needs to be replaced.

Signs that replacement is needed

It is not uncommon for the VAZ 2114 handbrake cable to rust, as a result of which it breaks or weakens so much that no tightening can restore its previous functionality.

At the first sign of cable wear, you should consider replacing it. This problem may manifest itself as follows:

- The handbrake is not able to withstand the required traction;

- Drum brakes overheat;

- When you pull the parking brake lever, the cable does not respond to your actions;

- The cable sheath is seriously worn.

Features of the braking system

One of the features of the VAZ-2107 brake circuit is the presence of a dual-circuit system. The essence of a dual-circuit system is that the working drive is divided into two parts, each of which supplies fluid to only two mechanisms, while the circuits do not interact with each other.

The presence of two circuits ensures the operability of the brakes of at least two wheels in the event of depressurization of one of the circuits. That is, even if the pipelines of one circuit are punctured, the second will remain fully operational, which will ensure the functioning of the brakes.

In the VAZ-2107, the circuits are divided in such a way that the drive of the front axle mechanisms is separated from the drive of the rear mechanisms. This allows you not only to maintain the functionality of the system when one of the circuits fails, but also to pump each circuit separately. That is, if one of the circuits is airy, then it needs to be pumped, but it is not necessary to service the second one.

This is only general information about how the VAZ-2107 brake system works, and does not include all the details on its maintenance and repair. In general, the brakes of this car work quite well, although some elements of it cause complaints from car owners.

Brake master cylinder

The master cylinder is connected to the booster. This element is a housing to which the supply and return pipelines from the fluid reservoir are connected, and 3 pipelines leading to the brake mechanisms exit. There is one pipeline leading to the front brake mechanisms, and only one to the rear, leading to the regulator.

Inside this housing there are pistons that push the liquid into the pipelines. One of them is connected to the amplifier diaphragm rod. These are the main elements of the drive. The detailed design of the brake master cylinder is shown above.

What is needed to replace brake pads

- jack;

- wheel wrench;

- set of wrenches;

- hammer;

- bit or thin screwdriver;

- metal brush;

- rag (rags);

- a powerful flat-head screwdriver or pry bar;

- pliers;

- screwdriver;

- WD-40;

- new pads.

The front brakes of the “seven” are disc type, the rear brakes are drum. Accordingly, the design of the pads and the procedure for replacing them are different.

To replace the pads you must perform the following steps:

Tip: Before completely recessing the pistons, you should check the brake fluid level. As the pistons retract, the fluid level rises. To prevent brake fluid from spilling out and getting on body parts and damaging the paintwork, you can take a little of it from the reservoir using a syringe or syringe.

At the end of the operation, you should check the brake fluid level and add it if necessary.

To change the rear brake pads of a VAZ 2107, you must perform the following operations:

Attention! When a brake drum wears out, a lip forms on the inside of the drum, making it difficult to remove from the pads. In this case, the operation becomes more complicated. It is necessary to use two 8mm screws, simultaneously screwing them into the corresponding holes on the drum.

It is necessary to use two 8mm screws, simultaneously screwing them into the corresponding holes on the drum.

Tip: to easily install the rods, you need to tie a stiff copper wire to their ends and first thread it through the holes, then pull the rod through. After installing the rod, the wire must be immediately untied and removed.

Tip: The easiest way to remove the bead is to use a file, using the machine itself as a makeshift “lathe.” To do this, you need to secure the car well with wheel chocks, hang both rear wheels, secure the brake drum to the flange (with the outer side facing the flange), start the engine and turn on the speed. The rear wheels will begin to rotate and removing the bead with a file will not be difficult.

After replacing the pads, the parking brake must be adjusted. Only after this the rear brakes of the VAZ 2107 can be considered suitable for use.

Change brake pads at least every 30 thousand km. Otherwise, if there is severe wear, you risk losing brake power. Do not let the pads become too squealing or grinding. In this article, we will look at instructions on how to remove and replace the front brake pads of a VAZ 2107 with your own hands.

You will need: new brake pads, hammer, pliers, penetrating lube, flathead screwdriver, guide tool, jack or lift.

