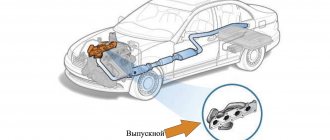

The collector (resonator, “pants”) is an engine attachment; it is a closed reservoir of complex shape with a common chamber (receiver) and outlet pipes. Depending on the nature of the functions performed in a car, there are two types of manifolds - exhaust and intake.

The main task of the intake manifold is to supply air from the distribution system, mix it with fuel and transform it into an air-fuel mixture of the desired consistency, followed by a uniform supply to the combustion chamber of the cylinders. Therefore, the main task of the exhaust manifold is to collect exhaust gases from the engine cylinders into a single pipe.

When is it necessary to replace and remove the intake manifold on a VAZ-2114

Huge temperature changes are the main problem faced by the exhaust manifold and the gasket, for which it is removed. The collector itself is made of a special grade of cast iron; it can withstand high temperatures (up to 800-900 degrees) , however, these are critical values, after which the collector may warp or crack.

Exhaust manifold VAZ-2114

Its main task is to collect exhaust gases and distribute them into the exhaust pipe of the muffler.

Replacing or dismantling the VAZ-2114 exhaust manifold is necessary in the following cases:

- Mechanical damage to the collector.

- Warping and loss of tightness at the junction with the cylinder head.

- Burnout of the gasket between the head and the manifold.

- The appearance of cracks as a result of engine overheating.

- Replacing the collector with a device of a different configuration, adapted to a more severe operating mode.

In the event that we are not going to participate in high-speed races for the prize of the head of the regional traffic police, replacing or dismantling the collector may be necessary in a number of cases.

Causes of malfunctions

The key factor that causes 90% of exhaust manifold malfunctions on VAZ 2114 cars is high temperature and poor quality materials from which the parts are made. During operation, the steel repeatedly heats up and cools down, which leads to the appearance of cracks in the body. This is a common occurrence for VAZ cars older than 7-8 years.

Auto repair shops offer crack welding services using argon welding. However, for a number of reasons, this activity is useless for cars older than 7 years.

1) Just removing and installing the exhaust manifold will cost about 2.5 thousand rubles. Taking into account the work of the welder and other actions, the cost of repairs can be 4-5 thousand rubles. If you do the work yourself, buying a new part will cost less.

2) Welding, even argon welding, disrupts the structure of “tired” metal. A boiled part rarely lasts longer than a year, after which new holes appear. The older the car, the faster the problem returns, and the collector has to be removed again. If the car is older than 8 years and there are problems with cracks in the manifold, it is better to remove the part and replace it with a new one.

- Wear . During operation, the car emits hot gases that destroy the surface of the gasket, as a result of which it can tear or delaminate.

- Since there is only one gasket for the intake and exhaust manifolds, gasoline entering through the first channel can get on the gasket, which also affects the integrity and structure of the material from which it is made.

- Part quality, not always high, even original, so when choosing, you should pay special attention to this.

Bent valves due to irregular valve timing do not threaten the 8-valve valve

Signs of trouble

Exhaust manifold gasket One of the main signs of a leak in the system is a “sporty” growling sound when the engine speed increases. This may be a symptom of various exhaust system problems. To check, it is better to take an assistant and go to a garage with a pit or to an overpass. Most often, you can determine by eye whether the problem lies in the muffler, resonator or exhaust.

Gasket wear may become apparent during planting. Open the hood and start the car - white or grayish smoke rising from the manifold during warm-up indicates a leak for this reason. VAZ car owners usually encounter this problem once every 3-4 years. When using low-quality spare parts and before. The solution may be to manufacture a custom-made steel gasket. It can last as long as the entire collector.

Service specialists, when attracting clients, like to tell scary stories about the explosion of the exhaust manifold on VAZ 2114 cars due to cracks. In reality this is nothing more than a myth. But the real problems are no less serious, so there is no point in putting off repairs.

A cracked exhaust manifold or worn gasket can cause your engine to run rough.

