When in a dark car interior people begin to fumble with their hands along the trim in search of a handle, the driver can only hope for the efficiency and confident coordination of the movements of his passengers. Such situations happen all the time, and if you have to transport guests after a noisy feast, a country picnic or a barbecue party, the condition of the doors can deteriorate sharply.

Illumination of door handles, done independently and at no special cost, will help correct the situation. This is one of the interior tuning options, which is not a mandatory procedure, but, unlike many other types of finishing, can bring practical benefits.

A combination of aesthetics and functionality

The interior lighting of a VAZ as its tuning, done by hand, is usually designed by the developer to solve several problems at the same time.

The first of these tasks in relation to the VAZ-2110 is the creation of an appropriate image, which is achieved by using additional sources of varying brightness and color.

As for the functional role played by car interior lighting, its practical achievement is much more difficult. For the VAZ-2110, the presence of additional light sources means that in the dark, very comfortable conditions are provided not only for the driver, but also for passengers. Let's name just a few of them:

- tuning in the form of lighting helps to quickly find various objects, including small ones, both in the handbag and glove box, and on the seats;

- the so-called polite interior lighting makes getting into the VAZ-2110 much more comfortable, by delaying the turning off of the light after closing the door, and gradually reducing the brightness of the standard light bulb;

- illumination of the lower part of the VAZ-2110 interior allows you to quickly detect objects that have fallen to the floor near the feet;

- Illuminated door handles make it easier for passengers to get in and out.

The list of advantages can be continued if desired.

DIY LED lighting installation

In order to get the job done, we will need:

- heat shrink pipe;

- electric wires;

- LED strip and LED lights.

Installation is carried out, as a rule, on the dashboard, in places where lamps and standard lighting elements are located. They can be simply replaced with LEDs if desired. The base of the diode lamp is the same as that of a standard lamp, so replacement is carried out without any difficulties.

Next, you need to install the tape at the bottom in the foot area and around the perimeter of the top of the car. After the necessary measurements, cut off the amount of tape that is needed. Cuts should be made in areas where solder contacts are located.

When measuring, you need to provide some excess wires for reserve. After cutting and soldering to the contacts of the tape, you need to put on the heat-shrinkable tube and heat it with a hair dryer until there is no shrinkage. We process the following fragments in a similar way.

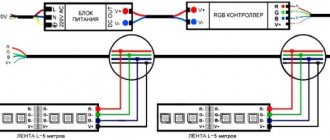

The connection must be made through an RGB block container or in the same way as neon lights. This will ensure that the lights turn on when the car doors are opened.

It is very important to maintain the correct polarity here - this was discussed above

After connecting it yourself, the car door lights will be ready for use - check its operation. If everything is in order, you can be congratulated on your success.

Backlight design options

The motorist himself must choose which lighting option, based on its operating principle, is best installed on the bottom of his own vehicle.

In total, the following options can be distinguished:

- Direct connection. This is the simplest and most elementary connection. Here, additional lighting fixtures are directly connected to the machine’s electrical network.

- On remote control. The control element can be a button installed on the dashboard, or a remote control.

- Flashing backlight. Here you will need a special controller with the appropriate function.

- Autonomous work. The point is that the backlight will not depend on the machine's electrical network. The lamps have their own power source.

Systems can be complicated and simplified by choosing only one option, or combining them.

The backlight can have only one color, or several lamps of different colors. If you wish, you can even make a system that will adjust and work to the beat of the music you turn on. A kind of light show under the car. Looks impressive.

