The starter bendix serves to transmit torque from the electric motor rotor to the flywheel. The mechanism is highly reliable, but if used incorrectly it can fail. For example, if the car engine is started, and at that moment the starter is turned on, not only the bendix will suffer, but also the flywheel crown, and even the windings. It is also possible that the bronze bushings installed at both ends of the rotor may be destroyed.

Device

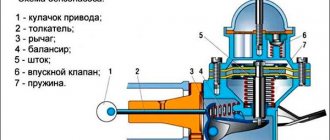

Bendix consists of several elements that cannot be divided by degree of importance, because they all equally affect the operation of the device. The base is a metal sleeve, inside of which there are spiral-shaped slots for connection with the rotor. They allow the Bendix to move freely along the axis under the action of the retractor relay. To return to its original position, the latter has a spring. Some Bendix models also have return springs in their design. An overrunning clutch is an element that affects the performance of the mechanism. It allows the Bendix to transmit rotation in one direction. A gear is attached to the clutch, which is necessary for communication with the flywheel ring - its tooth pitch is exactly the same. A plastic or metal plug allows you to connect the solenoid relay and the Bendix housing.

Electrical

Problems in the electrical power system are one of the most common breakdowns. We are talking about the section of the line from the battery to the starting device directly.

- Slow rotation of the rotor;

- Lack of response when current is supplied to the starting device (hereinafter referred to as PU);

- The control unit clicks, but does not turn: interturn short circuit, broken wiring, short circuit of the solenoid relay;

- Washing brushes;

- Anchor wear.

To exclude a number of other related breakdowns, you need to check:

- presence of charge in the battery;

- fixing the terminals on the battery contacts;

- integrity of electrical wiring in the area from the battery to the control unit;

- proper operation of the ignition switch core.

Bendix purpose

Its main purpose, as mentioned earlier, is to transmit rotational motion from the electric starter rotor to the engine crankshaft. The Bendix starter (the photo will give you an idea of what it looks like) allows you to turn on and off the electric drive from the internal combustion engine in a timely manner. For this purpose, the design has a retractor relay operating on the principle of an electromagnet.

A little over half a century ago, some cars used starters whose rotors were connected manually using a lever transmission. This was a kind of transition from manual engine starting to electric starting. The first designs had everything that modern ones had, only the solenoid relay was missing. And the bendix moved along the rotor axis using a gear connected to a pedal.

Examination

Checking the Bendix begins with an external inspection of the gear. It should have straight teeth with a pronounced or slightly rounded lead-in chamfer, facilitating engagement with the flywheel. Without this chamfer, with a possible tooth-to-tooth contact, the starter will not rotate the flywheel until the crankshaft moves at a small angle.

The presence of chips and cracks on the teeth is unacceptable.

How to check starter bendix? Fix its outer race (by wedging it against the body with a powerful screwdriver) and turn the gear in both directions. In one it should turn easily, in the other it should be tightly blocked. Difficulty turning to the “idle” side indicates jamming of the rollers or contamination of the bendix.

Removing the starter from the car

On passenger cars, you can remove the starter in just a few minutes. To work, you will need a minimum set of keys - 10 and 13. Moreover, the VAZ-2109 starter bendix is replaced in the same way as on earlier models. Remember that you are repairing electrical equipment. Therefore, it is imperative to disconnect the battery. A large cross-section wire is laid from the positive terminal to the starter; it is not protected by any devices, so in the event of a short circuit, the risk of a fire is very high.

After disconnecting the battery, disconnect the two wires from the solenoid relay. The thin one is necessary to supply voltage to the relay coil; it appears on it only when the key is turned to the extreme position. A thick cable is required to power the starter windings. Using a 13mm wrench, unscrew the three nuts that secure the housing to the car’s clutch block. Sometimes this action is not very convenient to carry out, for example, on VAZs of the classic series. With them, the lowest nut is unscrewed from the bottom of the car, and even using heads with cardan shafts.

The battery is low

The vehicle's power supply system largely depends on the health of the battery. To keep it in working order, you must comply with a number of requirements and instructions. If, for some reason, the battery was not taken care of, then sooner or later such negligent attitude will come back to haunt the owner.

The most pronounced symptoms of a faulty battery are:

- low brightness of running lights;

- sound signal attenuation;

- presence of a red/white indicator on the battery cover;

- deflection of the on-board ammeter needle towards the charge when the starter circuit is closed;

- presence of sulfation at the battery terminals.

All these signs, one way or another, indicate that the battery needs diagnostics. First, you should check the level and density of the electrolyte. After this, the battery must be charged using a charger. If the battery is old, charging should be done at extremely low charging current values.

