A question such as replacing brake hoses on a VAZ 2109 and 2110, at first glance, seems simple for a car enthusiast who has an idea of what a wrench and a screwdriver are. But there are still some nuances that you need to know about for high-quality technical performance. We will talk about them in this article.

Replacing the front brake hoses on a VAZ 2109 and 2110 does not require any additional equipment from the car owner. This can be done even without a hole, right in the yard or garage, on a homemade small overpass, or just on the asphalt in a convenient place. The rear ones will most likely require an inspection hole or a lift.

Why do you need to change?

Why is it necessary to periodically inspect the brake system, in particular the hoses? One of my friends on the highway, at a speed of 100 kilometers per hour, when pressing the pedal, suddenly “lost the brakes.” The pedal simply went to the floor, and the car continued to rush towards the accident. It’s good that he knew how to slow down the car by changing gears, so to speak, “with the engine.” Gradually slowing down, he stopped on the side of the road and, wiping sweat from his forehead, opened the hood.

As it turned out, the brake fluid was “gone”, and at the nearest service station they discovered a break in the rear right brake hose, and all the others had such a degree of wear that they could “shoot” at any moment.

Required tools and replacement

- Using a jack, lift the front wheel and remove it. Don't forget that the wheel bolts can also become stuck. To make them easily unscrew, spray WD-40 from a can several times and wait about 10 minutes. If the bolts are unscrewed but the wheel cannot be removed, there is also a “folk” method. For these purposes, some drivers carry a piece of board and a small sledgehammer in the trunk. We place the board next to the wheel and hit it with a sledgehammer several times. The wheel should come off;

- Hold the tip on the brake hose with a “15” wrench. At the same time, turn the fitting on the tube with a “ten”;

- To prevent brake fluid from leaking, put on a protective cap. If the nut is stuck, use VD. We wait 10-15 minutes, unscrew;

- Next, you need to remove the sensor wires from the rubber holders based on pad wear;

- The hose coupling must be removed from the shock absorber strut holder;

- Unscrew the “15” hose fitting from the cylinder. The copper seal ring also needs to be replaced. Usually seals are sold as a set;

- Install the new hose, carefully tightening the nuts;

- We repeat the procedure in a similar way on the other front wheel (since, we remind you, it is best to change the hoses at least in pairs);

- After everything, we bleed the brake system, checking the presence of fluid in the reservoir (by level). If necessary, top up!

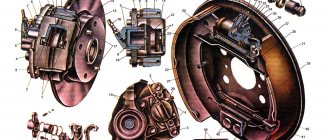

Possible malfunctions of the brake system

Malfunctions of the VAZ 2109 brake system can be of different nature and there are quite a lot of them. In this paragraph we will look at the most basic ones:

- Brake pedal malfunction. In this case, it may not only not work, but also not work as it should. This means that when you press the pedal, the load increases. That is, the driver presses lightly, but the braking occurs too sharply. With such a breakdown, the car may brake irregularly;

- Long braking distance. In this case, when you press the brake, braking itself does not occur or the braking distance of the car increases several times;

- The wheels do not brake at the same time. This case is quite rare, but if it occurs, the braking distance of the vehicle increases several times and the car begins to wobble when braking.

- As for the cost of repairing these faults, everything is ambiguous. After all, the price of the VAZ 2109 brake system may depend both on the region of residence of the car owner and on the service you use.

On average, a major overhaul costs about 10-15 thousand, taking into account the replacement/repair of all parts.

Despite its simplicity and relatively outdated design, the brake system of the VAZ 2109 has more advantages than disadvantages. It should be noted that the repair of the brake system is cheap, which allows people with even low incomes to service the car. On our website you can also watch a video about the brake system of the VAZ 2109.

A question such as replacing brake hoses on a VAZ 2109 and 2110, at first glance, seems simple for a car enthusiast who has an idea of what a wrench and a screwdriver are. But there are still some nuances that you need to know about for high-quality technical performance. We will talk about them in this article.

Replacing the front brake hoses on a VAZ 2109 and 2110 does not require any additional equipment from the car owner. This can be done even without a hole, right in the yard or garage, on a homemade small overpass, or just on the asphalt in a convenient place. The rear ones will most likely require an inspection hole or a lift.

Replacing the rear brake hose

- We unscrew the fitting using two keys: 10 and 15;

- Remove the hose from the eyelet securing the rear beam to the body;

- We put a protective cap on the end of the tube;

- Using two wrenches, disconnect the hose and tube. Remove the brake hose. When replacing it, do not forget about the seals;

- We put everything back in reverse order. We perform the same procedure on the other rear wheel. We pump the hydraulic drive (brake).

Thus, you are convinced that replacing brake hoses on VAZ 2109 and 2110 is not such a difficult matter. And with your own hands, if you have certain skills, it’s quite possible!

Brake hoses have to be changed quite often; according to the “garage guys”, this consumable part often does not last even six months. But, if you use the car carefully, it will require replacement in a year, or even two.

To extend their service life, wipe them with special additives, for example, Roil Platinum™ and wrap them with textile tape. At the same time, you need to remember that from time to time you need to check the condition under the electrical tape.