How to troubleshoot door switches on a Grant

We invite you to study in detail simple methods for troubleshooting door limit switches on the popular Lada Granta. In practice, every car owner can cope with repairs. So, what can you do when, in the cold season, the door switch stops working correctly:

One of the simplest ways is to treat the surface of the mechanism with a water-repellent specialized liquid. This will help until the air temperature reaches minus 50 degrees. However, such a measure is temporary and rather short-term. It is necessary to remove the anthers from the end switches. It must be remembered that special rubber caps perform a purely protective function, and if you remove them, you will have to more carefully monitor the cleanliness of the mechanism

It is important that the anthers can be removed for a short time when there is severe frost outside, which negatively affects the operation of the device. It is recommended to lubricate rubber surfaces with silicone. However, this method will be useful to you at an air temperature of at least minus 10 degrees. Standard caps can be replaced with analogues

You can use boots from other mechanisms, for example, a good version of Toprun, they are almost identical to the original LADA Granta caps. The most important thing is that such anthers are made of a material that does not lose its elasticity in cold weather. You can install a small spring under the boot. To do this, you can use springs with a diameter of 12-13mm, a length of 18-20mm, with a wire thickness of 1mm. The springs are installed directly on the switch rods under the anthers. If the spring is good, then it will allow the cap to be compressed, and at a temperature of minus 40 degrees it will never let you down.

Illumination of interior car handles

I often read and saw some photos of the interior door handles. I didn’t see it in person, but I really wanted to... In order not to put off meeting the beautiful, and not wanting to overpay for second-hand illuminated pens, I decided to illuminate them myself. LED was chosen as the light. But then I came across the fact that there are no red ones of the required shade on sale. In BMW, all the lighting is coral red. The diodes I came across were either ruby red (like the stars of the Kremlin) or almost orange. There was no middle ground (maybe I was looking poorly...), so I resorted to a trick. I used white light diodes...(?)

I bought regular SMD 5060 flat diodes of warm white color (there were also cold and white moon ones) for 3 volts. I cut out light guides from 4mm plexiglass and polished them on all sides. And to obtain the desired shade, I used a light filter made of red plexiglass, which I subsequently also polished and installed between the diode and the light guide.

Next, square holes were cut out in the handles with a knife.

The light guides fit tightly into the holes. A red stripe filter was soldered to the end of each.

Having attached an LED with soldered wires and resistance to the light filter, I filled the whole thing with hot-melt glue from a gun.

I connected it to all the batteries in the house (9 volts accumulated)

And satisfied with the result, I went to install the handles in the car. This is how they shine in their place. As you can see, the color tone does not differ at all from the original backlight. The only negative is that the light is brighter than I wanted. But I think so. By matting with fine sandpaper you can achieve a decrease in the brightness of the illuminated area and a more uniform beam of light.

That's it. I’ll go look on the Internet for courses on photography in the dark... Since the latest photos do not stand up to any criticism... And if the light was on in the cabin and I could see everything perfectly, then the camera refused to look at the world through my eyes. And although the camera seems to be quite sophisticated (7 years ago it was sold as a semi-professional one), I am unable to figure out this number of settings... As they say: either the skis don’t work, or I’m a *****...

PS Maybe one of the photographers can advise whether it is possible to take decent photos in the dark with my camera... only in Russian, without terms.

Well, as usual, I couldn’t find peace... My work of art was gnawing and tormenting my soul

Installation

Method number 1. Self-installation of LEDs in door handles

.

- Treat the LED with fine sandpaper so that it shines not as a point, but as a scattering light.

- We make a hole in the plastic door handle of the required diameter (for example, 6 mm) using a drill.

- We install the LED in the hole and fix it with glue (for example, hot glue).

The installation process is also shown in the video:

Method number 2. Ready solution

.

- We make a hole in the niche behind the handle.

- We fix the accessory with the inscription “Vesta” inside the door handle.

Thinking through the design

Of course, a car with neon lights looks amazing! And neon interior lighting, when installed correctly, can significantly change the interior of a car. Such lighting looks most advantageous in the dark, as well as on a snowy road in winter.

ADVICE! Think about the color scheme of your lighting in advance. Leading automobile designers, when choosing any type of lighting tuning, recommend choosing it not to match the body, but to contrast it. For example, if you have a blue car, then cherry-colored neon lighting will look much more impressive. Is it difficult to decide on colors? No problem! "Da Vinci's color wheel" can help you.

A car with neon lights looks amazing

Let's start installation

You purchased a brand new neon kit for your car, brought it home and are ready to install. To get started, please read the instructions carefully.