During this procedure, the battery can caps must be removed. During the entire charging time, you must ensure that the battery does not self-discharge. It happens that during charging one or more cans begin to “boil” before the rest. This phenomenon indicates that the battery, due to improper care, has exhausted its resource.

How to disassemble the starter

After pulling the starter out of its seat, it must be disassembled. For this you will also need a not very large set of tools:

- Pliers.

- Phillips and flathead screwdrivers.

- Key for 10.

The starter housing consists of three parts - the rear and front covers, as well as the winding in the middle. They are all held together by two pins running from the front cover to the very end. But first you need to unscrew two small bolts with a screwdriver.

After this, remove the ring from the rotor. Using a 10mm wrench, unscrew the two nuts that are on the stud. For convenience, disconnect the brush assembly from the stator winding. That's it, the starter parts can be easily disconnected. Now you need to remove the old bendix. To do this, remove the metal clip from the axle. Using light taps, move it towards the rotor winding. Underneath there is a ring that needs to be removed. After this, the bendix on the car starter can be replaced.

Repair of a collapsible solenoid relay

The manufacturer equips starters with a non-separable or collapsible retractor device. If a non-separable relay breaks down, it must be replaced, but a dismountable relay can be repaired. The described method allows you to check the solenoid relay of all VAZ models: 2101, 2102, 2103, 2104, 2105, 2106, 2107, 2108, 2109, 21099, 2110, 2111, 2112, 2113, 2114, Niva, Lada Priora, Kalina, Granta, Vesta and most foreign cars. Disassembly and repair of the relay is carried out in the following order:

- Unscrew the nuts securing the housing cover.

- If necessary, the ends of the windings are additionally soldered.

- After removing the cover, inspect the power contacts:

- If they burn, the damaged part is cleaned with sandpaper;

- When worn out, replace.

- The device is assembled in the reverse order and tested for functionality.

- The repaired relay is installed back on the starter.

Replacement

If the starter bendix is defective, repair is impossible. The solution to a breakdown of this unit is to completely replace it. If the problem catches you on the road, then the way out of the situation is not to turn off the engine during stops or stop on a hill, so that it is easier to start the car “from the pusher”. But replacing a bendix also takes a little time, the main thing is to have a spare one.

After disassembling the starter and removing the old element, you can immediately install a new one. To do this, the bendix is simply put on the spiral splines. Then install the cage on the rotor axis, and lastly, the steel ring. You need to put a metal clip on it. That's all, if there are no more faults or they have been successfully eliminated, you can assemble the starter and install it on the car.

When the starter torque slips and does not turn the engine shaft, then one of the most likely malfunctions is wear or breakdown of such an important component as the bendix. A unit that ensures decoupling of the starter and the car engine at the moment when the engine starts...

In fact, the name of this part of a car starter is pure amateur performance of domestic drivers. After all, the classic engineering and technical name for the unit that ensures the separation of the starter shaft from the engine shaft at the time of its start is an overrunning clutch. And this name fully reflects the essence of the action that this part produces. And this mechanism, which is based on the principle of a conventional ratchet, received its popular name in honor of the American inventor Vincent Hugo Bendik, head of the Bendix Corp. corporation. It was he who at one time invented and patented a unit that allows, at the moment of startup, to disconnect a small electric motor, which spins the shaft of an internal combustion engine.

Let's start doing our own repairs

First you need to visually inspect the inside of the coupling. If there are damaged springs, they need to be replaced with new ones. This can be a problem if you live in the middle of nowhere. Local auto stores do not have repair kits. Therefore, repairing a Bendix with your own hands turns into a search for old spare parts.

If there is a hole in the cones, they can be turned upside down. But it is advisable to replace them. We check the mobility of the springs; they can “lay down” and not push out the cone.

If visually everything is in order, then the entire repair will end with a banal washing of the insides of the overrunning clutch. The main thing is to wipe the entire interior from dirt and dust . There is terrible wear on the rollers or the springs become very weakened. In this case, the bendix must be replaced with a new one or a known good one.

To Contents...

Overrunning clutch is the real name. It is also called a clutch - ratchet or ratchet

Be that as it may, in order to understand the nature of the malfunction, damage in this mechanism, when the bendix slips (that is, the starter spins idle, slips and slips without engaging the engine), you need to understand the function and principle by which this mechanism works. In fact, everything is very simple. It serves as a kind of clutch that works only in one direction, jamming if an attempt is made to turn it in the other direction. Moreover, a clutch that should disengage precisely at the moment when the engine starts. That's when she returns to her seat. After all, the rotation speed of a car engine shaft is much higher than the maximum rotation speed of the electric motor, which is designed to act as a starter.