The worst thing is when the hose breaks on the road. The first sign of a breakdown is that the pedal “goes to the floor.” At the same time, it is impossible to brake quickly. In this case, you need to plug the torn end, for example, with a bolt. When one of the circuits does not work, the ABS also stops working, and during sharp braking the car turns around. The following is step-by-step instructions for replacing them with new ones.

How does CO work?

CO scheme

- On the 8-valve injection VAZ 2110, the cooling system operates due to coolant forcedly circulating through it. When the engine heats up, excess pressure arises, which is released through the exhaust valve.

- For the 16 valve injection VAZ 2110, the cooling system has an optimal operating temperature in the range of 90-95 degrees Celsius. And the valve is activated when pressure occurs with indicators from 1.2 to 1.4 kgf/cm2.

- When the excess pressure is released, the engine returns to normal temperature and the intake valve is turned on. This happens cycle after cycle.

- If the pressure balance is disturbed, overheating occurs, the consequences of which can be various types of breakdowns, including the need to completely replace the power unit.

- Due to the operation of the thermostat and electric fan, the VAZ 2110 maintains the required constant operating temperature. There is a sensor on the cylinder head that transmits information about the current coolant temperature to the control unit.

- A command is sent from the coolant temperature sensor to the cooling system, which begins to work in order to reduce engine heating.

- If there is electronic injection in the car design, it also has a special sensor that sends a message to the electronic control unit about overheating of the power unit.

- The pump supplies coolant, distributed by the thermostat.

- When you turn on the engine, it needs to warm up to operating temperature. To do this, the thermostat directs the coolant through a small circuit, without including circulation through the radiator. The small circuit includes: Heater for warming up the interior;

- Carburetor heating unit (naturally, only on carburetor VAZ 2110);

- Heating of the throttle unit;

- Intake manifold.

When the engine warms up to approximately 90 degrees Celsius, the thermostat sends some of the coolant to the radiator. When the engine overheating sensor is triggered, all the cooling liquid circulates through a large circuit. Article on the topic: Replacing the boot of the outer CV joint on a VAZ 2109 (Video)Source

How to change the brake hose on a VAZ 2109-2115?

1. The first thing to do is disconnect the negative (-) cable from the battery terminal.

2. Next, you need to remove the wheel whose brake hose needs to be replaced.

3. Then remove the wire connecting the block and the wear sensor.

4. With a sharp movement, push the tip of the wire out of the block on the other side.

6. Holding the tip of the tube with a “10” wrench, unscrew the hose from the brake pipe. At the same time, use the “15” key to hold the tip. If the nuts have “soured” in the tube mount, it should be cut in half and the tip removed from the tube.

7. Remove the tip and seal from the bracket on the rack and body. Using a 15mm wrench, unscrew the tip from the wheel cylinder... remove the hose.

everything useful is here

Removing the rear brake hose

We carry out the work on an inspection ditch or a lift.

Holding the tip of the flexible hose with a 15 wrench, use a 10 wrench to unscrew the brake pipe fitting.

We remove the hose from the eye of the bracket securing the rear suspension beam to the body.

To reduce brake fluid losses, we put a protective cap on the end of the tube for the wheel cylinder bleeder fitting.

Using the “10” and “15” wrenches, we disconnect the hose and brake pipe secured in the eye of the rear suspension beam.

Remove the flexible hose.

After installing the hose, it is necessary to bleed the hydraulic brakes.

When is it necessary to replace pipes and other elements of the brake system?

Brake pipes are changed quite rarely. The need for this arises only if the machine has been in use for a long time, in unfavorable conditions conducive to the development of corrosion, or in the event of any mechanical damage.

You can assess the condition of these components yourself by looking under the car body, or by bringing your “iron horse” for inspection by technicians from the service center. According to the regulations, diagnostics of all components of the brake system must be carried out at least once a year, preferably at the end of the winter period. You can combine the inspection with the next oil change.

Rubber hoses on all wheel cylinders must be replaced, regardless of their condition, every 70-100 thousand km. mileage Pipelines are replaced only as needed.

To carry out the work you will need the following tools:

- Jack;

- Phillips screwdrivers;

- Set of wrenches for: “10”, “14”, “17”;

- Clamping key to “10”;

- Clamping pliers;

- Balloon wrench;

- Anti-corrosion composition;

- Brake fluid (to replenish the system).

What to consider?

The design of the brake system and the principle of its operation are almost identical for all car models. Accordingly, the method of its restoration is also the same for all brands of vehicles.

All pipeline repair work can be carried out in a repair pit, overpass or on a flat area by lifting the machine with a jack.

A set of tubes can be purchased at any auto store. You can order a pipeline of a given length, already bent as required, specifically for a specific car model. Or you can buy a universal copper line, and then give it the required shape and length yourself. The latter option is more economical, however, and there is much more fuss.