If you decide to install neon lighting for the car interior, then the tape is attached starting from the rear of the car to the trim using superglue or a special adhesive strip included in the kit. Just glue the cord in the right place and connect the batteries to it - car electrics, regular batteries or an inverter for connecting to the cigarette lighter. Connect the wires in the correct sequence: from the + contact of the battery to the place where you plan to install the switch, and connect the negative contact to the body. For a neon cord up to 5 meters long, a 12-volt inverter is sufficient. It can be used to create designs, variations of shapes and colors that are limited only by your imagination.

If, for example, the bottom of a car is chosen as the location for installing the neon, then first you need to mark the fastening. And then:

- Don't forget to buy the necessary tools, silicone for insulation, fastenings (staples, screws, clamps), wires and a transformer.

- Install the tubes according to the intended pattern.

- Now feel free to tackle the electrics. The wire connection is serial. Observe polarity.

- The transformer is secured under the hood with screws. We connect to the battery with high-voltage wires. Then we pull the switch from minus into the interior. All that remains is to connect the wires from the tubes to the high-voltage unit.

Ready! Your car has been completely transformed. Now get ready for the admiring glances of passers-by and other motorists. Good luck on the roads.

A combination of aesthetics and functionality

The interior lighting of a VAZ as its tuning, done by hand, is usually designed by the developer to solve several problems at the same time.

The first of these tasks in relation to the VAZ-2110 is the creation of an appropriate image, which is achieved by using additional sources of varying brightness and color.

As for the functional role played by car interior lighting, its practical achievement is much more difficult. For the VAZ-2110, the presence of additional light sources means that in the dark, very comfortable conditions are provided not only for the driver, but also for passengers. Let's name just a few of them:

- tuning in the form of lighting helps to quickly find various objects, including small ones, both in the handbag and glove box, and on the seats;

- the so-called polite interior lighting makes getting into the VAZ-2110 much more comfortable, by delaying the turning off of the light after closing the door, and gradually reducing the brightness of the standard light bulb;

- illumination of the lower part of the VAZ-2110 interior allows you to quickly detect objects that have fallen to the floor near the feet;

- Illuminated door handles make it easier for passengers to get in and out.

The list of advantages can be continued if desired.

Let there be light

If you are wondering how to make the wheels illuminated, then our instructions will answer it for you. Let's do this job using LEDs, as they are best suited for this purpose. We will not describe installation on all four wheels. Let's look at the whole process using one wheel as an example, and the rest are performed in a similar way:

- To begin, we will need several LED strips, four current stabilizers, corrugated tubes, wires, sealant, glue and wire.

- Then we lift one side of the car and. If desired, the car can be placed on safety stands, since working with a car mounted on a jack is extremely dangerous due to poor stability.

- After removing the wheel, you must thoroughly wash the brake disc casing with gasoline and dry thoroughly.

- After everything has dried, you need to measure the length of the LED strip. This is quite easy to do - just wrap the tape around the casing and cut off the excess. Remember that the tape should only be cut in places specially marked for this purpose. Every three diodes there is a white mark, cut along it (if you cut it in the wrong place, you will simply ruin the tape, since it will no longer work).

- We coat the finished diode strip with glue on the side that will be adjacent to the casing.

- Carefully glue the tape to the casing and let the glue set. After the glue has dried sufficiently, we additionally attach the tape with wire to the brake disc casing.

- The tape is fastened quite tightly. Carefully seal the cut end of the tape using sealant. This is necessary so that moisture does not get into the silicone tape with lamps and ruin all our beauty.

- Wires (plus and minus) are released from the untouched end of our ribbon. We solder the wires to them that will connect to the stabilizer.

- We carefully insulate the soldered wires and place them in a corrugated tube, after which we bring them into the cabin.

- Next, the wires are connected to the stabilizer and lead from it to the headlight wires. If you connect it not to the headlights, but directly to it, then you will have to install an additional switch in the cabin for our lighting. In our case, the illumination of the car wheels will work only when the headlights are on.

Do-it-yourself wheel lighting requires a lot of care and precision on your part. The main components of the backlight are very fragile and can easily fail if mishandled.