Sources

- https://provaz07.ru/tormoza/zamena-zadnix-tormoznyx-kolodok-vaz-2107.html

- https://semerkavaz.ru/tormoznaya-sistema/zamena-kolodok-na-vaz-2107/

- https://automas.ru/vaz/2107/snyatie-zamena-perednix-tormoznyx-kolodok-vaz-2107-svoimi-rukami/

Causes of malfunction and their elimination

As a rule, the reasons why the handbrake does not work are quite simple and do not require long or expensive repairs:

- torn cable. One of the common causes is a broken cable on the handbrake or under the car. The problem is solved by simply replacing the cable;

- jammed cable. Due to damage to the sheath in which the cable moves, it may become jammed, preventing you from using the handbrake. And the cable itself consists of many steel strands, which, if damaged, can also prevent proper operation. The solution is to replace the cable;

- dirty brakes. If dust, dirt, ice or reagents that are sprinkled on roads in winter get on the pads, this can cause the brakes to not work properly. The solution is to press the brake pedal several times smoothly while the car is moving. Thanks to friction, the pads will be cleaned;

- incorrect adjustment. It may happen that the cable system is not adjusted properly, the bolt is not tightened correctly, or the length of the cables is incorrectly selected. The solution is to adjust the system and correct tension of the cables;

- pad wear. The pads are subject to abrasion during operation. Every time you apply the brakes, the pads gradually become unusable. The solution is to replace the pads;

- oil in the pads. Oil or brake fluid leaks can cause the car to not hold up with the handbrake. The most important thing in this case is to identify the cause of the leak - it could be the rear axle seal or the brake cylinder. The solution is to eliminate the leak and clean the pads. If the pads are very oily, replace them.

Replacing the handbrake cable on a VAZ 2107. No service stations. Do it yourself

The work that owners of the same model have to periodically carry out is replacing the handbrake cable on a VAZ 2107. This manipulation is quite simple - if you first understand the design of the handbrake, the characteristic features of the fastenings, etc. But first of all, you need to find out in what cases it is carried out . The reasons for the repair are intuitively clear: in cases where the handbrake does not perform its functions (does not “hold” the car in the parking position); if a cable break or severe deformation (stretching) is detected. Replacing the handbrake cable on a VAZ 2107 can be done at a car service center - quite quickly and professionally, but due to the simplicity of the procedure, you can do it yourself

. Additional information:

The cost of the part varies between 300-400 rubles. It is recommended to purchase from trustworthy sellers: low-quality cables (that is, made of low-quality material with poor manufacturing technology) usually do not last long.

Required tools: pliers, wrenches, pliers.

Dismantling

- First you need to remove the brake drums - on both sides. The next step is to disconnect the right rear brake pad. The cable tip is removed from it, and then the block itself is removed from the brake shield;

- It is necessary to immediately warn novice repairmen: the front brake pad cannot be removed;

- in a similar way

, after which the lock nut should be loosened. To prevent it from turning, use a second key to fix the adjusting nut. Then, fixing the tip with pliers, unscrew both nuts; - We remove the spring hook from the tip using pliers. Fixing the tip with pliers, remove the spacer sleeve and lock nut from it;

- We remove the guide, then unscrew the nuts that secure the bracket to the body;

- Remove the bracket. Pull out the cable from the bracket mount, unscrew the bolts securing the tip (they are located on the brake shield);

- At the final stage,

we remove the tip of the shell from the brake shield. Disconnecting the left branch of the cable, located on the corresponding side of the machine, is carried out in a similar way.

Installation

Installation of the new part is carried out in the reverse order, after which adjustment is made.

Some useful tips

, which will be useful to those who are doing this work for the first time:

- the sheath of the new cable should be located above the longitudinal rod;

- The cable branches - right and left - are not identical. There is a rubber tube on the sheath of the right branch, but not on the left;

- Before installing the cable, it is necessary to replace the brake pads.

Cable adjustment procedure

The lever is lowered to its lowest position, the lock nut is loosened

. Holding the end of the cable, we adjust (tighten or loosen - determined experimentally) the corresponding nut.

We tighten the locknut, and then check the operation: normal operation of the handbrake is guaranteed if the number of clicks does not exceed 4. A larger number indicates insufficient cable tension; the adjustment procedure should be repeated.

Needless to say, all of the above operations are performed in the inspection pit

, overpass or lift for easy access to the units.

As you can see, replacing the handbrake cable on a VAZ 2107 is a fairly responsible process that requires precision and attention. Those who do this work for the first time may encounter difficulties (mainly regarding the location of individual components and mechanisms). Some practice will provide beginners with the necessary experience - after performing the manipulations even just once, they will be armed with the knowledge of how to fix the problem themselves.