1) A lambda probe is installed in the exhaust manifold, which affects the operation of the injection system. Strong air suction disrupts the oxygen mass content in the exhaust; the lambda incorrectly adjusts the quality of the mixture, causing tripping, uneven idling, loss of power, and “black” spark plugs.

This is interesting: Location and checking of the charging relay ("chocolate") on a VAZ 2107 - how to change it yourself

2) Another function is crankcase ventilation. Impaired air circulation causes disturbances in the operation of the gas distribution mechanism, increased wear of valves, the formation of carbon deposits on the pistons and other “joys”. If increased noise and unpleasant odors during engine operation are combined with dirty work, the car needs urgent repairs.

Places of possible suction

There are quite a few places through which air can get inside the fuel system, and during the test you will have to examine them all (we’ll talk about how to detect them a little lower).

For now, let's say that you have to check:

- The intake manifold gasket (its destruction or burnout in the vast majority of cases is the cause of suction).

- Hoses and pipes suitable for the manifold.

- Injector seals.

- Throttle gaskets.

- Plugs placed on the manifold.

- Bushings.

- Vacuum brake boosters.

If symptoms of air leaks appear in the VAZ 2114 injector, all these elements will have to be checked.

You should also check and, if necessary, replace the idle speed sensor. Very often they are of poor workmanship and are not sealed, leading to air entering the manifold.

How to find the leak location

There are 3 main methods by which you can find a leaky area:

- by monitoring the rarefaction of air in the line;

- using a smoke generator;

- using a volatile flammable liquid.

We will omit the first method, since it requires special equipment, which is not available at all service stations. But the second method deserves a lot of attention, since it is quite simple to implement and at the same time very accurate. It will require a compressor, a blow gun and cigarettes (the latter will serve as a source of smoke).

Before checking the air intake of the VAZ 2114, you will need to assemble the entire installation, namely, connect the gun to the compressor receiver, and insert a cigarette into the nozzle of the gun. After this, a pressure of about 0.8 atmospheres is built up and the smoke is directed into the collector using a gun.

The smoke itself created by such an installation is quite thick and quickly fills the entire system. All that remains for the motorist is to carefully monitor the place where the smoke is coming out, and after detecting it, carry out repair work.

In some cases, the leak can be found without additional means - the damaged area can be easily detected by the characteristic whistle or hiss that is produced by the intake air when the engine is running. True, this only happens if there are serious cracks and breaks.

If the proposed method using a smoke generator is not suitable (for example, there is no compressor available), then the test can also be performed using volatile flammable liquids packaged in pressurized cans. As such, you can use ethyl ether (although it is almost impossible to get it in its pure form now), a means for winter starting diesel engines (the main component of which is the same ether), as well as special cleaning products based on hydrocarbons.

In order to find the location of the leak, you need to start the car engine and, while idling, begin to spray all possible components, joints, plugs and hoses that relate to the manifold and may cause air penetration.

This should be done with pauses - after spraying one place, you should wait a few seconds. If you notice that the engine speed has increased sharply after the procedure, then the detected area should be thickly sprayed again. If after this the revolutions quickly go up again, then the leak point has been successfully found.

What does a faulty collector affect?

There are many stories about the rupture (and even explosion) of a cracked manifold while the car is moving.

Of course, none of them are true, but nevertheless, a leaky manifold is a very serious problem that requires an immediate solution, and here’s why: through burnouts and cracks, air can enter the exhaust system, diluting the exhaust gases.

As a result of this, the lambda sensor will incorrectly determine their composition and incorrectly adjust the composition of the fuel-air mixture injected into the engine, which will lead to tripping, a drop in speed and carbon deposits on the spark plugs.

Bent valves due to incorrect valve timing

These same cracks will affect the crankcase ventilation, disrupting it. This will lead to timing problems and increased valve wear. And finally, exhaust gases escaping through the burnouts will enter the engine compartment and, partially, into the interior, causing unpleasant odors and discomfort during trips.

A severely burnt manifold gasket can lead to exactly the same consequences as cracks on the part itself.

Main causes of malfunction

The engine exhaust manifold is a part that operates under high loads.