Do not forget that when connecting LED strips it is very important to observe the polarity (plus and minus), since if you connect the poles incorrectly, the diodes will not work

If you lower your financial priorities, you can purchase a ready-made kit. Ready-made car wheel lighting has many unique features. For example, sound sensors that respond to musical compositions. As a result, “light music” is produced on wheels. If the lighting kit is multi-colored, then the wheels will play with different colors of the light spectrum. The kits, as a rule, always contain detailed instructions for installing and operating a specific device.

Keep up with auto fashion and let your “steel friend” be the most beautiful, bright and memorable!

One of the easiest and most exciting ways to give your car an unusual look is light tuning. This is a fairly common art that allows you to add zest to any car and make the underbody, radiator grilles and even wheels shine with neon colors. Wheel illumination, as a method of light tuning, always looks very unusual and attracts attention; the contrasting glowing wheels of the car are mesmerizing.

In fact, this effect can be obtained from the primitive installation of LED light equipment in the wheels of a car. For this, an LED strip is used, which should be installed and connected. Next we will look at these processes in more detail.

DIY door handle lighting

When in a dark car interior people begin to fumble with their hands along the trim in search of a handle, the driver can only hope for the efficiency and confident coordination of the movements of his passengers. Such situations happen all the time, and if you have to transport guests after a noisy feast, a country picnic or a barbecue party, the condition of the doors can deteriorate sharply.

Illumination of door handles, done independently and at no special cost, will help correct the situation. This is one of the interior tuning options, which is not a mandatory procedure, but, unlike many other types of finishing, can bring practical benefits.

Main conclusions

Illumination of door handles in the car interior is a convenient and visually attractive tuning option that decorates and increases visibility in a dark interior. There are different options for implementing the method, from simply installing an LED on the back of the case, to using a special panel with a luminous inscription.

Perhaps there are other options, original, successful in decorative terms. We encourage all our readers who have their own experience in this matter to comment on this article and publish their own ideas, lighting options, or share thoughts on improving existing methods.

Previous LEDsCharacteristics and advantages of the Piranha LED Next LEDsFeatures, characteristics and maintenance of LED lamps for street lighting

Tape placement

First, we select a place to place the tape. Ideally, it should not be visible. But it should shine well on the rug. Having decided on the installation location, you can proceed to preparing the tape:

- First you need to measure out the desired piece of tape. Please note that it can only be cut in certain places. In this regard, it is better to make it a little shorter than to allow it to sag;

- Next you need to carefully solder small pieces of four-wire wire to the tape;

- We are testing, to do this you need to connect the resulting structure to a power source;

- If everything is in order, then isolate the connections. The easiest way is to use silicone sealant, but you can get by with regular electrical tape;

- We fasten the resulting lighting device into place. To do this, you can use plastic ties or silicone glue.

This work will have to be carried out with any connection method. After this, you need to decide where to connect the backlight. A lot depends on your goals and wishes.

Installing a diode in the handle

Fittings with LED lighting.

Next, you will need to install the diode directly into the handle itself. This is where an electric drill comes in handy. But first, try to place the diode inside the handle and temporarily fix it on the door. Usually in modern cars the design allows this to be done. After this, be sure to connect the diode to the electrics and check the operation.

Experts advise always pointing the diode lamp downward - this way the light will best illuminate the handle. They also recommend connecting the other ends of the wire to a power source in the form of a window lifter if you don't want a constant glow. But if on the contrary, it makes sense to solder the wires to the cigarette lighter power supply.

When this is ready, make the necessary markings on the handle in those places where the wiring will come out and where the diode will be visible. This is not always necessary and depends on the specific design of the handle. But if it comes to this, then you will have to work with a drill, drilling holes. Choose the minimum drill diameter. After all, you can make the hole bigger, but you can’t make it smaller.

Now all you have to do is finish connecting the wires and diode. Now that all the main work is finished, you can safely put the plastic protective plugs on the small terminals first, and then put on them the plastic case that was originally removed.