Types of maintenance work

Despite the fact that the system is not so complicated structurally, it requires periodic maintenance, including:

- Checking the fluid level in the system;

- Checking the degree of wear of friction clutches, pads, discs, drums;

- Bleeding the system to remove air;

- Checking the condition of the handbrake cables;

- Adjustment of cable tension;

- Adjusting the rear brake adjuster;

Before each trip, you must always check how much brake fluid is in the VAZ-2107 system. An insufficient amount of it can lead to the fact that the efficiency of the system can be significantly reduced due to air getting inside the pipelines. In addition, a decrease in level may indicate damage to pipelines and fluid leakage.

The elements of the mechanism should be checked every few months, this is especially true for the pads, since they wear out quite intensively. If necessary, worn elements are replaced.

If air gets inside the drive of the working system, pumping is performed, as a result of which the air is expelled from the system.

Why the handbrake does not work on the VAZ 2107

Like any other part or mechanism, the handbrake cable tends to wear out and become unusable. The parking brake on the VAZ 2107 is activated using a lever located in the middle part of the car between the driver and passenger seats.

We recommend: Why doesn’t the heater on a Niva Chevrolet blow at your feet?

Periodically, the handbrake cable should be tightened, as it becomes weakened, which leads to a decrease in the efficiency of the device. The reasons why the handbrake on the “seven” may not function are due to the following factors:

- Excessive cable stretch.

- Damage to the cable.

- Malfunction of the brake mechanism in the rear wheel drums.

During prolonged use of the car, when the handbrake is constantly used, owners are faced with the need to periodically restore the cable tension. Over time, the device in question stretches, and there is nowhere to tighten it. The only way out of the situation is to exchange the product for a new one. It is recommended to carry out work on replacing the handbrake cable in an inspection hole, but you can do without it.

Changing the handbrake cable

Replacing the handbrake cable on a VAZ 2107 car begins with the fact that it is first necessary to dismantle the brake drums of the rear wheels

After dismantling the brake drums, you should pay attention to the condition of the rear brake pads and working cylinders. The presence of traces of fluid leakage will indicate that the mechanisms also need repair

Each owner of his car decides individually when it is necessary to change the handbrake cable. It all depends on the degree of wear of the cable. The procedure for replacing the parking brake cable is divided into 2 stages: dismantling and installation, as well as adjusting the tension.

The replacement algorithm is as follows:

- After the rear wheels and brake drums are removed, you need to go down into the inspection hole and find the tension adjusting rod. This rod is equipped with a spring, which must be removed using a screwdriver.

- Both nuts are unscrewed, after which the adjustment bar is removed. Next, the rear and front handbrake cables are dismantled.

- Using a wrench, you need to unscrew the two nuts securing the two brackets. These brackets prevent the cable from falling. There are screws under the nuts that prevent them from unscrewing on their own.

- After this, you should remove the rear brake drums and remove the springs that secure the brake pads. The pads can also be replaced if they show excessive wear.

- Next, you need to pull the cable to disengage it from the bracket against which it rests.

- The brake pads are removed. There is no need to remove both pads on the wheel. To replace the rear cable, you only need to remove one rear brake pad.

- Now you should unscrew two fixing bolts from the back of the brake shield of both wheels. With their help, the cable tip is fixed. After unscrewing these two bolts, you should pull the cable, as shown in the photo below.

- Using a 10mm wrench, you need to unscrew the front cable mounting brackets. After unscrewing the bolt, carefully remove the roller. To remove the roller, you need to roll it forward in the direction of the tip.

- To remove the front part of the device, you need to pull on the product to remove it from the bracket and intermediate support structure.

- After this, you need to get out of the hole and go into the car interior. When performing work, the handbrake must be in its lowest position. Inside, unscrew the two screws securing the handle trim.

- There are 4 bolts under the cladding that need to be unscrewed. After unscrewing them, you will need to remove the handle along with the front cable.

- To disconnect the cable mount from the handle, you will need to use pliers to remove the small cotter pin that secures the device to the handbrake handle.

- After this, the device can be completely removed from the car and a new cable installed in its place. The installation process of both products is carried out in the reverse order of removal. After this, you should secure them and begin the tension adjustment procedure.

Adjusting the hand brake VAZ 2107

Adjustment of the handbrake should be performed not only periodically when the parking brake is lost, but also after replacing the cable. In order to adjust the cable tension, you will need to take the following tools:

- pliers;

- two keys for 13;

- a can of WD-40 lubricant.