During the operation of the car, it is affected by such negative factors as:

- high temperature transmitted to it from exhaust gases;

- exposure to gasoline vapors caused by the fact that the VAZ 2114 intake manifold and exhaust manifold have a common gasket;

- exposure to exhaust gases;

- exposure to vibration transmitted from the motor.

All this leads to the fact that almost all cars that are more than 7 years old (with the exception of those whose owners drive a couple of times a year) have a badly worn manifold that requires replacement.

Damaged exhaust manifold gasket

It is immediately worth noting that many car repair shops offer services for argon-arc welding of cracks in worn-out collectors. Such a service, as a rule, costs several times more than a new part, and the durability of such repairs in most cases does not exceed one year, after which new cracks appear.

It is for this reason that you should not think about possible repairs - if the collector fails, it needs to be replaced.

Another problem, which, for obvious reasons, occurs even more often, is a burnt-out manifold gasket 2114. With very active use of the car, it can fail almost every year. You can also replace it with your own hands, and the replacement procedure itself is no different from replacing the collector (its sequence will be discussed below).

Preparation stages

To replace the manifold or its gasket, in any case you will have to dismantle the VK. But before you get to the element you are looking for, you will first need to go through some preparatory steps. Namely, tighten the fasteners, and then remove the air filter and carburetor if the first stage does not help.

This is interesting: Signs and symptoms of a blown cylinder head gasket

| Stage of work | Your actions |

| Tightening the fastenings | Often, loose manifold fastenings caused the entry of contaminants, which disrupted the performance of the exhaust system. If the tightening did not give any result, then the gasket is definitely burned out or the collector itself is damaged, which is less likely |

| Removing the air filter |

|

| Removing the carburetor | Removing the carburetor is carried out in the following sequence:

|

Dismantling the unit

All dismantling work must be carried out only on a cold engine. To make it easy to unscrew all fasteners, you can pre-treat them with WD40, several hours or even a day before the repair begins.

Part selection

21083-1008081 – original catalog number of the gasket for the intake and exhaust manifold. It consists of two parts or, on newer models, one. This part is produced at the AvtoVAZ plant. The average cost is 250 rubles per piece (if there are two of them) or 450 rubles (for a whole one).

One-piece manifold gasket A gasket that consists of two parts A one-piece gasket and one that consists of two parts together

In addition to the fact that there is an original part, you can also find a number of analogues that are recommended for installation. Let's consider which gaskets can be installed under the VAZ-2114 manifolds:

- Trialli GZ 102 0013 is a well-known Russian manufacturer that produces a wide range of analog parts for domestically produced cars. The cost of the gasket is 200 rubles per piece.

- AJUSA 13065200 is another domestic manufacturer that has won consumers over the quality of its products. The cost of the product is 450 rubles.

- Ukrainian also produces and supplies this gasket. But, if you look at it, the quality of the product leaves much to be desired, since the resource is designed for only 20,000 km.

Required tool for replacement

Before you begin the process itself, you need to decide on the necessary tools. To remove the exhaust manifold on a VAZ 2114 in order to replace the gasket or entire part, you will need the following tool:

- open-end and ring wrenches for 8, 10, 13, 17;

- wrench with heads 17, 19;

- screwdrivers, pliers.

It is also a good idea to have tools such as a Dremel, nut saw or nut pick on hand. As a rule, the fasteners on the exhaust system parts stick tightly.

A few days before your planned repair, begin treating accessible nuts with WD-40 or another penetrating lubricant. Repeat the operation 2-3 times. This will make the task of removing the manifold a little easier .

The question often arises: is it worth using a sealant after removing and replacing the gasket? Experts believe that if you apply sealant to the gasket, it should only be high-quality silicone. A bad sealant can bring a lot of trouble to a VAZ 2114 engine: when it burns out, it turns into “pellets” that are pulled into the crankcase. And this is unnecessary contamination of the piston system.

Now that everything is prepared, you can start working directly. In order for the manifold to be removed without any problems and rusted bolts not to create trouble, everything must be lubricated with WD-40 before performing the operation. It is advisable to do this several times. Before performing the operation, you need to think again, weigh everything and calculate your strength.