As for the power part, here you first need to insulate it using small pieces of electrical tape, and then just put plastic protection on the wiring. But keep in mind that the protection is already applied when the LED wires are connected to the main power wires.

Connection

There are several suitable options for how to make the lighting in your car yourself to ensure an original glow in your legs.

Each motorist will decide for himself how it will be more convenient and easier for him to connect the LED footlights in the car. But there are 3 main options:

- to the lighting of the interior itself;

- through the cigarette lighter;

- from dimensions.

The choice depends on the format in which the driver wants to see the backlight. After all, each scheme provides its own version of when and how the glow will be activated.

Through interior lighting

Some motorists prefer to install footwell lighting in their car by connecting to the main lighting system of the vehicle interior.

This connection method ensures that the backlight will always turn on exactly when the doors are opened or when the car interior lighting is turned on.

If you connect LED lighting for the footwell area in a car through interior lighting, then the light source will need to be connected according to the following algorithm:

- remove the interior lamp;

- connect the wires, observing polarity;

- the white wire usually goes to the plus;

- the negative wire is connected to the red wire;

- the wires are hidden under the interior trim;

- It’s most convenient to stretch them directly along the side post;

- Next, connect the wires of the installed LED strips to each other;

- connect them to a power source;

- check the system for functionality;

- if everything is functioning, perform high-quality insulation;

- return the lampshade to its place.

If you install an additional controller, the light will gradually dim rather than suddenly turn off.

If you are not sure about the polarity of the wiring, use a tester or multimeter. This will make it clear where is the plus and where is the minus. However, the wires may differ in color, depending on the car.

In this way you can connect to functioning interior lighting, but this is not the only option.

Through the cigarette lighter

You can also activate the LED strip from the cigarette lighter, which is done quite often.

By connecting the strip to the cigarette lighter, the light will turn on when the doors are opened.

Not the worst option, since most drivers do not need backlighting while driving. They use it for comfortable getting in and out of the car.

The connection itself is performed according to the following algorithm:

- plus the LED strip connects to the cigarette lighter;

- the minus must be connected to the limit switch on the door;

- the tape wiring is brought out together with the rest of the wires, connecting into a single bundle;

- All contacts are insulated and secured with a tie if necessary.

How exactly to remove and hide the wires depends on the specific car and the driver’s ideas.

Through dimensions

If you connect from the dimensions, then the backlight will function constantly, in parallel with the operation of the dimensions. That is, this is the most relevant option for many, since the system will turn on at night while traveling.

You can connect the plus from any backlight bulb. For example, the glove compartment or dashboard. The minus is thrown onto the body.

If you connect the minus to the door limit switch, then the backlight will turn on provided that the door is open and the lights are on.

Here, each motorist decides for himself how and in what situations he needs the LED strip in his legs to work. Therefore, you can choose different connection options.

By installing the tape in the legs, you can achieve the original appearance of the interior, as well as get some practicality from such a solution. Having chosen the appropriate work option, all that remains is to implement the scheme. Moreover, you can do this yourself, without having a wealth of experience and special specialized education.

Connection to 220 Volt voltage

As mentioned above, to supply power to 12-volt spotlights, additional equipment, a converter, transformer or driver is required. However, recently a new product has appeared on the lighting market - spots operating on 220 Volts. In this regard, it became necessary to study in more detail the scheme for connecting and installing spots directly to a 220 Volt network, without using transformers.

Serial connection

The simplest scheme to implement, requiring a minimum amount of materials. Spots are connected sequentially one after another, but it is advisable that their number does not exceed five or six pieces. Due to the serial connection, interruptions in lighting may occur, and if one lamp fails, the circuit will break and the others will stop working. To restore the functionality of the circuit, you will have to disassemble it and check each spot separately.

To implement it, you need to connect the phase from one lamp to another, and connect the neutral wire to the latter. The phase is pre-supplied to the switch, which guarantees its functionality.

If you want to connect triple wiring, you need to connect the ground wire to each lamp by finding the appropriate terminals. Grounding can be done through the nearest outlet or switch.