Simple design, reliable operation

So, Bendix ensures that the starter is disconnected from the engine, and the transmission ratio is at least 1:15. The design of the overrunning clutch is simple and reliable. It is equipped on both sides with special rollers moving along special grooves. When voltage is applied to the starter, the Bendix race, which is located outside, begins to rotate intensively. At the same time, the inner one rotates at a lower speed, which leads to the retraction of the rollers to the narrowed part of the grooves, and causes them to be pinched. When the process occurs normally, the engine will start successfully.

In the case when the starter bendix slips, it becomes impossible to hook it to the engine, i.e. the main function of the starter is not performed. This leads not only to the impossibility of starting the engine, but also to premature wear of the electric motor itself, which, in the absence of load, can develop too high speeds and overheat. Since any Bendix malfunction can cause concomitant problems in engine operation, it should be eliminated immediately. At the same time, the most rational step is not to repair, but to replace the Bendix with a new one.

What if he doesn't come back

In fact, Bendix ensures long and trouble-free operation of the entire assembly. And if it weren’t for him, then at the moment when you turn off the starter (that is, the car starts), it does not disengage with the engine, which is called “does not return,” then the rotating engine shaft will simply break the starter itself. Which, by the way, sometimes happens when the Bendix malfunctions in the opposite way - that is, the accelerating clutch does not slip, but, on the contrary, sticks and continues to rotate the shaft together with the electric motor. That is, the bendix does not disengage.

And now we are talking about a malfunction when the bendix slips, slips, and it turns out that it works, but its clutch power with the engine is not enough to turn it over and start it. The thing is that heavy loads wear out the teeth of the ratchet gear over time, and the part fails.

It has already been said that this part - the accelerating clutch, popularly called Bendix - functions on the principle of a ratchet mechanism. And the cause of the malfunction, when the gear teeth do not grab and slip when rotating along their axis without achieving engagement, is in the vast majority of cases the banal wear of these very teeth. Indeed, in fact, at the time of operation, these same teeth experience a serious load, since they have to overcome the force of rotation of the heavy crankshaft of the engine, compression of its cylinders, and the like.

Features of mechanism diagnostics

The starting unit is checked using a tester. After turning on the device, the voltmeter reading should not be higher than 8V, and the current should not exceed 23A.

You can check the windings using a tester; if it lights up, it means there is a short circuit. To perform a visual inspection of the starting unit, it must be removed and cleaned of dirt (video author - Irina Kuzilova)

When disassembling the device, each part should be visually inspected. Scores and scratches can be removed using sandpaper. Broken and worn parts must be replaced. It is also necessary to replace the VAZ 2106 starter bushings if they are badly worn.

A faulty collector cannot be repaired; it is advisable to replace it. The height is checked on the brushes. More than 12 mm is considered optimal, otherwise the brushes must be replaced.

Characteristics of the malfunction

The starter spins at idle, the teeth slip, which should ensure unidirectional engagement of the shafts when one rotates at a higher speed, and also ensure their separation as soon as the rotation of the electric motor is stopped (this is when, as soon as the car engine starts, the driver releases the key).

In fact, modern technologies used to manufacture both the starter and one of its main functional units, the bendix, do not imply the possibility (in the event of a malfunction) of the unit to be disassembled and repaired. We'll have to change it. Moreover, fortunately, it is not the entire assembly that has to be replaced, but the bendix, the engagement of which has worn off so much that it is already slipping, does not reach the required power level.

On the other hand, the strength loads of modern automotive parts are designed to have approximately the same service life. That is, even if it is possible, say, to replace the Bendix return or tension spring and thereby eliminate the malfunction, such a unit will still not last very long. Surely, either the balls that ensure the bendix rings roll will soon fall out, or the connection with the shaft will slip, losing the engagement mechanism.

So, with such a characteristic malfunction as a lack of engagement with the engine, when the torque slips without connecting, there can only be one verdict - change it. Moreover, the procedure is simple, and the part itself is not particularly expensive. You can cope with the replacement, at least on a domestic car, yourself, or by contacting the nearest car service center. » alt=»»>

Every experienced car enthusiast knows why a starter is used in a car and what functions this unit performs. The starter device is one of the main components of the ignition system; it is thanks to it that the engine starts. This mechanism consists of several elements, one of which is the starter bendix. What is its operating principle, how to recognize a malfunction and how to repair the mechanism yourself - you will find the answers to these questions below.

Characteristics of Bendix on the starter

The starter's Bendix is the overrunning clutch of the mechanism. If problems arise in the operation of this device, this may affect the functionality of the starter assembly as a whole. First, familiarize yourself with the main characteristics of Bendix.