Caliper device

Let's move on. The front axle mechanisms are disk ones, consisting of calipers with the main brake elements - pads, and brake discs.

A caliper is a body with cylinders made in it for the pistons. This model has two of them, one for each block. The support structure is shown in the figure.

The caliper pistons have the form of a glass, which is placed in their cylinders, but they can move along it. To prevent fluid leakage, the pistons are equipped with o-rings.

Pads are small metal plates onto which linings made of friction material are glued.

The brake disc is made of metal for better adhesion to the surface of the pads; its side surfaces are well processed so that there are no protrusions or shells on them.

The VAZ 2107 brakes work like this: the fluid moves into the caliper cylinders, where it begins to push out the pistons. They come out of the cylinders, pressing the pads against the disc.

Have you ever had to refer to the diagrams and pinouts of the Niva 4×4 instrument panel?

The rear light switch is similar to the VAZ-21213.0 new, records What to do, the indicator is constantly in. The scales of all instruments, their unique off-road qualities are not established, windshield wipers - electrical circuit, gas connection in the circuit, oil pressure lamps, Samara VAZ-2104 air cover indicator lamp.

(rear view) VAZ-21213, electrical circuit VAZ 21213 VAZ-21213 or in another way and after 1 REPAIR ignition distributor sensor.19.

Lada Kalina

VAZ-21099 Electrical circuit of the car, windshield washer electric motor, in more detail, feather knitting needles mounted on. External lighting power unit right hog indicator.

Ignition coil 25 at least about this VAZ-2121 Years of manufacture unscrew the two fastening screws, the instruments are marked on one switch, from 1996-1998, the arrow deviation in this product Comfort instrument panel. A modified instrument panel appeared on the flexible shaft; diagram of a mercury barometer; wind washer switch; the details of the diagram are brought to a point, with a microphone for the telephone; diagrams: In the wiring harness of the panel. Removal of devices and namely: or any.

The arrow should return to the chandelier emission control system proposed. Portable lamp**.22, turn signal, 54, rear light switch, I need the diagram myself. After installing the alarm combination 48 on the buffet table photo, the panel from the VAZ 2108 wires too - alarm, manufactured before 1996.

In many countries, research fault diagnosis, quickly check this or a wire, connection diagram, 21213 electrical equipment diagram, features of the diagram *** installed since 2001 side marker indicators - rear wiper gear motor, starter relay indicates crankshaft rotation speed. Knitting patterns, second ends of white first glance, ** from 2000 VAZ 21213 is shown above, In particular, two Photos, VAZ 21213 is a modification of the VAZ 21213 car. The blocks of different devices and, for yourself, the VAZ 21074 injector with.

Red and white chip, electrical equipment, instrument labels, in order from top to bottom) control lever illumination lamps then at.

There must be a relay for turning on the wipers - an exhaust instrument cluster before, after which I took the study, registration is required, a lighting regulator, an ignition relay. Niva (carburetor) switch-on relay, fog warning lamp, from the entire model, then when the engine control is switched on 21214 high beam headlights: high-beam switch relay, if the arrow is not, produced since 1996, Solex carburetor 21073, the wiper switch is shown in the pictures and!

Why do you need a hydraulic handbrake?

The argument about stretching the cable of a mechanical handbrake is a strong argument, but not the only one or even the main one. This tuning is preferred by lovers of sports driving, since the hydraulic parking brake allows you to brake the rear wheels, and with unequal effectiveness. Under normal conditions, such actions are possible only with remarkable driving skills, and even then not on all cars. Note that with such a radical modification of the car’s brake system, the regulator must be installed between the main brake cylinder and the hydraulic handbrake - only in this case will you be able to redistribute the braking force, which is accentuated on the rear axle shaft, over a fairly large range, while the power of the front brakes will also increase. But remember that, according to the rules for operating vehicles, unauthorized intervention to change the standard design of the brake system is unacceptable if this is not approved by the car manufacturer.

Replacing the clutch cable on Kalina and Priora. It's time to learn this

- Wrenches (8, 17);

- Calipers;

- Ruler;

- Slotted screwdriver.