Parallel connection diagrams

The approach is much more complicated than the previous one. There is a dependence: the more connected spots, the higher the cost of organizing lighting and time costs. On the other hand, when connecting each lamp separately, they will shine with the same intensity stated in the passport. Therefore, despite the difficulties, the current method is considered the most popular and widespread.

Parallel connection is implemented in two options:

- Beam method - each lamp has a separate pair of wires.

- Daisy chain connection - two wires are connected to the lamps alternately, and then fed from the output.

Methods

Parallel connection can be implemented in two ways:

- a pair of wires goes to each lamp (beam);

- daisy chain connection - when both wires alternately go to the lamps, and are fed further from the output. Two ways to parallel connect spotlights

Radial

The approach is the most complex, since a separate luminaire requires its own cable. The advantage is high reliability. If it fails, only the damaged spot will stop lighting. To implement the method, take the cable connected to the junction box and stretch it to the middle of the room. Secure using various elements, from here pull separate pieces for each recessed lamp.

Pay attention to safety as there are several wires radiating from one location. If a single-core cable is selected and a small number of spots are connected, the wiring is carried out using the twisting method, crimping with pliers and additional welding

The connection will be permanent. Another option is simpler: each conductor should be equipped with connectors that are inserted into the terminal block slot.

Daisy chain connection

The cable comes from the junction box and connects to the first lamp. Next, you need to take a piece of another wire and connect it to the output of the device, and the other end should be connected to the next spot. Repeat the steps for all spots until the circuit is connected.

The lamps will operate from one switch. If you need to divide them into two groups, then the connection should be made through a two-key switch. The circuit becomes slightly more complicated due to an increase in the number of cables. It is possible to install a backlit switch.

Preparing and connecting wires

Illuminated door handles from the inside.

Now let's get to work. First you need to disassemble the door handle. This is done using appropriate screwdrivers. Now take the LED lamp and remove the plastic housing from it. There you will see pins at the end of the lamp that will need to be soldered to the wiring. But before this, it is advisable to lightly clean the wiring and put small terminals on them. This will make soldering much more convenient for you, and the quality of work will be better.

Related article: Cleaning an old cast iron bathtub

Don’t rush to put plastic plugs on the wires for protection just yet, since in any case you will still have to remove them until the work is completely finished. On the other side of the wires, it is also necessary to lightly strip and put terminals on the ends, but of a larger size.

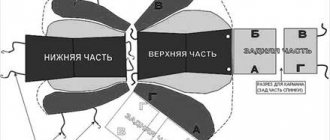

When doing this kind of work, it is important to consider one important point. As a rule, any door light in a car has two sides: one is the lamp itself that will glow, and the other is the part from which the main power will be supplied to this lamp

So this power can come either directly from the electrical part of the car (usually you need to open the box that is located near the steering wheel) or from the door card, if it has direct power (this is often observed in modern car brands).

In the first case, you need to calculate the length of the wires in advance so that it is completely enough to connect the backlight and at the same time for proper placement, so that in the end the wires do not get in the way under your feet. In the second case, small wires are usually used, since their location does not extend beyond the area of the handle. But still, in both the first and second cases, it is advisable to take long wires, since they can always be shortened.

After this, use an ammeter to check that all wiring is connected correctly. If you don’t understand electricity very well, then it is better to seek advice or direct help from an electrician so that in the future there are no unpleasant problems with a possible short circuit.

Tool for the job

Illumination scheme for external handles.

First of all, you need to stock up on the necessary materials and tools in advance. Moreover, you need to provide for the availability of everything right away, since working with electricity cannot be delayed, especially when it comes to a car. So, you will need:

- small LED light bulb;

- terminals;

- thin wires;

- blowtorch;

- screwdrivers;

- knife;

- insulating tape;

- drill;

- Super glue;

- plastic plugs for terminals;

- ammeter;

- pliers.

When everything you need is prepared, decide for yourself which door you want to start with. Experts recommend starting with lighting on the front doors, since access to the electrical part of the car in case of anything will always be closer here.