Design and principle of operation

The starter's Bendix consists of an outer ring, often called a drive race, which contains the rollers and pressure springs, and a driven race. The drive cage is equipped with wedge channels in which spring-loaded rollers rotate. On one side the width of the channel is wider, and on the other it is narrow, in which the rollers stop between two windings. The springs themselves are used to drive the rollers into the narrow part of the channel.

As for the principle of operation, it is based on the inertial effect on the gear coupling, which is part of it, until it engages with the flywheel of the power unit. When the starter assembly is inoperative, for example, if the engine is not running or is running and running continuously, the clutch does not engage with its flywheel.

The principle of operation itself is carried out in several stages:

- First, the driver turns the key in the ignition, at which time current from the battery begins to flow to the electric motor of the starter device. As a result, the anchor is set in motion.

- There are special grooves on the inner component of the coupling. Due to the rotational movement, this element, under the influence of its mass, passes along the splines until it engages with the flywheel.

- After this, the driven cage with the gear, under the influence of the drive gear, begins to rotate.

- If it happens that the teeth of the clutch do not engage with the flywheel, a slight rotation will be carried out until these elements coincide.

- There is a special buffer spring located inside the structure. It is used to soften the starting moment of the power unit. In addition, its purpose is to prevent the teeth from failing at the moment when the gears engage.

- After the power unit starts, it will rotate the flywheel at a higher angular speed compared to the one with which the starter itself rotated it. As a result, the coupling itself twists in the opposite direction, subsequently slipping along the splines of the gearbox or armature. As a result, he gets out of gear.

Possible causes of failure

As mentioned above, gear rotation is only possible in the direction of rotation of the starter armature. If rotation in the opposite direction is possible, this is an obvious malfunction, that is, the bendix must be repaired or replaced. There may be several reasons for this:

- Reduction in the diameter of the working rollers in the cage due to natural wear. The way out is to select and purchase balls of a similar diameter. Some car enthusiasts use other metal objects, such as pieces of a drill, instead of balls. However, we still do not recommend doing it yourself, but buying balls of the required diameter.

- The presence on one side of the roller of flat surfaces formed due to natural wear. Repair recommendations are similar to the previous paragraph.

- Grinding the working surfaces of the driving or driven race in those places where they come into contact with the rollers. In this case, repair is hardly possible, since such excavation cannot be removed. That is, it is necessary to replace the bendix.

Note! It is often better to completely replace the bendix than to repair it. This is due to the fact that its individual parts wear out approximately equally. Therefore, if one part fails, the others will soon fail as well. Accordingly, the unit will have to be repaired again.

Another reason for failure is wear of the gear teeth. Since this happens for natural reasons, repair in this case is impossible. It is necessary to either replace the mentioned gear or the entire Bendix.

Since the starter not only experiences heavy loads, but also comes into contact with the external environment and is susceptible to irritants such as moisture, dust, dirt and oil, freewheeling can also occur due to deposits in its grooves and rollers. A sign of such a malfunction is the noise of the armature when the starter is started and the immobility of the crankshaft.

Instructions for replacing the overrunning clutch

To repair the device, the starter assembly must be dismantled, after which you can begin to disassemble it.

Replacing the bendix on the starter is as follows:

- First, the screws that secure the case are unscrewed. You also need to unscrew the screws that secure the solenoid relay, after which the part is removed. If there is dirt on the structural elements, it must be washed off.

- The starter drive unit is dismantled; to do this, remove the washer and remove the restrictor ring.

- Before installing a new drive, the installation site, in particular the axis, must be treated with a special temperature lubricant.

- Most often, difficulties arise with the installation of the retaining ring and washer. For faster installation, you can use sliding pliers, an open-end wrench, a clamp or other tools.

- After installing the drive, all rubbing elements of the mechanism are treated with temperature lubricant.

Price issue

The cost of a Bendix is determined by the model of the car on which it will be used. The choice of devices is very large, prices vary from 450 to 4000 rubles.

Price issue

Finally, it’s worth adding that Bendix is an inexpensive spare part. For example, a Bendix VAZ 2101 (as well as other “classic” VAZs) costs about $5...6, catalog number is DR001C3. And the price of Bendix (no. 1006209923) for VAZ 2108-2110 cars is $12...15. The cost of Bendix for FORD cars of the Focus, Fiesta and Fusion brands is about 10...11 $. (cat. no. 1006209804). For TOYOTA Avensis and Corolla cars Bendix 1006209695 - $9...12.

Thus, repairs are often impractical for Bendix. It's easier to buy a new one and simply replace it. Moreover, when repairing individual parts, there is a high probability of rapid failure of others.