Manifold dismantling procedure - step-by-step instructions

The dismantling process itself is not so complicated; access to some nuts is difficult, so it is advisable to carry out the work on a lift or in an inspection pit. The algorithm of actions for the injection VAZ-2114 in this case looks like this:

- Remove the negative terminal from the battery or turn off the mains switch.

Remove the terminal from the battery - Drain the antifreeze from the system.

This point should not be neglected, despite the fact that the factory does not oblige you to empty the cooling system of liquid. Drain the coolant from the system - Disconnect the fuel pipes.

Removing the fuel pipes - We find the throttle position sensor, idle speed sensor and remove the wires from them.

Disabling the throttle position sensor - We remove the crankcase ventilation hoses and the hose from the vacuum brake booster.

Unscrew the pipes - We dismantle the receiver, disconnect the injector wires and remove the fuel rail assembly. We dismantle the receiver. We disconnect the electrical connector of the fuel rail. We dismantle the fuel rail.

- We get full access to the collector.

We dismantle the thermally reflective screen. Removing the thermal shield - Unscrew the muffler exhaust pipe from the manifold.

Disconnect the muffler exhaust pipe from the manifold - Unscrew the manifold mounting nuts from the studs in the block head.

Dismantling the exhaust manifold mountings - We dismantle the collector.

Removing the exhaust manifold

Replacement of gaskets and installation of manifold

After dismantling the manifold, it is rarely possible to remove the gasket intact. It changes in any case , but parts of the destroyed gasket will definitely remain on the mating plane on the head side and on the manifold side. They must be carefully removed.

Changing the manifold gasket

To do this, you can use a special spray that softens the gasket residues; you can carefully remove them with a blade. In this case, the plane must not be damaged, otherwise the tightness of the connection will be broken.

Also, when installing new exhaust manifold gaskets, it is not recommended to use sealants . They can be of different quality, and during crimping they can form particles that get into the crankcase, which is extremely undesirable.

Video about replacing the exhaust manifold gasket on a VAZ-2114

Replacing the Kalina catalyst gasket (8 valves)

Replacing the catalyst gasket on an 8-valve Lada Kalina begins with the preparatory stage: a set of tools, socket heads, rags, heat-resistant sealant, a new gasket - seal.

Dismantling work affects both the engine compartment and the underbody of the car. The service station master starts with the hood space:

- Opens the hood and removes the decorative plastic engine cover. Unscrews the four rubber clips located around the perimeter, as well as the plastic oil filler cap.

- Be sure to reduce the pressure in the fuel system of the power unit. To do this, you need to turn off the engine, remove the fuses from the block in the tunnel, and start the engine. Let it run again until all the fuel is used up, then insert the fuses.

- Resets the negative terminal from the battery.

- Removes the injection module. Unscrews the standard fasteners around the perimeter with a figured screwdriver.

- Disconnects the contact board of the wires from the fuel injectors and the engine, and moves the gasoline supply hose to the side.

- Disconnects the catalyst from the standard pipe of the additional muffler. Removes the rubber suspensions and the receiving pipe flange from the seat.

- Disconnects the contact group of oxygen sensor wires.

- Unscrews the heat-insulating shield from the motor housing.

- Unscrews the inlet pipe from its seat.

- Removes the spacer and damper tube.

- On the body part of the exhaust manifold, unscrew two nuts and remove the heat-insulating shield.

- Unscrew the six fastening nuts around the perimeter of the manifold, dismantle the inlet pipe of the cylinder head.

- Directly removes the sealing gasket itself from the block head.

- Use fine sandpaper to clean the perimeter of the cylinder head from remnants of the previous gasket.

- Conducts visual diagnostics of removed equipment and components.

Product delivery options

Note! Below are the shipping methods available specifically for this product. Payment options may vary depending on the shipping method. Detailed information can be found on the “Delivery and Payment” page.