LED lighting elements

Illumination, including in the leg area, can be created by various sources. Without big problems, you can implement all the varieties of known interior lighting options with your own hands.

The accumulated experience clearly demonstrates that such tuning provides the best results when using single and strip semiconductor light sources to illuminate the area around the legs and other places. This is determined by the fact that:

- they do not require high voltage for their operation and are powered from the vehicle’s on-board network;

- due to the low voltage, semiconductor sources are safe to use, even in the area of the feet;

- sources of this type are economical and do not create a serious load on the on-board network of the VAZ-2110;

- LED strips are very flexible and allow you to go around any contour;

- LED strips are available today in a variety of colors.

It is of no small importance that you can make such lighting yourself and connect it to the car network without deep knowledge in the field of electrical engineering

How to properly install an LED strip for car interior LED lighting?

Installation of a car with LED strip is carried out according to the standard scheme. First of all, you need to purchase a set of wires, heat shrink tubing, and tape.

It, like individual diodes, is purchased at automobile markets and/or in specialized automobile stores. You should not skimp on the quality and length of the tape; experts advise stocking up on good LEDs. It’s better to buy more diode strip than to realize at the last moment that you don’t have enough.

In addition to interior design, diode strips are actively used to illuminate car wheels.

Step-by-step instructions for diode connection of car interior lighting

Arrangement of lighting in the car, with your own hands, should begin with the instrument panel of the vehicle. To do this, standard equipment is removed: instruments, panel lighting, and diodes are installed. The installation process is very simple, since the diodes have bases similar to factory equipment.

Then you need to determine the installation locations. Many people prefer to mount diodes along the entire perimeter of the ceiling, parallel to the car body pillars. The summer is laid gradually, and the remains can be cut off.

The cut points are clearly visible: they are marked with special membranes. After the procedure, do not forget to clean the ends of the cut and solder them together. We close the connections with bushings and heat them with a hairdryer. In this case, it is better not to use an industrial hair dryer, since there is a high risk of overheating; an alternative is a regular household appliance.

Switching on is carried out similarly to the circuit of neon lamps. You need to be especially careful at this moment and not confuse the polarity points that are indicated on the tapes at the cut points.

Essentially, this is where the workflow ends. There is nothing complicated. Only the installation must be carried out sequentially and be careful about small elements when connecting them.

An important aspect when working is the combination of lighting aesthetics and its functionality, which will be discussed below.

Types of electrical wiring

Before proceeding directly to the installation process, we should decide on the type of wiring that we will install in each room. There are two types: open and hidden wiring. Each of these types has its own advantages and disadvantages.

Any of them can be used in any room, only the price and labor costs required to complete the work differ. Therefore, let's take a closer look at the installation standards for each of these types.

Open wiring type

The open type of wiring involves installing conductors along the surface of walls, ceilings or floors. In this case, wires can be laid both on the surface and inside special protective elements, such as ducts or pipes. In some cases, they require lining special materials between the wire and the wall. But let's talk about everything in order.

Open wiring type

To do this, first of all, let's decide on the surfaces on which installation will be carried out. These can be combustible, non-combustible and non-combustible surfaces. Regular wood can be classified as combustible. Fire-resistant wood is wood that has special fire-retardant impregnations. Fireproof surfaces include concrete, brick and other materials with similar properties.

Open wiring in special boxes

- Wires are also divided into combustible, non-combustible and non-combustible. You can determine this parameter by the wire marking.

- Another parameter that affects the installation method is the characteristics of the room itself. After all, you must agree that you cannot lay wires in a steam room or shower, just like in an ordinary room. Therefore, there are also such parameters as wet, damp, dusty, outdoor and dry rooms.

- As a result, it turns out that the laying method depends on what kind of wire and on what surface it is laid. In our article we will consider only the most common options. You can see how the house wiring should be done in each individual case in the table. 2.1.2 and 2.1.3 PUE.