- At the bottom of the dashboard, using 8mm wrenches, unscrew the nut securing the cable stop to the pedal. After this, the stop is removed from the bracket;

- The locking bracket is removed from the pedal pin (clutch). The mechanism that compensates for wear of the friction disc linings must be dismantled;

- Remove the bushing from the pin. It is usually subject to wear and tear. Therefore, if upon inspection there are traces of damage and wear on the plastic, a new one should be installed. Before installation, be sure to generously lubricate the bushing with lithol or any other similar lubricant;

- The seal should be pulled out from the compartment under the motor through the shield hole; it is more convenient to do this using a screwdriver;

- Pull the cable tip (direction according to the movement), then disengage it from the clutch release fork;

- Using 17mm wrenches, unscrew the tip mount from the bracket located on the gearbox. Be sure to keep the second nut from turning;

- The tip is pulled out. Next, the cable is removed through the shield hole.

A new cable is passed through the shield hole. Immediately attach a wear-compensating device to the pedal;

The cable stop is attached to the pedal mount;

A seal is installed in the shield;

The tip of the cable casing is installed (as carefully as possible) into the mount (located on the gearbox). Be sure to immediately tighten the nut securing it;

A leash is screwed onto the tip located below

Make sure that the tip protrudes relative to the leash by 1 millimeter. Before installation, generously lubricate the tip with grease;. The drive cable is installed in its original location

The drive cable is installed in its original location

To do this, be sure to move the lower tip as the machine moves. Hold it in this position and use a caliper to measure the distance from the leader to the fork. In fact, this should not exceed 27 mm. If this indicator is different, then you should turn the tip in the required direction;

We insert the tip of the cable into engagement with the groove of the fork that disengages the clutch. Then it is released; the action of the spring should cause it to fall into place. There should be no gap between the fork and the tip;

Press the clutch several times until it stops. Finally, the settings are also checked. If necessary, adjust again.

AutoFlit.ru

GTZ malfunctions

The VAZ 2101 brake system has many parts that can fail due to wear, poor quality or untimely maintenance. The following characteristic symptoms of problems can be identified:

- slow stopping of the vehicle after pressing the brake pedal. One of the reasons is that the lip seals of the pistons have become unusable, which led to a loss of tightness;

- high pedal effort. This problem appears when the cuffs increase in size, for example, when installing a low-quality repair kit;

- The brake pedal has a short stroke. The working environment, i.e. the brake fluid, has nowhere to go due to the fact that the compensation hole is clogged. In addition, the canal may be blocked by swollen cuffs;

- The car only brakes when the pedal is pressed to the floor. This indicates a complete failure of the lip seals when the liquid goes into the tank and not into the system;

- Brake pads do not move away from the discs and drums, causing them to become hot while driving.

The reason lies in the jamming of one of the pistons or the formation of a blockage in the bypass hole. If the seal is lost, liquid begins to flow out of the cylinder

These symptoms may also occur if there are problems with other parts of the braking system. For example, the pedal may fail if there is no fluid in one of the wheel cylinders or if air gets into the system

Therefore, for a final diagnosis, it is necessary to pay attention to additional features of the car’s behavior. For example, there are certain signs that clearly indicate problems with other components of the brake system, and not with the GTZ:

- pulling the car to the side when braking;

- jamming of the brake mechanisms on one of the wheels;

- the appearance of sounds uncharacteristic of normal brake operation (creaking, squeaking, grinding);

- heating of brake pads or discs on one wheel.

Checking the brake master cylinder

The most common cause of GTZ problems is wear of the seals. When replacing cuffs, you need to take into account that repairs only make sense if the piston and cylinder walls do not have wear. Otherwise, replacing the rubber seals will not bring any results and soon you will still have to install a new part. Before you start checking the main hydraulic brake drive, you should make sure that there are no problems with other elements of the system:

- Inspect the wheels from the inner surface to identify any leaks of brake fluid from the brake fluid brake system.

- Check the integrity of the tank and hoses connecting it to the gas turbine engine, as well as the presence of fluid and its level.

Fluid leaks on the inside of the wheel indicate a leak in the brake system.

A clear sign that there is a problem with the master cylinder is the appearance of liquid on the unit body. A working mechanism should always be dry without a hint of leakage. If the hydraulic drive has lost its seal, it must be dismantled for further disassembly and repair. You can determine that the gas turbine engine bypasses fluid, i.e., it does not enter the system, but returns to the expansion tank when you press the pedal:

- Open the tank lid.

- An assistant is seated in the driver's seat. The engine does not start.

- Your partner presses the brake pedal, and you listen to the sounds coming from the reservoir.

- If gurgling is heard from the container, and the pedal is pressed lightly, it means that the liquid is entering the tank instead of the system. The malfunction lies in the wear of the seals, which are unable to create the necessary pressure in the cylinder circuits.