Parcel by Russian Post

Available payment methods:

- Cash on delivery (payment upon receipt)

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Shipping throughout Russia. Delivery time is from 5 to 12 days.

Parcel by Russian Post 1st class

Available payment methods:

- Cash on delivery (payment upon receipt)

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Shipping throughout Russia. Delivery time is from 2 to 5 days. More expensive than regular delivery by Russian Post, approximately 50%. Parcel weight up to 2.5 kg

Express Parcel EMS

Available payment methods:

- Cash on delivery (payment upon receipt)

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Shipping throughout Russia. Delivery time is from 3 to 7 days. More expensive than regular delivery by Russian Post, approximately 100%.

What does the muffler consist of?

The main part of the exhaust system serves to absorb noise. On the Lada Kalina car, this function is performed by a pipe, which includes the muffler itself and its resonator.

The thickening is the resonator, the end is the muffler itself

The pipe has a completely sealed body, which is manufactured using the rolling method, that is, without the use of a welding machine. Thanks to this, the muffler is durable and does not corrode. And the resonator, which is also located in the pipe, consists of several closed chambers. These chambers are connected to each other by small tubes with holes in them. Thanks to this structure, the resonator can quickly smooth out all acoustic vibrations. In the latest modifications of the Lada Kalina, the inside of the resonator is lined with sound-absorbing material.

How to install a 4-2-1 spider in place of the standard converter on a Lada Kalina 8V

In a car exhaust system, a catalytic converter is needed to burn harmful elements in the exhaust gases to the level of H2O and CO2. It is quite difficult to predict its service life, since it depends on many factors. But many owners of VAZ cars prefer to get rid of the collector before the end of its service life. For these purposes, they use special inserts, which are an inexpensive alternative to a neutralizer.

Contents Some car enthusiasts are sure that even a working neutralizer prevents the engine from developing the power it needs. This is not true. As for clogged or melted honeycombs, this phenomenon is the result of careless handling of the vehicle and its operation with a faulty fuel supply and ignition system.

The main reasons for device failure:

- Unbalanced fuel-air mixture due to a broken oxygen sensor.

- Unsatisfactory fuel quality.

- Incorrect ignition operation.

- Mechanical damage to the collector.

- Use of fuel additives.

For the most part, replacing the catalyst on Kalina 8 valves is done as a result of using low quality fuel. Its slow combustion occurs partly in the exhaust. The detonation of gasoline destroys the ceramic structure of the honeycomb, which over time begins to crumble and clog thin passages.

The engine begins to overheat and loses traction. An obstacle to the free passage of gases contributes to an increase in their pressure.

Signs of damage

Problems in operation are immediately noticeable. The first sign is the engine starting and stopping, or no start at all. In a service station, diagnostics are performed by a specialist. The oxygen sensor is unscrewed from its seat and the technician tries to start the engine; if it works the first time, then the reason is the catalytic filler and the tightness of the system. Otherwise, the reason lies elsewhere.

Secondary signs: reduced dynamics of vehicle acceleration, average speeds are reduced, fuel consumption increases, the “CHECK ENGINE” error indicator lights up on the central instrument panel.

The above symptoms may not always objectively indicate the exact cause of the breakdown. Auto mechanics recommend using several at the same time. For example, increased fuel consumption may not always indicate a problem with the exhaust system. There are many related breakdowns that can give such a symptom.

In 99% of cases, a clear whistle in the area of the engine compartment is guaranteed to identify the breakdown. Of course, if a turbine is not installed. But it is not provided in Lada Kalina.

Content

Actions in emergency situations Daily checks Operating instructions Warnings and technical rules Basic instruments, measuring Engine and its systems Transmission Chassis Steering Brake system Vehicle electrical equipment Body Interior ventilation and heating system Applications Fault codes Electrical diagrams

Sources

- https://expertvaz.ru/2110/premer-komplektatsii-tsena.html

- https://videoremont-mashin.ru/remont-kpp-vaz-21108/ustanovka-konditsionera-v-vaz-2110-ot-priory-svoimi-rukami/

- https://monolith.in.ua/predohraniteli-lada-2110/