Open wiring in a room made of fireproof materials

If we have an ordinary apartment with walls made of concrete or brick, then there are several options for open wiring. Unprotected wires can be laid on insulators, rollers or strings. Can be laid in combustible boxes and trays with opening lids. Can be mounted in special shells made of fire-resistant or combustible materials directly on the surface of the walls of the ceiling or floor. In this case, we are usually talking about the use of plastic corrugation.

Open wiring in rooms made of combustible materials

- If wiring is installed for a private house made of wood, then everything is a little more complicated. In this case, if you use rollers, insulators or strings, then a fireproof material must be placed between the wire and the wall.

- If a box or pipe is used, it must be made of fireproof material. Usually it is metal. If this is not the case, then you will also need a lining of fireproof materials.

Hidden wiring type

Hidden wiring is a conductor laid inside construction channels, or under a layer of plaster in special grooves - grooves. From an aesthetic point of view, this method seems more attractive, but from a financial point of view, this is not always the case.

Hidden wiring

- As in the case of open wiring, the tables become decisive when making a decision. 2.1.2 and 2.1.3 PUE. Therefore, the factors influencing the choice of wiring remain the same.

- Let's look at a few options. To begin with, as in the first case, let's take a brick or concrete wall. As the instructions say, we can even lay an unprotected wire if it is solidly hidden under a layer of plaster. To increase the maintainability of wiring, you can use installation in combustible pipes - corrugated pipes.

Hidden wiring in a room made of fireproof materials

Hidden wiring in rooms made of combustible materials

But if the installation is carried out using combustible or difficult-to-burn materials, then in this case a lining of non-combustible materials is necessary. The shells themselves must be covered with a layer of plaster or other fireproof material on all sides.

Turn off the backlight in the switch

If there are no other ways to get rid of the flickering lamp lamp, you will need to completely turn off the LED or neon lighting on the switch. Let's look at how to do it yourself and what are the main stages of this procedure.

Preparatory stage

For those who have never installed switches or done electrical work, it is recommended that you carefully consider your actions. Pre-requisite:

- Disconnect the general power supply in the apartment/house from the switchboard switch (by checking its absence with an electrical probe or an indicator screwdriver).

- Prepare a set of necessary tools (mostly a flat-tip screwdriver).

Operating principle of the lighting device

To create illumination, an LED or neon bulb is introduced into the switch circuit parallel to the main contacts. The disconnected chandelier base circuit allows electrical current to reach the switch lighting system. Turned on, on the contrary, leads to disconnection of its power supply. The mechanism of action is based on the difference in resistance between the lamp and the additional light source.

The current passing through the switch LED is clearly not enough to heat the filament of the incandescent light bulb. However, if the chandelier contains an energy-saving lamp or an ice element, then a driver system is used that can operate on low current. Due to the latter, the semiconductor crystal may begin to blink due to the gradual accumulation of potential in the resistor and its periodic release.

What turns on the light

All LEDs and fluorescent lamps operate on direct current. Therefore, at the beginning of their case, a special driver is installed, which includes two required elements:

- Diode bridge – AC to DC converter.

- An electrolytic capacitor is a smoother for voltage pulse dips.

The latter is the main culprit for spontaneous turning on of the light. The fact is that, although weak, current passes through the backlight system - it is impossible to turn it off (only if you completely remove this parallel circuit) - and this is quite enough for the capacitor to accumulate charge. When its potential reaches a predetermined value, a discharge occurs - the light bulb flashes. Although such an event occurs fragmentarily, it nevertheless worsens the life of the lamp, especially gas-discharge ones. In addition, this reduces the comfort of a person’s stay in such a room.

Lighting systems with movable lamps on rails

Track lighting is a specialized lighting fixture or lighting system. The system is ceiling or wall mounted and accepts and powers individual luminaires or heads.

It is often used to bring light into corners and work areas in the kitchen. A section of heads can extend over the area where you walk and sit while you work, or a path can be laid directly over an island or peninsula with pendant heads to illuminate those surfaces. This type of lighting is often used in workshops and greenhouses.

A track lighting system can also be useful for delivering light into a long, narrow space such as a hallway. You can run the track parallel to a wall where photographs or paintings hang, positioning and aligning the heads to highlight every detail.