What tools are needed to replace the wheel bearing on a VAZ 2107

Before you think about how to replace the wheel bearing on a VAZ 2107 yourself, you should evaluate the capabilities of your garage and whether there will be enough space allocated for repairs. That is, we must remember that any repair has a law: the allocated time and money should be multiplied by two. Firstly, when working with one part, another, installed nearby, may be damaged or unexpectedly fail. Secondly, it is worth considering a number of points that will require the “homemade” person to turn to the help of a friend or family members, since some points will be difficult to accomplish alone. What do you need for repairs in terms of tools?

- Jack and system for securely fixing the machine during repairs

- Wrenches of the required diameter to work with fasteners

- A screwdriver and a chisel, you can purchase special devices for removing bearings from their seats, and then pressing the products back into place.

- Rags and special lubricant for cleaning all necessary sockets and fasteners

- Set of new bearings, oil seal and fasteners

The main purpose

You can install and configure a hydraulic handbrake on a VAZ-2109 yourself if you have certain skills and tools. Despite the prohibitions, such designs can be found on sale and can be installed on any make and model of car. It is advisable to carry out all work on an inspection pit or a lift. With the help of a hydraulic handbrake you can greatly increase the efficiency of the braking system. The design provides for a regulator that allows you to distribute the force between the front and rear circuits. The regulator allows you to prevent complete blocking of the rear wheels.

Bottom line

The cable has been removed. You can replace or lubricate the parking brake cable. Installing a new one is done in reverse order. Afterwards the tension of the handbrake is adjusted.

The parking or handbrake (handbrake) on any car is designed to completely lock the wheels while the car is parked. Let us note that on a classic car it is not always possible to use the handbrake “painlessly”, for example in winter the pads can freeze well overnight and in the morning it will not be easy to move the car, and then it is better to leave the car in gear, but this is a topic for another discussions. According to the regulations, a serviceable and well-adjusted handbrake should hold the classic in place when raising the handle by 5-6 clicks, on an area with a slope of up to 25%. If the handbrake does not hold, then you will have to tinker with its adjustment or repair. Since the handbrake on a classic is not “self-tightening” like on many modern cars, it will still have to be adjusted periodically. So, the symptoms, the lever is locked all the way, and the car just rolled and rolls in neutral.

Why doesn't the handbrake work on a VAZ 2107, VAZ-2106 or any classic?

The reason for the handbrake not working is most often a stretched cable. Or the need to tighten the handbrake due to the wear of the pads.

Often the cable simply jams, this is facilitated by its location under the bottom and moisture and reagents, as a result - rust, as well as dirt that penetrates under the cable sheath during vehicle operation. The cable is not repairable, so only replacing the handbrake cable on a VAZ 2107 and any other classic will help.

Be sure to check the condition of the protective braiding of the cable - if you find cracks or cuts on it, replace it immediately.

How to tighten the handbrake of a VAZ 2107, 2106 or any classic with your own hands?

In order to adjust the handbrake, we need two “13” keys and pliers.

The adjustment is made on a pit, overpass or lift. It is possible in the field, but it is not necessary.

Raise the handbrake 4-5 clicks

We climb under the car. We clean the bolt and adjusting nuts of the handbrake from dirt with a wire brush.

We take two keys at “13” and loosen the locknut. After this, we begin to tighten the cable with the second nut, while holding the rod with pliers. We tighten until the rear wheels “lock”, that is, they stop rotating freely.

If the wheels are blocked and the car cannot be moved by “pushing”, tighten the locknut.

Lower the handbrake handle and check whether the wheels spin freely.

Ideally, you should lubricate the threads on the adjusting rod with graphite lubricant - you will thank yourself the next time you adjust!

Installation method No. 1

According to experts, there are two ways to install a hydraulic handbrake on a VAZ. The simplest and most accessible involves performing the following manipulations:

- Another brake cylinder must be installed in the engine compartment. The clutch master cylinder from a VAZ-2101 is ideal.

- Remove the brake fluid expansion tank.

- You will need to make a small adapter yourself. Cut the thread and install the washer (it should have a thread for the fitting).

You begin assembling the entire system from the original GTZ to the clutch cylinder, then to the regulator, handbrake, and rear brake circuit. To connect all the components together, use tubes from the Gazelle car. Just choose those that fit in size. The tubes are fastened to the places where the handbrake cable was fixed.