Front brake hose PILENGA VAZ 2108-21099, 2110-2112, 2113-2115, Kalina, Priora, Granta

APPLICABILITY: VAZ 2108, 2109, 21099, VAZ 2110, 2111, 2112, VAZ 2113, 2114, 2115, VAZ 1117, 1118, 1119 (Lada-Kalina), VAZ 2170, 2171, 2172 (Lada-Priora ), VAZ 2190, 2191 (Lada-Granta), VAZ 2192, 2194 (Lada-Kalina 2).

founded in 1947 in the Italian city of Comun Nuovo, Bergamo. Pilenga ironworks produced plates for household irons. The crisis in the early 60s forced the company to consider other alternatives, and Pilenga began to develop a specialized workshop responsible for giving the finished shape of the brake disc. In the first years of its existence, Pilenga produced only castings for the needs of automobile factories. Pilenga production program consists of 35% of final products (brake discs and drums), and 65% of finished products (brake cylinder bodies, clutch pressure plates, pad frames, various gears, pins, rods, racks, etc.) for several dozen European manufacturers of spare parts.

Currently, Pilenga is the largest manufacturer of brake discs and drums for assembly lines of car factories in Europe and the USA (Chrysler and Harley Davidson). After a change in management, in 2000 Pilenga began supplying products to the aftermarket under its own name. Deliveries to Russia began only at the end of 2001.

The range of products produced under the Pilenga brand:

* brake and clutch master and slave cylinders * ball joints and steering ends * clutch kits * steering racks * wheel bearings * gearbox bearings * CV joints and drive assemblies * disc and drum brake pads * brake hoses * VAZ engine parts

All Pilenga fully comply with the quality standards adopted in the EU. Orders for Russian cars are made on the same equipment and using the same technology as orders from buyers from EU countries. Pilenga products manage to achieve competitive prices on the Russian market due to large sales volumes.

The company has its own research and development center, which is engaged in the development of formulations for alloys of non-ferrous and ferrous metals for the entire range of products. Much attention is paid to improving machining technology and control methods at all stages of production. In metallurgical production there is a computer system for controlling metal welding, which makes it possible to eliminate the slightest deviations from the given recipe. All products are manufactured on modern equipment using the latest advances in the field of metal production and processing. Modern 3D design technologies allow the brake disc development process to be carried out incredibly quickly, calculating the weight and dimensions that form the basis of the foundry phase of production. The number of items in the company's catalog is constantly growing, which is a consequence of the company's rapid adaptation to market requirements.

Pilenga produces about 200 types of clutch pressure plates. Over the past few years Pilenga has undergone many changes: the machining department has acquired a significant role and become an integral part of the foundry, quality control has become incredibly strict...

Just recently, Pilenga received an order to produce several hundred wheels for a Daewoo car, a very rare car in Italy for which the company had never produced wheels before.

Over 80% of the company's turnover is provided by exports. 90% of brake discs produced go abroad, on par with Germany, which occupies a leading position in this area. As for unprocessed cast iron billets, which account for 22-23% of turnover, the company has several foreign buyers.

The main stages of replacing brake pipes on a VAZ 2109, 2110

You can replace the pipeline lines in the direction from the main brake cylinder to each wheel according to the following diagram.

- Disconnect the battery terminals.

- Raise the car to the desired height using a jack.

- Remove the car wheels.

- Using a “10” wrench, unscrew the nut securing the tube to the master cylinder and install a plug for dust and dirt in the supply hole.

- Carefully release the pipeline towards the wheels. Remove the protective plastic box and remove the line from the metal and plastic holders. Try to do this carefully so as not to damage the clips.

- Unscrew the brake hose fitting and remove the damaged line.

- Start installing the new tube in the opposite direction: from the wheel to the master cylinder.

- Reinstall all holders, replacing worn or damaged parts as necessary.

- Blow out the pipeline with compressed air, connect it to the system and bleed the brake system according to the instructions, replenishing the missing fluid as necessary.

Tip: when replacing a pipeline, it is advisable to fill the system with new brake fluid.

Important: when installing a new line, plug it at the inlet and outlet. Dry all connections to prevent dirt from entering the system. During the installation process, it is advisable to treat the surface of the copper or steel pipeline with an anti-corrosion coating.

Don't forget to change the connecting tube between the wheel calipers. To do this, use a brake wrench set to “10” so as not to strip the thread, unscrew the fittings and install a new tube. This element is replaced after replacing the elastic hose on the wheel.

Features of replacing brake hoses

When replacing brake pipes on a VAZ 2110, it is a good idea to check the condition of the elastic hoses. If you notice even minor cracks and mechanical damage on them, replace them. Also install new hoses if the service life of the old ones has already exceeded the required limit.

The elastic hose replacement scheme consists of the following steps:

- Clean the cylinder well with a wire brush, treating it with rust remover if necessary;

- Using a “14” wrench, unscrew the wheel caliper fitting;

- Plug the caliper hole to prevent dirt from getting into it;

- Using wrenches “17” and “10”, unscrew the fitting and disconnect the hose from the tube;

- Remove the elastic hose holder;

- Install the new hose in sequence from tube to caliper.

Replacing the brake system elements described above is not a very pleasant matter. However, if you are going to replace the piping and hoses, be glad that you won't have to do it anytime soon.